Bridge expansion joint with sweeping mechanism

A cleaning mechanism and expansion joint technology, applied in the field of bridge expansion joints, can solve the problems of dust falling, the gap between the conveyor belt and the expansion joint increasing, and the lack of a correcting mechanism, so as to increase the running time and reduce the maintenance time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

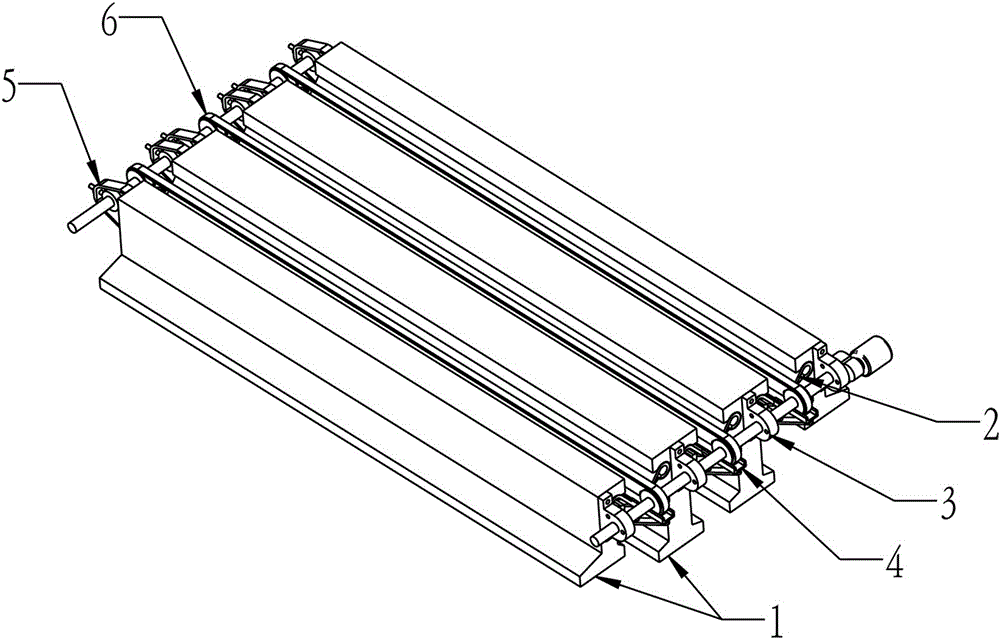

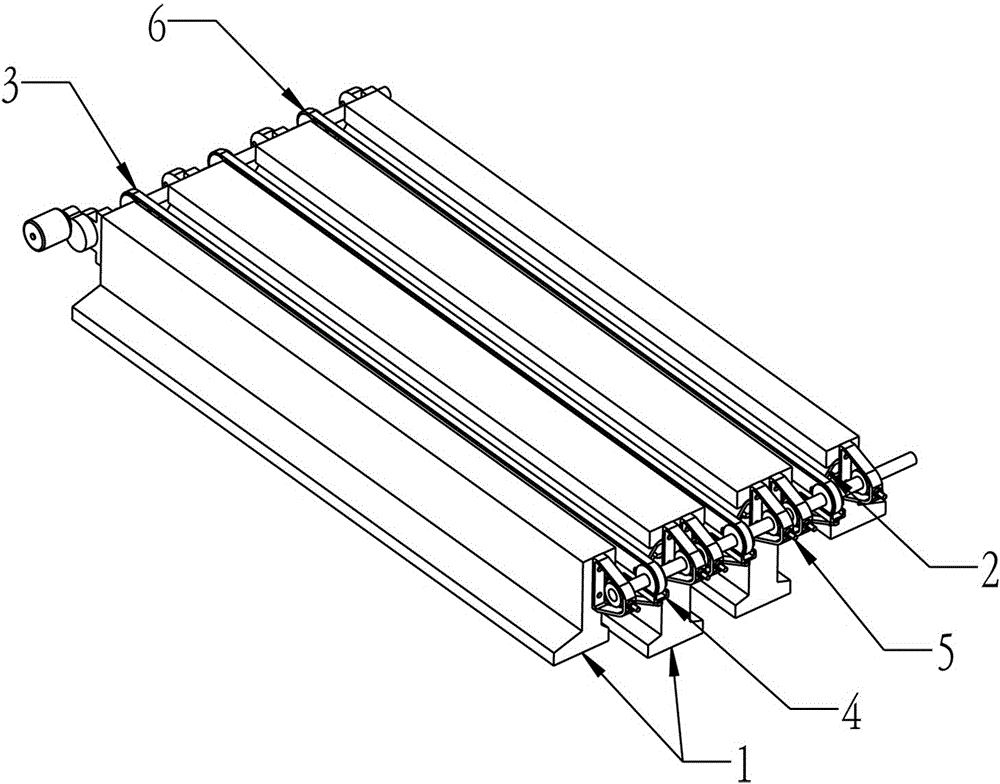

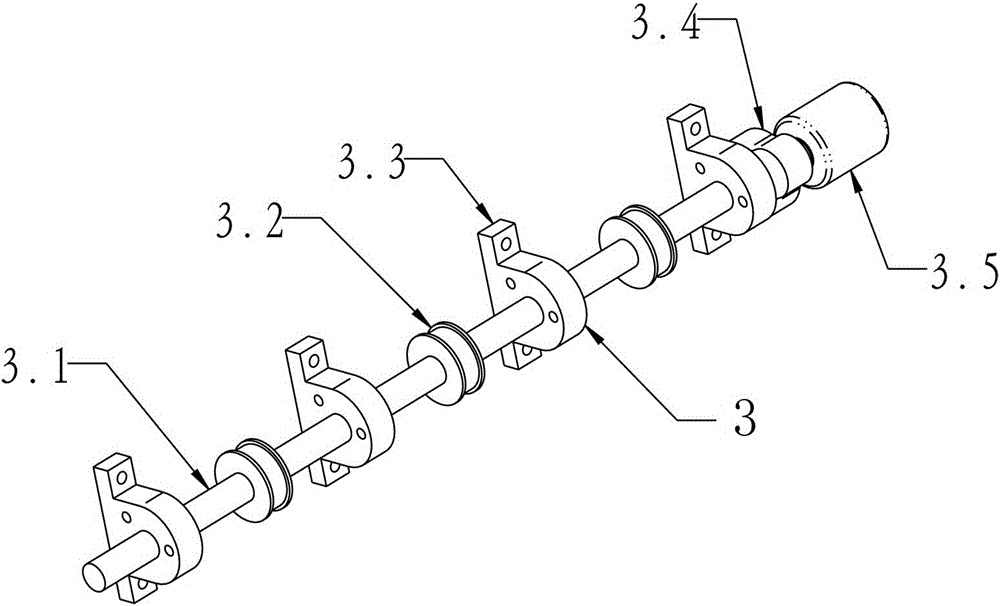

[0013] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 Among them, a V-shaped waterstop 2 is embedded in the groove of the beam 1, and there is a cleaning belt 6 at the bottom of the V-shaped waterstop 2 between the beams 1. The connection method is: one end of the cleaning belt 6 is wound around the pulley 3.2 In the groove, the other end of the cleaning belt 6 is wound in the groove of the driven pulley 5.2; the structure of the driving pulley part 3 is: there is a driving shaft 3.1 in the center hole of the pulley 3.2, and the driving shaft 3.1 also passes through the pulley 3.2 The shaft seat 3.3 at both ends of the drive shaft 3.1 is connected to the output shaft of the gear box 3.4, and the input shaft of the gear box 3.4 is connected to the motor 3.5; note that the pulley 3.2 must be able to slide left and right on the drive shaft 3.1, so the belt The cooperation between the wheel 3.2 and the drive shaft 3.1 can be a spline structure or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com