Patents

Literature

30results about How to "Realize up and down displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

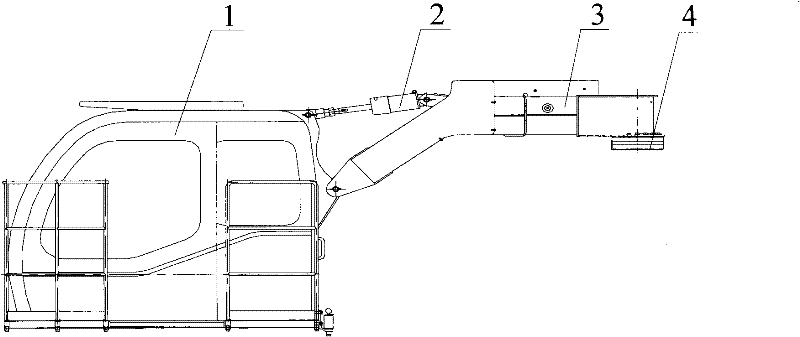

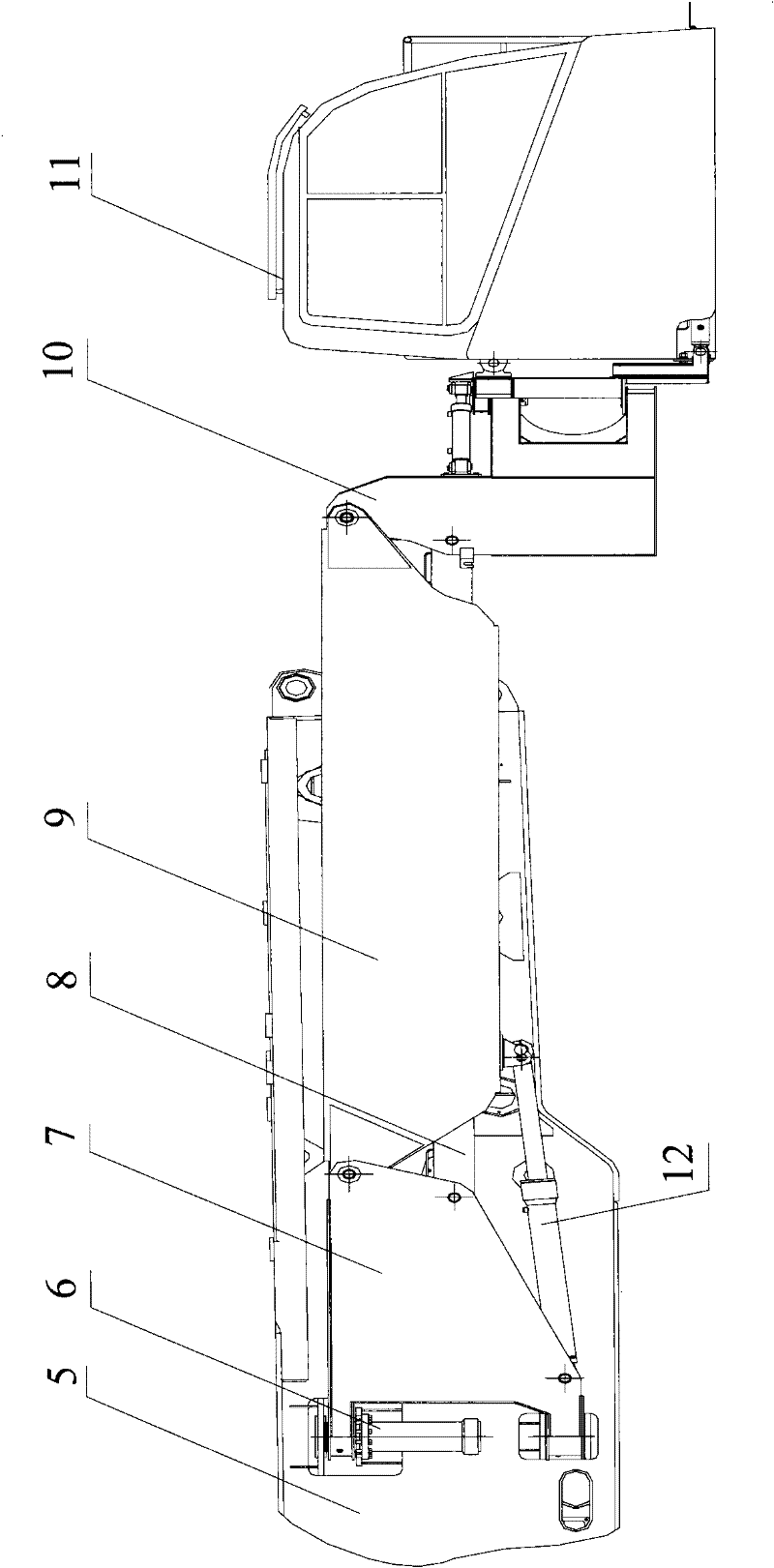

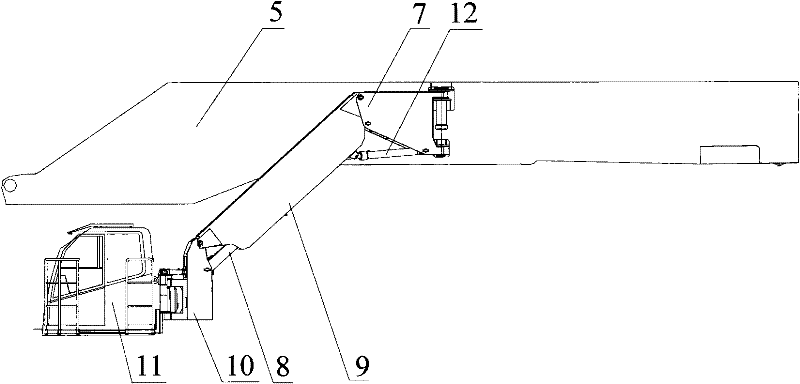

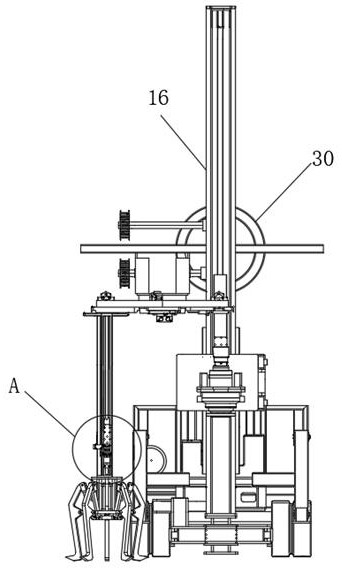

Crane and its displacement device

InactiveCN102408066AAdd position changeRealize up and down displacementLoad-engaging elementsEngineeringHorizon

The invention provides a displacement device disposed between the rotary table and control room of an engineering machine. The displacement device comprises a four-bar linkage and a first transmission mechanism. The four-bar linkage consists of a frame body, an upper side link body, a connecting rod body and a lower side link body that are hinged in order. The first transmission mechanism is disposed between the frame body and the rotary table, and used for driving the four-bar linkage to rotate relative to the rotary table horizontally. A first oil cylinder is positioned between the frame body and one of the upper side link body and the lower side link body. The connecting rod body is in connection with the control room. The displacement device of the invention can be convenient for staff to get in and out of the control room and can broaden the horizon of staff. In addition, the invention also provides a crane with the above displacement device.

Owner:XUZHOU HEAVY MASCH CO LTD

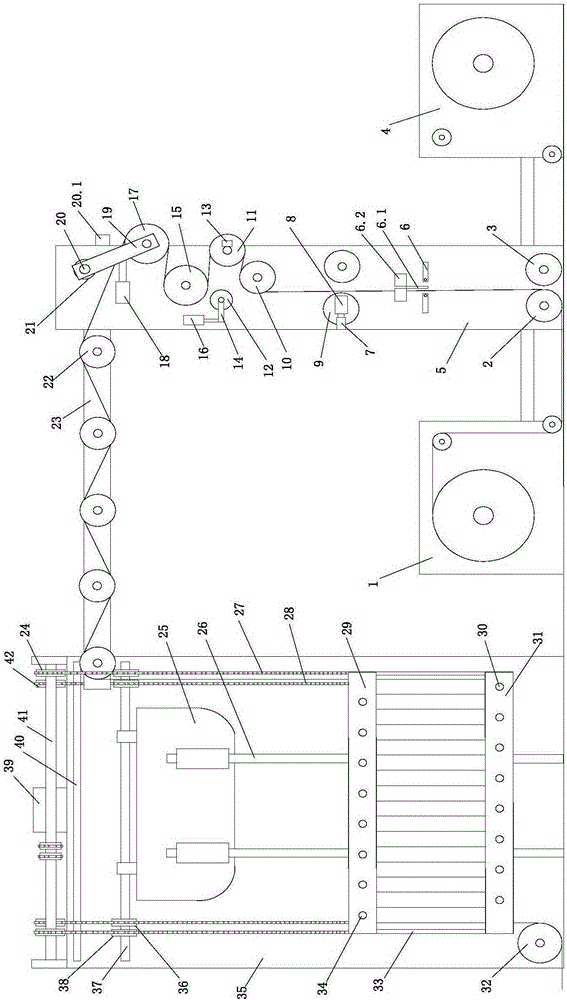

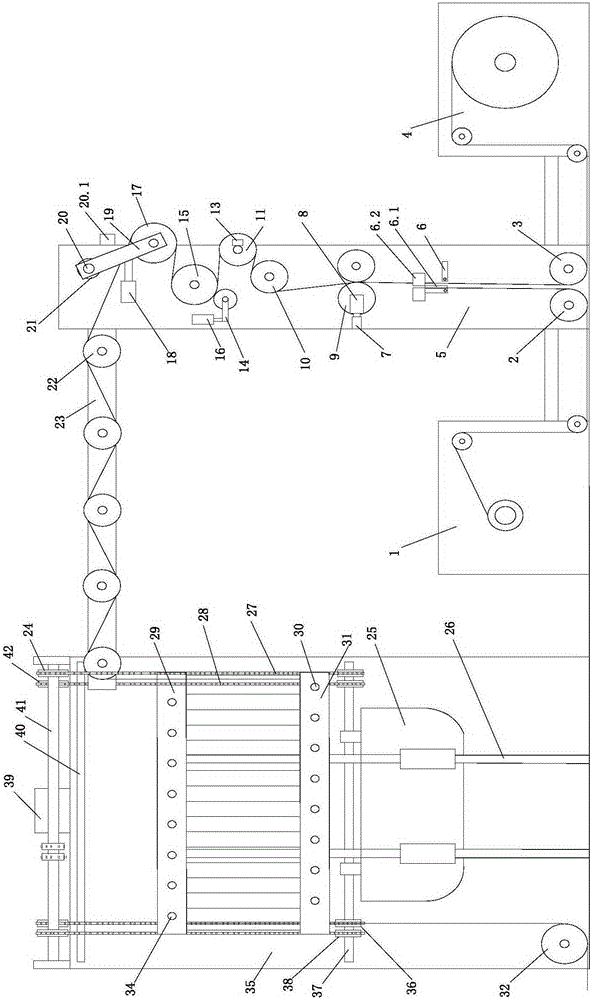

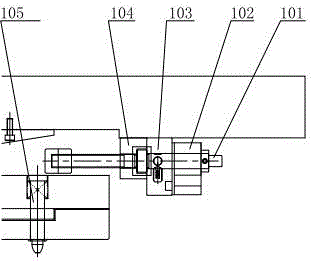

Continuous web feeding system

The invention relates to a continuous production machining system, in particular to a continuous web feeding system. The continuous web feeding system comprises a first web feeding machine, a second web feeding machine, a web cutting device, a web receiving device, a web storage roller pair and a web storage box; the web storage roller pair vertically shifts in the web storage box to store and release webs to be printed; in the process of storing the webs to be printed by the web storage roller pair, the web cutting device and the web receiving device finish web changing work of the web to be printed on the first web feeding machine and the web to be printed on the second web feeding machine, so that the function of continuously feeding webs without halt is achieved, the production efficiency is improved, energy loss is reduced, and then the production cost is reduced.

Owner:CHONGQING HONGJIN PRINTING

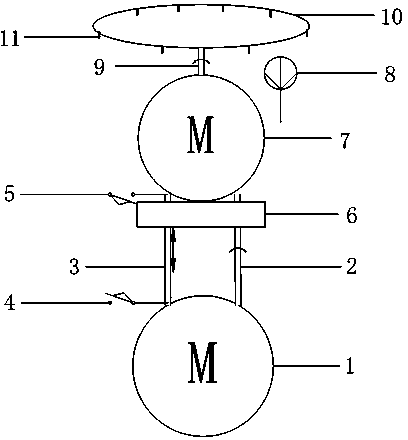

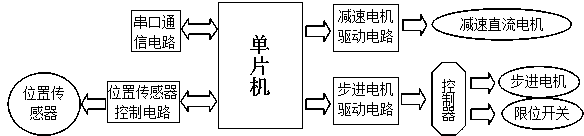

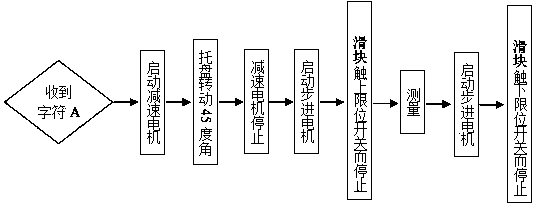

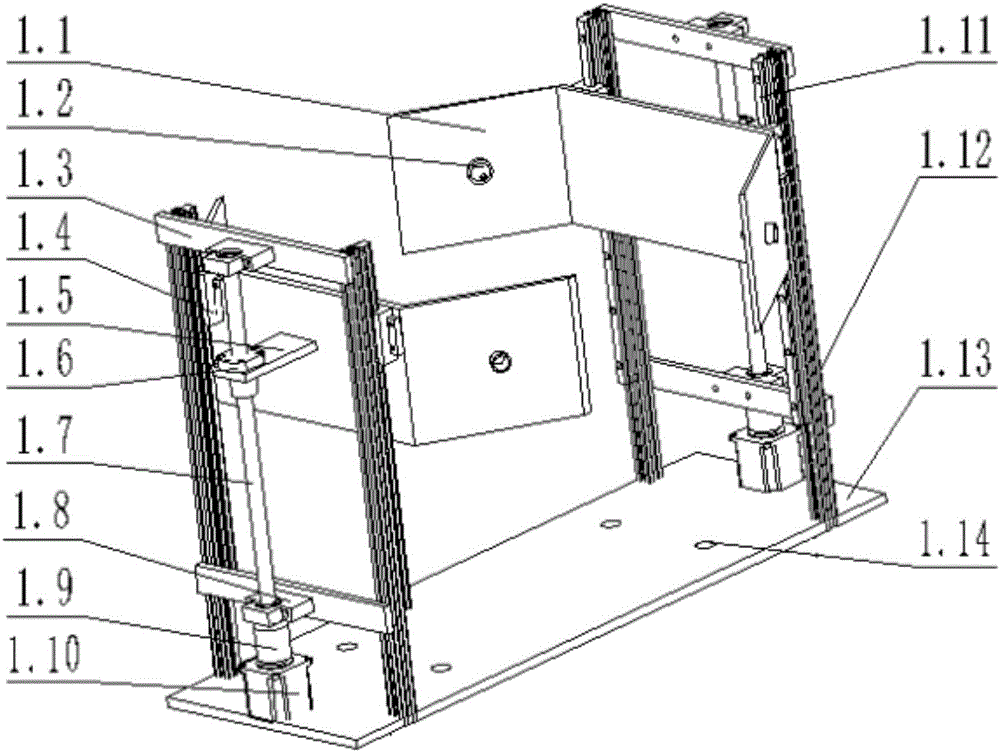

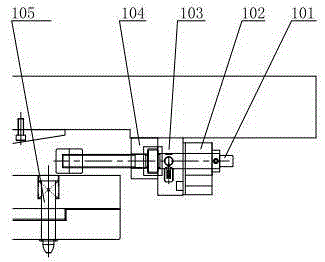

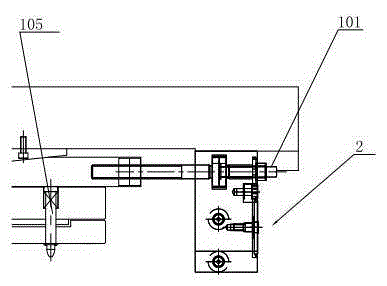

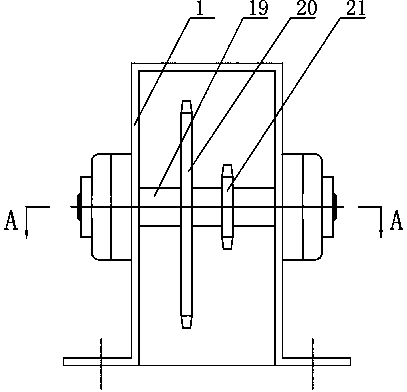

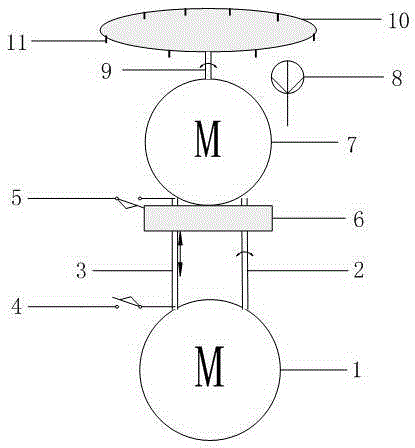

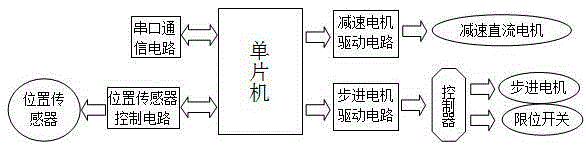

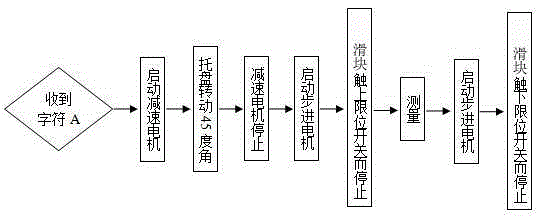

Wet pulp sample placement apparatus and control method thereof

InactiveCN103487311AThe result of whiteness test is accurateSimple structurePreparing sample for investigationMicrocontrollerElectricity

The present invention relates to the technical field of paper pulp whiteness detection during a pulping papermaking process, more particularly to a wet pulp sample placement apparatus and a control method thereof. The wet pulp sample placement apparatus comprises a first motor, a sliding track connected with the first motor, and a sliding block arranged on the sliding track, wherein the upper end portion and the lower end portion of the sliding track are respectively provided with an upper position limitation switch and a lower position limitation switch. The wet pulp sample placement apparatus further comprises a second motor, a rotation shaft and a tray, wherein the second motor is fixed on the sliding block, one end of the rotation shaft is connected with the second motor, the other end is connected with the tray, and the second motor is provided for driving the tray to rotate through the rotation shaft. The wet pulp sample placement apparatus further comprises a single-chip computer arranged inside the wet pulp sample placement apparatus, wherein the single-chip computer is respectively and electrically connected with the first motor, the second motor, the upper position limitation switch and the lower position limitation switch. The wet pulp sample placement apparatus has the following characteristics that: the structure is simple, up and down displacement can be achieved, 360 DEG rotation can be achieved, and the apparatus can be adopted to replace manual rotation of a sample requiring detection, such that the whiteness detection result of the sample is accurate.

