Passive hydraulic self-balancing adjusting and controlling device

A control device, self-balancing technology, applied in the direction of transmission, transportation and packaging, conveyor, etc., can solve the problem of inability to transmit power evenly, convey materials smoothly, difficult to have multiple belts, chain consistency, belt and chain tension Uneven force and other problems, to ensure continuous production, avoid unbalanced material transportation, and improve transfer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

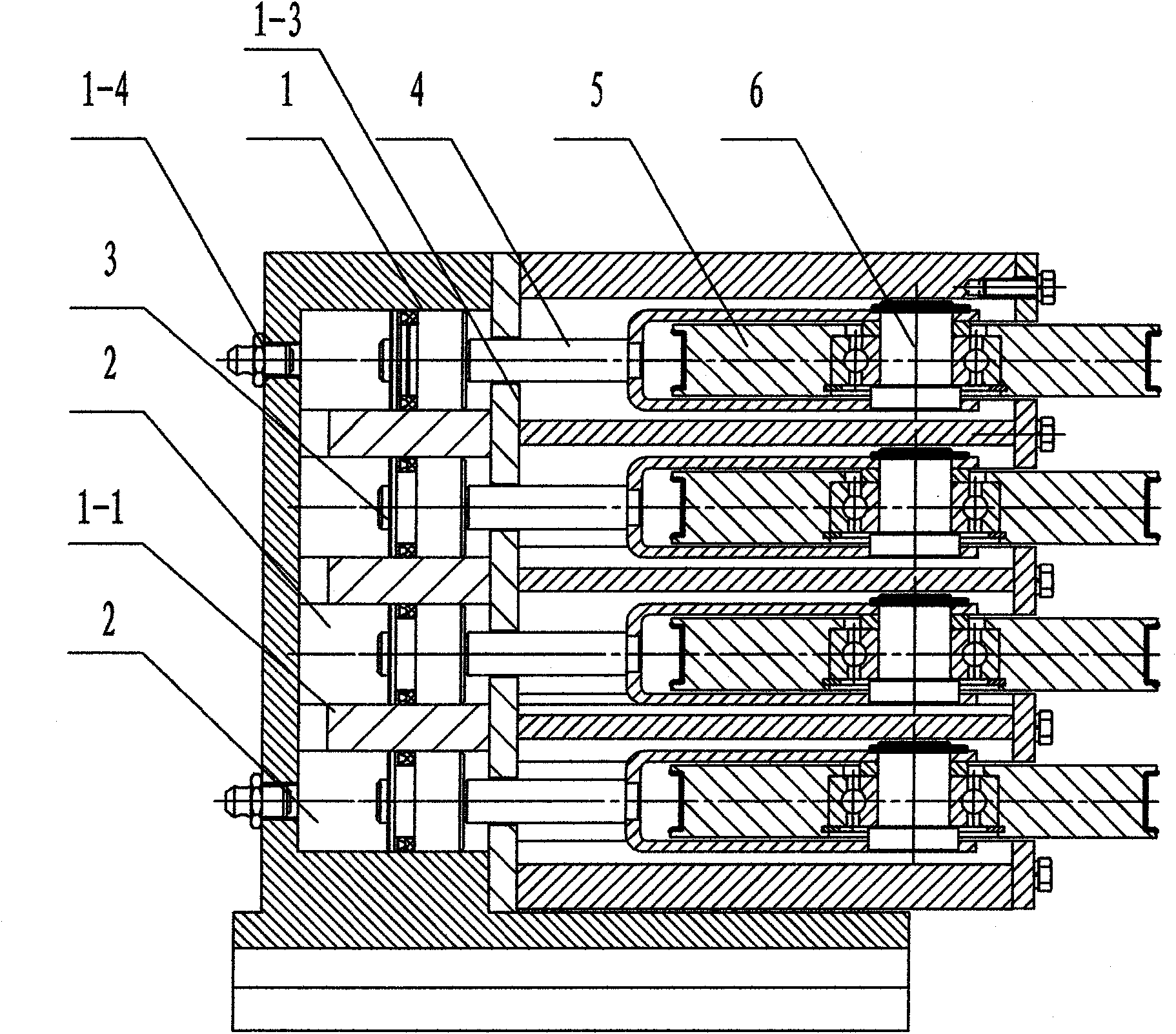

