Continuous-spinning assembly and disassembly frame and torque and rotation speed control method

A technology of speed control and disassembly rack, applied in earth-moving drilling, drilling equipment, drill pipe, etc., can solve problems such as low work efficiency, exit from the market, and excessive torque, so as to improve work efficiency and achieve relatively accurate torque control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described below with a specific embodiment as an example:

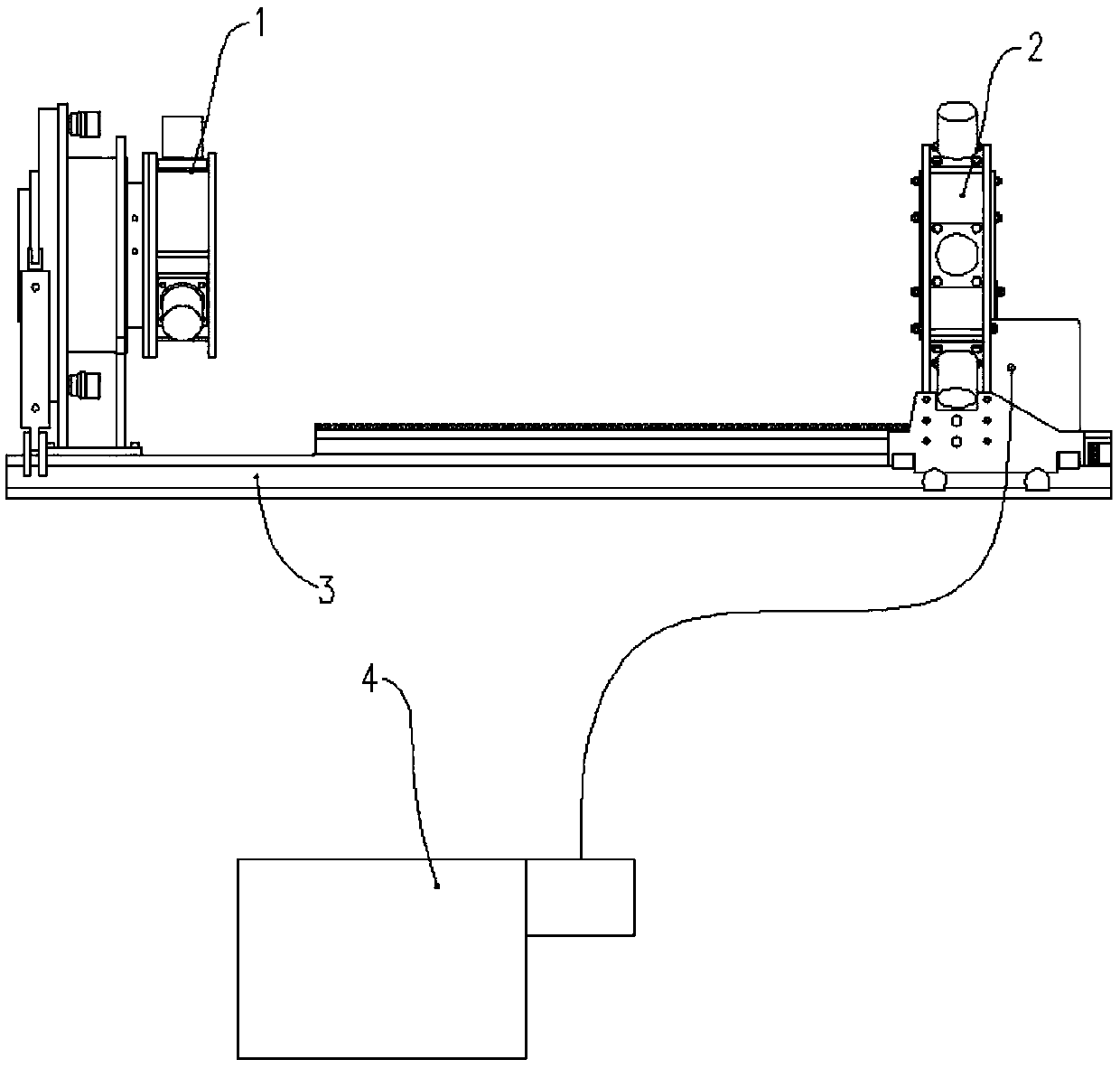

