Engine vibration isolation system based on combined suspension and its control method

An engine and vibration isolation technology, applied in motor-driven engines, non-rotational vibration suppression, power units, etc., to achieve the effects of improving durability and riding comfort, cost-effectiveness and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

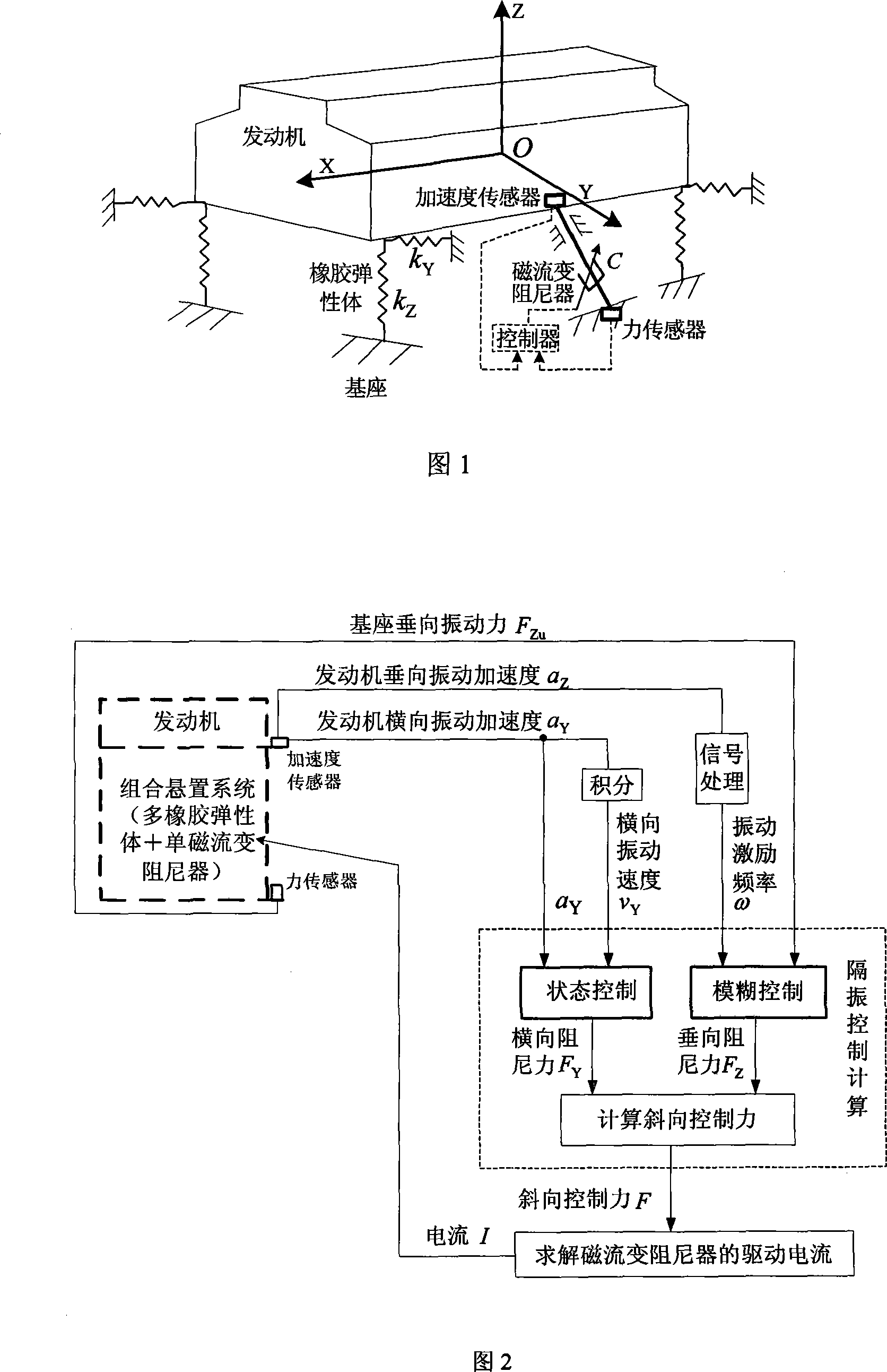

[0019] As shown in Figure 1, the engine vibration isolation system based on the combined suspension of rubber elastic body and magneto-rheological damper constructed by the present invention is shown.

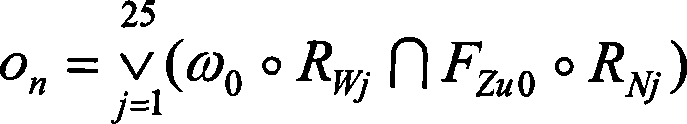

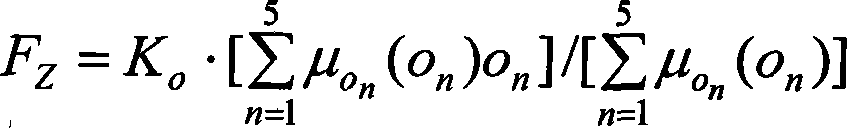

[0020] Due to the limitation of external connection conditions such as transmission devices, the forced vibration of the complete engine is mainly manifested as vertical motion, followed by lateral vibration. In the figure, the origin O represents the position of the center of mass of the engine, the X-axis is parallel to the crankshaft of the engine, the Y-axis is perpendicular to the X-axis and parallel to the base plane, and the Z-axis is determined according to the right-hand rule and is perpendicular to the base plane. K Z Indicates the vertical stiffness of the rubber elastic body, K Y Represents the transverse st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com