Combined type stirring impeller for increasing leaching rate of manganese metal electrolyte

An electrolyte and metal manganese technology, applied in the field of stirring paddles, can solve problems such as difficulty in sweeping, and achieve the effects of saving energy, improving leaching rate, and reducing overall costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

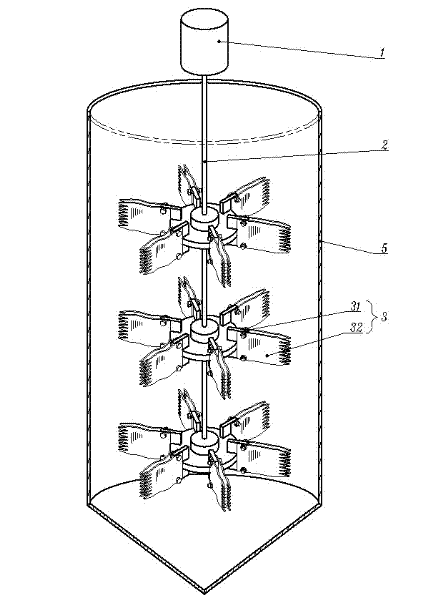

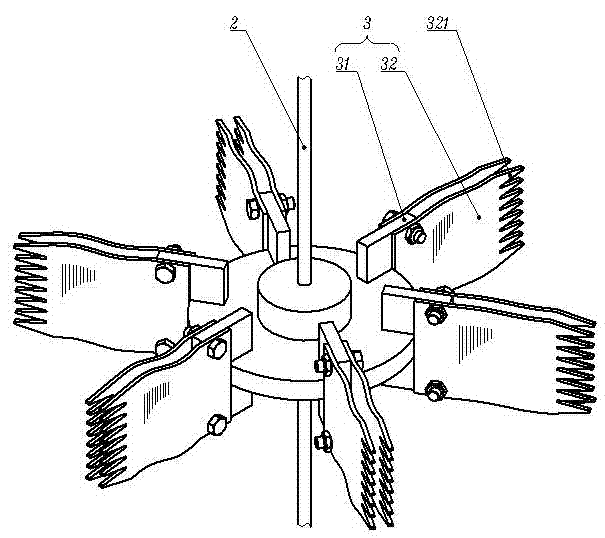

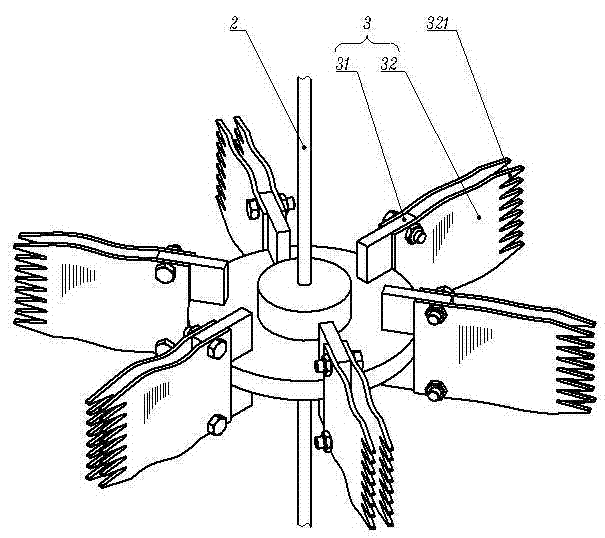

[0009] Combined stirring paddle to improve the leaching rate of metal manganese electrolyte (refer to figure 1 , 2 ), the stirring paddle has several layers, and they are all fixedly installed on the stirring shaft (2) coaxial with the leaching tank (5) of metal manganese electrolyte, and the stirring shaft (2) is driven by the motor (1); , the paddles (3) of each layer of stirring paddles are combined paddles, which are connected by a rigid blade segment (31) close to the stirring shaft (2) and a flexible blade segment (32) far away from the stirring shaft (2). become. In the present invention, the rigid leaf section (31) is in the shape of a flat plate, and the flexible leaf section (32) is a flexible sheet or two flexible sheets clamped on both sides of the rigid leaf section (31); the flexible sheet The thickness is not less than 1.0mm.

[0010] Through the understanding of the beneficial effects of the present invention, those skilled in the art must be clear that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com