Industrial electric automatic material conveying device

An electrical automation and industrial technology, applied in the direction of cleaning devices, transportation and packaging, conveyors, etc., can solve the problems of pollution of conveying machinery parts, fixed conveyor belt structure, and cannot be adjusted, so as to avoid pollution and meet the needs of transportation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

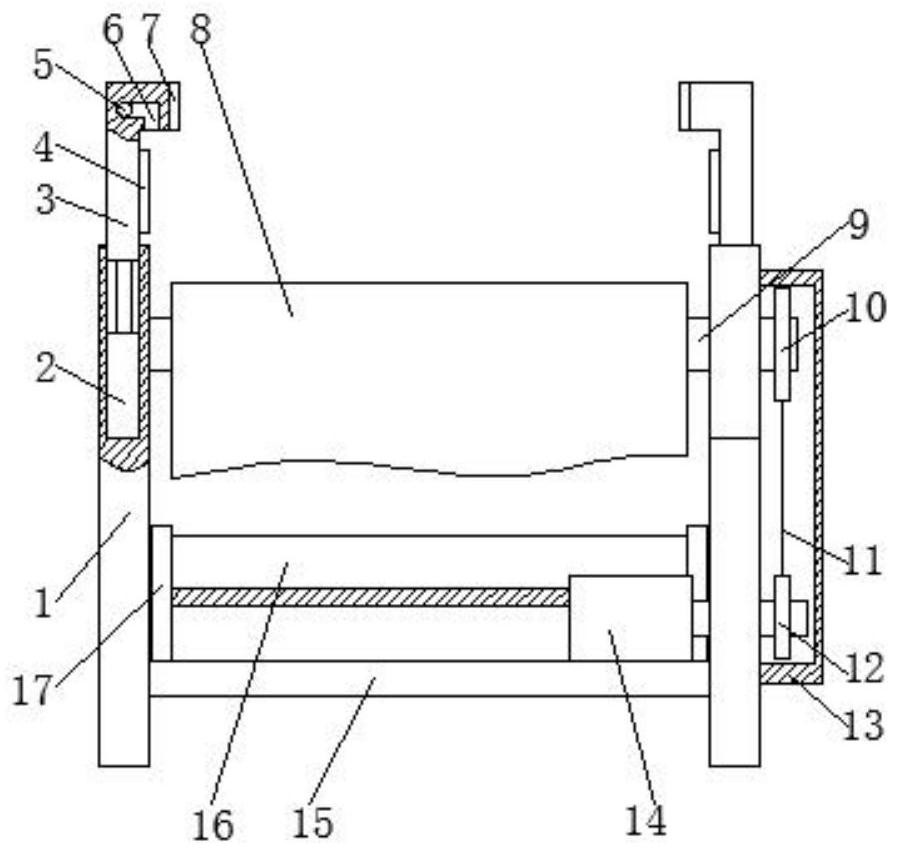

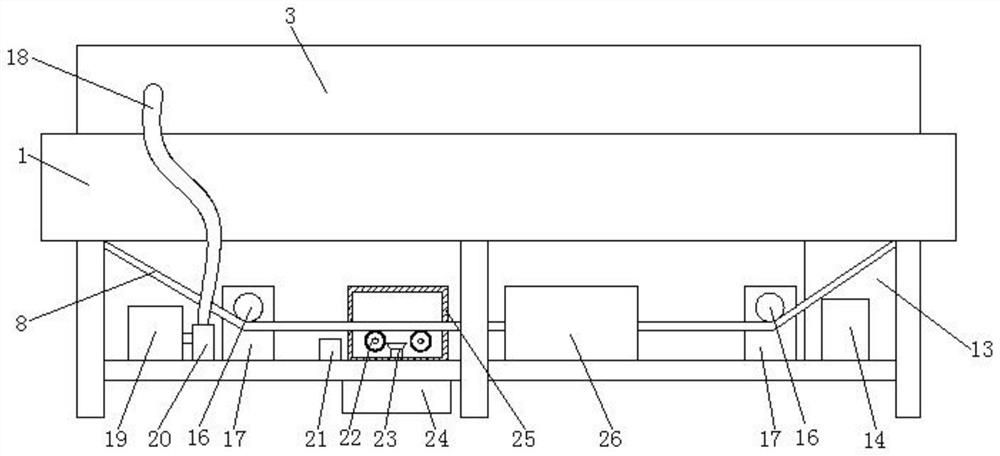

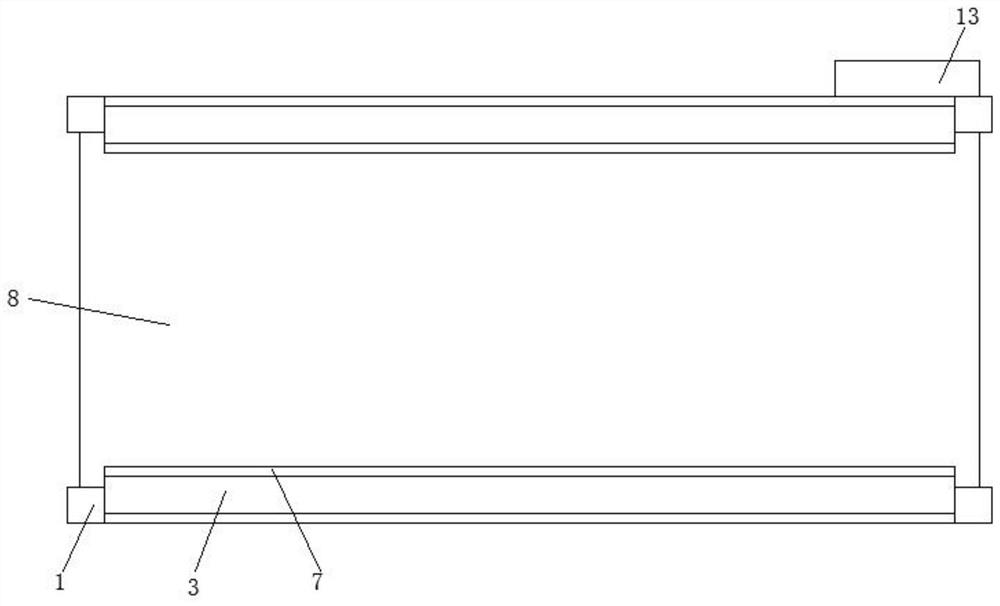

[0029] Such as Figure 1-5 As shown, the embodiment of the present invention provides a kind of industrial electrical automatic material conveying device, which includes a frame 1, and the inner side of the frame 1 is rotatably connected with a conveying roller 9, which is used to drive the conveyor belt 8 to rotate. The inside of the frame 1 is provided with a second A cylinder 2 is used to drive the limit plate 3 up and down to realize the limit needs of different mechanical parts. The output end of the first cylinder 2 is fixedly connected to the limit plate 3, and the right side of the limit plate 3 is located near the first One side of the cylinder 2 is provided with dust-absorbing cotton 4, which is used to absorb the flying dust entering the conveyor belt 8 or mechanical parts, and the right side of the limit plate 3 and the side away from the first cylinder 2 are provided with a rubber strip 7 Place the mechanical parts and hit the limit plate 3 to cause damage. An air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com