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

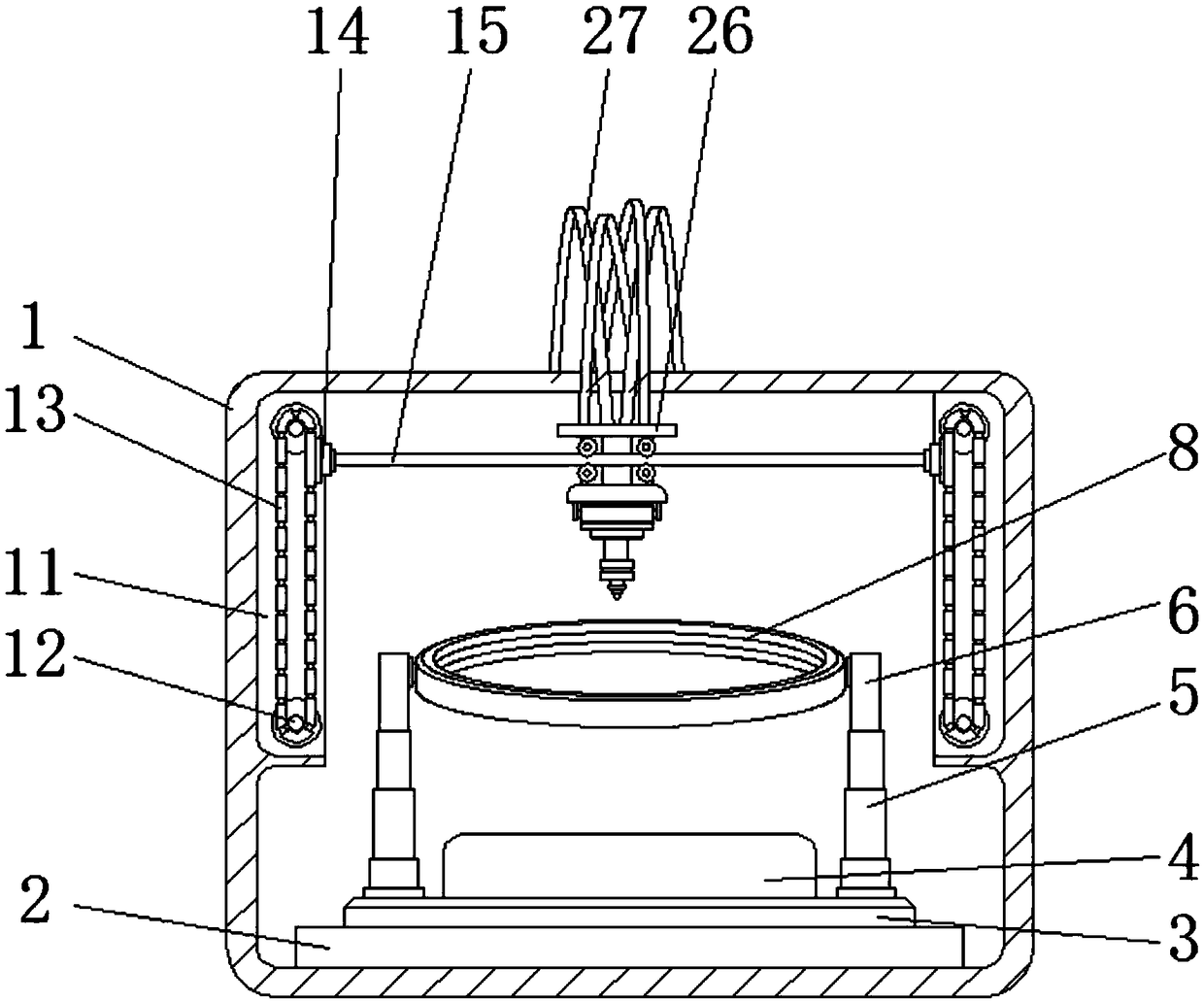

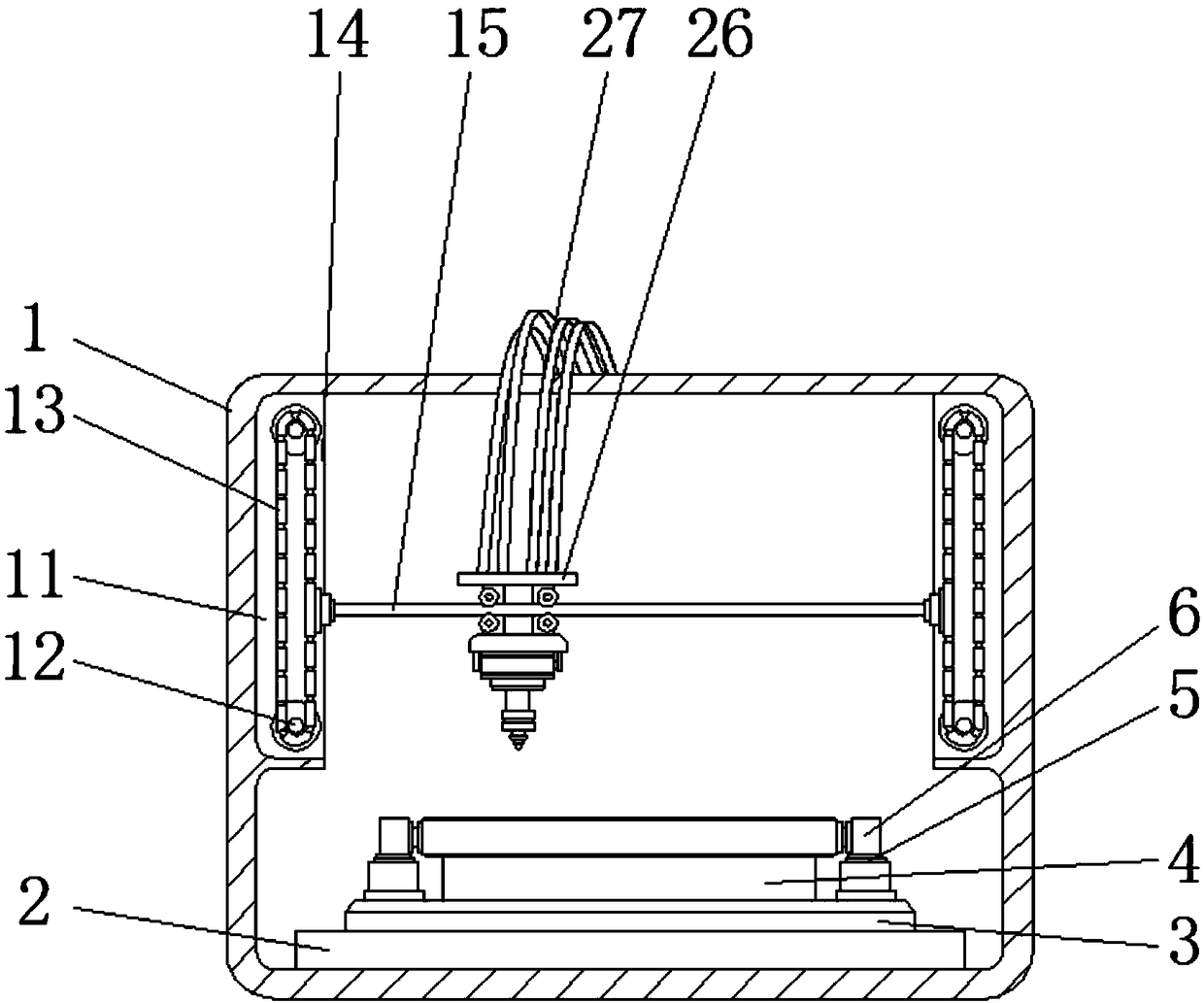

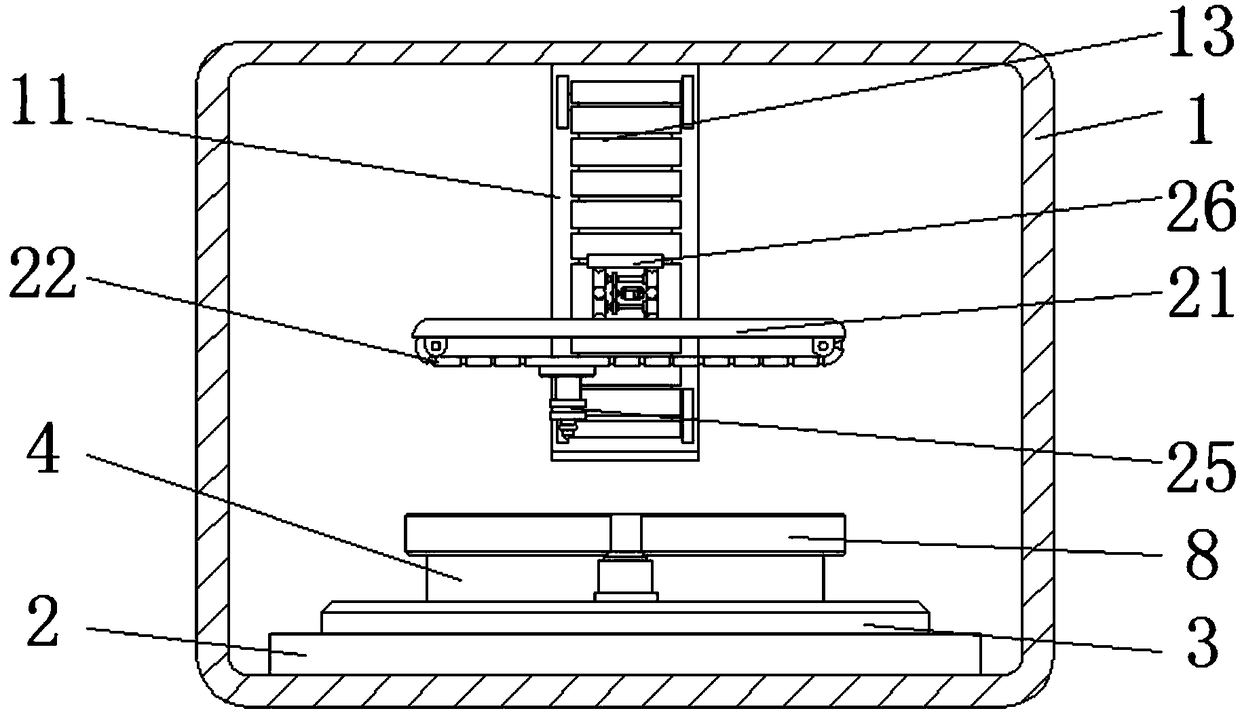

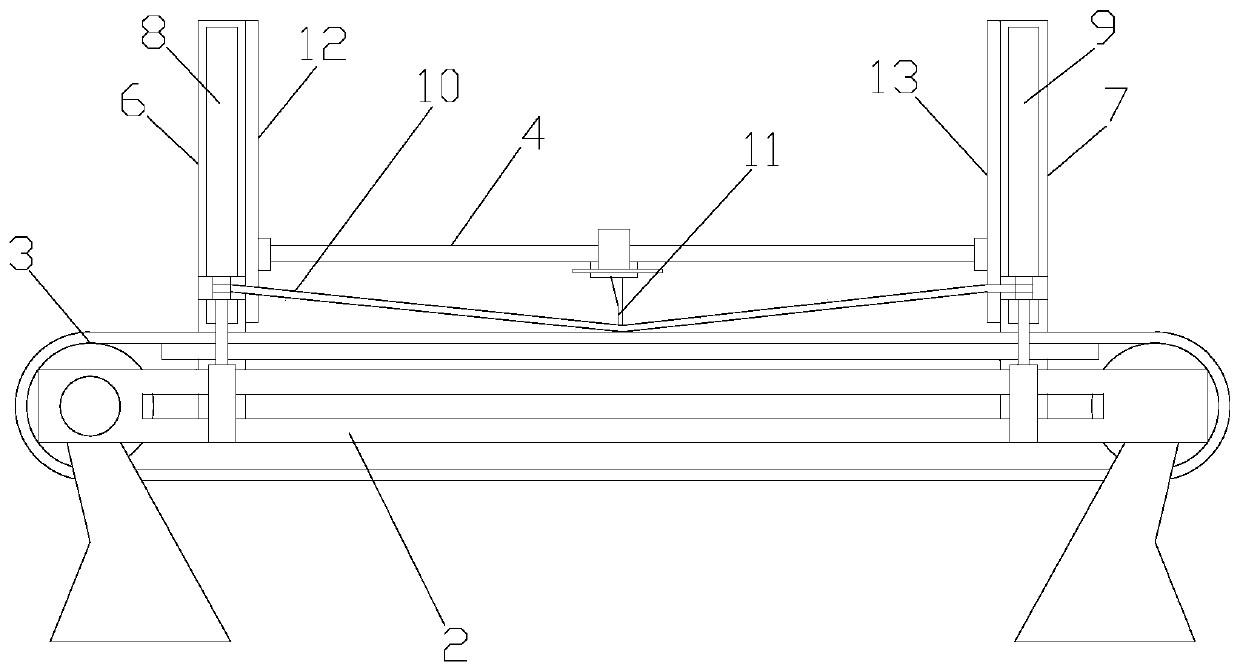

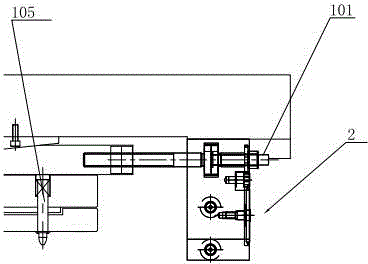

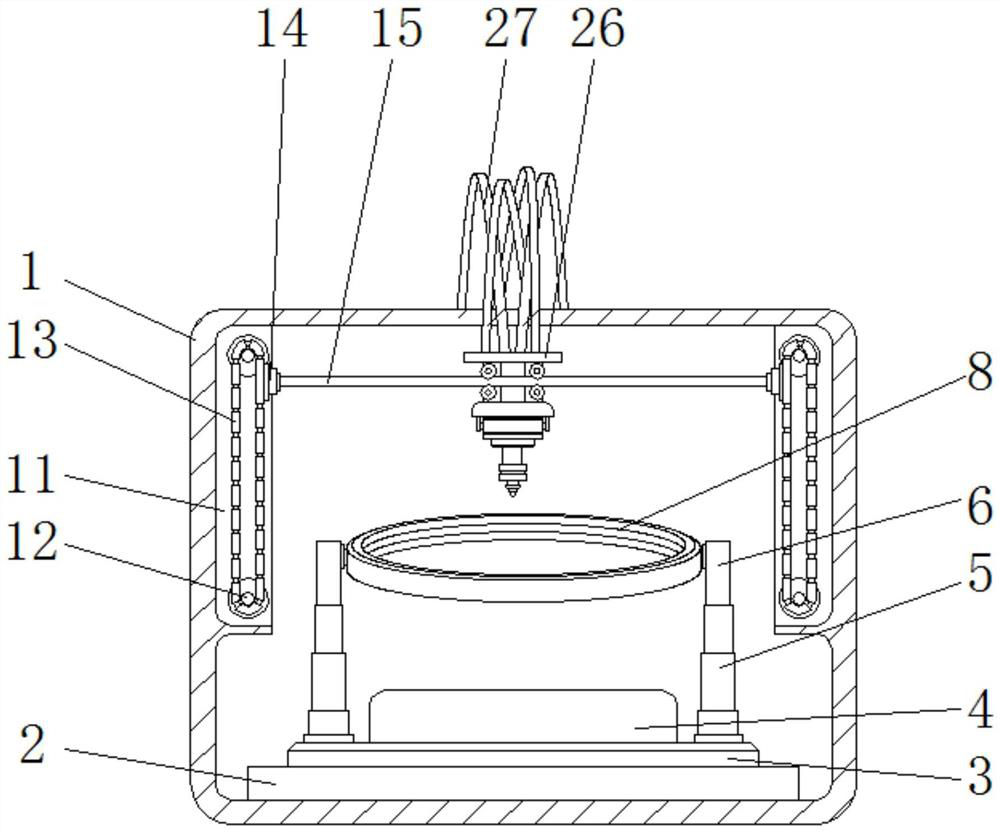

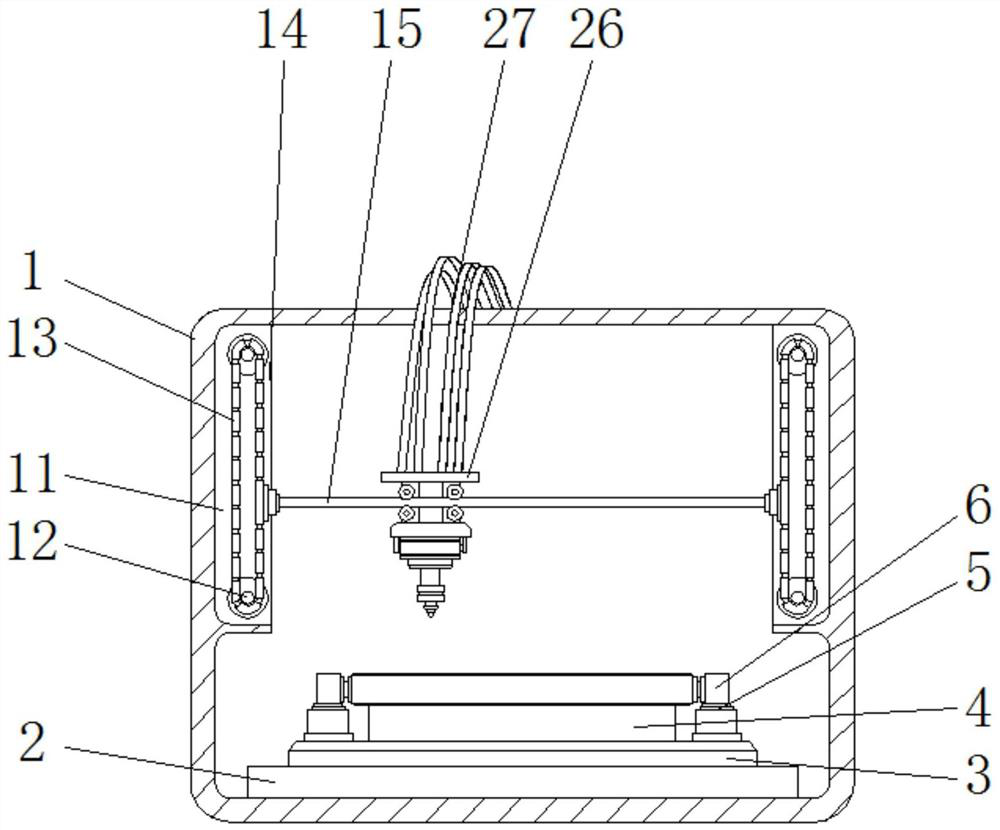

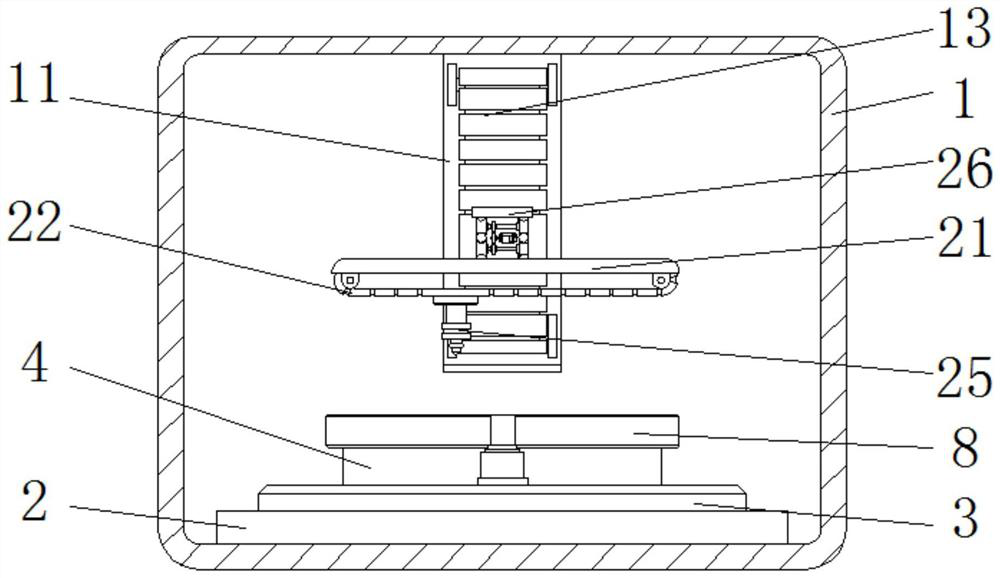

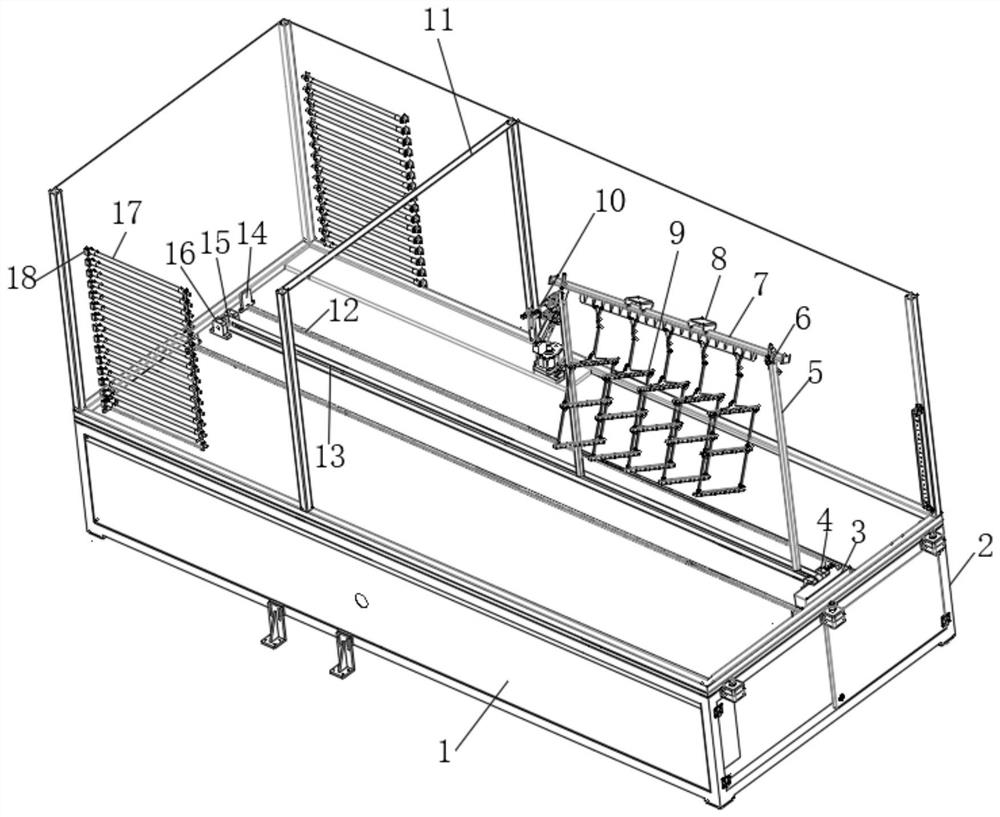

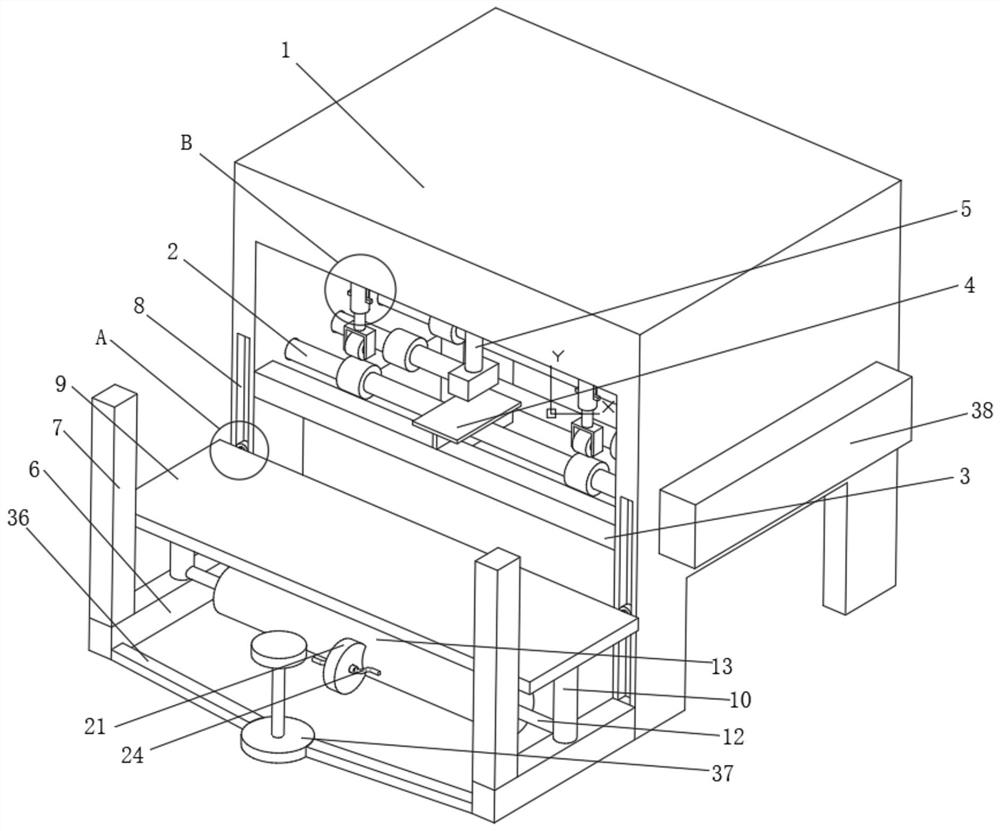

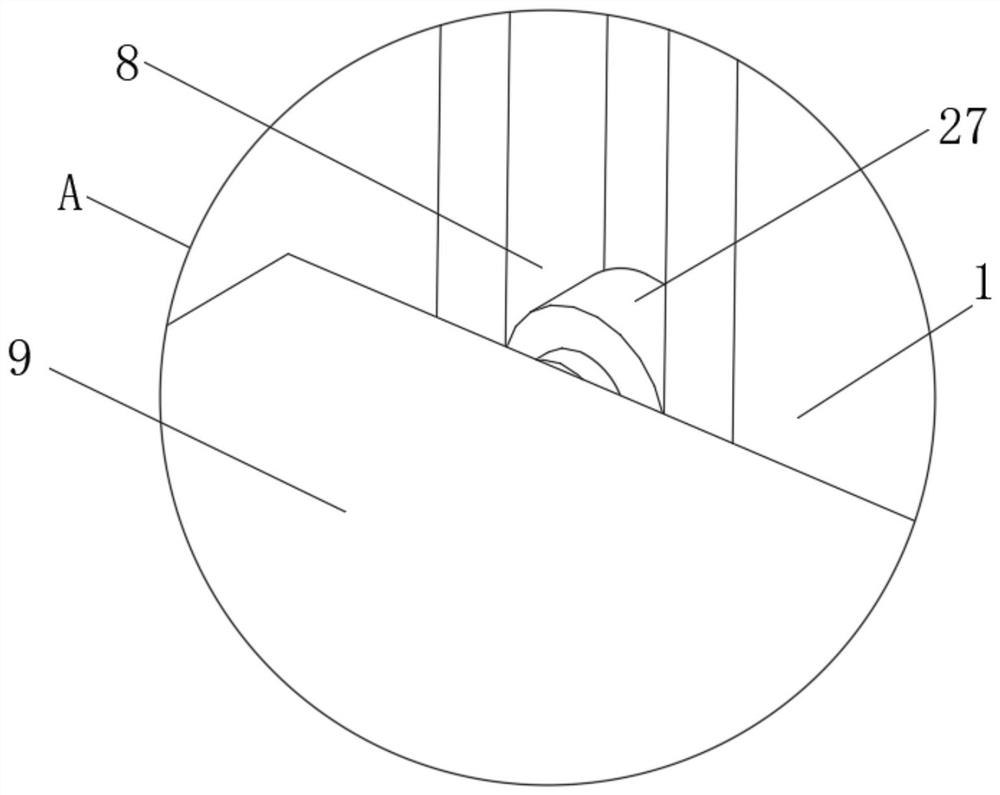

3D printer with rotating automatic coloring structure

ActiveCN108312541ARealize up and down displacementAchieve forward and backward displacementAdditive manufacturing apparatusAdditive manufacturing with liquids3d printSprayer

The invention discloses a 3D printer with a rotating automatic coloring structure. The 3D printer comprises a body shell, a coloring ring, braking areas, a drive gear and a movable base. An inner bottom plate is arranged at the lower portion in the body shell. An operation table is fixed to the upper portion of the inner base. A control rod is arranged above a telescopic rod. A sliding groove is formed in the coloring ring and internally provided with a coloring sprayer. A fixing rotation shaft is arranged at the lower end in each braking area, wherein a vertical moving crawler belt is arranged above the fixing rotation shaft. Compared with an existing ordinary 3D printer, according to the 3D printer with the rotating automatic coloring structure, equipment inner structures are reduced asmuch as possible under the situation that the printing performance of the 3D printer is guaranteed, the equipment production and usage cost is effectively reduced, the original manner that productionis conducted through basic material colors is abandoned, automatic coloring during machining or after machining can be achieved, and the application range of the whole equipment is greatly enlarged.

