timing belt tensioner

A technology of tensioning device and synchronous belt, which is applied in the direction of belt fasteners, belt/chain/gear, mechanical equipment, etc. Tight adjustment and other problems, to achieve the effect of convenient installation and maintenance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

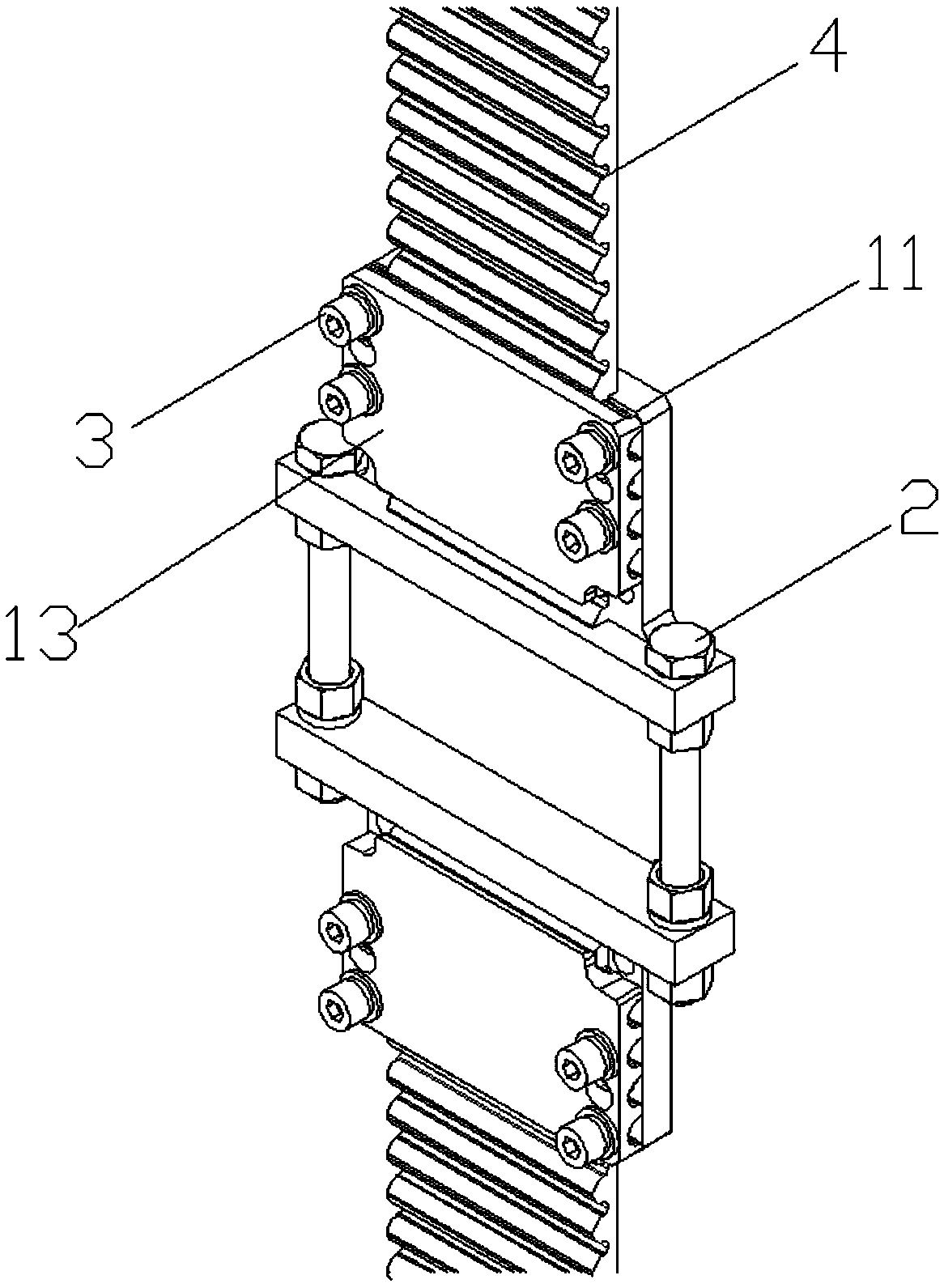

