A double-material spring vibration isolation buffer

A spring vibration isolation and buffer technology, applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve the problems of hydrophobic particle piston friction bearing capacity, short piston stroke, inconvenient adjustment, etc., to improve the working range , Increase the stroke, the effect of low working stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

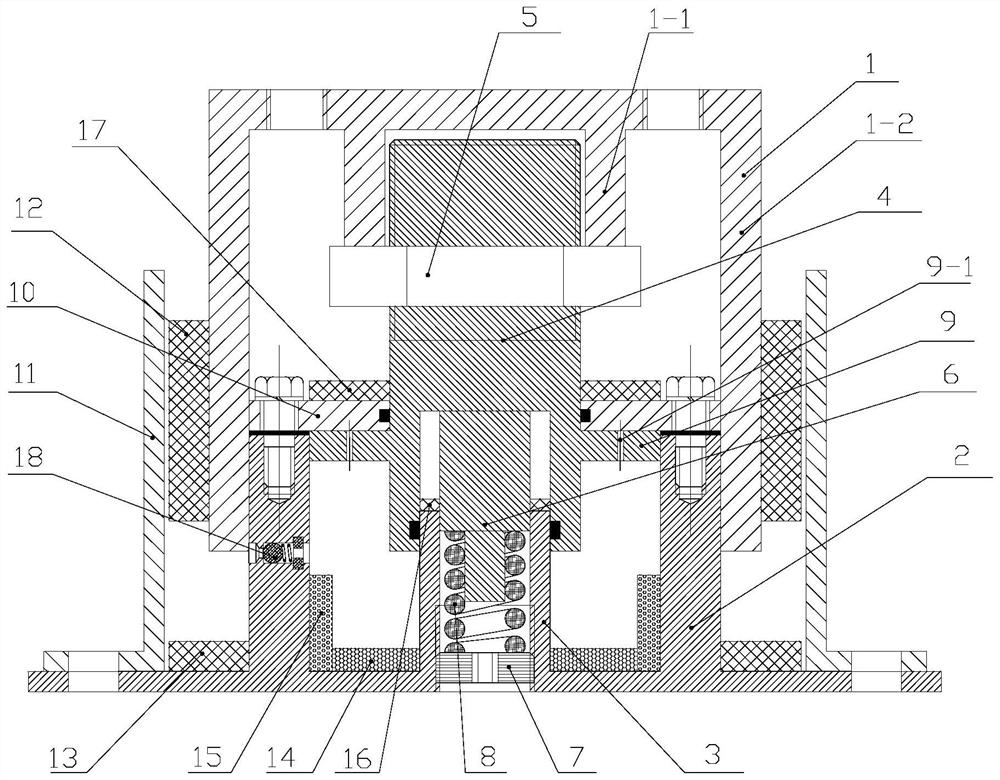

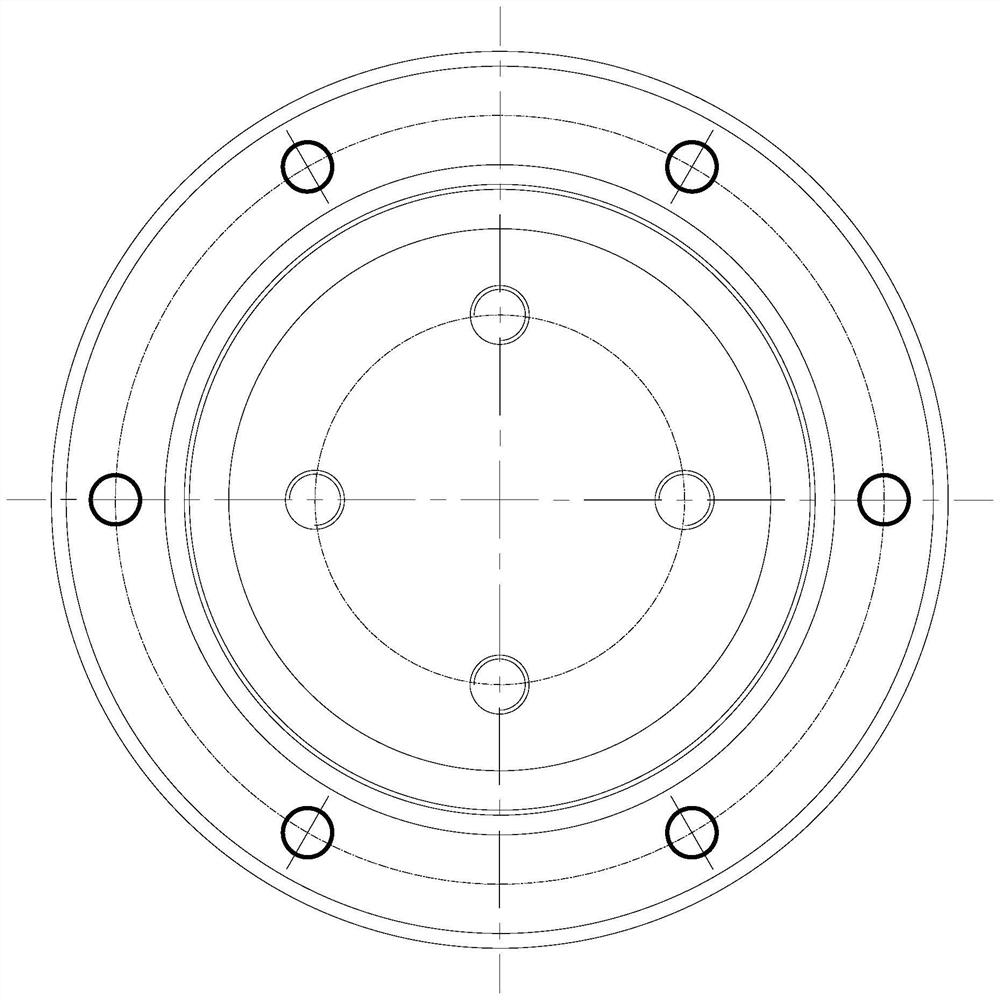

[0024] Specific implementation mode one: combine Figure 1~5 Describe this embodiment, a double-material spring vibration isolation buffer, which includes a first guide cylinder 1, a cylinder body 2, a second guide cylinder 3, a main piston 4, a fastening nut 5, a secondary piston 6, and a preload block 7 and a pre-tension spring 8, the first guide cylinder 1 is coaxially sleeved outside the cylinder body 2, the fastening nut 5 is coaxially fixed inside the first guide cylinder 1, and the fastening nut 5 is threaded Connected to the upper part of the main piston 4, the lower part of the main piston 4 is provided with a groove opening downward, the secondary piston 6 is coaxially arranged in the groove, and the second guide cylinder 3 is coaxially fixed on the cylinder body 2 Inside, the main piston 4 and the secondary piston 6 are respectively slidingly arranged on the inner side and the outer side of the second guide cylinder 3, and the lower part of the second guide cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com