Efficient light flexible heat conduction chain based on graphene macroscopic assembly film

A heat conduction chain and graphene technology, applied in the field of heat conduction chain, can solve problems such as difficult to cover normal temperature to deep low temperature area, difficult to apply vibration reduction requirements, heavy weight, etc., and achieve the effect of three-dimensional conformal arrangement and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

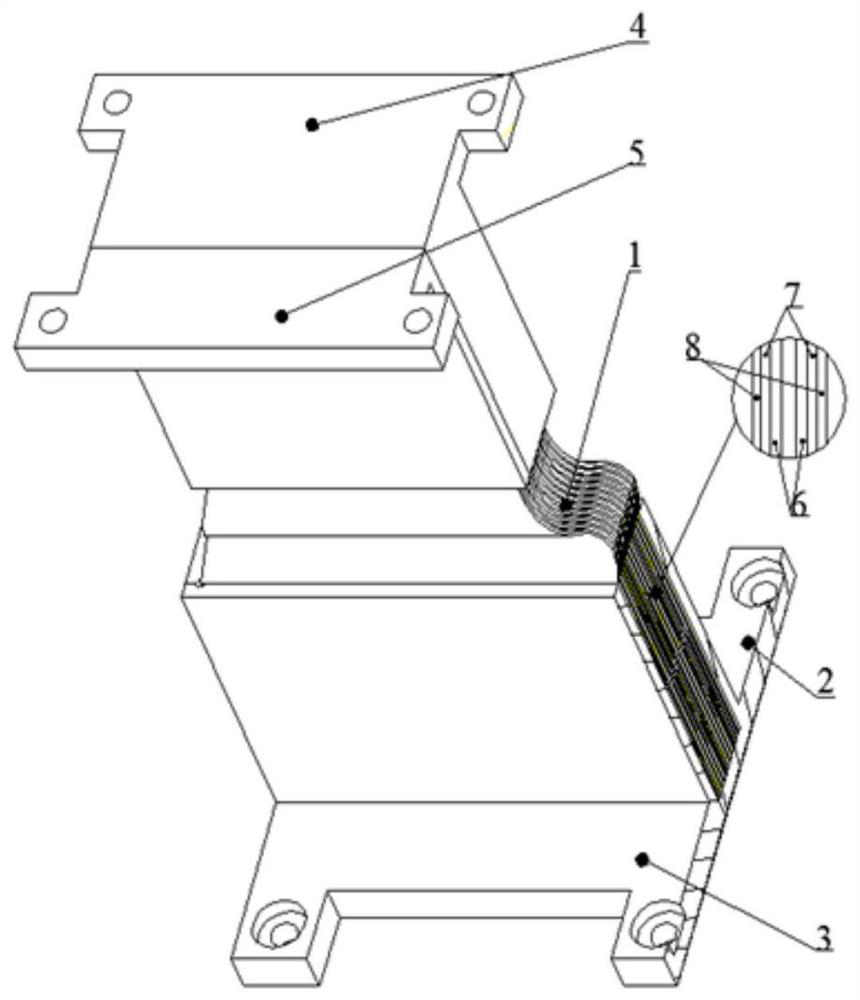

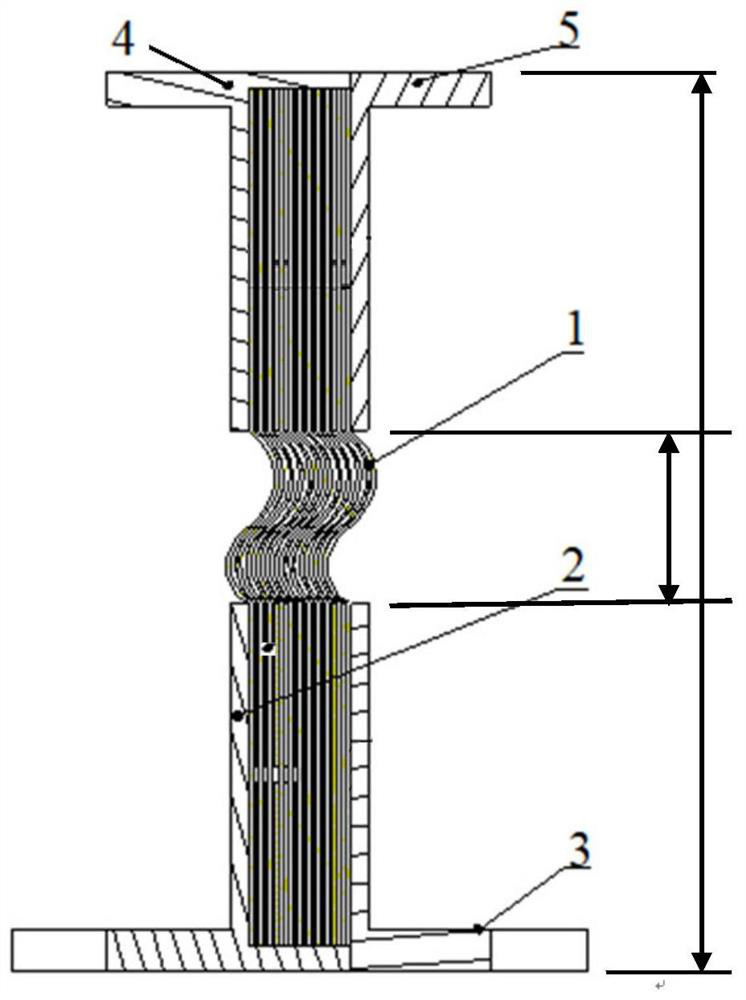

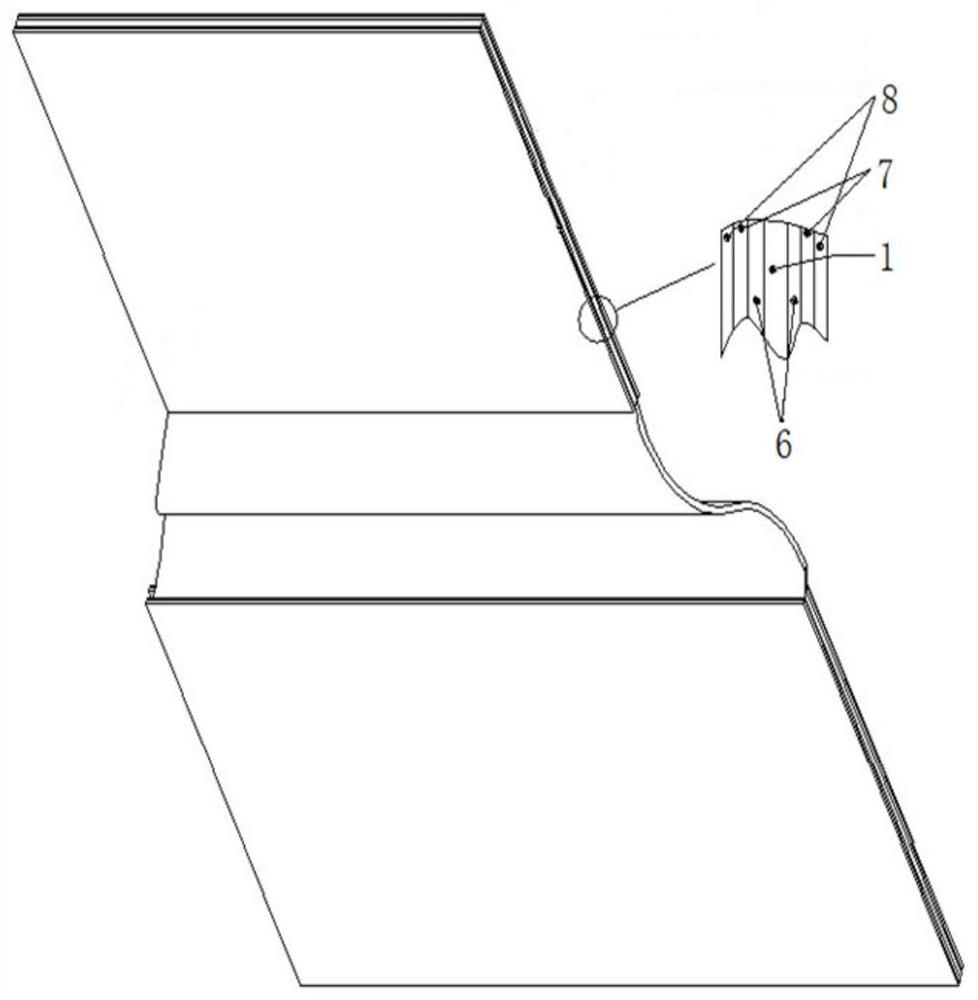

[0036] Such as image 3 As shown, the heat conduction chain involved in this embodiment includes a graphene film composed of a plurality of graphene layers 1 and a normal heat conduction layer located between the graphene layers 1, and the normal heat conduction layer includes a solder layer 8, so The solder layer 8 is connected to the surface of the graphene layer 1 through the magnetron sputtering metal layer 7 and the metal transition layer 6; located at the cold and hot ends. The middle part of the graphene film does not have the above-mentioned solder layer 8 .

[0037] In practical application, the ends of the above-mentioned heat conduction chains are encapsulated in the casing, which are respectively the hot end casing and the cold end casing, such as figure 1 and 2As shown, wherein, the cold end shell includes the cold end joint 4, the cold end joint cover plate 5, the hot end shell includes the hot end joint 2 and the hot end joint cover plate 3 of the hot end, an...

Embodiment 2

