Large motor belt tensioning device

A technology for tensioning devices and large motors, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as short service life, inconvenient movement, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

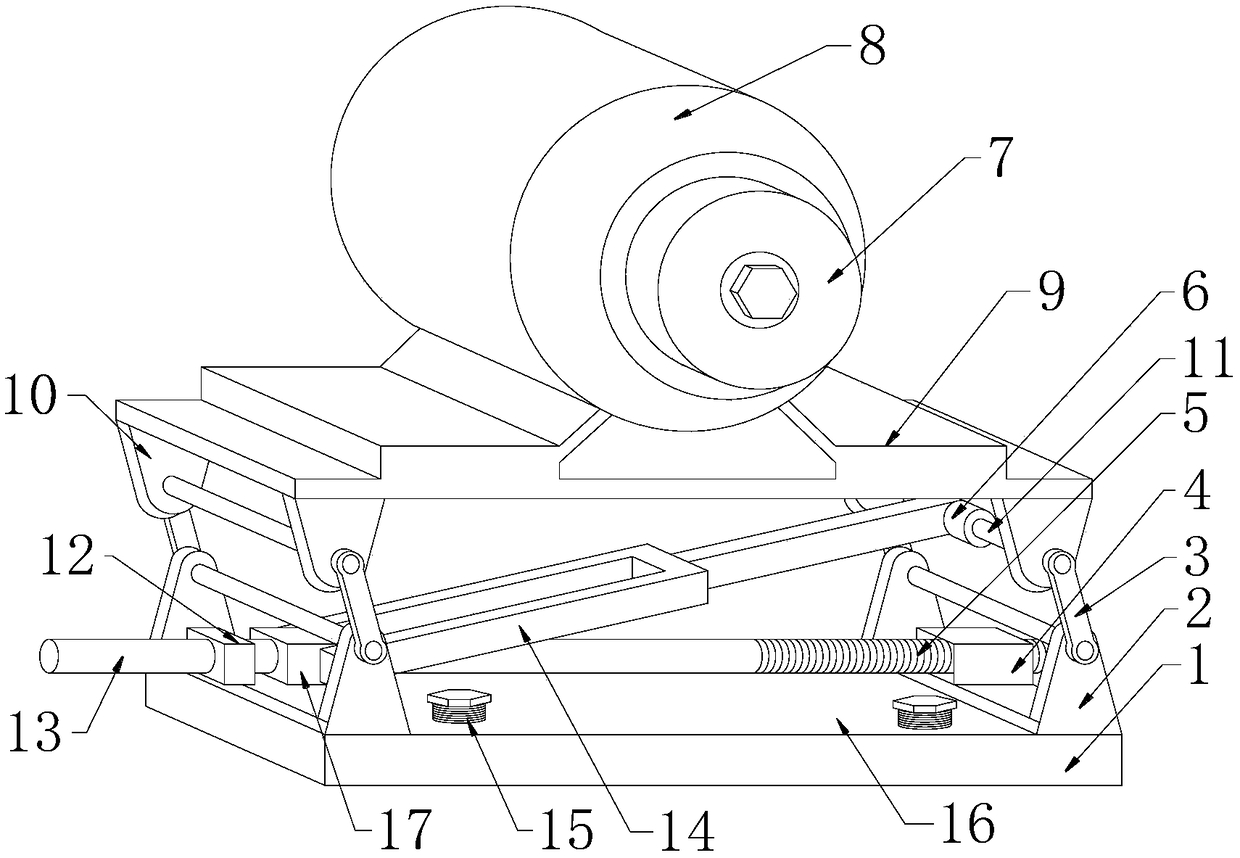

[0019] like Figure 1 to Figure 3 As shown, the present invention is a large-scale motor belt tensioner,