Owner:WANGYUN WUHAN 3D TECH CO LTD

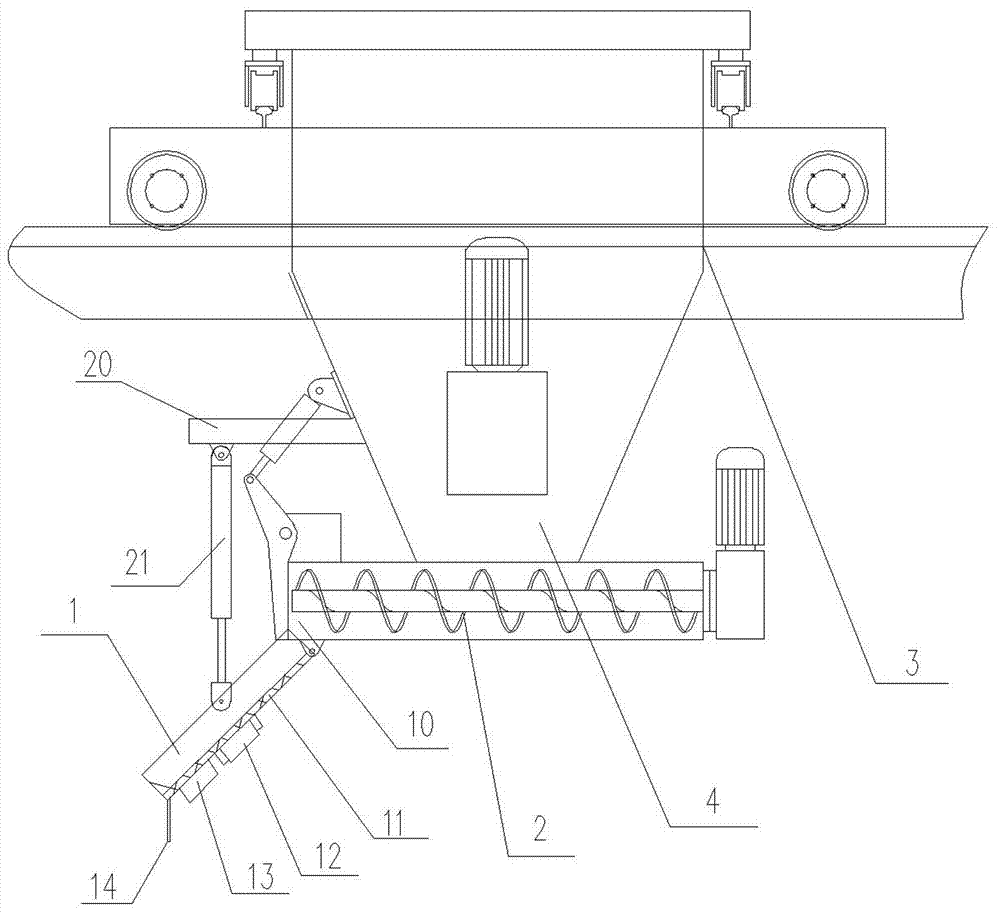

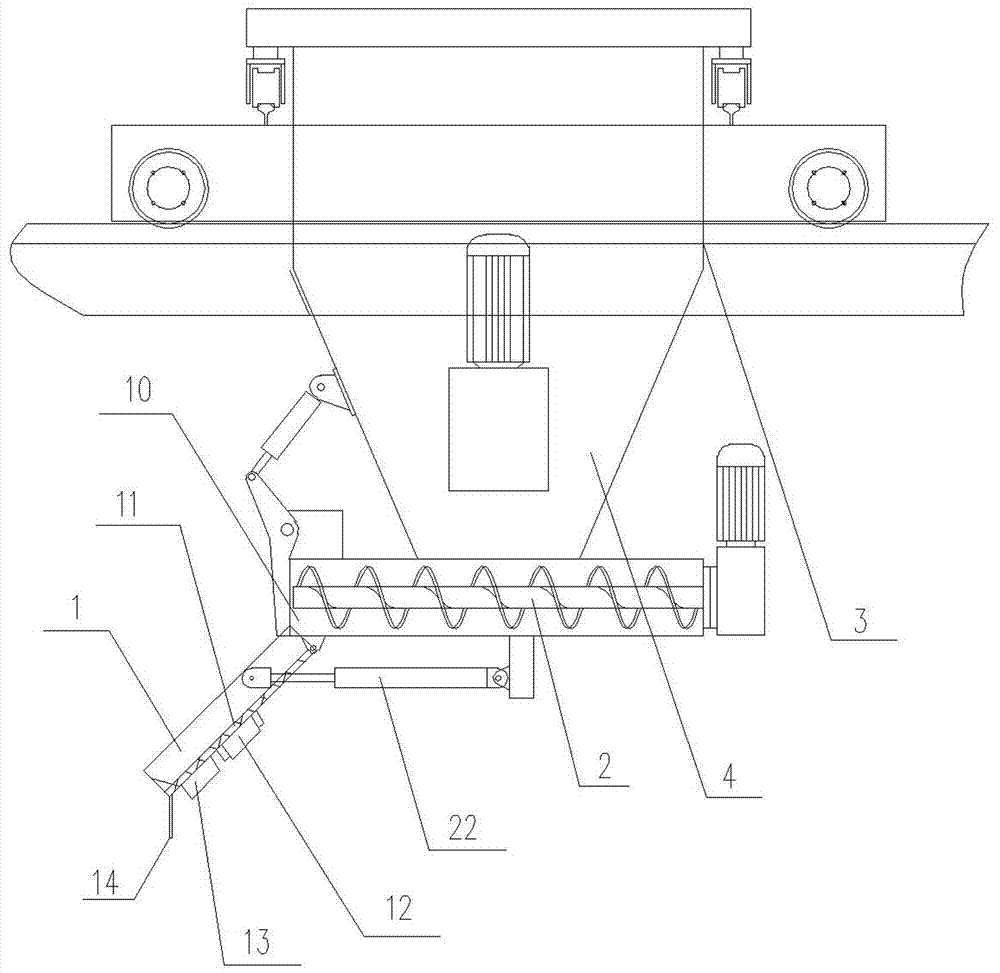

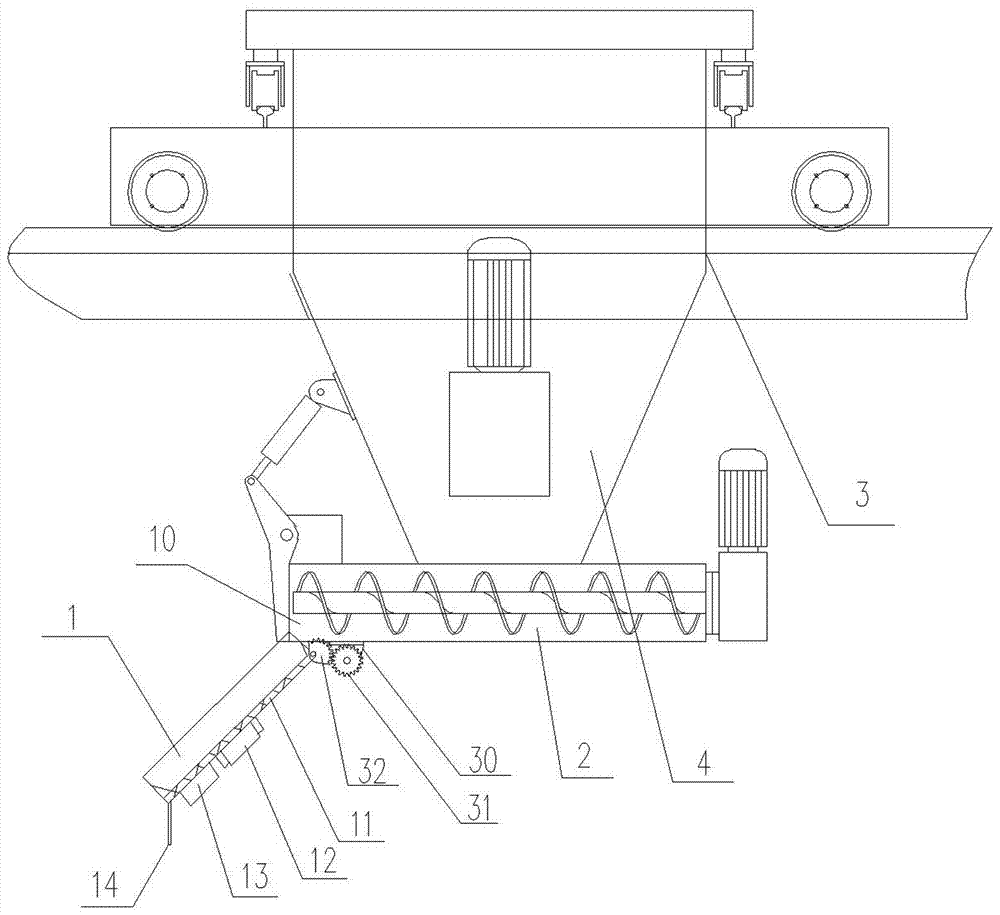

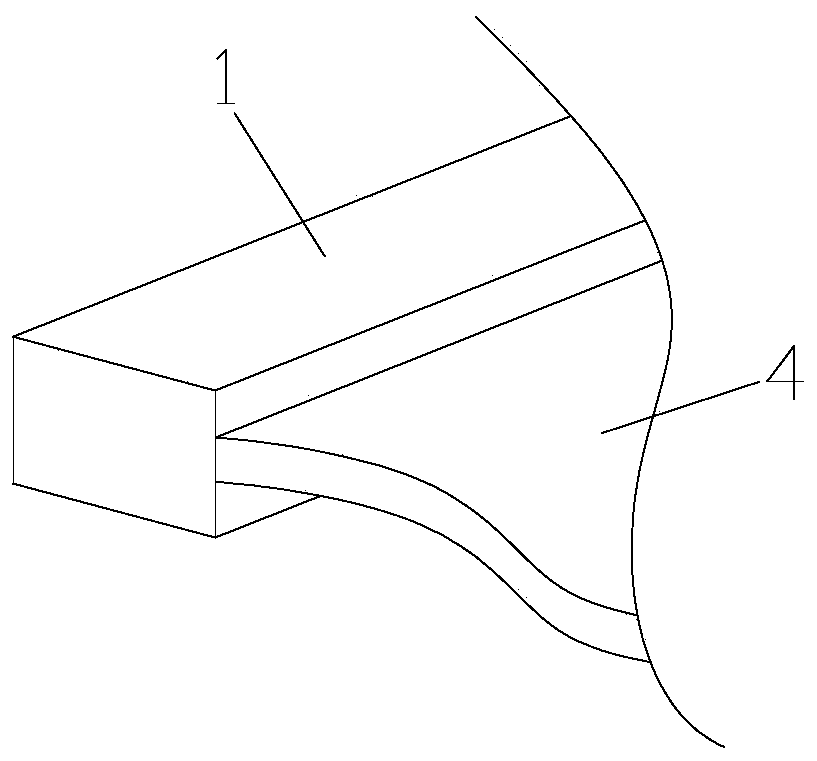

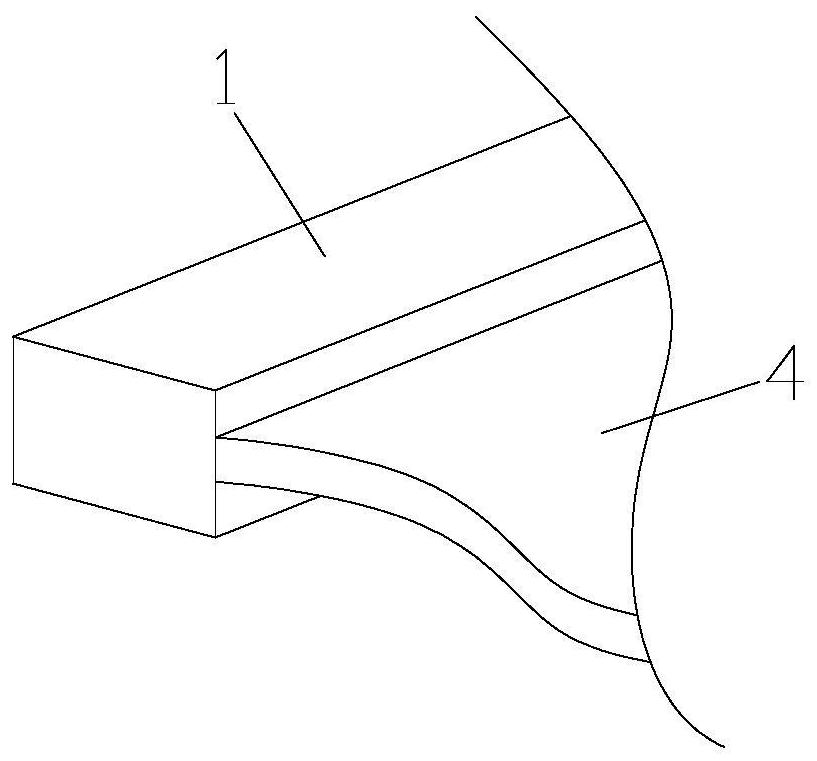

Cloth chute device for cloth machine

InactiveCN107322776ALow failure rateImplementation failureFeeding arrangmentsProcess engineeringMechanical engineering

The invention relates to a cloth chute device for a cloth machine. The cloth chute device comprises a cloth chute and a driving device, wherein the cloth chute is hinged to the bottom of a cloth outlet of the cloth machine; and one end of the driving device is mounted onto the cloth machine, and the other end of the driving device is connected with the cloth chute. The cloth chute serves as a cloth machine accessory which is arranged externally, can be rapidly and conveniently mounted at a discharging opening of the cloth machine and is convenient to demount. By means of the cloth machine, the height of an outlet of the cloth chute is adjusted through the driving device; the cloth chute can be better adapted to production of concrete parts of different thicknesses; the cloth chute is simple in structure, low in failure rate and low in production cost; when the cloth chute is in the feeding process, compared with the mode that a whole feeding funnel moves up and down, vertical displacement of a discharging opening of the cloth chute is achieved through swing of the cloth chute under the effect of small driving force, and height adjustment can also be achieved; the requirement that the cloth chute device is adapted to different workpieces is met; the structure is simple; and the driving device operates independently and is not prone to failure, so that reliability is high.

Owner:河北华远冶金设备有限公司

Cleaning device for insulators of electric lines

ActiveCN106076941ASave human effortEnsure personal safetyCleaning using liquidsApparatus for overhead lines/cablesWater tanksNozzle

The invention relates to a cleaning device for insulators of electric lines. The cleaning device is characterized by comprising a cleaning module, a lifting module, a walking module, a water pipe box, a water tank and a water pump, wherein the cleaning module is fixed to the walking module by virtue of the lifting module, the water pipe box, the water tank and the water pump are all fixed to the walking module, and the water pipe box is connected with the water tank by virtue of the water pump; the cleaning module comprises a cleaning arm, a nozzle, a sliding block, a screw-nut mechanism, a guide rail, guide rail brackets and a workbench; a workbench water outlet is formed in the workbench, the guide rail brackets are arranged on the outer side of the workbench water outlet, the guide rail is fixed to the guide rail brackets by virtue of screws, a connecting frame is horizontally connected between the two adjacent guide rail brackets, the screw-nut mechanism is fixed to the outer side of the middle of the connecting frame along a vertical direction, and the screw-nut mechanism comprises a screw connecting plate, a screw nut, a screw, bearing seats, a coupling and a stepping motor; the stepping motor is connected with screw by virtue of the coupling, and the bearing seats sleeve both ends of the screw.

Owner:HEBEI UNIV OF TECH

Screen printer

The invention discloses a screen printer. The screen printer comprises a net frame, a support frame, a conveyor and an electric linear guide rail, wherein a supporting plate used for supporting a conveyor belt is arranged on the supporting frame, the supporting plate is fixedly connected with the supporting frame, the conveyor is mounted on the support frame, the belt of the conveyor is clung to the supporting plate, a first connecting plate and a second connecting plate are arranged on the supporting frame, a first sliding guide rail and a second sliding guide rail are arranged on the front surface of the first connecting plate and the front surface of the second connecting plate respectively, clamps used for clamping the net frame is arranged on the first sliding guide rail and the second sliding guide rail, a net plate is arranged on the net frame, the net plate is located right above the supporting plate, the electric linear guide rail is mounted between the first connecting plateand the second connecting plate, and a scraping plate matched with the net plate is arranged on a slider of the electric linear guide rail. The screen printer can adjust the screen height so as to prevent the scraping plate from working under the condition of high load for a long time.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

