Hollow shafting particle damper

A particle damper and hollow shaft technology, which is applied in the field of damping and vibration reduction, can solve the problems of occupying space, increasing research costs, and the space outside the shaft occupied by the damper, so as to achieve the effect of controlling eccentricity and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

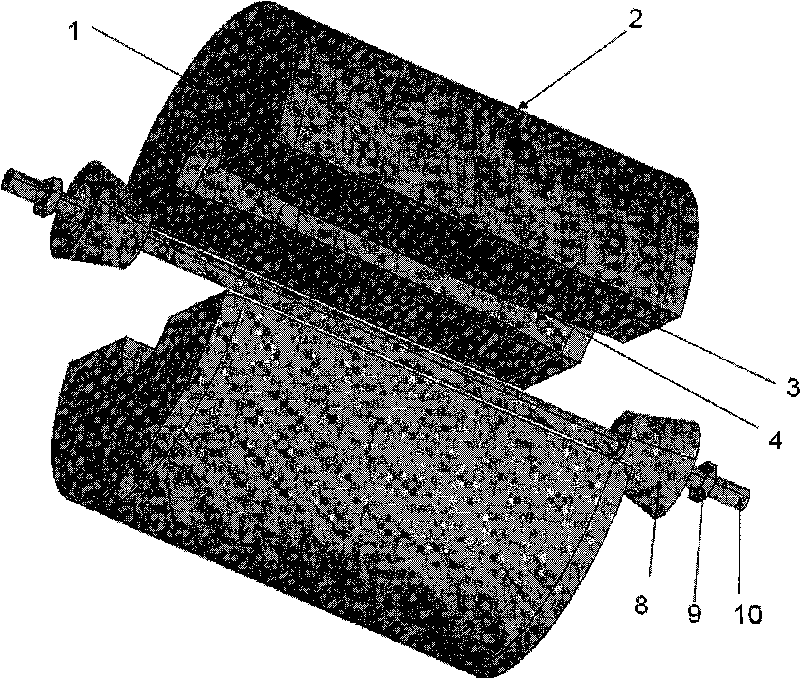

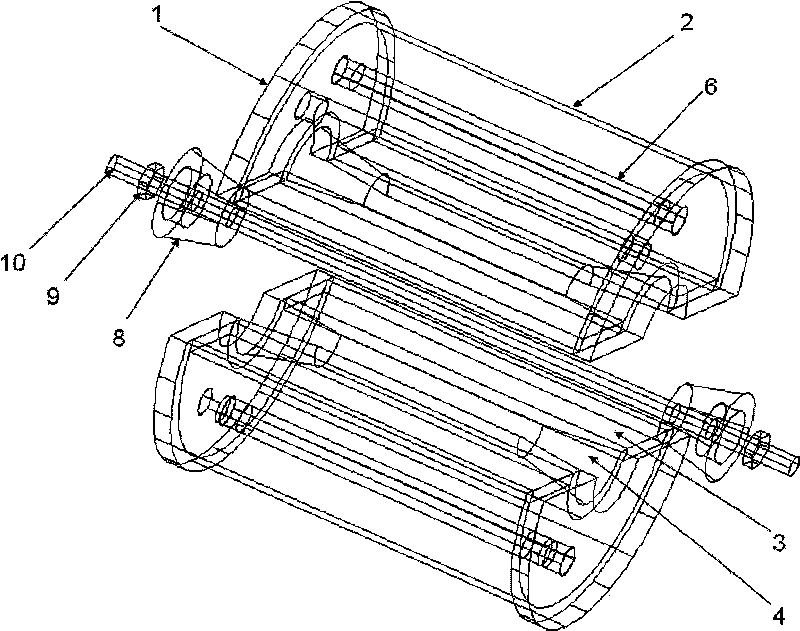

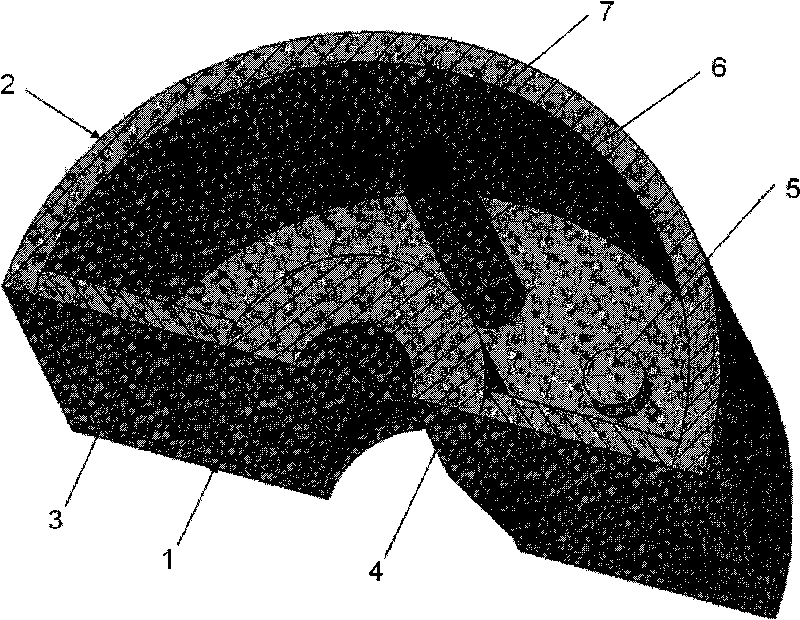

[0017] Schematic by the structure of the damper figure 1 , 2 And 3, it can be known that the outer wall 2 of the semi-cylindrical, the inner wall 4 of the semi-cylindrical (formed by cutting off a circular platform at both ends of the hollow cylinder), the inner wall plate 3, and the caps 5 evenly distributed along the circumferential direction are all fixed on the side plate 1 by bolts , both ends of the thin-walled steel pipe 6 are inserted into the platform 5 for fixation, and the damping particles 7 are filled in the thin-walled steel pipe 6 with a certain filling rate. Insert the two petals of the damper into the cavity of the shaft system, and apply axial pretightening force to the pusher 8 through the nut 9 and screw 10, so that the pusher 8 exerts a radial force on the inner cylinder 4 to spread it tightly. On the inner wall of the hollow shaft, so as to realize the positioning of the damper in the hollow shaft.

[0018] When the shaft system vibrates, collisions and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com