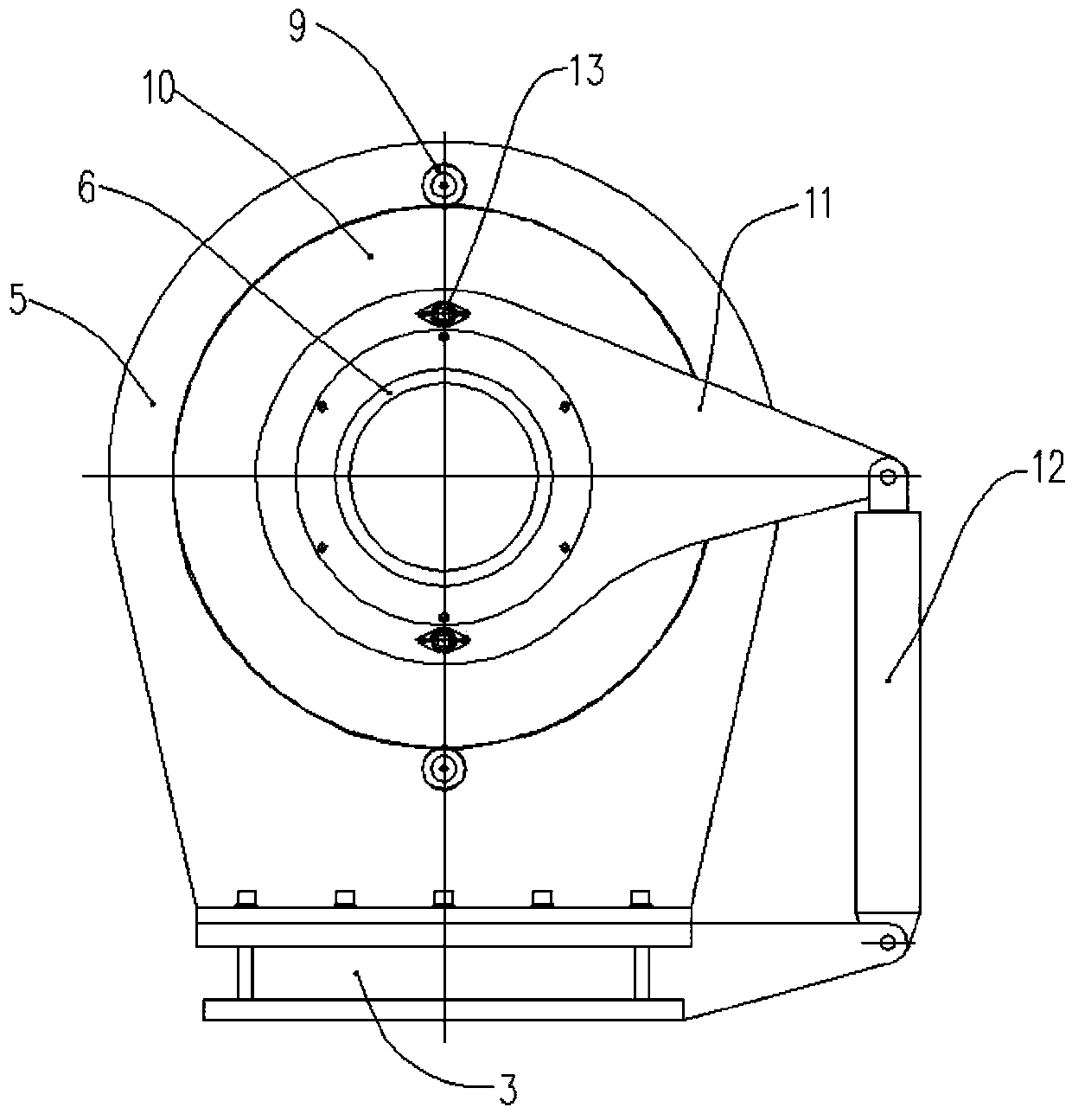

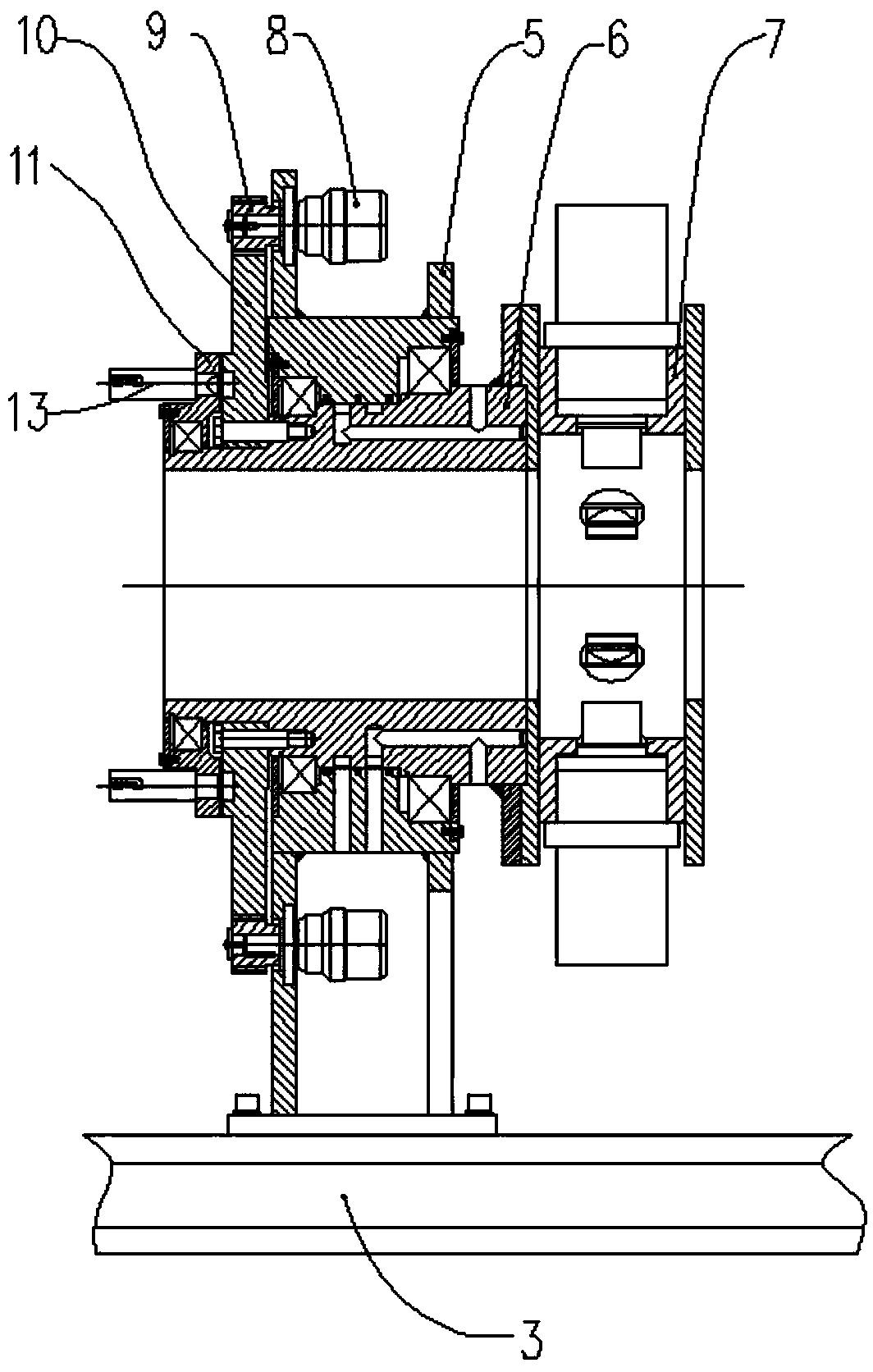

[0040] Refer to the attached figure 1 , for the current disassembly rack with continuous turn buckle function, its basic structure usually includes the following basic components:

[0041] The first is a base 3 which serves as a base for the rest of the installation, usually in a certain orientation, such as figure 1 There is a section of track in the left and right direction shown in , which is the basis of the pincer structure, used to clamp the pipe body, so as to perform continuous rotation.

[0042] Configured as a jaw, two parts are required, one part is the mobile back tong 2, the movement is reflected in the movement on the track, thus, the movement of the mobile back tong 2 is controllable, and it is locked after moving in place. Of course, the lock Tightness can also be expressed as a continuous force component, which is used to provide continuous clamping force.

[0043] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com