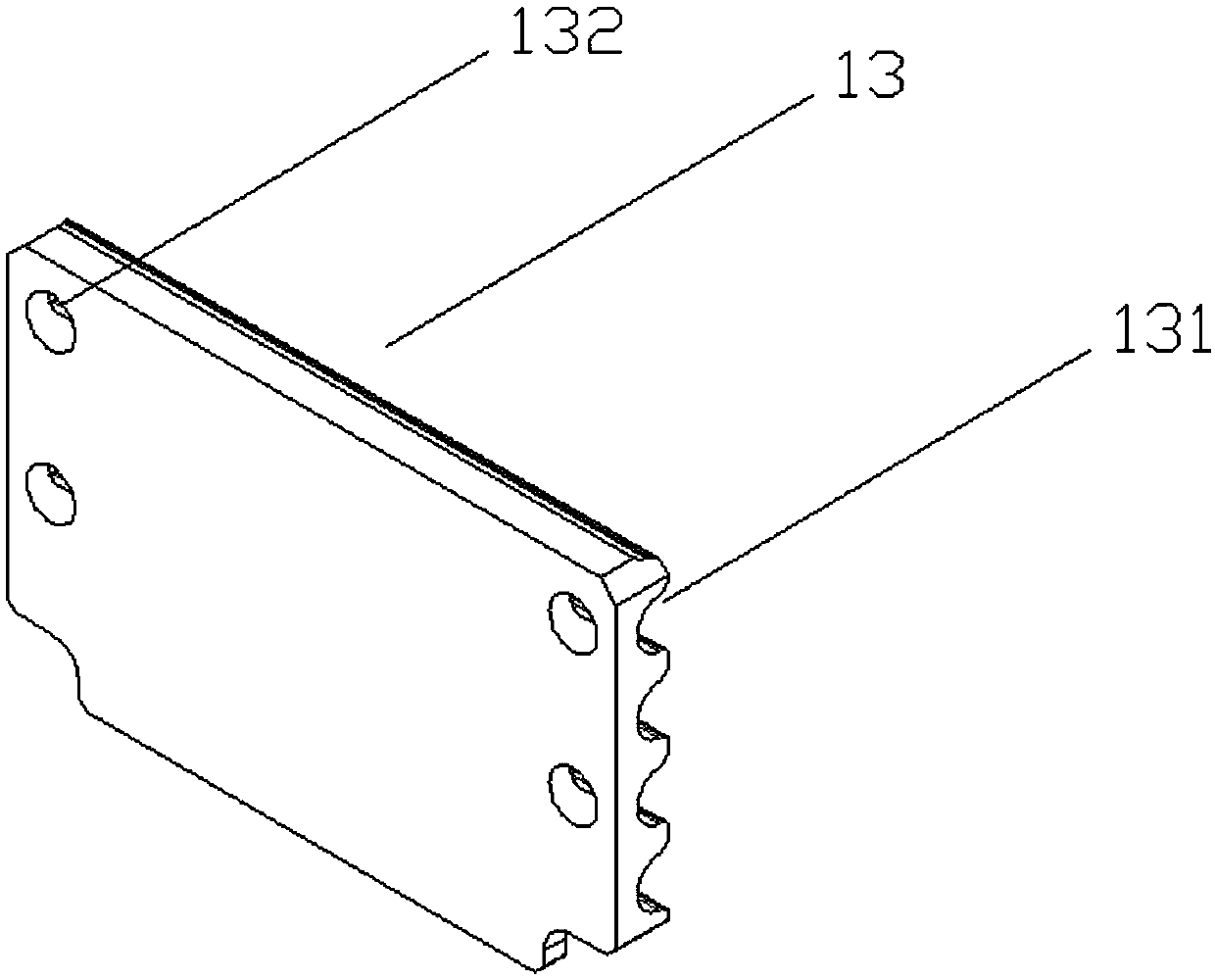

[0013] refer to Figure 1 to Figure 3 As shown, a synchronous belt tensioning device of the present invention is composed of two clamping blocks, the two are connected by bolts 2, and the distance between the two is changed by adjusting the bolts 2; the clamping blocks include: the first A splint 11 and a second splint 13;