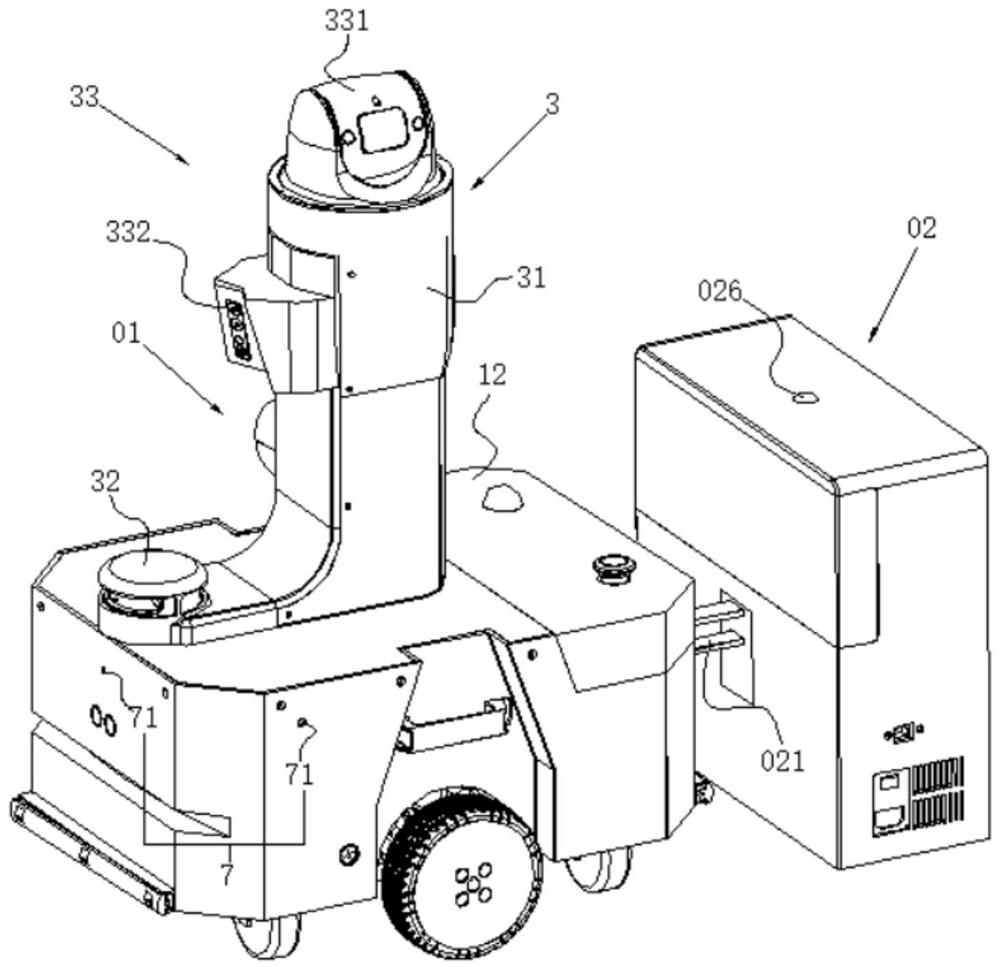

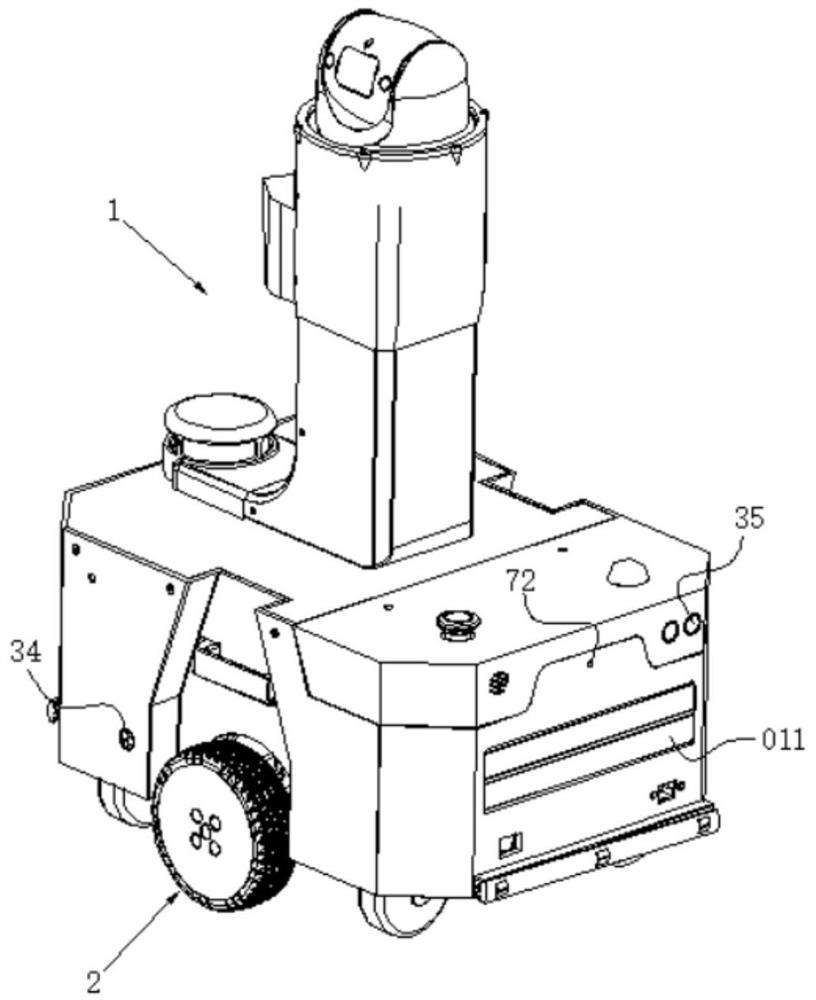

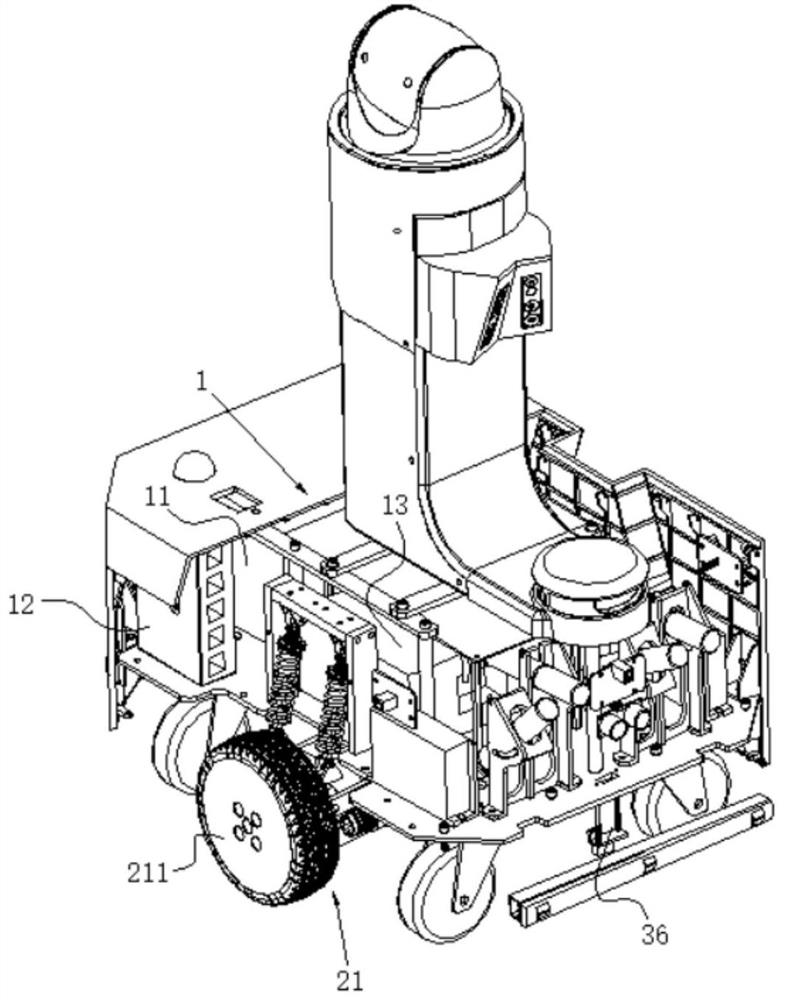

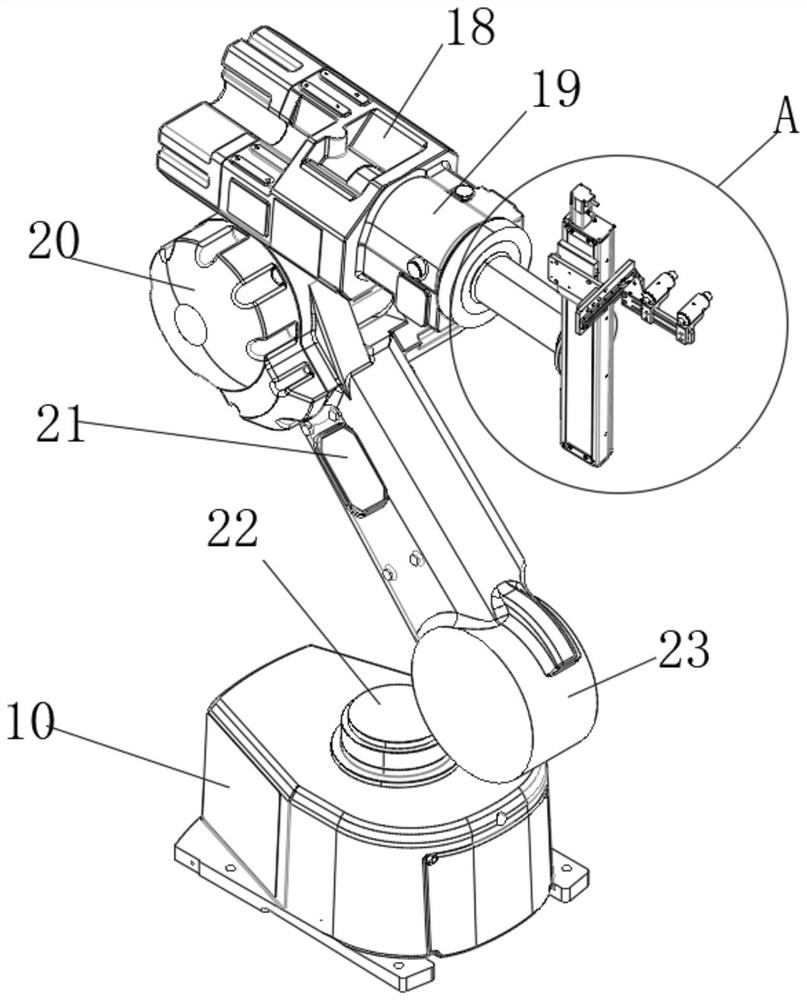

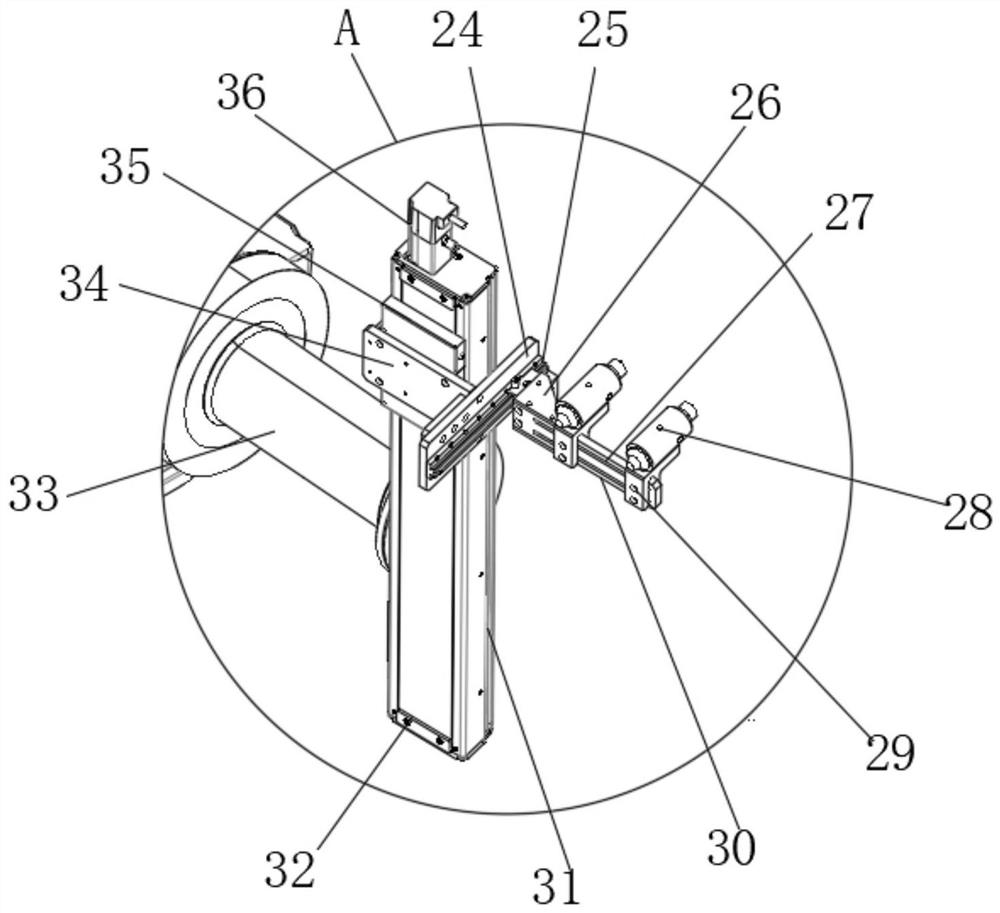

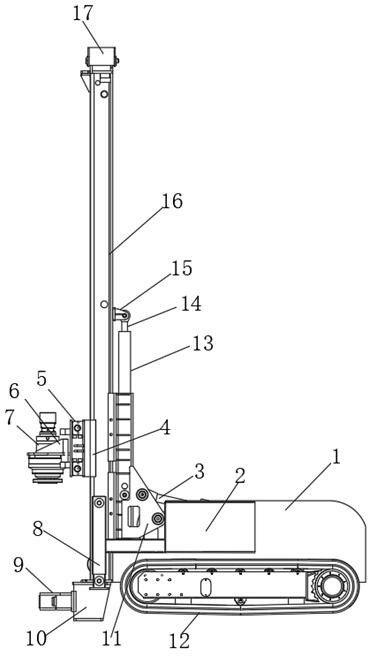

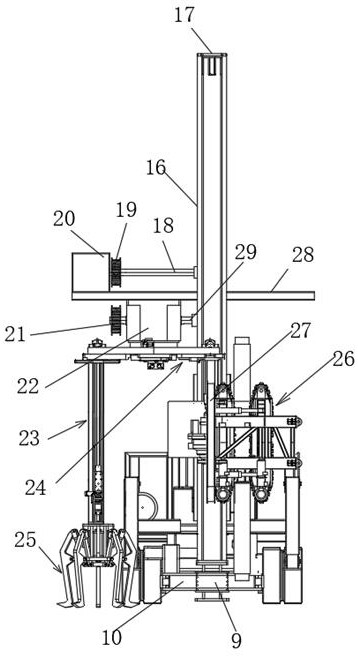

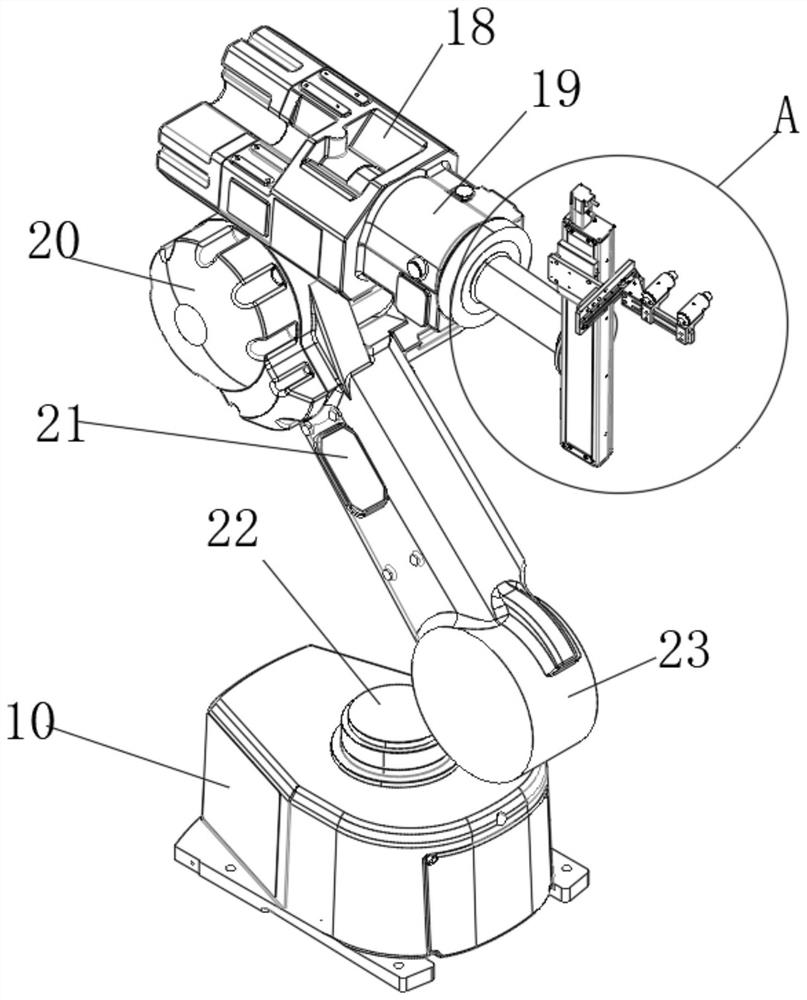

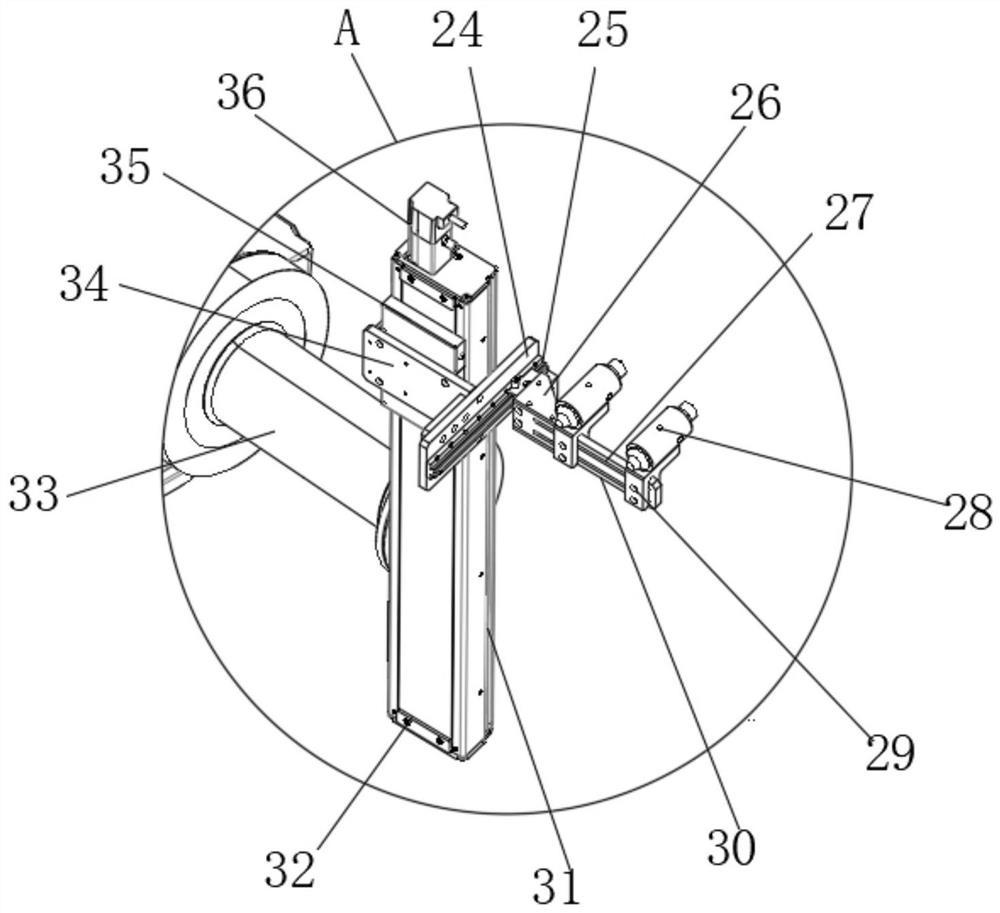

Intelligent inspection robot

InactiveCN113547502AReduce labor costsImprove inspection efficiencyManipulatorSimulationElectronic map

The invention discloses an intelligent inspection robot which comprises a robot body and a charging cabinet, a positive and negative charging panel is arranged on the periphery of the robot body, and the charging cabinet is provided with a charging contact matched with the positive and negative charging panel; and the robot body comprises a control device, a driving device and an inspection device, and the inspection device comprises a stand column located on a shell, a laser radar and a camera shooting assembly. Through cooperation of the control device, the driving device and the inspection device on the robot body, the robot moves in the inspection space to collect the surrounding environment, draws an electronic map, plans an inspection route, periodically controls the robot body to inspect and collects the surrounding information, fully automatically completes the inspection work, reduces the labor cost, and improves the inspection efficiency and effect; and meanwhile, full-automatic charging of the robot body is completed in cooperation with the charging cabinet arranged in the space, the long-term inspection requirement is met, and great convenience is achieved.

