Roving frame upper and lower dragon rib spindle belt transmission device and roving frame

A technology of transmission device and roving frame, which is applied in the direction of textiles and papermaking, etc. It can solve the problems of low speed and easy damage, and achieve the effects of high transmission speed, convenient installation and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

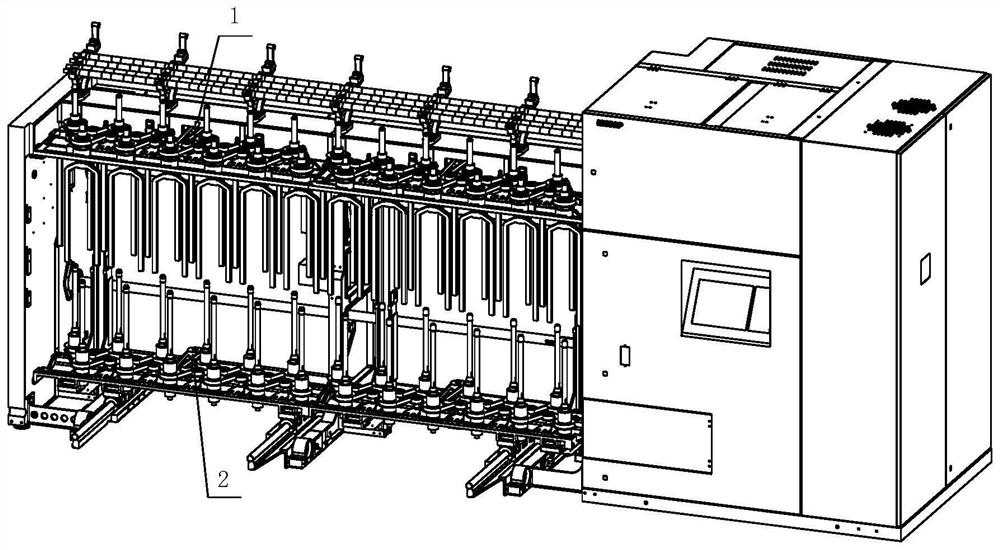

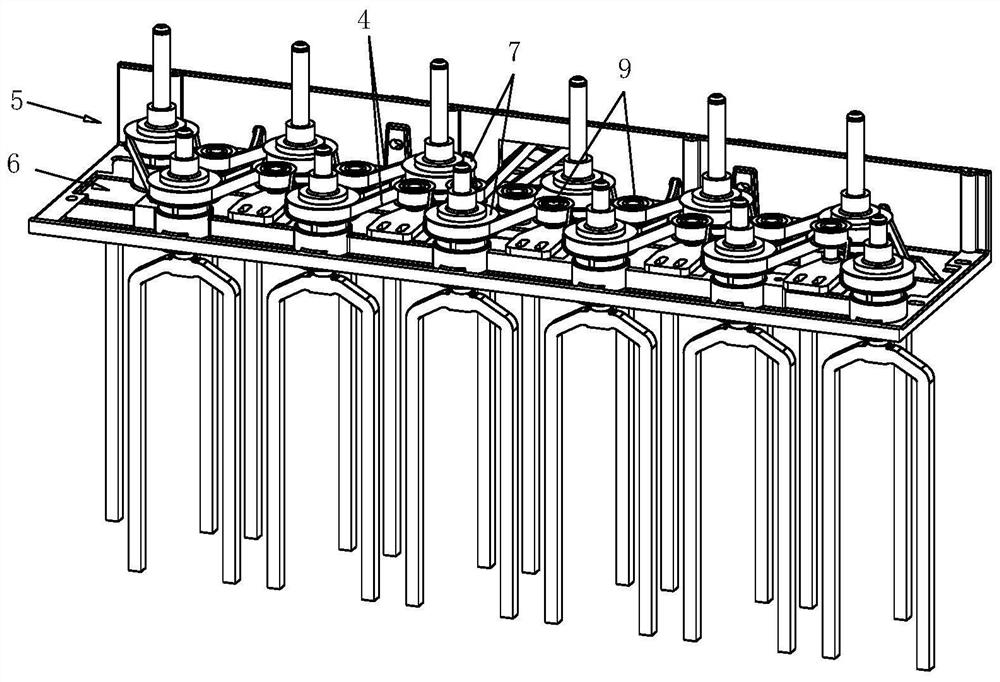

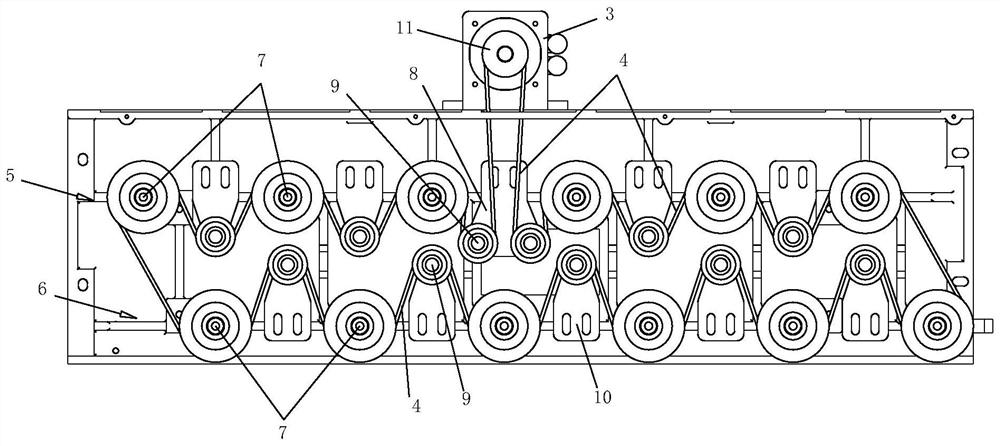

[0030] combine Figure 1 to Figure 5 , the transmission device for the upper and lower dragon rib spindle belts of the roving frame, including the multi-section upper dragon rib part 1 and the multi-section lower dragon rib part 2, each upper dragon rib part and each lower dragon rib part are provided with a transmission structure.

[0031] The transmission structure includes a servo motor 3, a spindle belt 4, a friction disc mechanism and a tension wheel mechanism, and the spindle belt connects the servo motor, the friction disc mechanism and the tension wheel mechanism in series.

[0032] Specifically, the friction disc mechanism includes a front friction disc part 5 and a rear friction disc part 6, both of which are composed of a plurality of friction discs 7 arranged in a row.

[0033] The front friction disk part and the rear friction disk part are alternately arranged, and the number of friction disks in the front friction disk part and the rear friction disk part is th...

Embodiment 2

[0046] A roving frame is provided with the transmission device for upper and lower rib spindle belts of the roving frame described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com