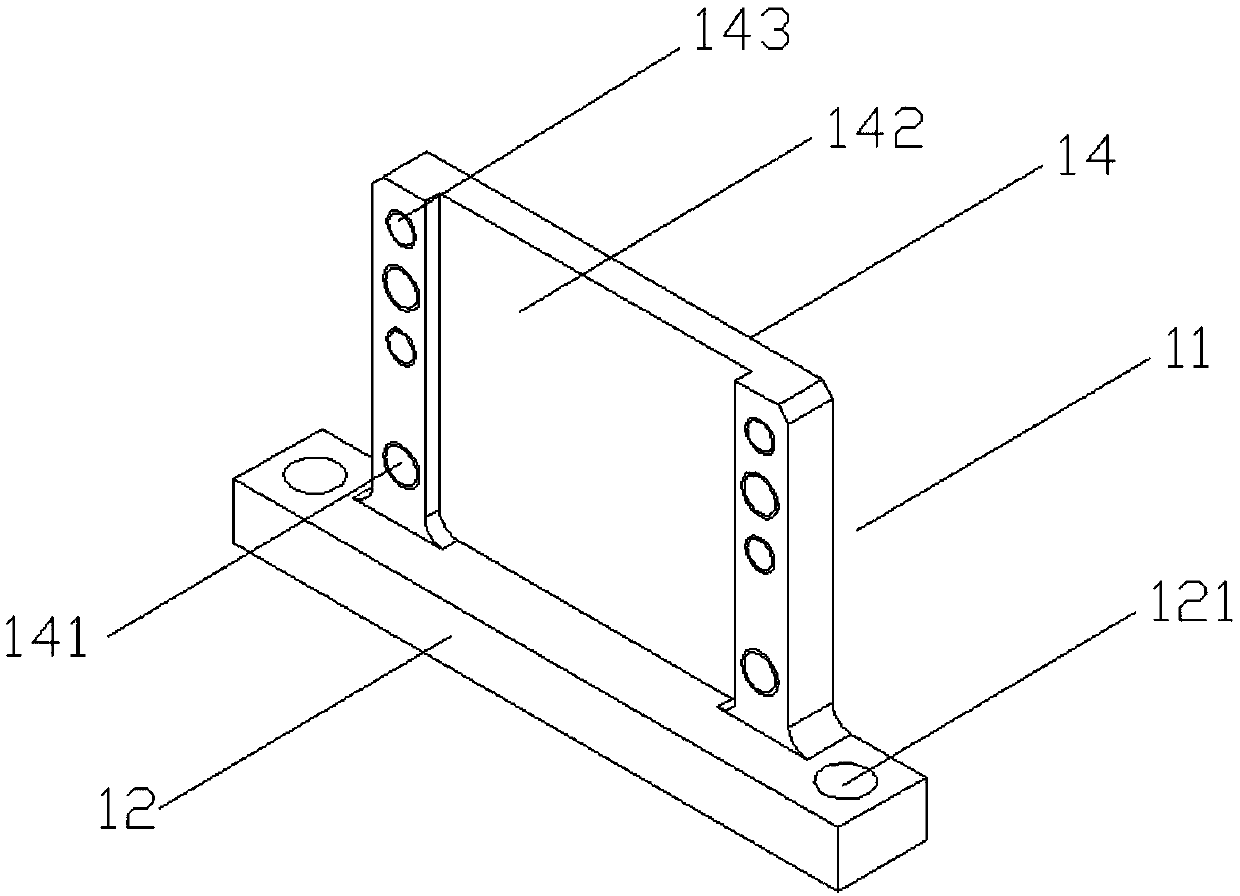

[0014] The first splint 11 is of T-shaped design, and a bolt adjusting hole 121 is respectively provided at both ends of its transverse portion 12 to accommodate the above-mentioned bolt 2; and several mounting holes 141 are respectively provided at both ends of its longitudinal portion 14 ( There are four), the first clamping block 11 is fixedly connected to the loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com