Owner:TOUCHAIR TECH

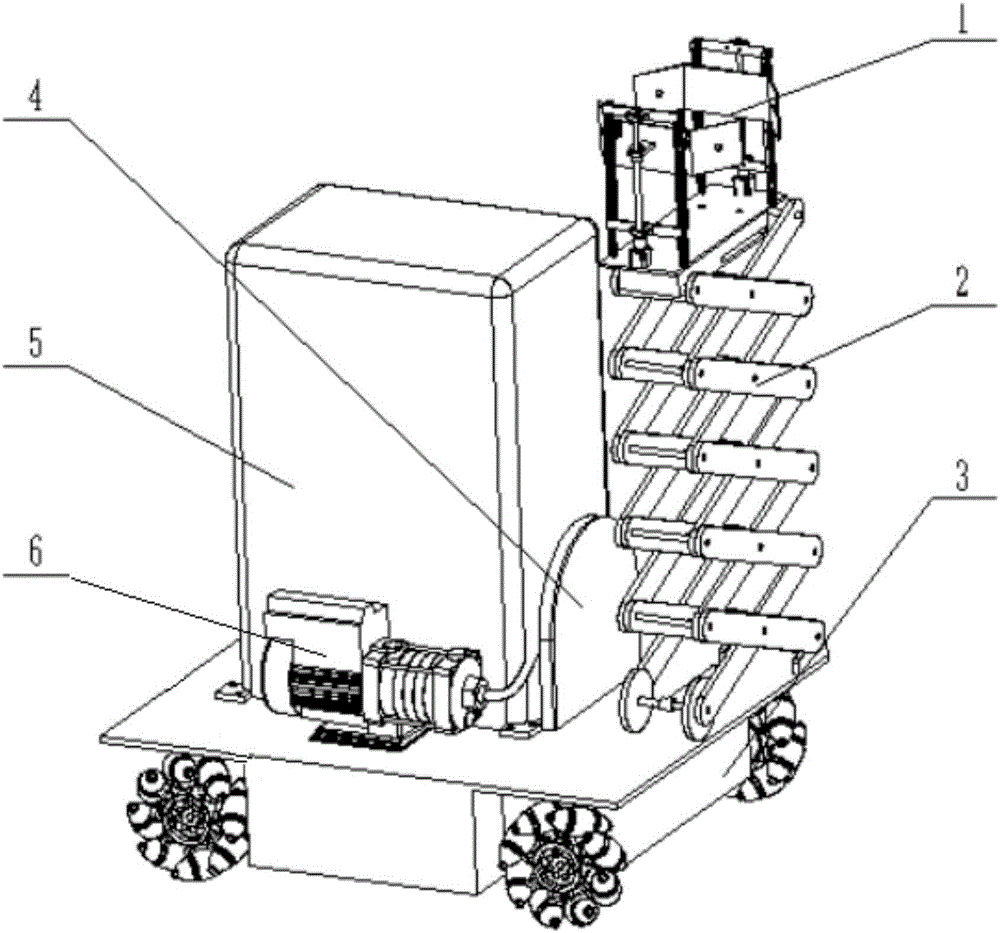

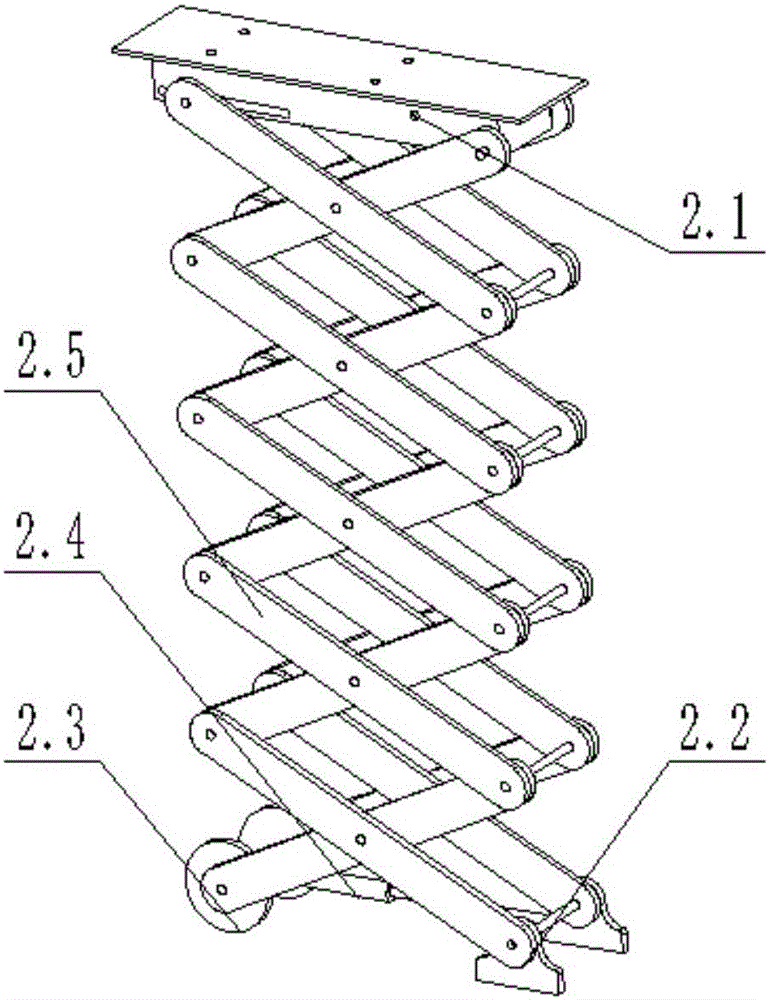

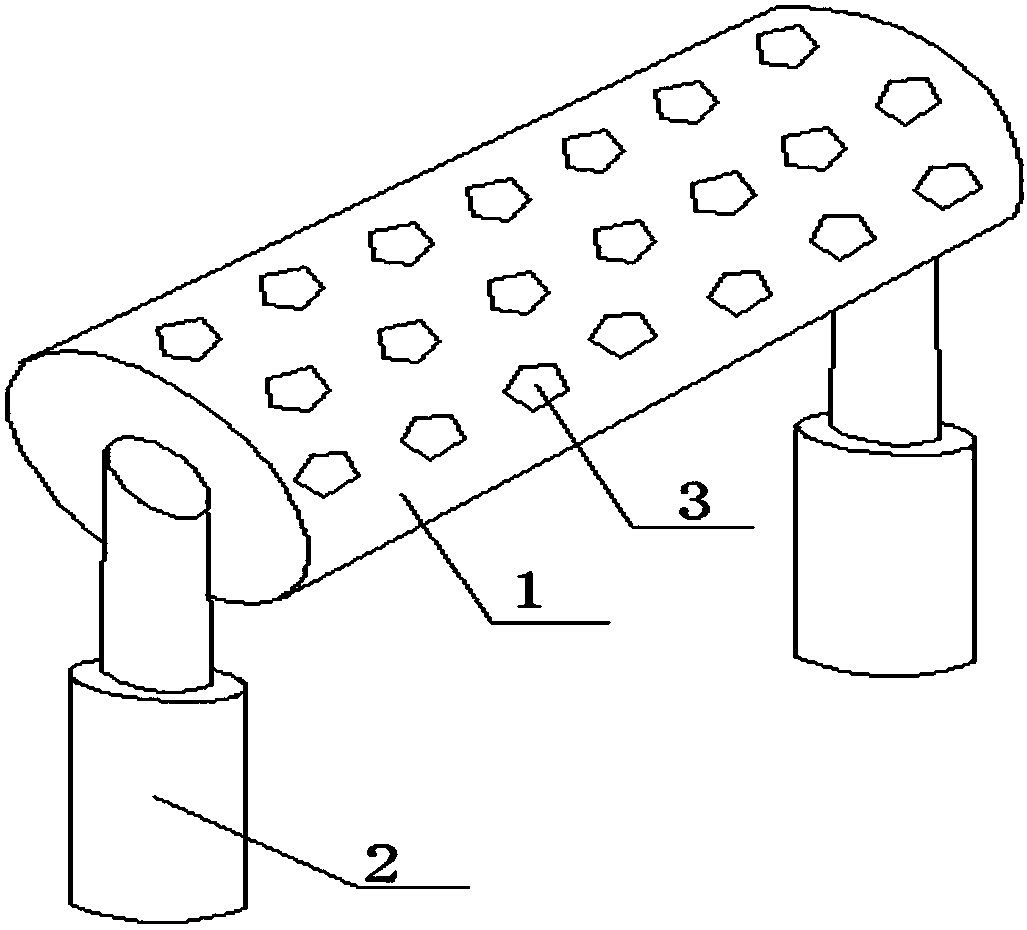

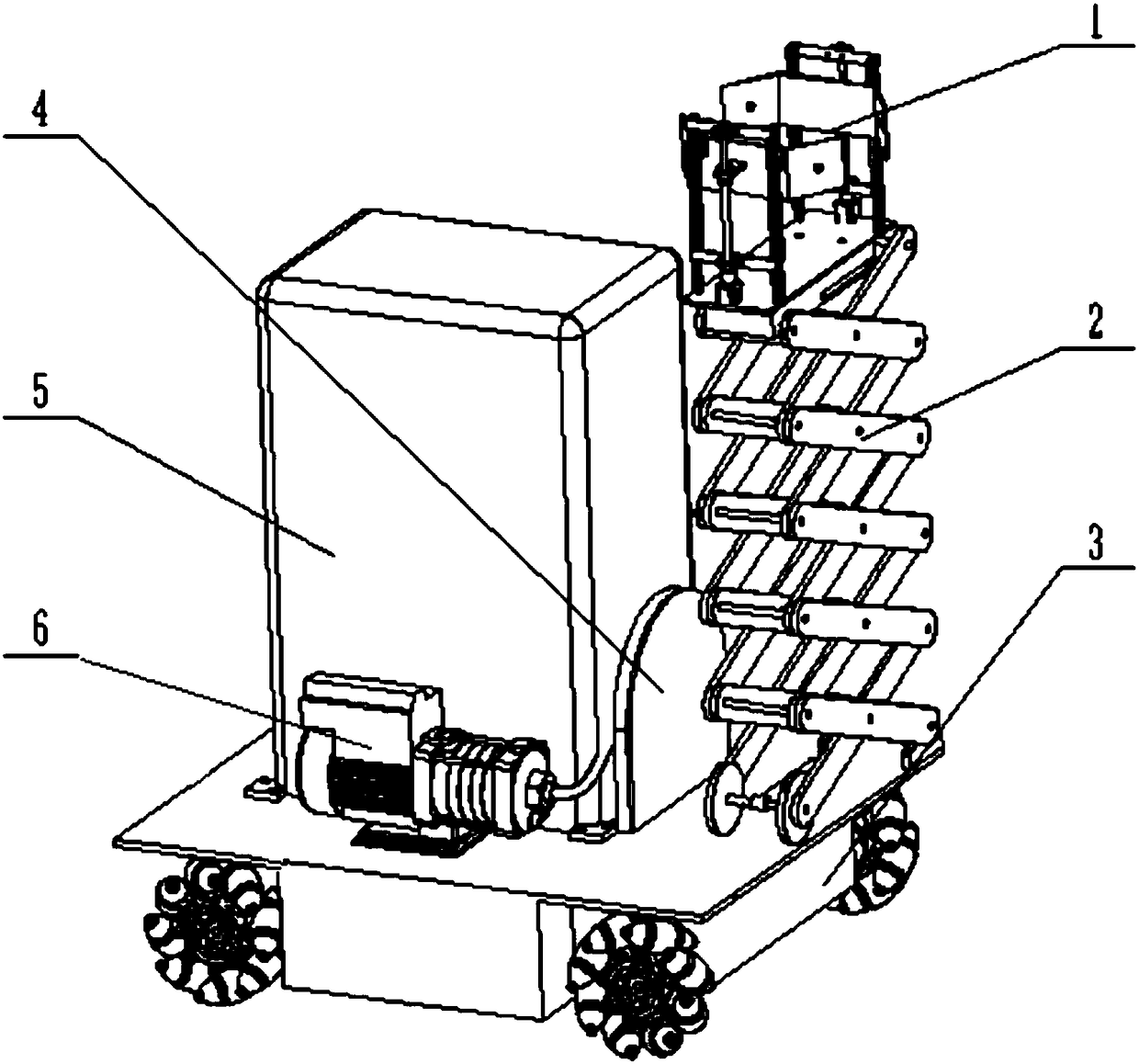

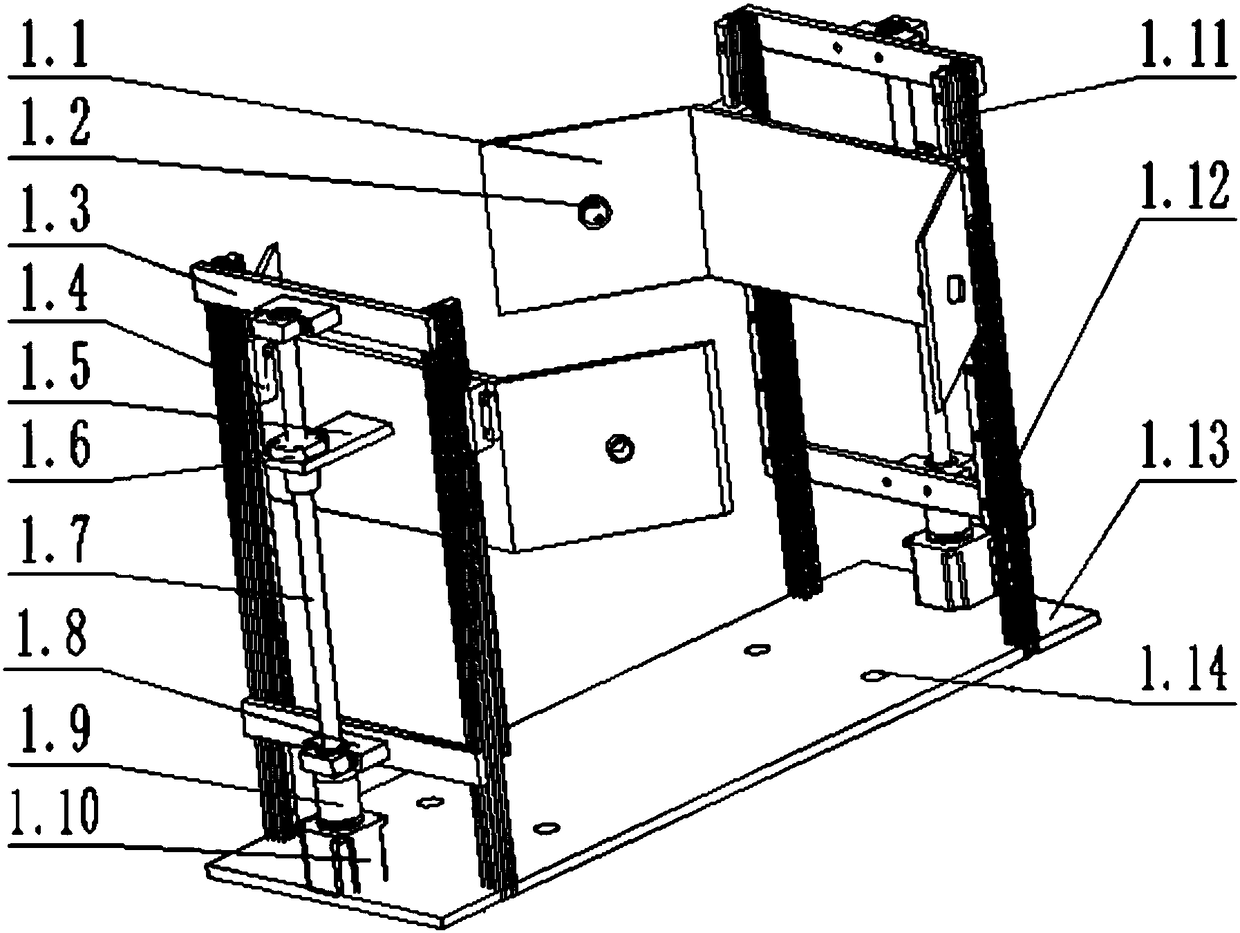

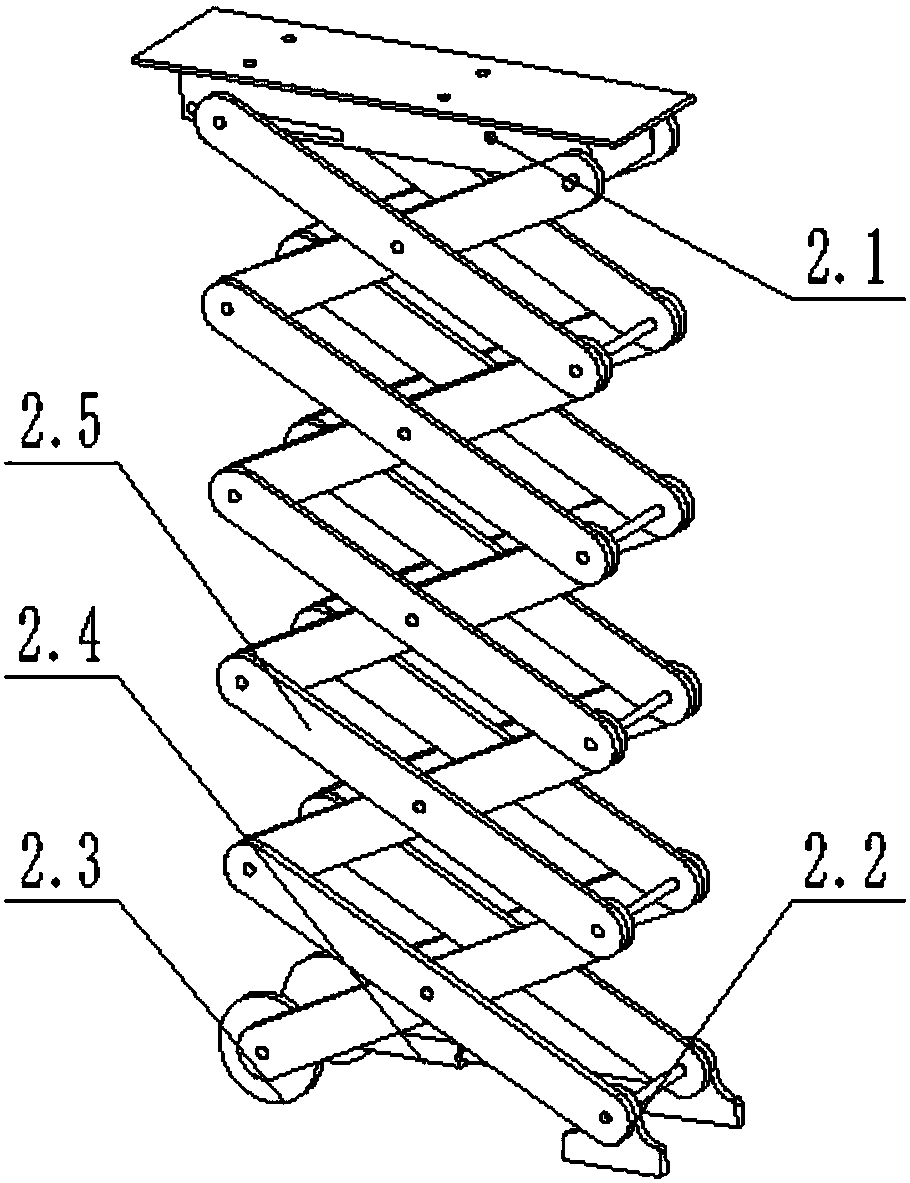

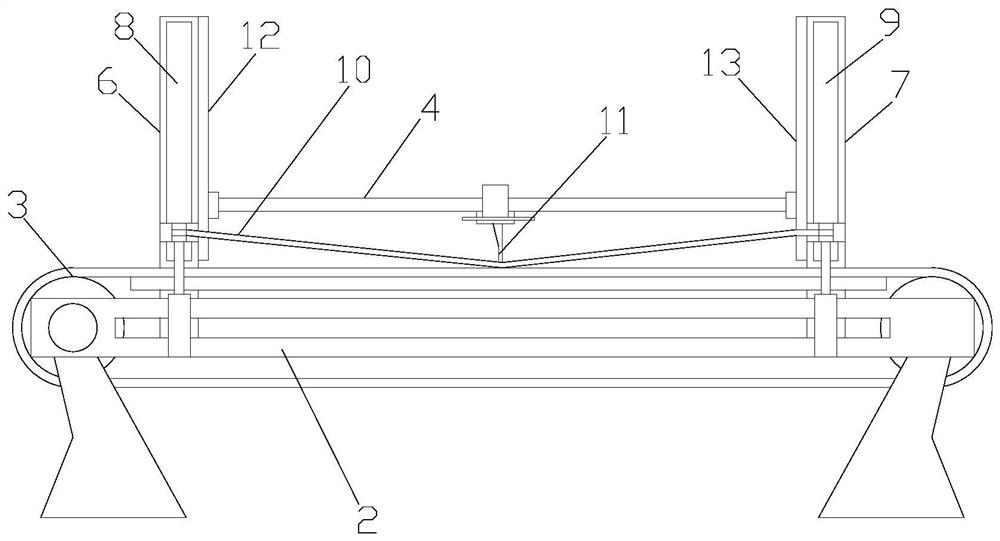

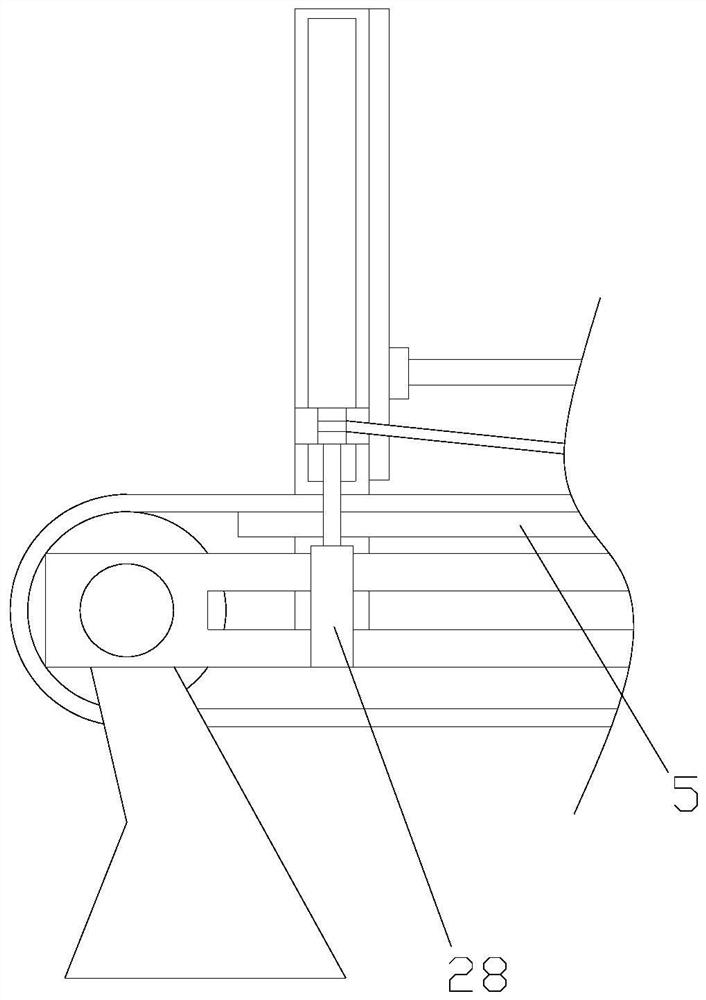

Belt line unloading machine

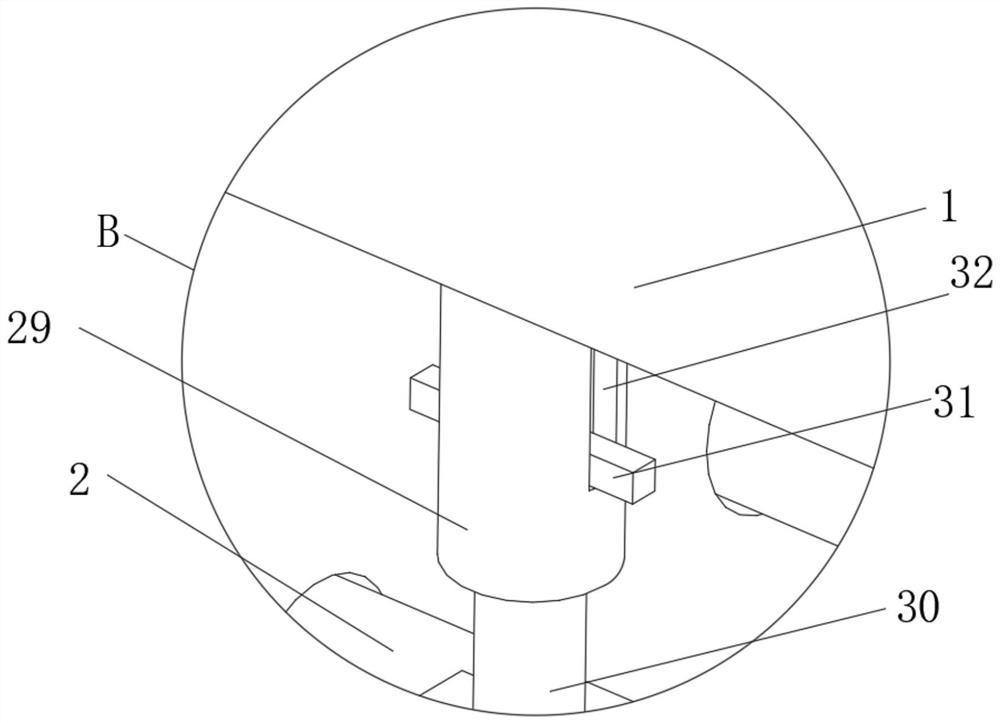

InactiveCN105819202ARealize up and down displacementSmooth motionConveyorsConveyor partsAutomationEngineering

The invention discloses a belt line unloading machine. The belt line unloading machine is characterized in that two symmetrically-arranged vertical plates (1) are included; a horizontal plate (2) is connected with the top ends of the two vertical plates (1) and symmetrically provided with two sliding ways (3); a sliding block (4) is arranged on each sliding way (3); a supporting plate (5) is connected to the two sliding blocks (4); a through hole (6) is formed in the position, between the two sliding ways (3), of the horizontal plate (2); a first drive piece (7) is fixedly arranged in the middle of the supporting plate (5), and a shaft of the first drive piece (7) penetrates the supporting plate (5) and the through hole (6); and vertical connecting rods (8) are arranged at the positions, on the left side and the right side of the first drive piece (7), of the supporting plate (5). The belt line unloading machine is high in automation degree, free of damage to test pieces and suitable for unloading of the fragile test pieces or precision test pieces.

Owner:SUZHOU ZHUOCHENG TITANIUM EQUIP

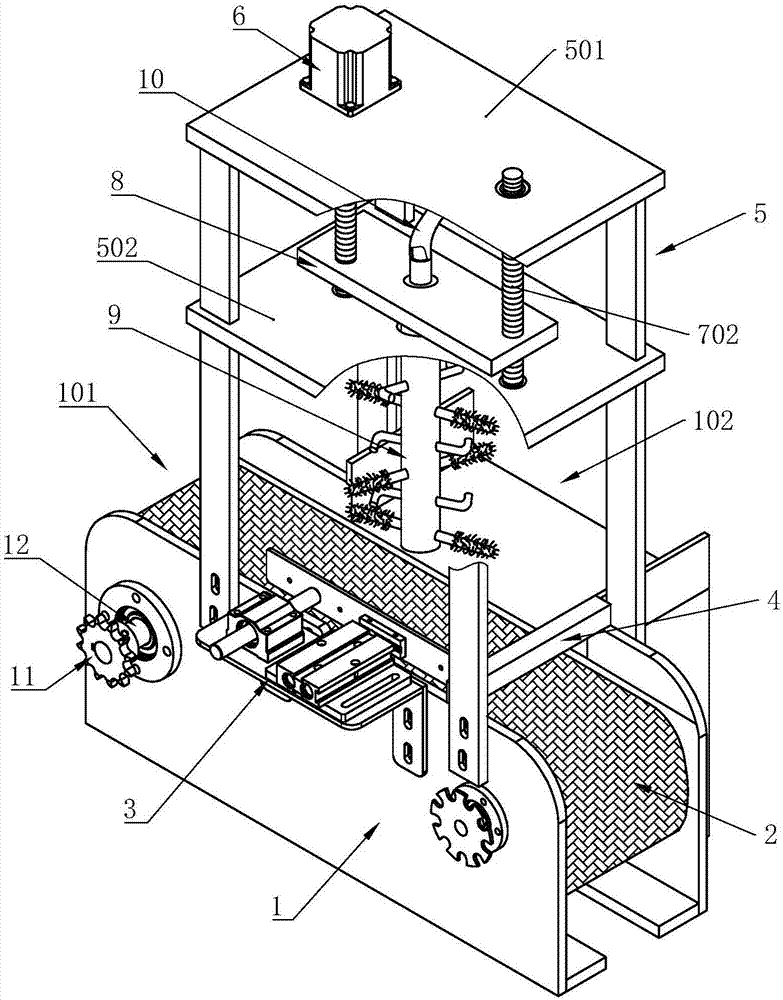

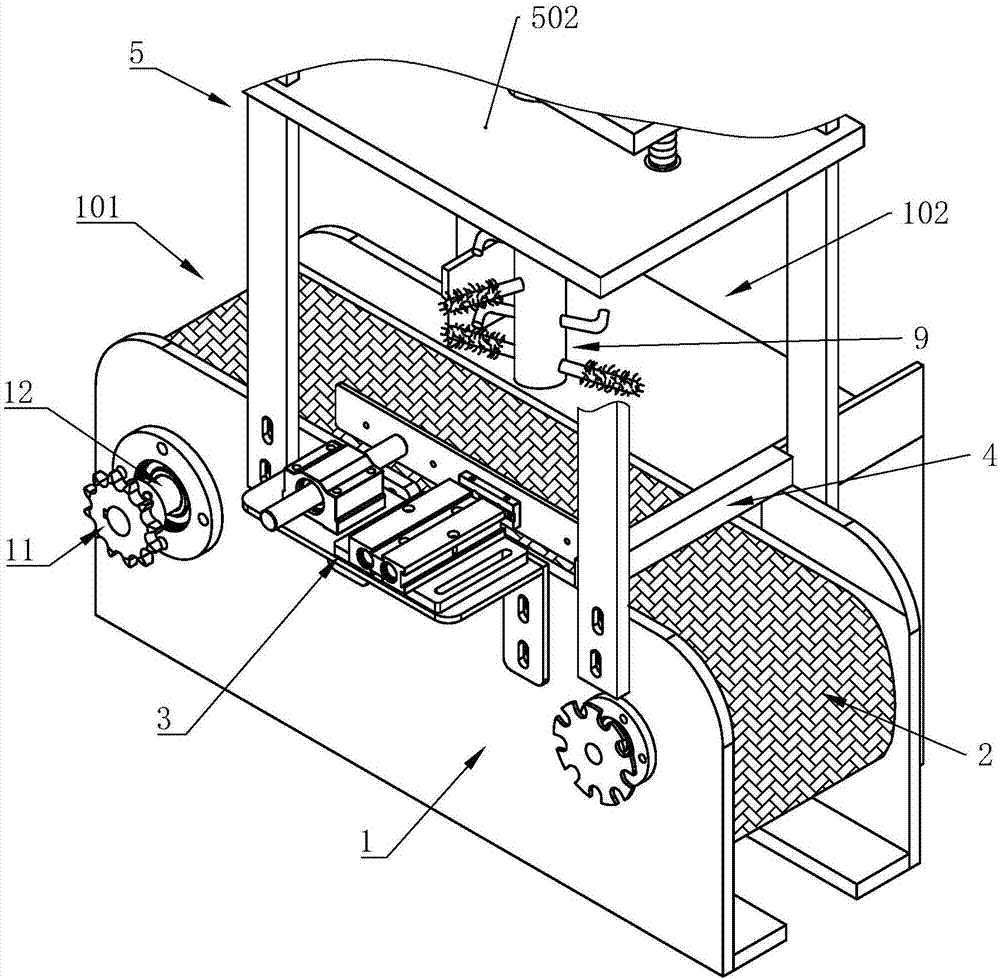

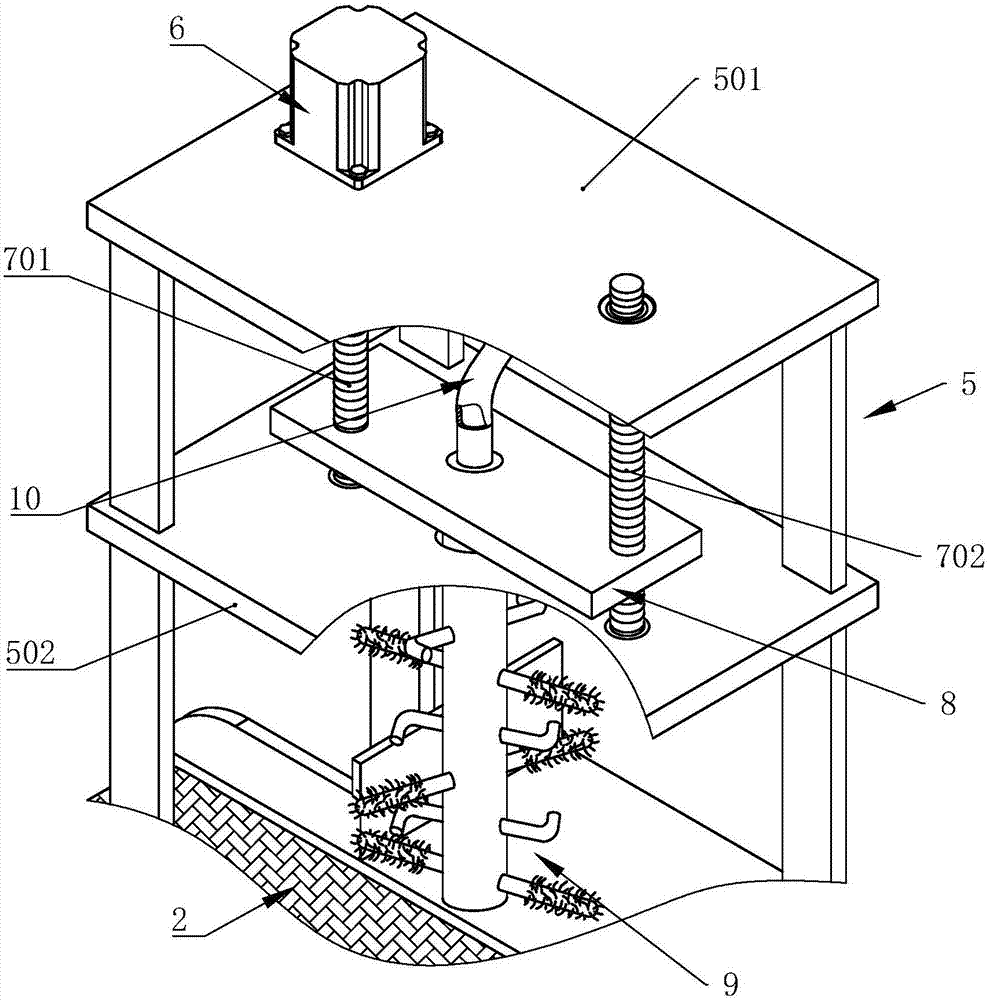

Milk powder can cleaning machine

InactiveCN107234116ANeat and orderly deliveryPrevent tilting and tiltingHollow article cleaningElectric machineryEngineering

The invention belongs to the technical field of milk powder can cleaning devices and provides a milk powder can cleaning machine. The milk powder can cleaning machine comprises a conveying device and a can clearing device. The conveying device comprises a rack provided with a can inlet, and a conveying belt driven by a power device is arranged on the rack; and one side of the rack is provided with a pushing mechanism, the other side of the rack is provided with a can outlet corresponding to the pushing mechanism, and the end, away from the can outlet, of the rack is provided with a can blocking plate. The can clearing device comprises an installation frame installed on the rack, a drive motor connected with a transmission mechanism is installed on an upper installation plate of the installation frame, and a sliding plate in transmission connection with the drive motor through the transmission mechanism is arranged between the upper installation plate and a lower installation plate; and a brush roll is rotatably installed on the sliding plate, and the brush roll is provided with an air inlet communicating with an air supplying device through an air tube. The milk powder can cleaning machine is small in size, the clearing efficiency and clearing quality of milk powder cans are greatly improved, and the phenomena that in the conveying process of the milk powder cans, the milk powder cans are damaged, and due to not thorough clearing of the milk powder cans, milk powder containing is insanitary are prevented from occurring.

Owner:ZAOZHUANG PANGU PRECISION MACHINERY TECH CO LTD

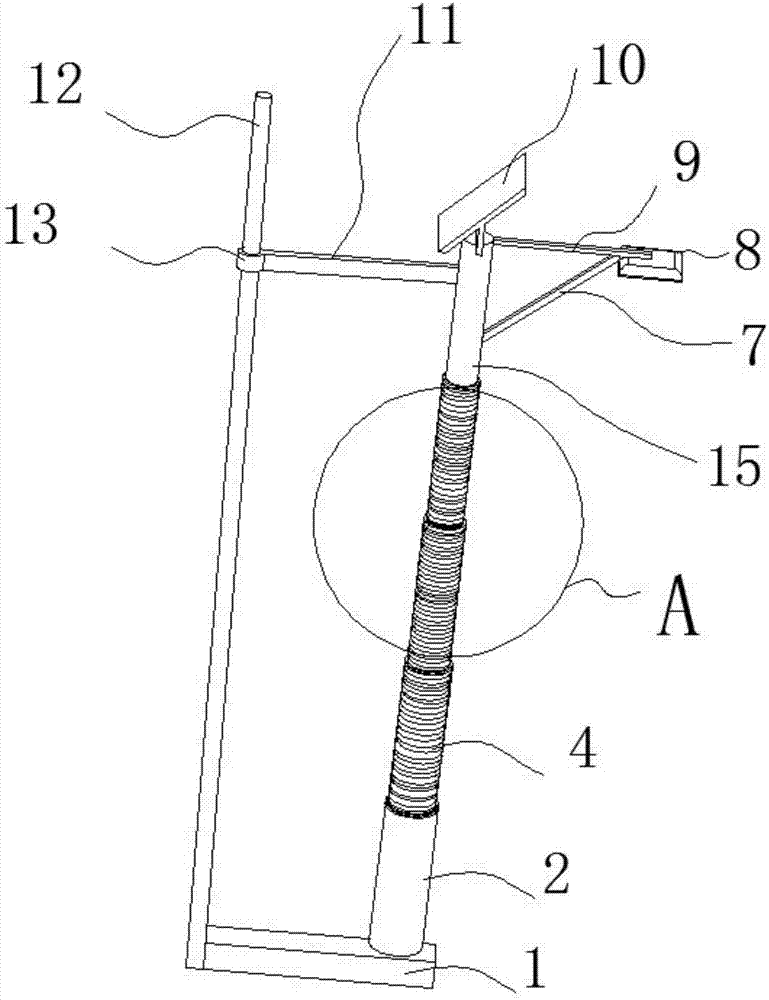

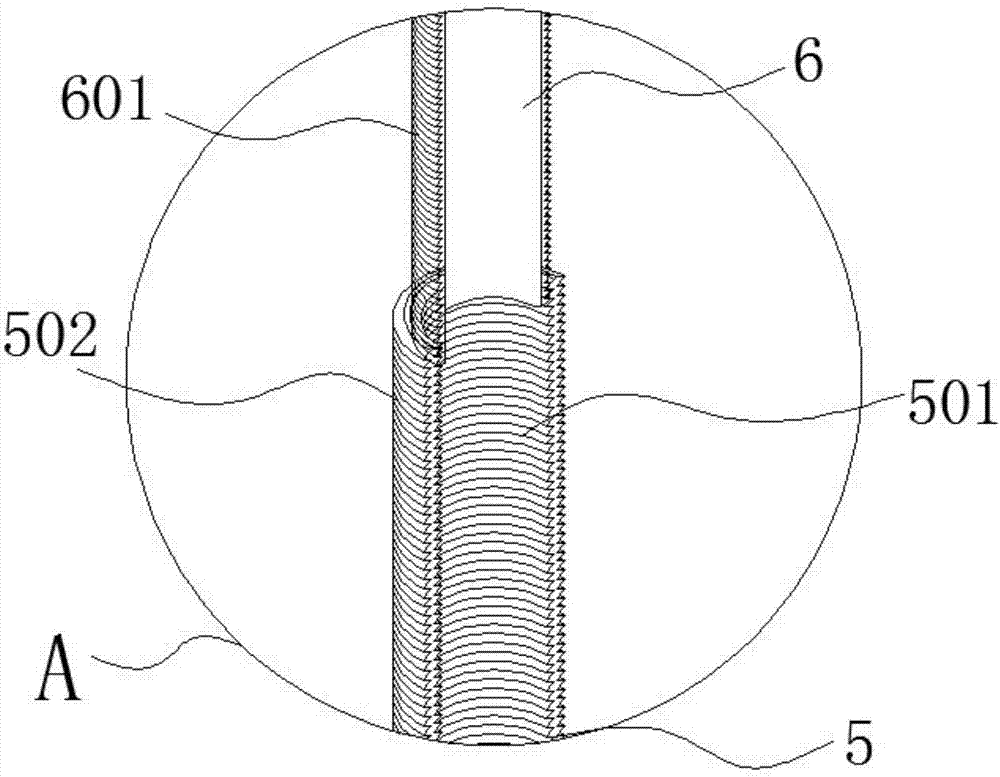

Solar energy-based liftable roadway lighting facility

InactiveCN107388175ARealize transmissionRealize up and down displacementMechanical apparatusLighting support devicesThreaded pipeEffect light

The invention discloses a solar energy-based liftable roadway lighting facility, and relates to the technical field of roadway lighting engineering. The solar energy-based liftable roadway lighting facility comprises a base, a second threaded pipe, a third threaded pipe and a fourth threaded pipe; a motor is fixedly mounted in the base; a basic pipe body is fixedly mounted on one surface of the base, wherein the first threaded pipe is fixed to an output end of a motor; the first threaded pipe is rotatably connected with the basic pipe body; first internal screw threads are formed in the inner wall of the first threaded pipe; first external screw threads are formed in the peripheral side surface of the second threaded pipe; the first internal screw threads are connected with the first external screw threads rotatably; and second internal screw threads are formed in the inner wall of the second threaded pipe. According to the solar energy-based liftable roadway lighting facility, transmission among the threaded pipes is realized by forming the screw threads in the inner sides and the outer sides of the threaded pipes; a supporting post is fixedly connected with a third supporting rod, and a sliding ring is connected with a vertical post in a sliding manner, so that vertical displacement of the vertical post is realized; the lifting property of the lighting facility is realized; and the lighting facility is maintained, transported and mounted more conveniently and safely.