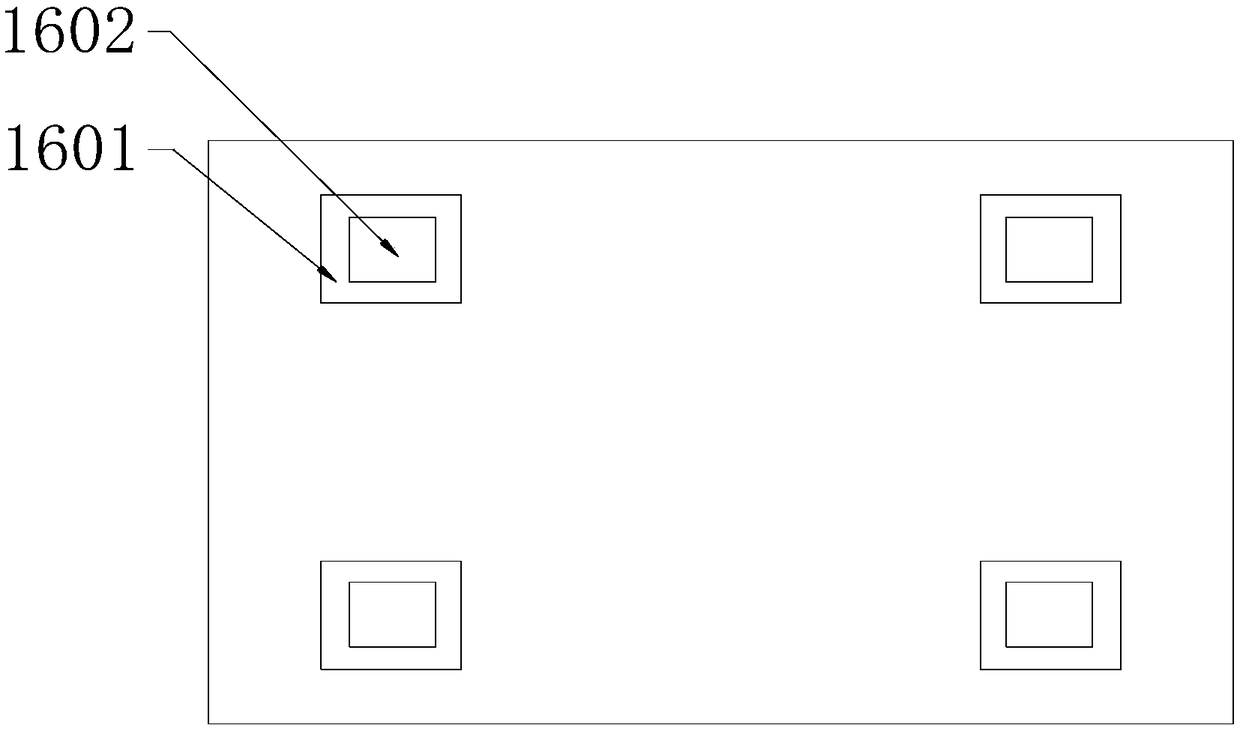

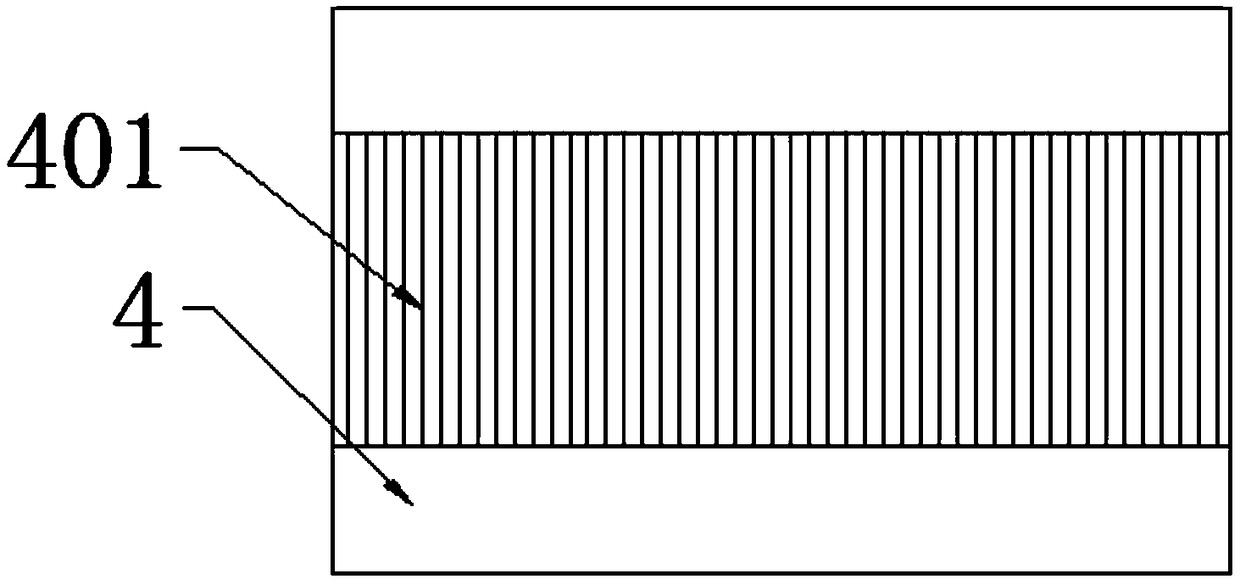

[0020] Specifically, if Figure 1 to Figure 3 As shown, it includes a device main body 1, a motor base 9 and a floor seat 16. The bottom of the device body 1 is provided with a floor seat 16. The hinged seat 2, the lower hinged seat 2 is fixedly connected with the bottom plate seat 16, the top of the lower hinged seat 2 is provided with a remote sensing group 3, the remote sensing group 3 is movably connected with the lower hinged seat 2, and the middle of the lower hinged seat 2 at the rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com