Handle-frame-type rolling pole

A rolling pin and stand-type technology, applied in the field of rolling pins, can solve the problems of cumbersome operation and inconvenience, and achieve the effect of strong applicability and widening of the plane working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

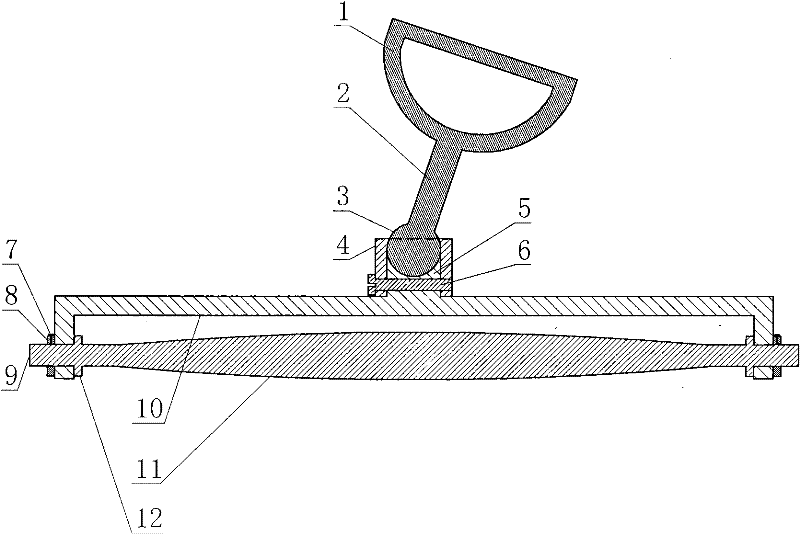

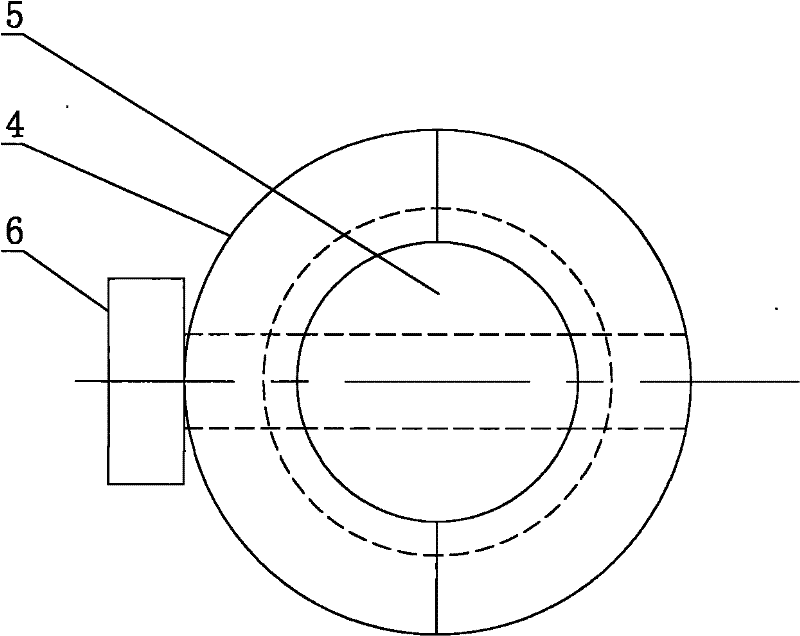

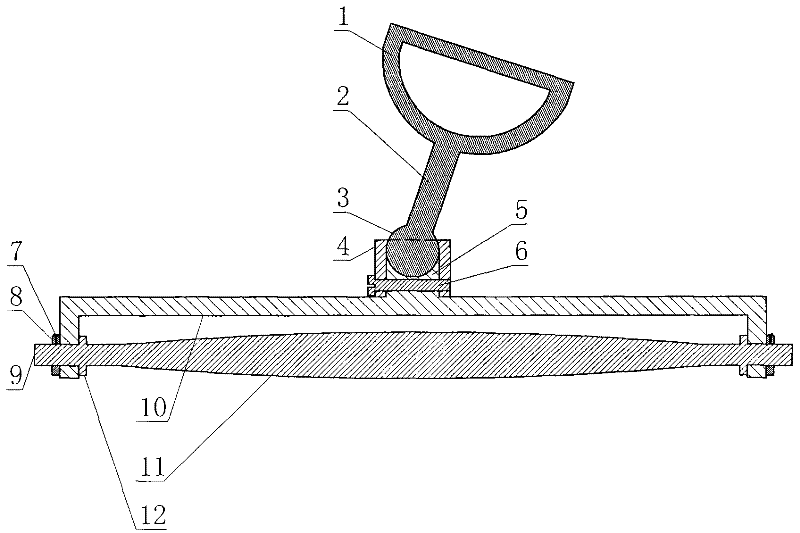

[0012] The handle rack type rolling pin consists of a handle 1, a handle 2, a handle ball 3, a clamping ball tube 4, a concave column 5, a tie screw 6, a locking screw 7, a nut 8, a stick handle 9, a fixed frame 10, a stick body 11 and a clamp Ring 12 constitutes. The handle 1 is a D-shaped ring body, and the middle part of the arc segment of the handle 1 is welded with a cylindrical handle 2. The other end of the handle 2 is a handle ball 3 integral with the handle 2. The handle 3 is a hemispherical concave cylinder with the same radian, and the diameter of the concave column 5 is the same as that of the handle 3 . The lower half of handle 3 is in the concavity of concave post 5 upper ends, and card ball tube 4 is made of two half cylinders, and the upper end inner side of each half cylinder has the arc surface identical with handle 3 radians. The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com