Owner:合肥千聚环保科技有限公司

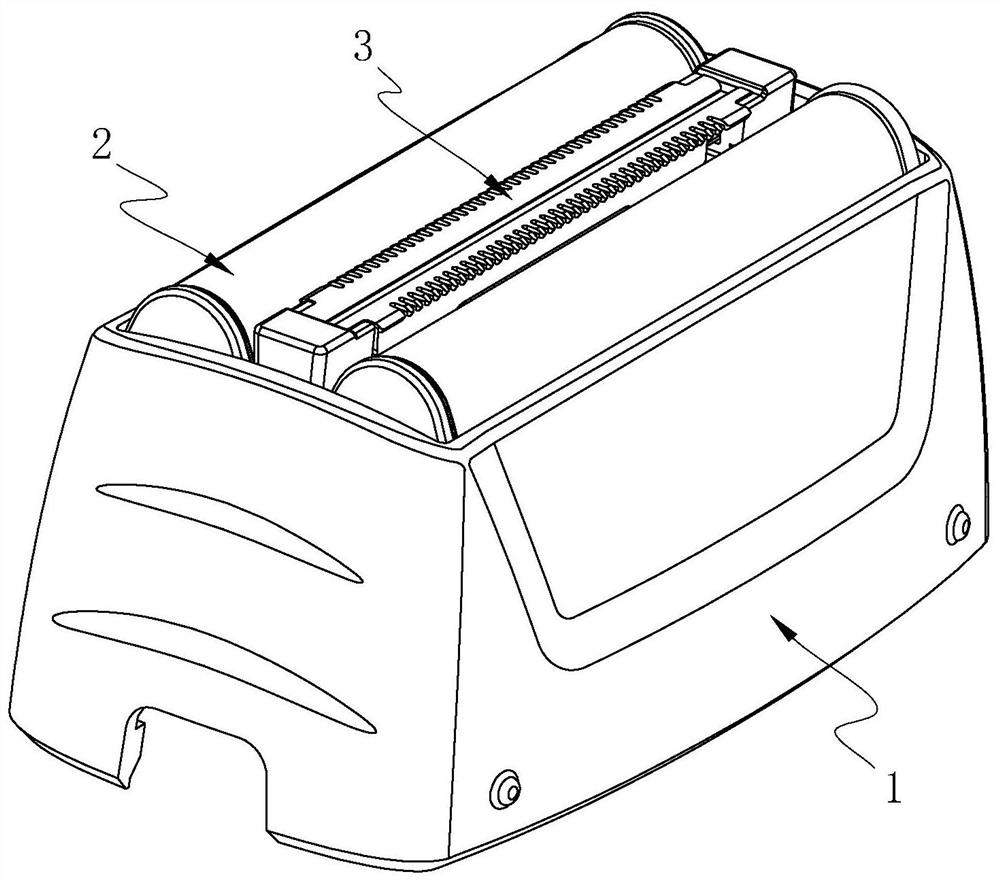

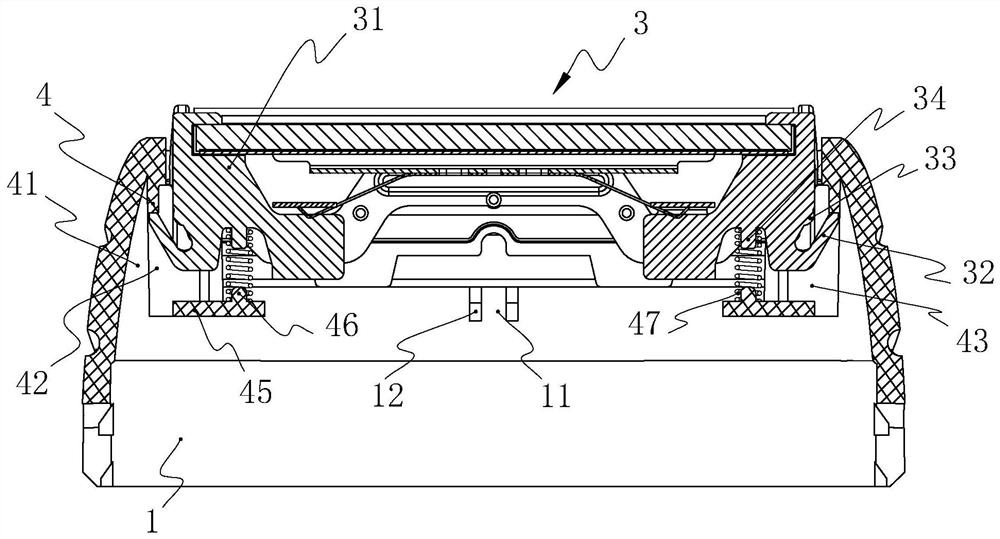

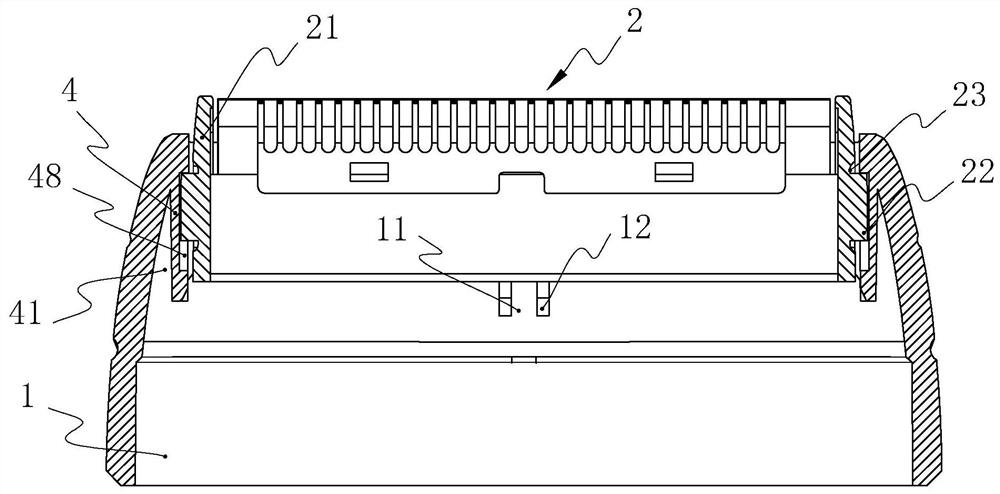

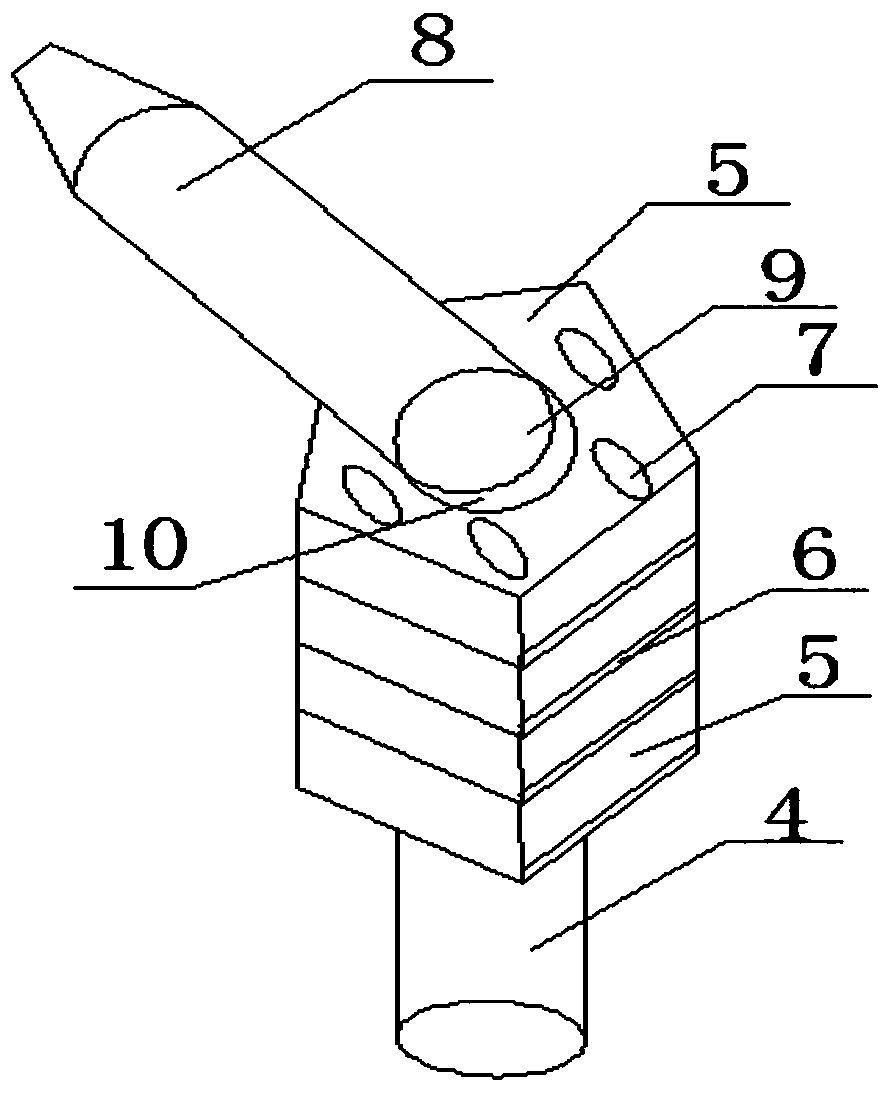

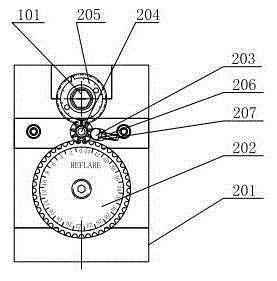

Reciprocating type tool bit assembly

PendingCN113829394AEasy to install and removeEnsure the firmness of the installationMetal working apparatusEngineeringTool bit

The invention relates to a reciprocating type tool bit assembly which is characterized in that elastic pieces are arranged at the two ends in a shell respectively, so that at least one mesh blade set is connected with the elastic pieces in the shell in a buckled mode, and at least one middle blade set is connected with the elastic pieces of the shell in a hooking mode and can move up and down. The reciprocating type tool bit assembly has the beneficial effects that the elastic pieces are arranged at the two ends of the shell, and the flexibility of the elastic pieces is utilized, so that the installation firmness of the mesh cutter set and the shell can be guaranteed while the mesh cutter set is convenient to install and disassemble; secondly, the middle blade set is connected with the elastic pieces in a hooking manner, so that the middle blade set can move up and down while the mounting and dismounting of the middle blade set are improved, the middle blade set can automatically move downwards when the middle blade set is stressed during operation, a blade is protected, the use safety of the middle blade set is improved, the fitting degree of the middle blade set and the skin is improved, and the shaving effect of the tool bit assembly is improved.

Owner:浙江海顺电工有限公司

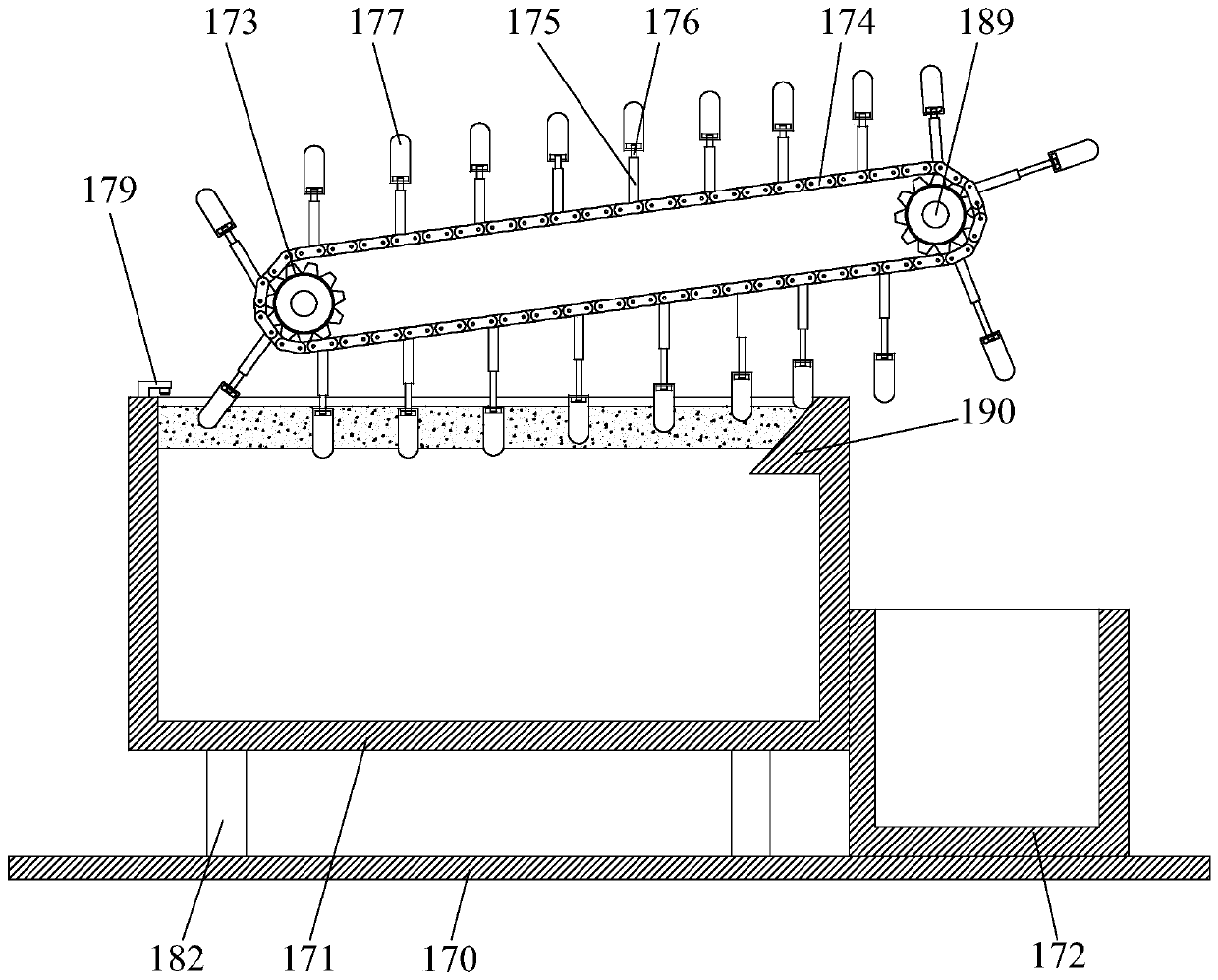

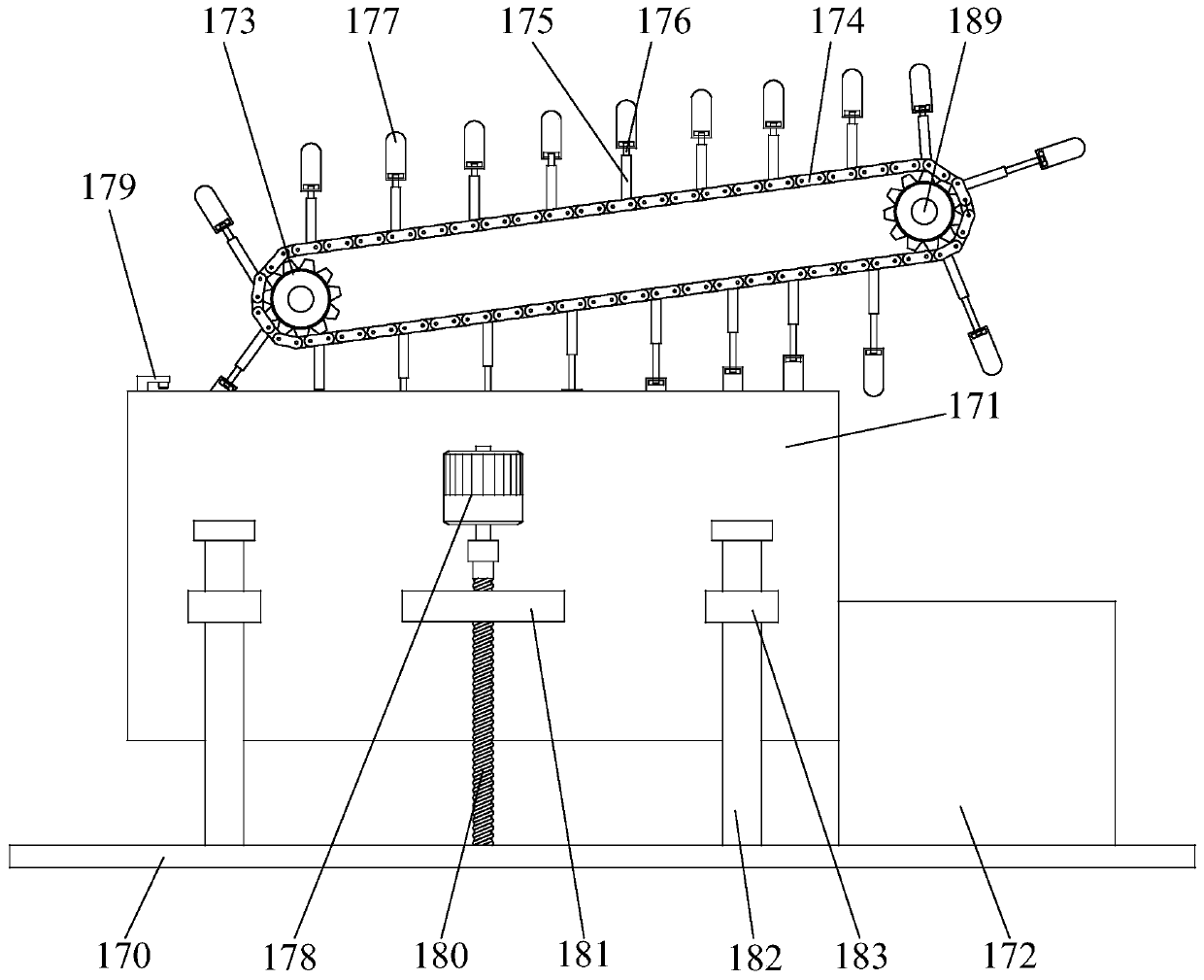

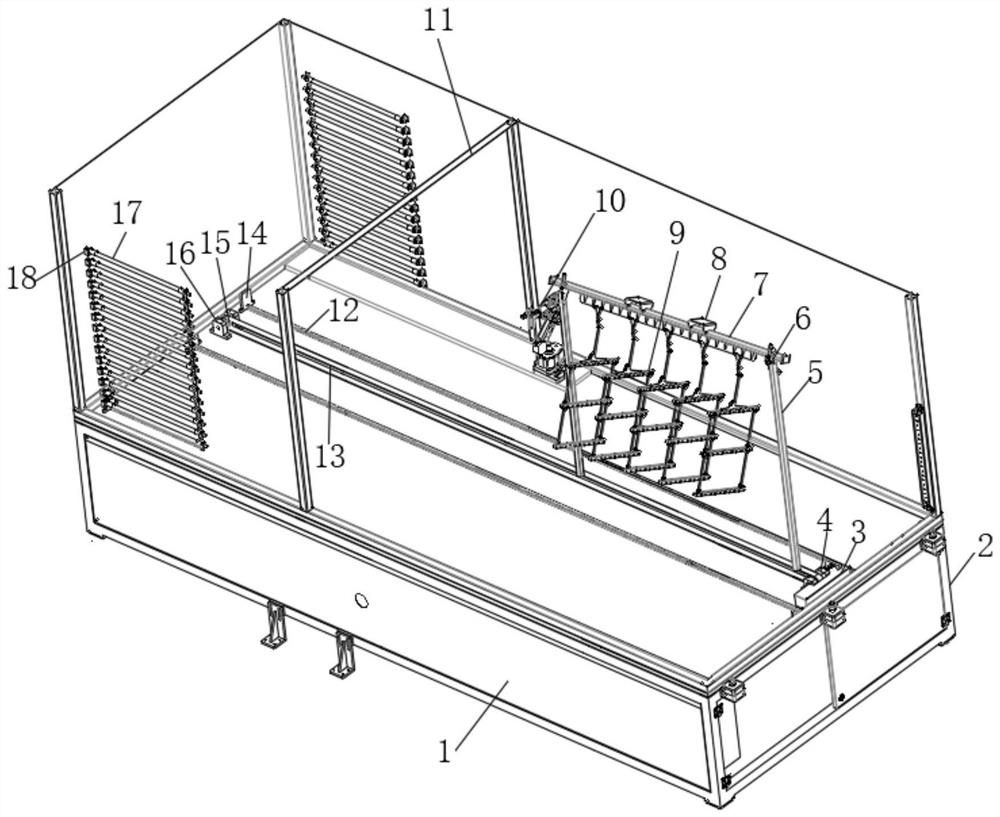

Automatic oil scraping system for swill separation and automatic oil scraping method thereof

ActiveCN110975337AImprove scraping efficiencyLarge amount of scraping oilLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesElectric machineryBuoyant flow

The invention discloses an automatic oil scraping system for swill separation and an automatic oil scraping method thereof. The automatic oil scraping system comprises an oil scraping frame, a storagetank, an oil collecting tank, an automatic oil scraping mechanism, a lifting mechanism, a liquid level sensor and an oil scraping controller. The storage tank is used for separating an oil-water mixture into a water layer and an oil layer. The automatic oil scraping mechanism comprises an oil scraping motor, a chain wheel, a chain and an oil scraping assembly. The lifting mechanism comprises a driving assembly and a lifting assembly. The driving assembly is used for driving the storage tank to be close to the chain in the vertical direction, and the liquid level sensor is used for detecting the relative height between the oil level of the oil layer and the bottom wall of the storage tank. The oil scraping controller is used for judging whether the relative height is greater than a presetheight or not and driving the lifting mechanism to conduct related actions. The oil scraping amount and the oil scraping efficiency are improved, it is guaranteed that oil at different depths is scraped, oil scraping is realized through buoyancy, the oil scraping efficiency can be further improved and the purity of the scraped oil is guaranteed.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

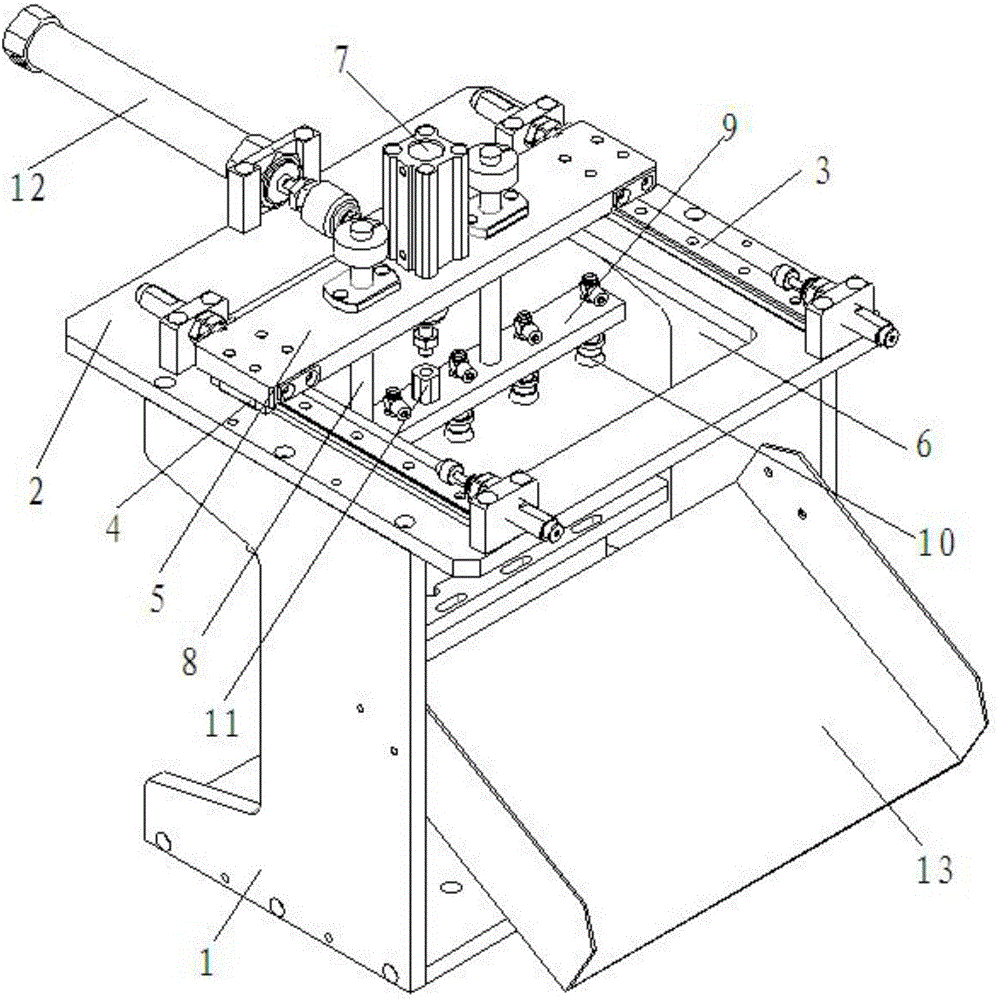

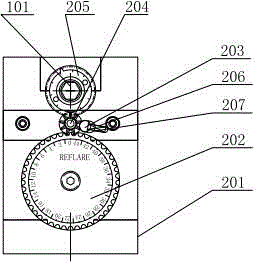

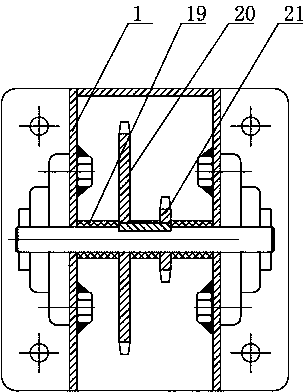

Automatic adjustment structure for flanging sub mold or extending sub mold

ActiveCN104148505ARealize up and down displacementRealize automatic adjustmentShaping toolsGear wheelEngineering

The invention relates to an automatic adjustment structure for a flanging sub mold or an extending sub mold. The automatic adjustment structure comprises a shell, wherein a screw rod penetrates through the shell, and a first oil cylinder cavity and a second oil cylinder cavity are arranged in the shell respectively. A first piston is arranged in the first oil cylinder cavity, a first ejector block is connected with the end of the first piston, and the first ejector block is connected with a first ratchet wheel in an abutting mode. The automatic adjustment structure is simple in structure and convenient to use, two oil cylinders in the shell are used for driving two ratchet wheels to rotate in different directions to achieve moving of the screw rod, finally vertical moving of the flanging convex mold is achieved, and automatically adjustment of the flanging height is achieved, so that the laminated heights of the whole fins of a heat exchanger are uniform. Meanwhile, in the moving process of the screw rod, by means of the transmission mode of gear meshing, a dial records the flanging height, a rotation stopping block is arranged to prevent the revolution number of a gear from being too large, and the phenomenon that the dial can not accurately record subsequently is avoided.

