Composite support plate device between double-layer hull board with high-silence-low-motion stiffness and modeling method of composite support plate device

A technology with low dynamic stiffness and modeling method, which is applied in the direction of warships, etc., can solve the problems of reducing the stiffness of the double-hull hull connection, radial relative displacement structure damage, and insufficient static stiffness, so as to facilitate maintenance and replacement and reduce radiation Noise line spectrum, effect of low working stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

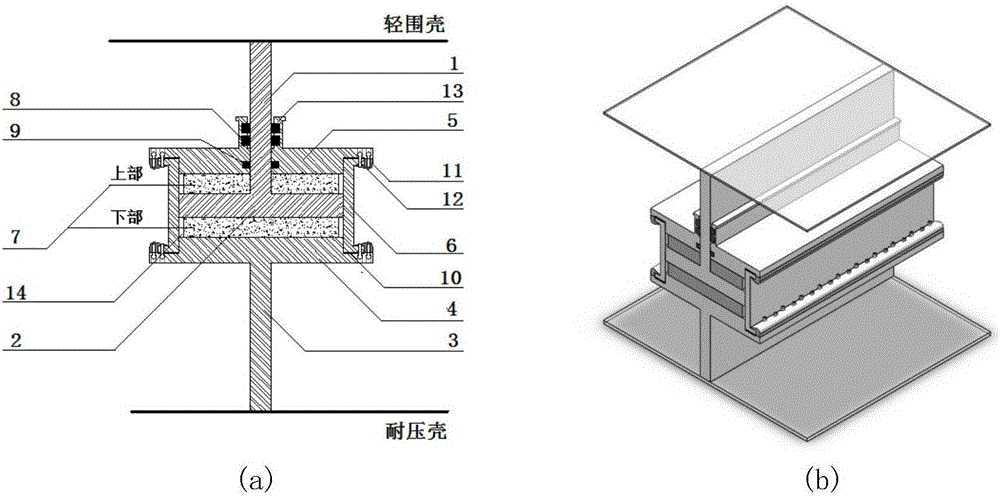

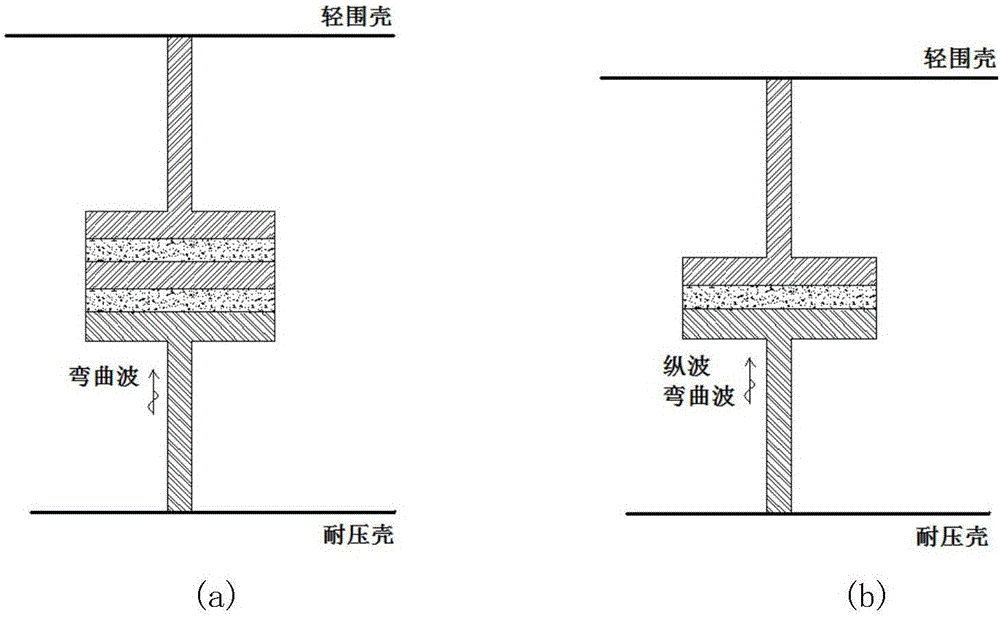

[0066] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

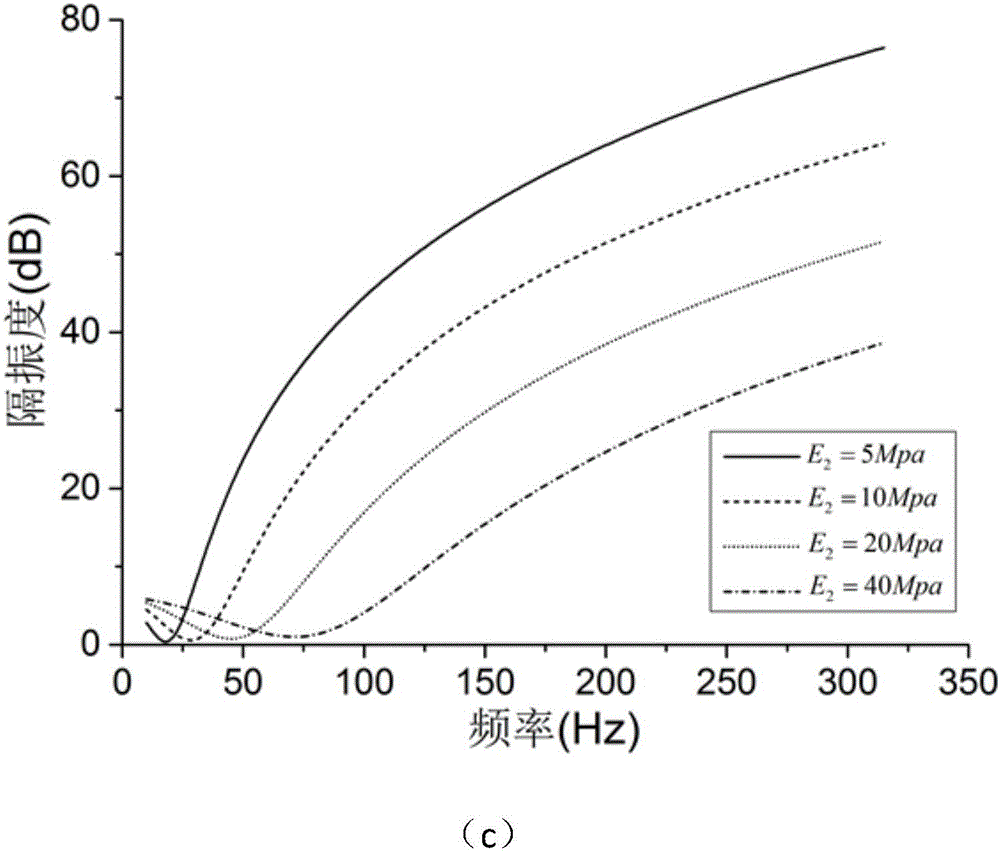

[0067] The present invention utilizes the characteristic of high loss factor of the viscoelastic material, and is designed so that the stiffness of the composite pallet is controlled by the modulus of elasticity of the viscoelastic material under normal working conditions so as to present a lower dynamic stiffness. When the load is large and the deformation is large, the stiffness of the composite pallet is controlled by the bulk modulus, showing a high static stiffness of the radial connection. On the basis of the design concept of "high static and low dynamic" stiffness, the present invention further proposes the design of a composite pallet with a multi-layer viscoelastic material sandwich, pointing out that multiple sandwich layers will greatly increase the impedance mismatch and the vibration isolation effect will be better Significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com