[0047] Such as Figure 5 As shown, the heat conduction chain involved in this embodiment includes a graphene film composed of a plurality of graphene layers 1 and a normal heat conduction layer located between the graphene layers 1, and the normal heat conduction layer includes a solder layer 8, so The solder layer 8 is connected to the surface of the graphene layer 1 through the magnetron sputtering metal layer 7 and the metal transition layer 6; located at the cold and hot ends. The middle part of the graphene film does not have the above-mentioned solder layer 8 .

[0048] In this embodiment, the thickness of a single graphene layer 1 is 25 μm to 30 μm, the carbon-oxygen ratio is greater than 99.8, ID / IG is less than 0.1, the interlayer distance is not greater than 0.336 nm, and the width of one end is 8 cm, which is used as the cold end, and the size of the other end is 12 cm as the hot end. (Purchased from Hangzhou Gaoxi Technology Co., Ltd., product model: GX-HT-1300)...

Embodiment 3

[0057] Such as Figure 7 As shown, this embodiment is the same as Embodiment 2, the difference is that the columnar protrusions are arranged on the cover plate of the cold end joint and the cover plate of the hot end joint, and the clearance fit is adopted between the columnar protrusion and the through hole, and the gap is filled with a metal medium (melting gold tin solder or silver tin solder).

[0058] Test results such as Figure 8 , it can be seen that compared with the metal-based cold chain commonly used in my country's aerospace industry, the thermal conductivity in the 80K-220K temperature zone is increased by 2-3 times, and the heat flux is increased to 7-8 times when the mass and length are the same .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com