Owner:WUXI MICRO RES

Rice transplanting mechanism of rice transplanter

InactiveCN108243688ARealize up and down displacementImprove work efficiencySowingTransplantingWater soluble polymersPiston

The invention discloses a rice transplanting mechanism of a rice transplanter, and relates to the technical field of agricultural apparatuses. The rice transplanting mechanism of the rice transplantercomprises a rice transplanting roller, telescopic pistons are arranged at two ends of the rice transplanting roller, and the bottom ends of the telescopic pistons are fixedly connected to the rice transplanter; the side surface of the rice transplanting roller is provided with a plurality of cutting chambers; a cutting mechanism is arranged in every cutting chamber; every cutting mechanism includes a cutting rod detachably connected to the rice transplanting roller and a plurality of cutting plates sleeving the cutting rod and matched with the cutting chamber in shape; a folding mechanism isarranged between every two adjacent cutting plates to achieve mutual superposing, and a touch sensor is arranged at the combining part of every two adjacent cutting plates, and is connected with a single chip microcomputer; and the material of the cutting plates is a water-soluble polymer material, and a plurality of seed storage chambers are arranged in every cutting plate. The technical problemto be solved in the invention is to provide the rice transplanting mechanism with a high automation degree.

Owner:天津忆香科技有限公司

An automatic adjustment structure for flanging sub-mould or extension sub-mould

ActiveCN104148505BRealize up and down displacementRealize automatic adjustmentShaping toolsFlangingEngineering

The invention relates to an automatic adjustment structure for a flanging sub mold or an extending sub mold. The automatic adjustment structure comprises a shell, wherein a screw rod penetrates through the shell, and a first oil cylinder cavity and a second oil cylinder cavity are arranged in the shell respectively. A first piston is arranged in the first oil cylinder cavity, a first ejector block is connected with the end of the first piston, and the first ejector block is connected with a first ratchet wheel in an abutting mode. The automatic adjustment structure is simple in structure and convenient to use, two oil cylinders in the shell are used for driving two ratchet wheels to rotate in different directions to achieve moving of the screw rod, finally vertical moving of the flanging convex mold is achieved, and automatically adjustment of the flanging height is achieved, so that the laminated heights of the whole fins of a heat exchanger are uniform. Meanwhile, in the moving process of the screw rod, by means of the transmission mode of gear meshing, a dial records the flanging height, a rotation stopping block is arranged to prevent the revolution number of a gear from being too large, and the phenomenon that the dial can not accurately record subsequently is avoided.

Owner:WUXI MICRO RES

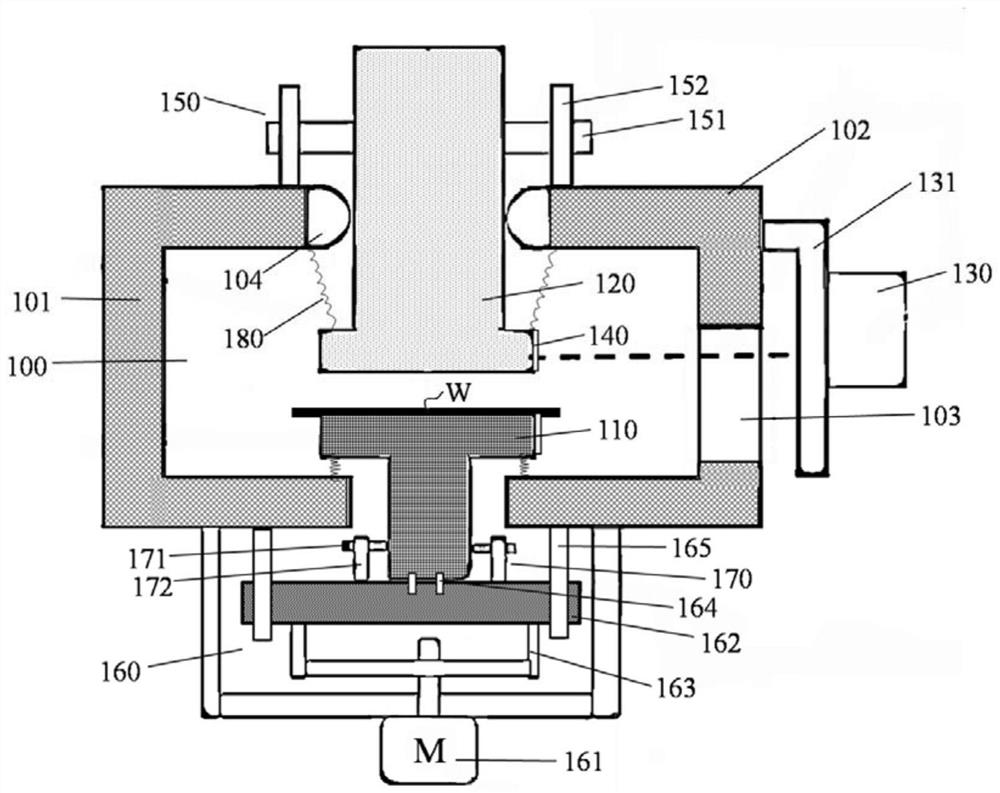

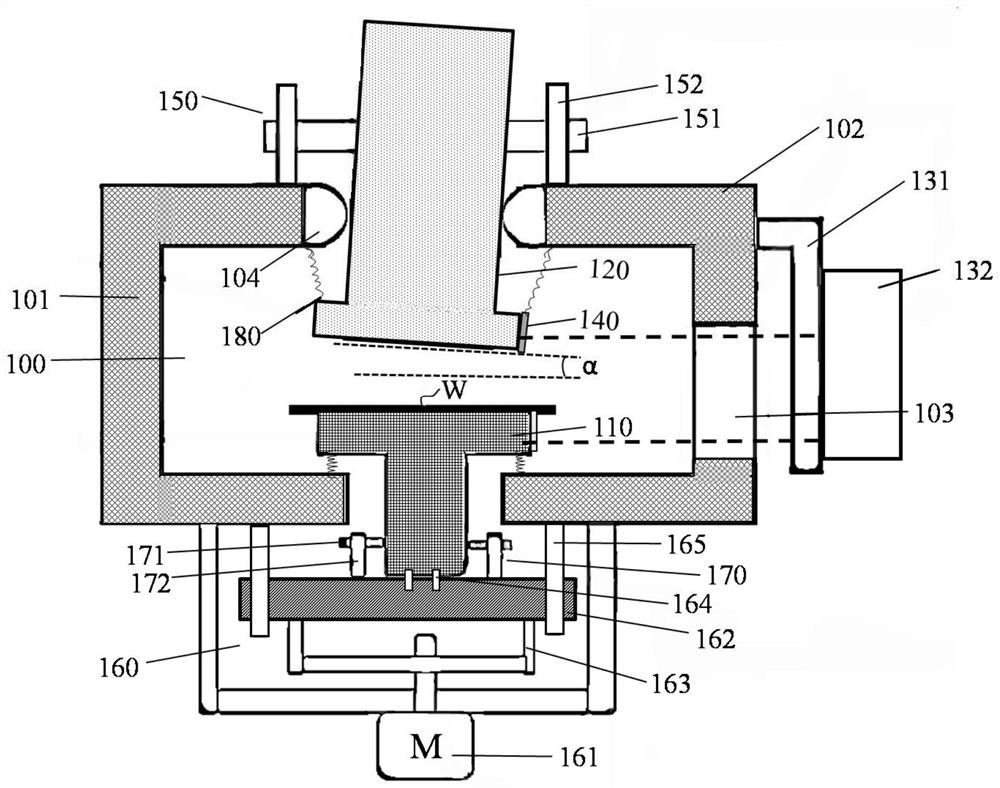

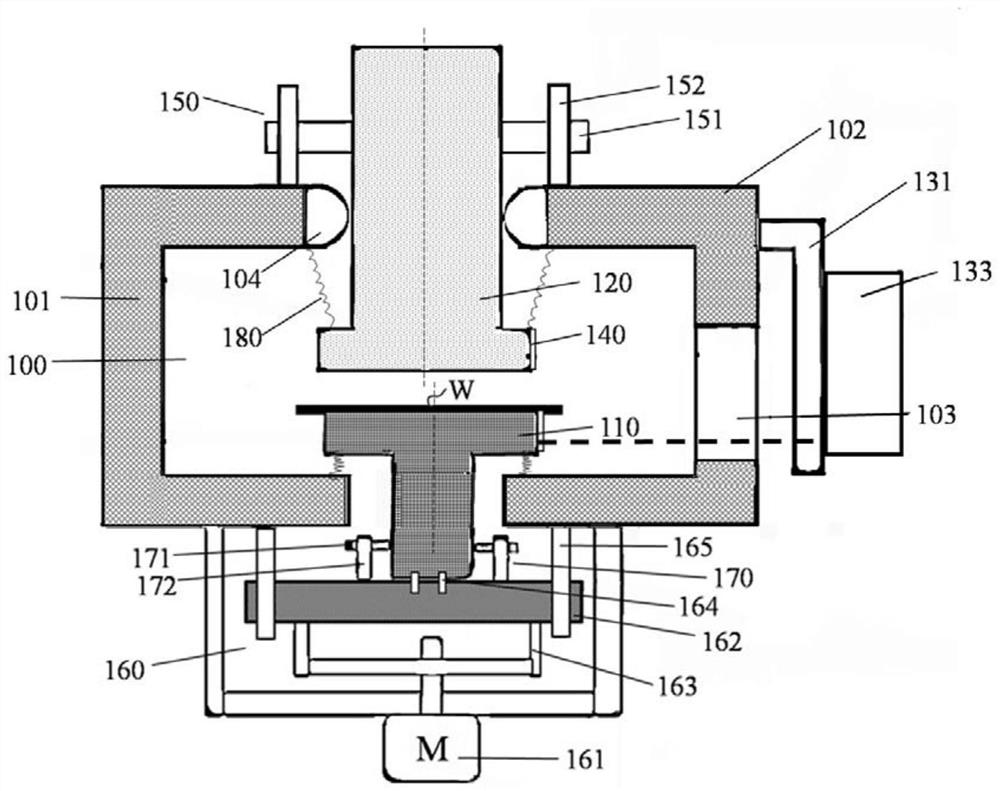

Plasma processing device and working method thereof

PendingCN114446748AEasy to understandReduce time spentElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringMaterials science

The invention discloses a plasma processing device and a working method thereof, and the plasma processing device comprises a vacuum reaction cavity which is formed by the surrounding of a reaction cavity body and a cavity body end cover; the lower electrode assembly is arranged in the vacuum reaction cavity; the movable upper electrode assembly is arranged opposite to the lower electrode assembly, and a plasma environment is formed between the movable upper electrode assembly and the lower electrode assembly; the reaction cavity body is provided with a plurality of observation windows, a plurality of movable monitors are arranged outside the observation windows, and the movable monitors are used for monitoring the included angle and concentricity between the movable upper electrode assembly and the lower electrode assembly. The wafer etching observation window has the advantages that the observation window is combined with the movable monitor, the structure is simple, observation is convenient, daily maintenance and use of workers are facilitated, and the wafer etching effect is further guaranteed.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

An automatic oil scraping system and automatic oil scraping method for swill separation

ActiveCN110975337BScrape GuaranteeRealize the collectionLiquid separation auxillary apparatusFatty/oily/floating substances removal devicesElectric machinerySprocket

The invention discloses an automatic oil scraping system and an automatic oil scraping method for swill separation. The automatic oil scraping system includes an oil scraping frame, a storage tank, an oil collecting tank, an automatic oil scraping mechanism, a lifting mechanism, a liquid level sensor and an oil scraping controller. The storage tank is used to separate the oil-water mixture into a water layer and an oil layer. The automatic oil scraping mechanism includes an oil scraping motor, a sprocket, a chain and an oil scraping assembly. The lifting mechanism includes a driving assembly and a lifting assembly, the driving assembly is used to drive the storage tank and the chain close in the vertical direction, and the liquid level sensor is used to detect the relative height between the oil level of the oil layer and the bottom wall of the storage tank. The oil scraping controller is used to judge whether the relative height is greater than a preset height, and to drive the lifting mechanism to perform relevant actions. The invention improves the oil scraping volume and oil scraping efficiency, ensures oil scraping at different depths, and realizes oil scraping through buoyancy, can further improve oil scraping efficiency and ensure the purity of the scraped oil.

Owner:ANHUI TIANJIAN ENVIRONMENTAL PROTECTION

Processing and spraying device and method for photocatalyst plate for indoor and outdoor decoration

InactiveCN112354734ARealize multi-angle adjustmentAchieve sprayingSpraying apparatusStructural engineeringLeather belt

The invention discloses a processing and spraying device and method for photocatalyst plate for indoor and outdoor decoration. The device comprises a base table. Mounting columns are welded to the four corners of the base table correspondingly, a welding base is welded to the position, close to the right side, of the middle of the upper surface of the base table, a first rotating shaft mounting block is arranged on the outer side of the welding base, a reinforcing rib frame is welded to the middle of an inner frame of the base table, two second rotating shaft mounting blocks are mounted on theportion, close to the left, of the upper surface of the base table, and a rotating shaft is mounted between the opposite faces of the two second rotating shaft mounting blocks. According to processing and spraying device for photocatalyst plate for indoor and outdoor decoration, a support is placed between two sliding blocks, specifically, the sliding protruding blocks on the lower portion of theouter wall of the support are in sliding butt joint with notches formed in the outer sides of the sliding blocks so that the support can be limited, the bottom end of the support is located on the upper surface of a belt, and during belt transmission, the support can be driven to move.

Owner:杭州御诺装饰有限公司

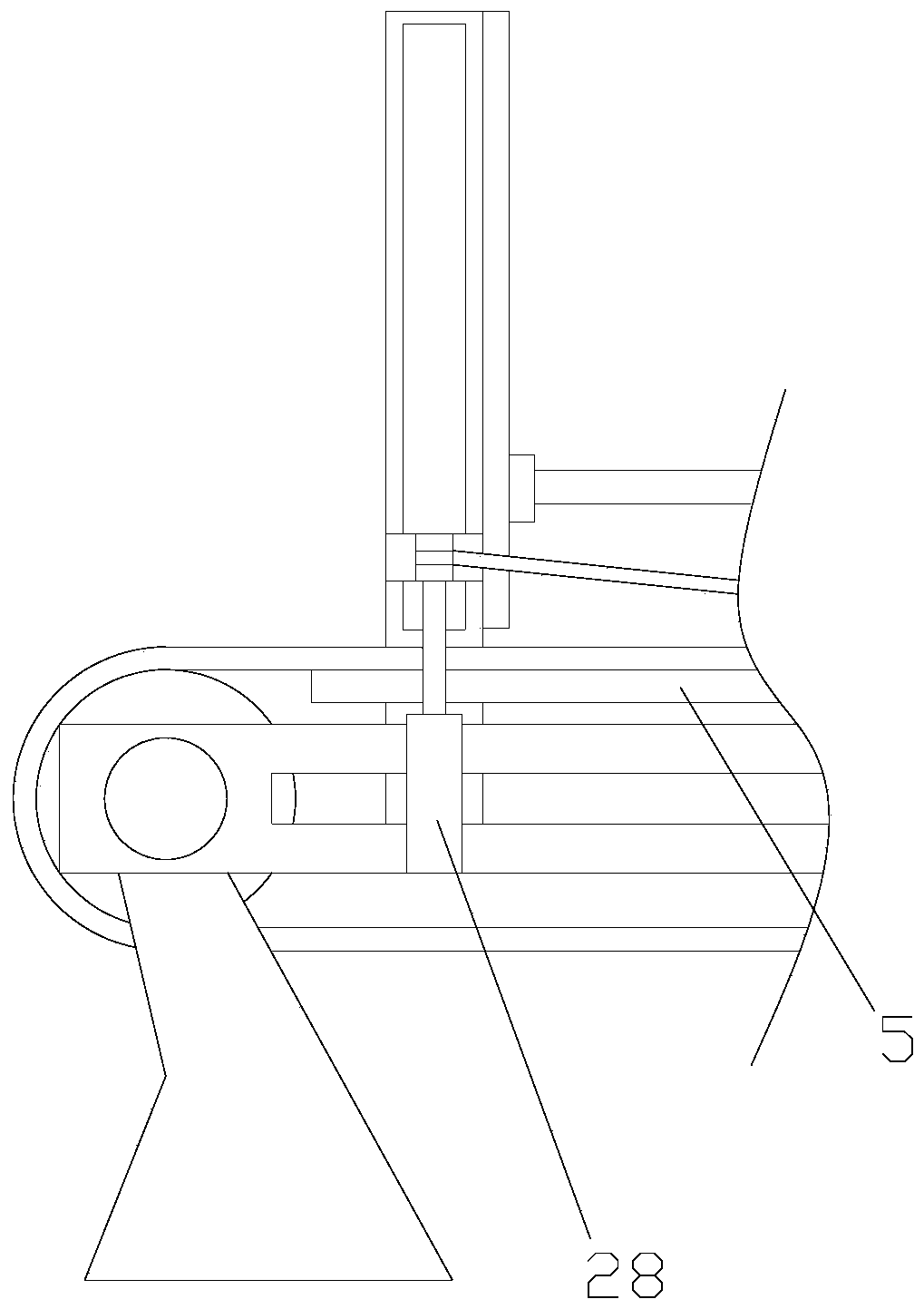

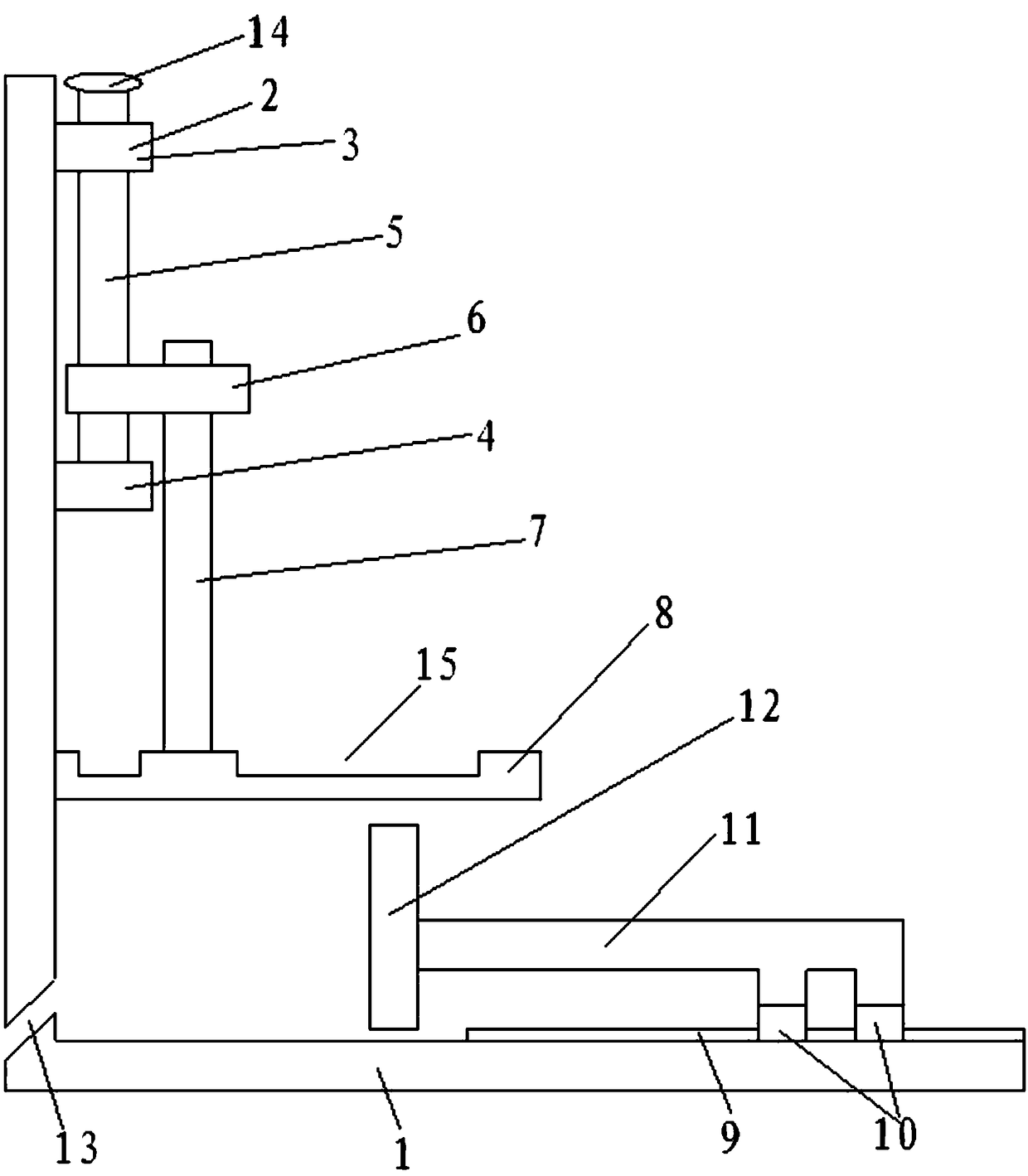

Anti-impact car airbag stiffness testing device

The invention discloses an impact-proof automobile air bag rigidity detection device. The impact-proof automobile air bag rigidity detection device comprises an L-shaped operation bench (1). Two fixed blocks are arranged on a vertical surface of the operation bench (1) in an up-down manner. The fixed blocks include an upper fixed block (3) and a lower fixed block (4). A smooth through hole penetrating a screw (5) is formed in the upper fixed block (3). A circular groove for accommodating the bottom end of the screw (5) is formed in the upper surface of the lower fixed block (4). The screw (5) is in threaded connection with a movable block (6). The movable block (6) is connected with a horizontal upper extruding plate (8) through an upright column (7). A plurality of grooves (15) for accommodating heavy objects are formed in the upper surface of the upper extruding plate (8). The impact-proof automobile air bag rigidity detection device provided by the invention is high in automatic degree and is real and reliable in detection result, the upper extruding plat has an impact-proof function, and the universality is high.