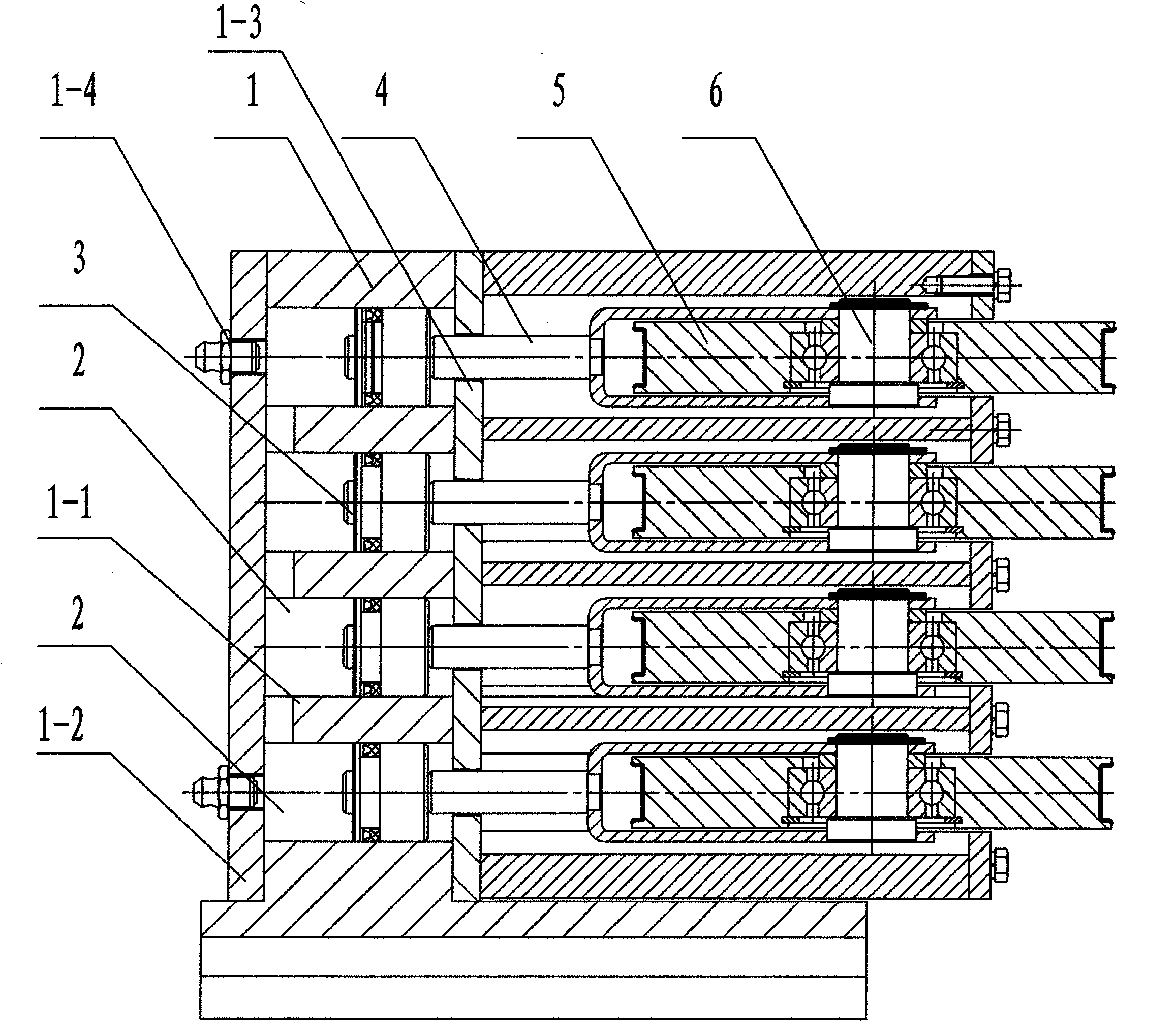

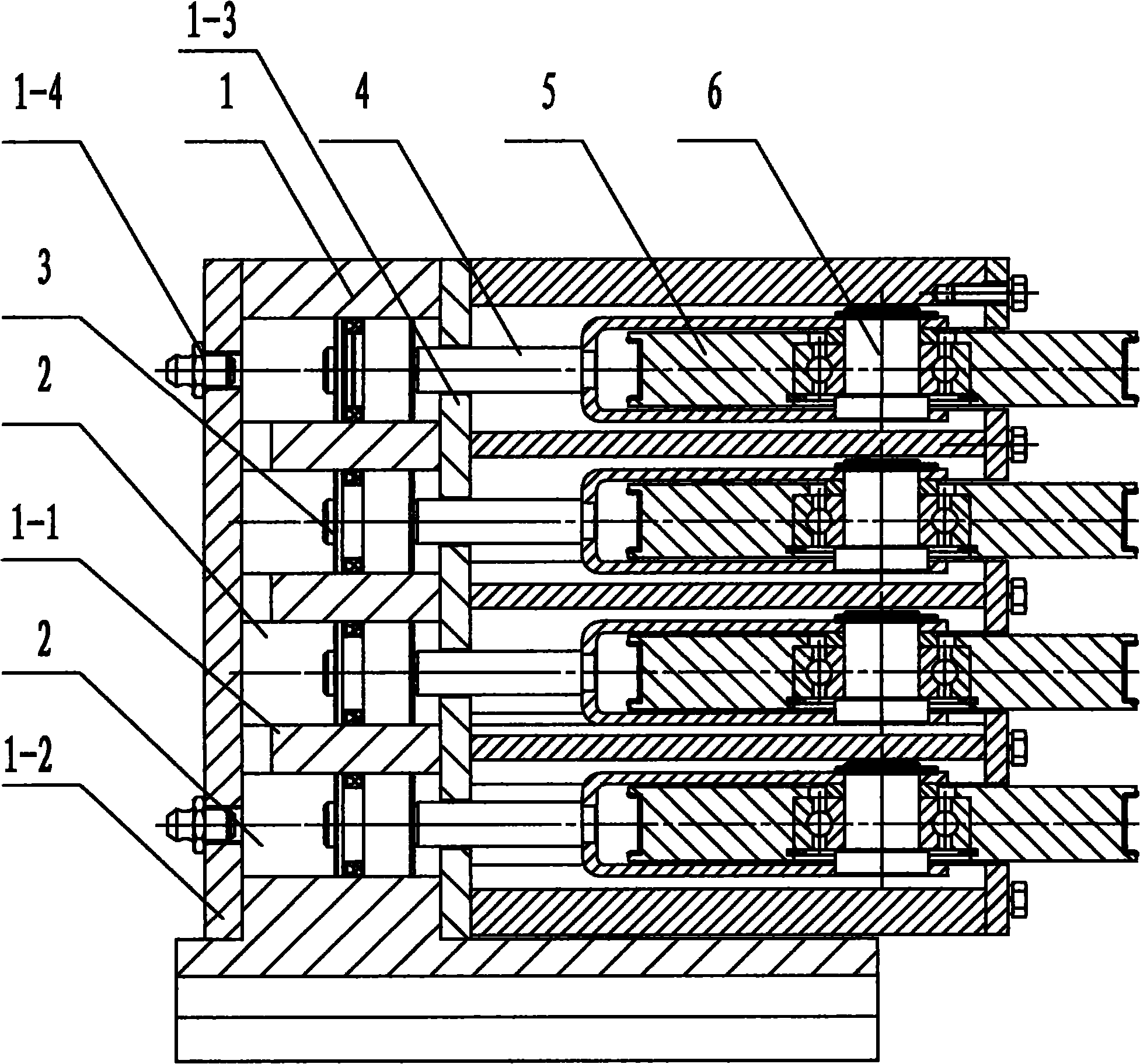

[0010] Referring to the accompanying drawings, the present invention provides a tensioning device with a simple structure, which can tension multiple belts, chains, etc., transmit power in a balanced manner, and transport materials in a hydraulic self-balancing and other force tensioning device.

[0011] The technical solutions adopted are:

[0012] (1), the described balance adjustment control device is provided with a group of cylinders 2 on the same cylinder 1, a piston 3 and a piston rod 4 are arranged in the cylinder 2, and one end of the piston rod 4 is connected with the piston 3 in the cylinder 2 , the other end of the piston rod 4 is connected with the adjustment control bracket 5 outside the cylinder 2 .

[0013] (2), the adjustment control wheel 6 is set on the adjustment control bracket 5 .

[0014] (3), a group of cylinder barrels 2 communicate with each other, and the other side where the piston rod 4 is installed on the piston 3 communicates with each other.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com