Variable force spring device for sodium pipe system of fast reactor

A variable force spring, sodium tube technology, applied in cooling devices, low internal friction springs, reactors, etc., can solve the problems of small load and small stroke range, achieve overall structural stability, improve the working stroke range, and facilitate real-time detection and detection. The effect of overload shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

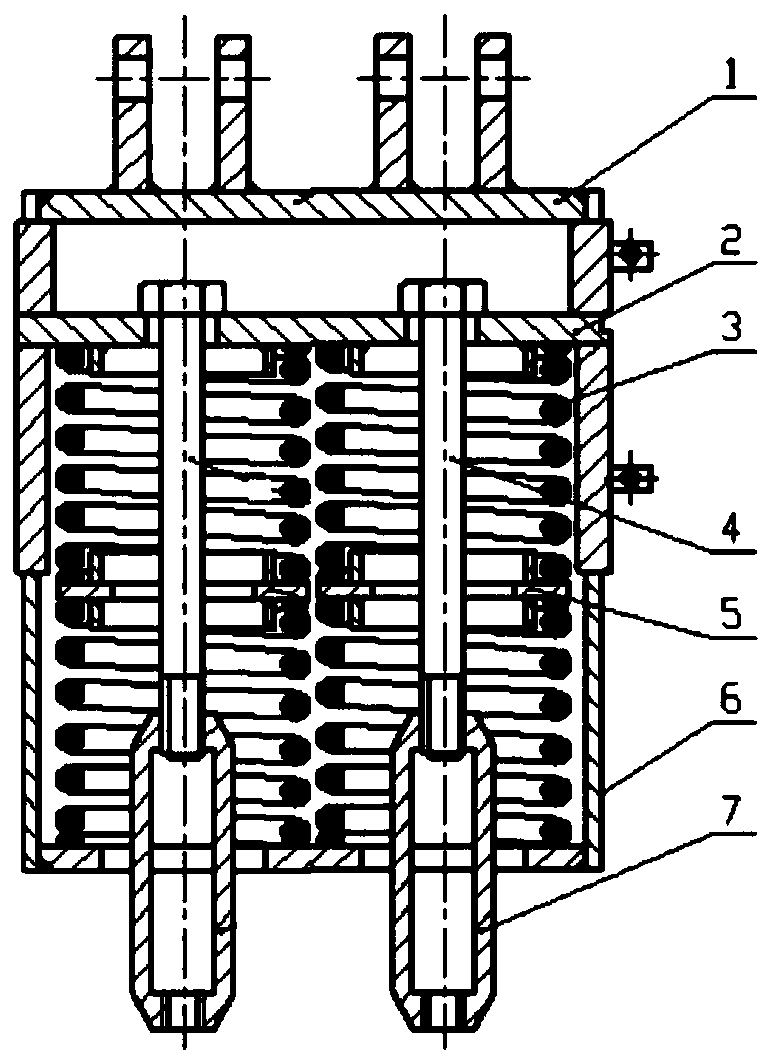

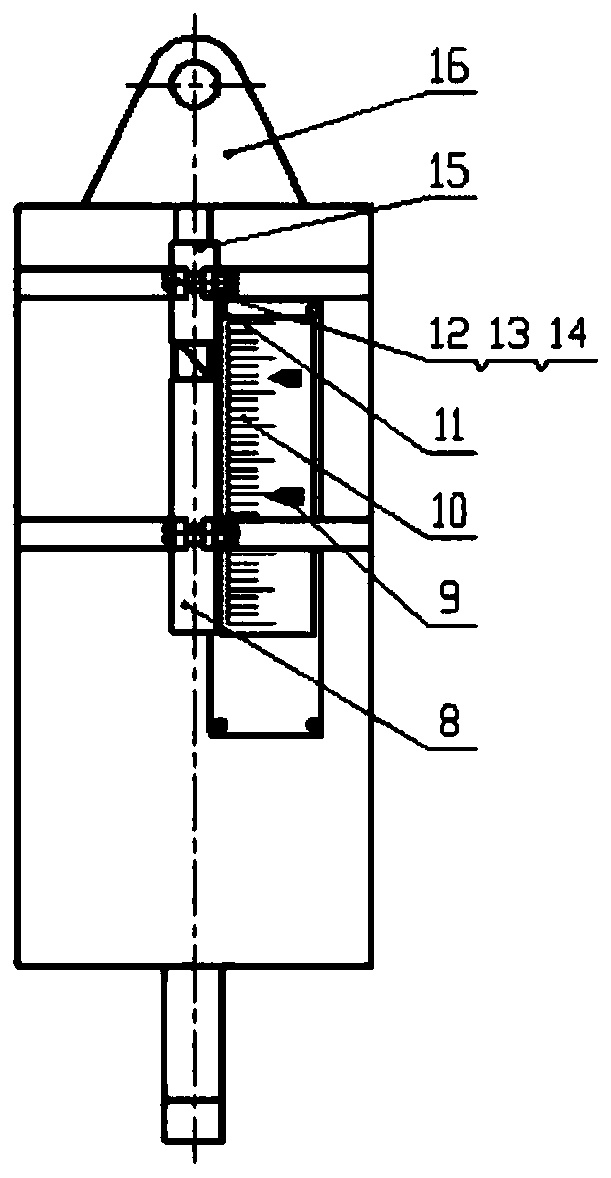

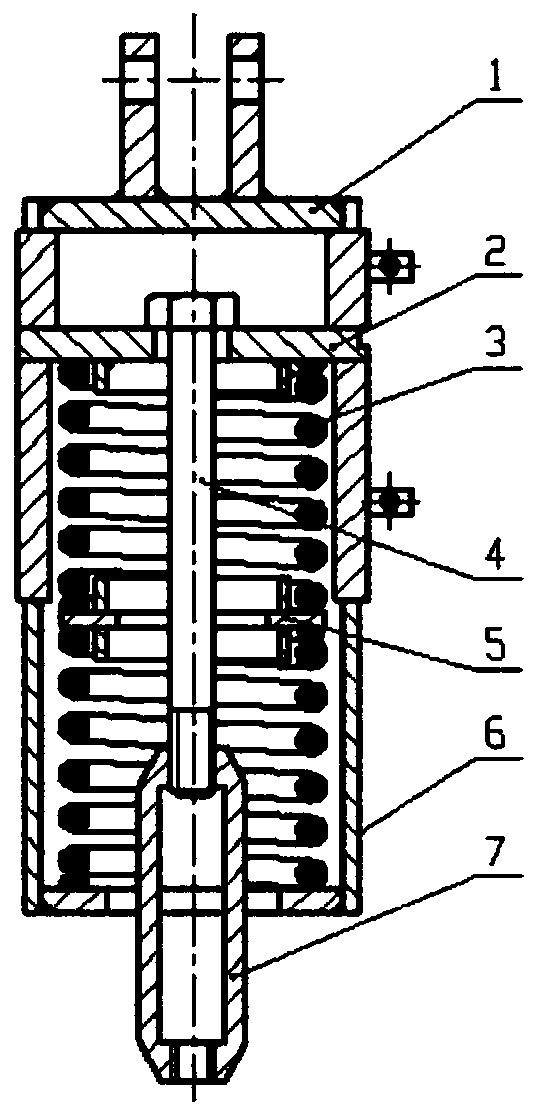

[0022] Such as Figure 1-Figure 4 As shown, the present invention schematically shows a variable force spring device for fast reactor sodium piping system.

[0023] Such as figure 1 As shown, the present invention relates to a variable force spring device for fast stack sodium piping system, including a top plate 1, an indicator plate assembly 2, a spring 3, a bolt assembly 4, a housing assembly 6 and a loose nut 7, and the top plate 1 is fixedly connected Above the housing assembly 6, the spring 3 is arranged inside the housing assembly 6, the bolt assembly 4 passes through the center of the spring 3, the upper end of the bolt assembly 4 is connected to the indicating plate assembly 2, and the lower end is connected to the elastic nut 7, and the indicating plate assembly 2 is pressed on On the upper end of the spring 3, the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com