Owner:WM MOTOR TECH GRP CO LTD

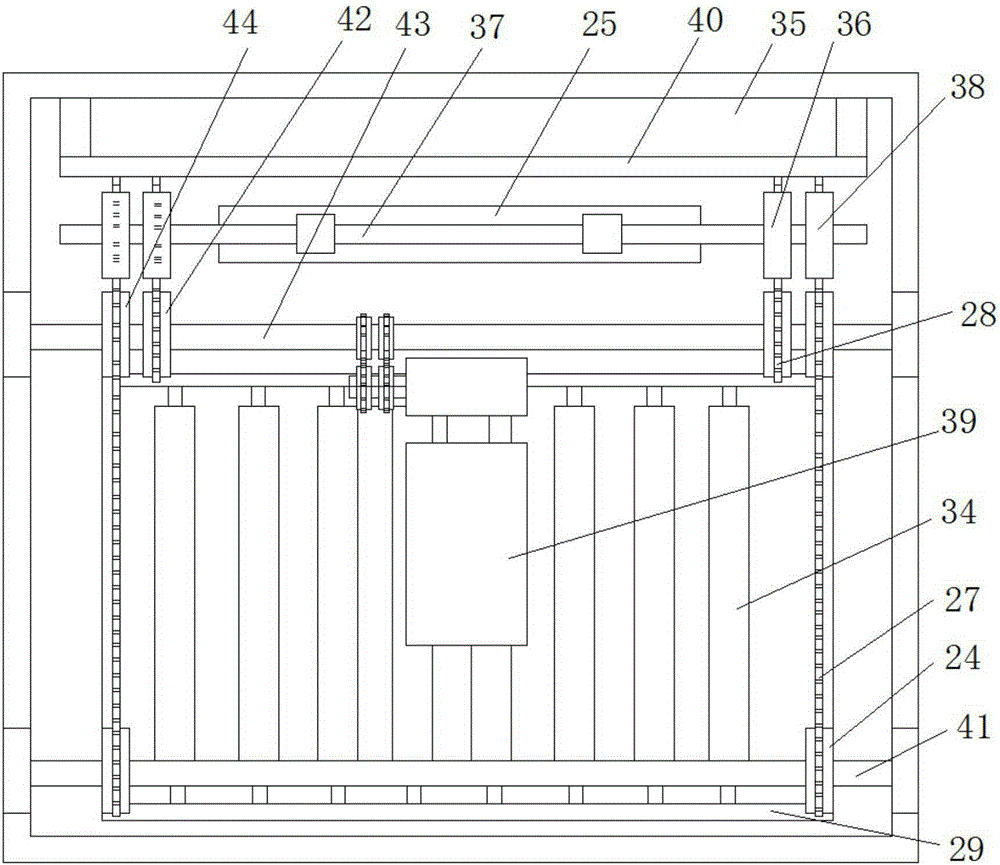

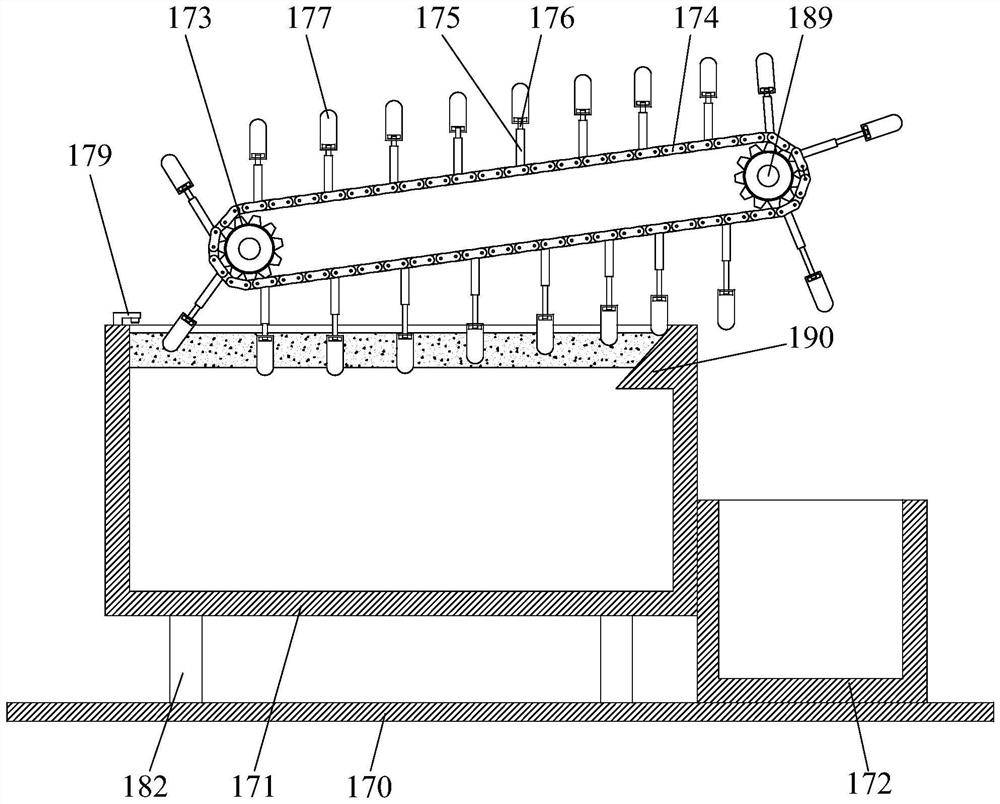

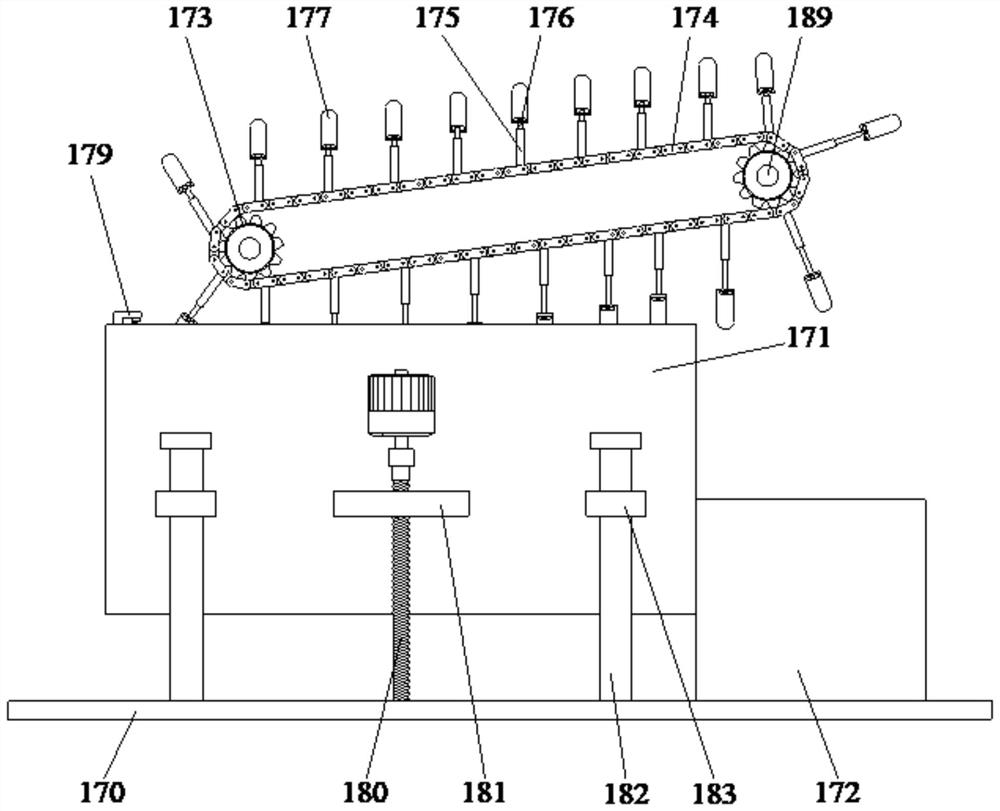

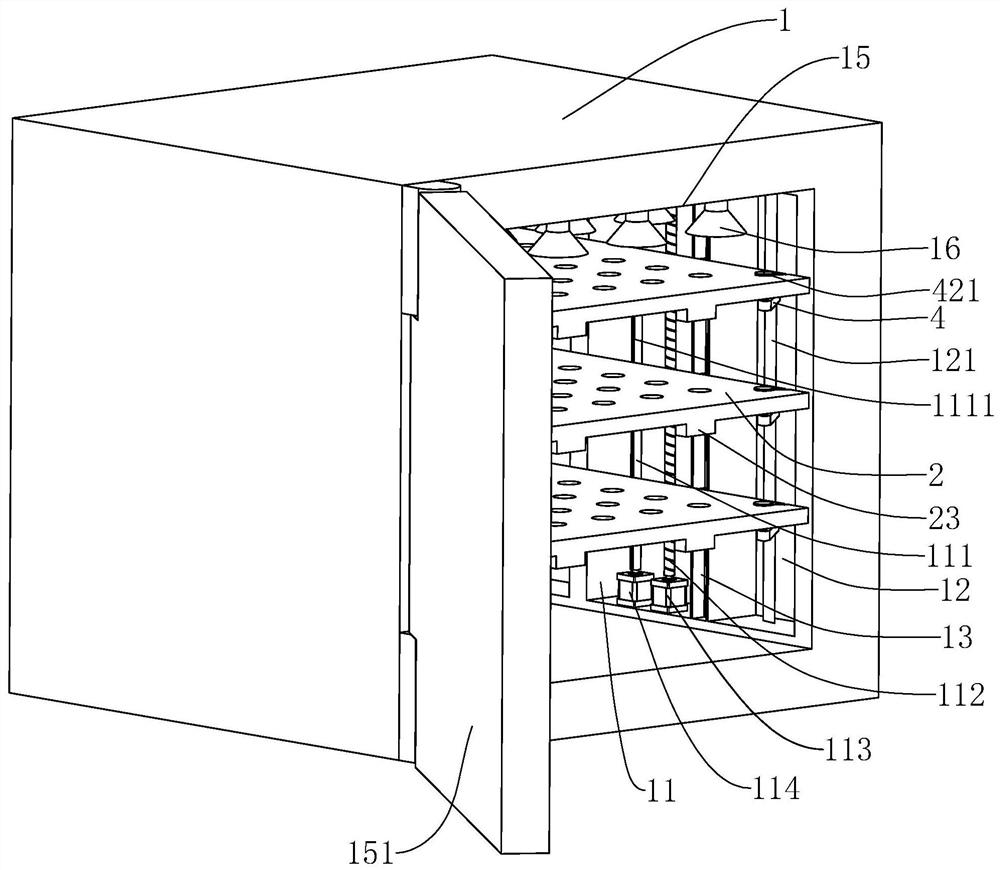

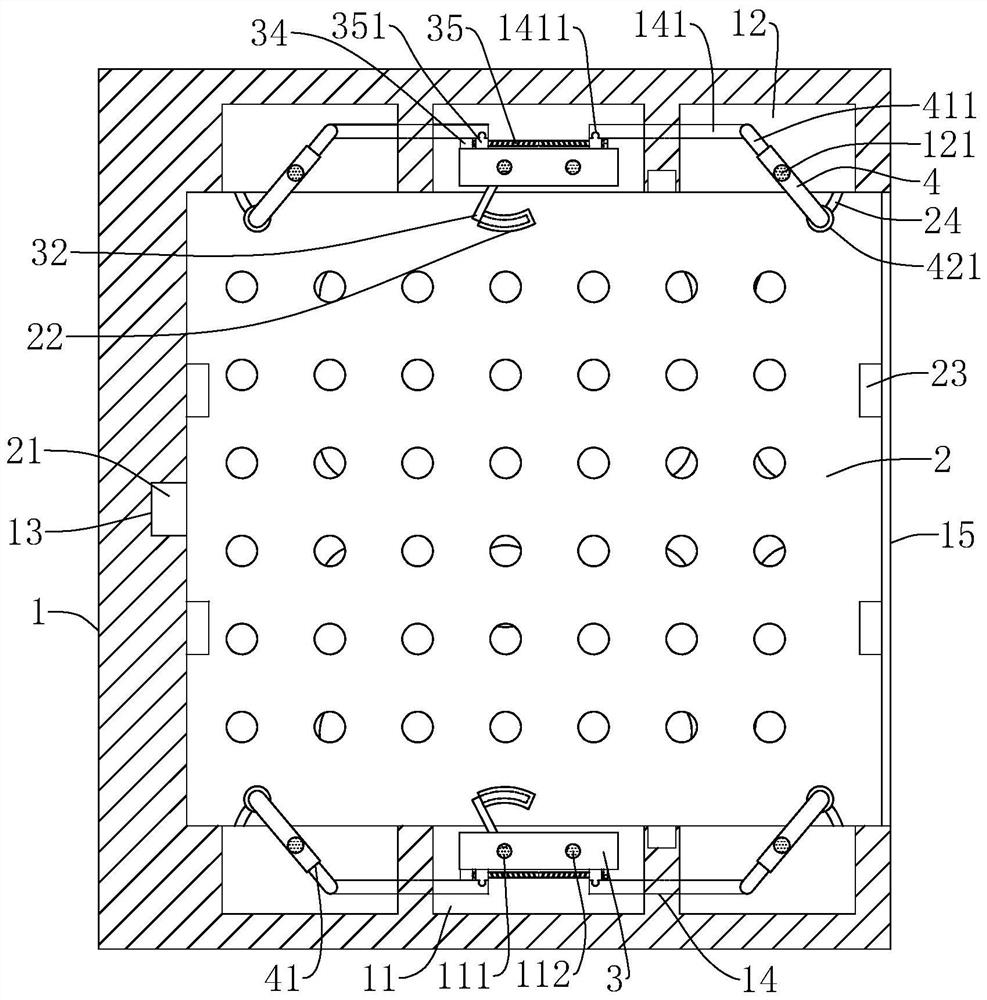

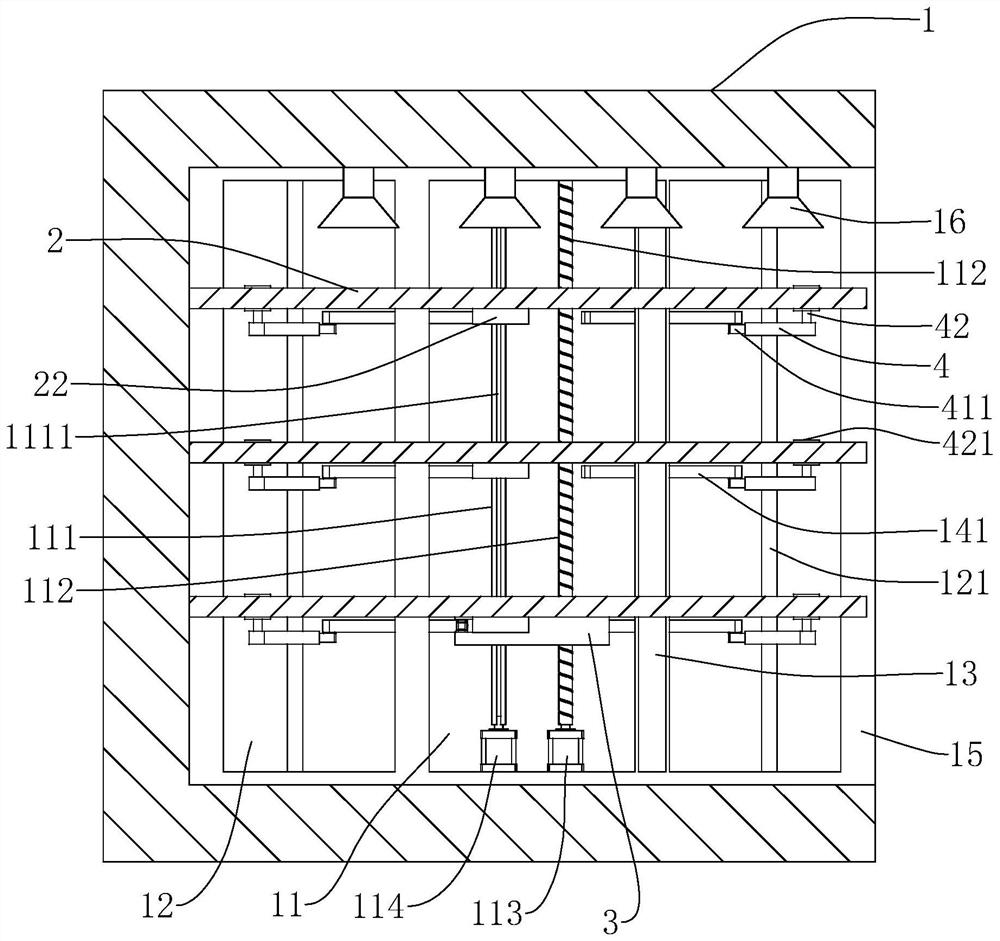

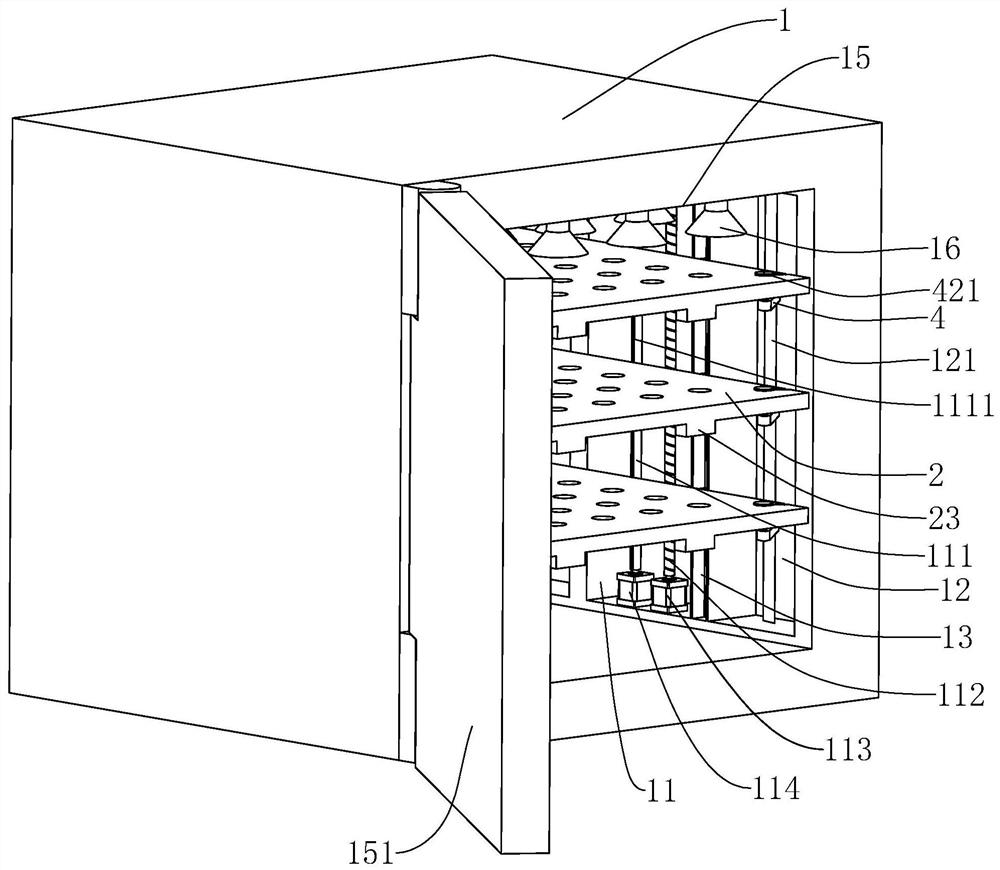

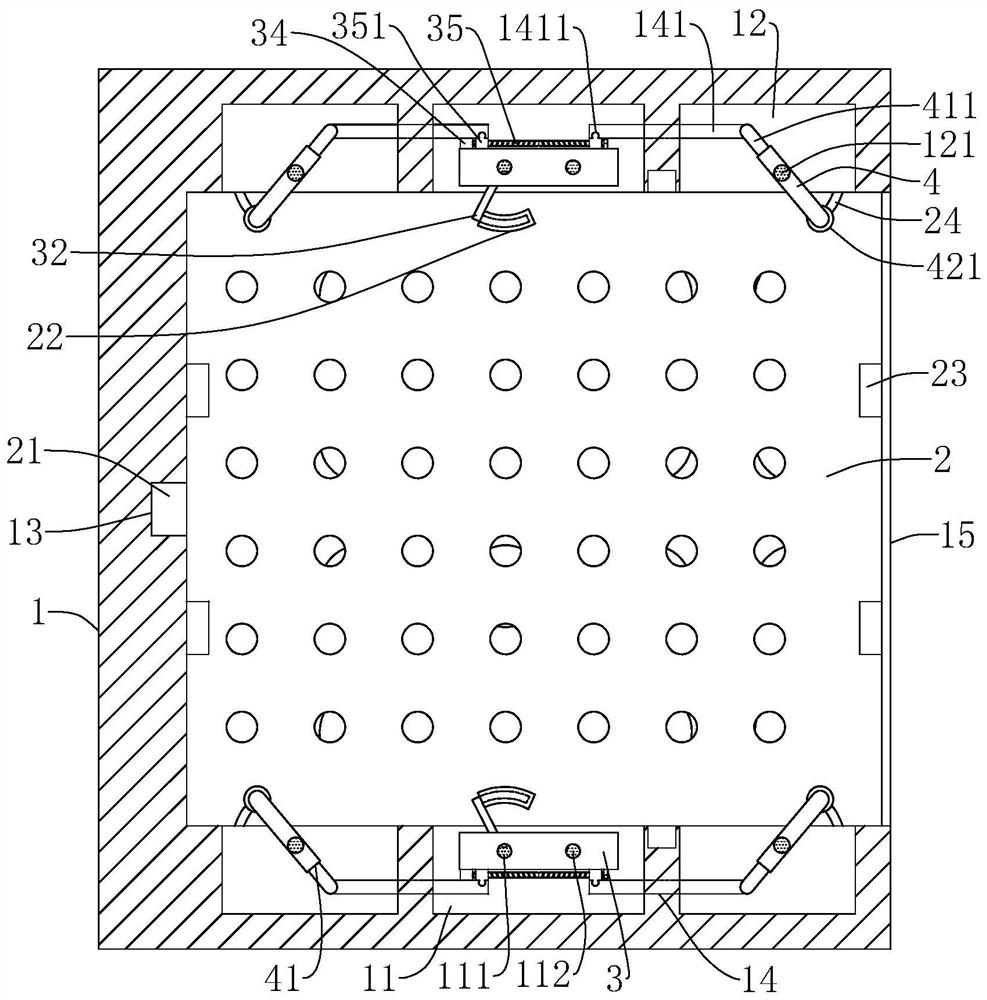

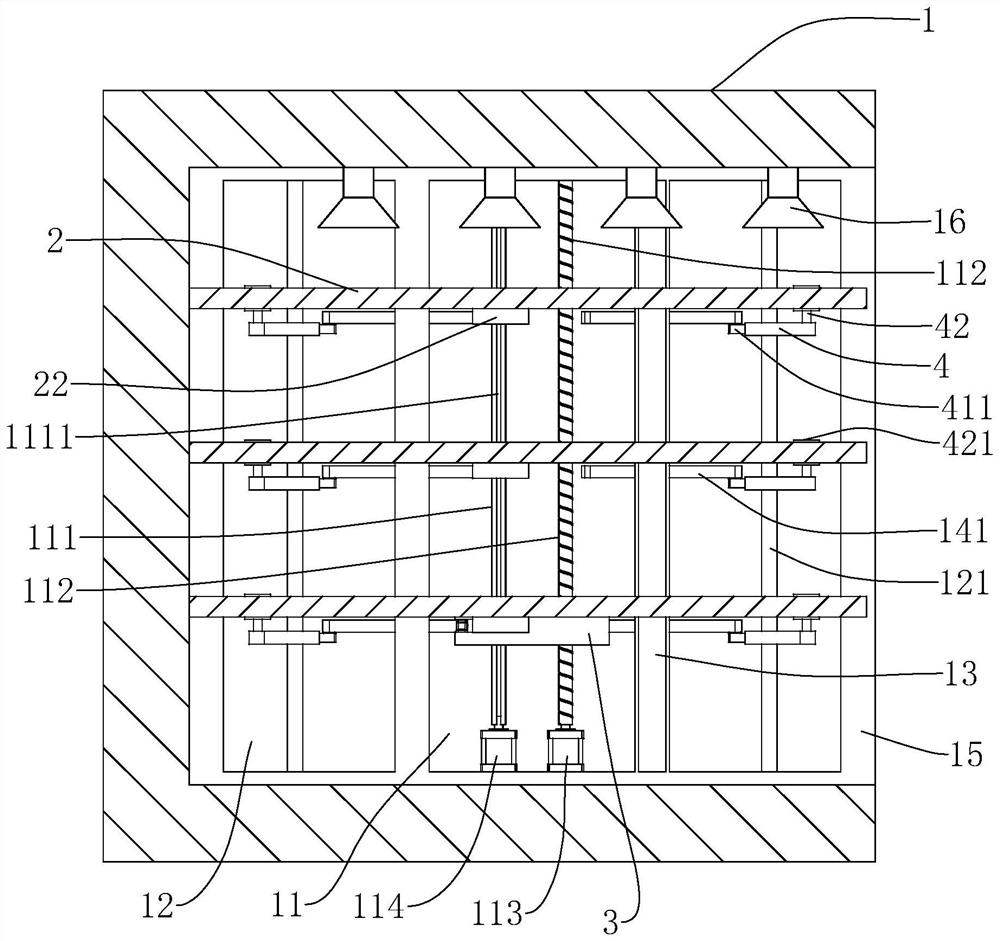

Curing chamber for recycled concrete test blocks

ActiveCN112497462ALower the altitudeEasy accessCeramic shaping apparatusArchitectural engineeringMechanical engineering

The invention relates to a curing chamber for recycled concrete test blocks. The curing chamber comprises a curing chamber body with one side provided with an opening and a curing door covering the opening, a humidifying assembly is arranged on the inner wall of the curing chamber body, the curing chamber body is connected with a plurality of horizontally-arranged curing plates in an up-down sliding manner, and the curing chamber body is provided with a lifting assembly for driving the multiple curing plates to move up and down in sequence; and the curing chamber body is provided with a bearing assembly used for fixing the curing plate moving to the designated position. According to the curing chamber, the lifting assembly is used for driving to achieve downward movement, so that the height of the curing plates is reduced, workers can place and take the concrete test blocks on the curing plates conveniently, and the workload of the workers is reduced.

Owner:深圳市汇基砼混凝土有限公司

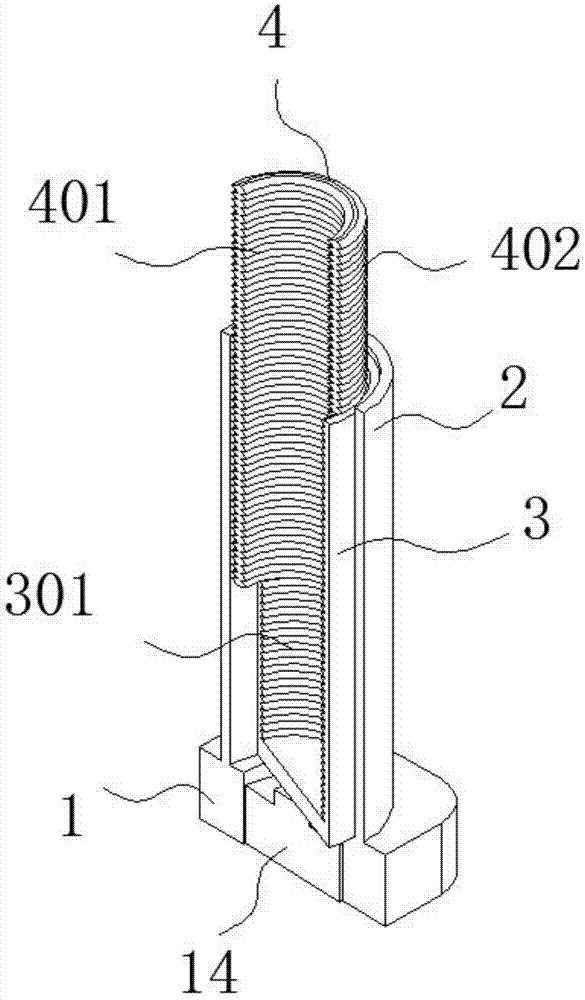

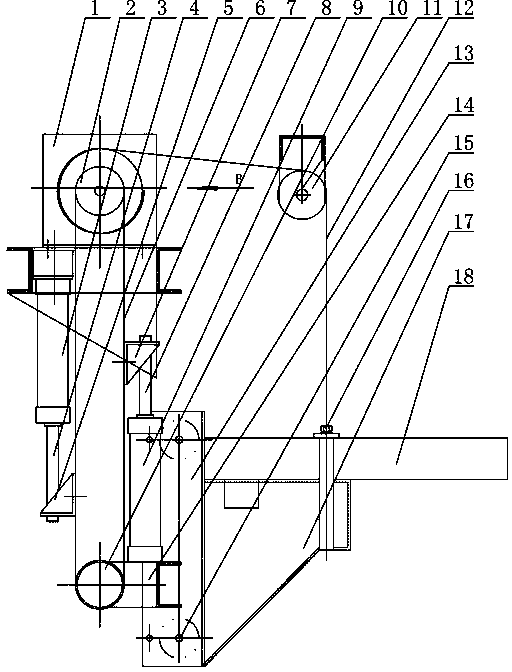

Lifting mechanism

ActiveCN103193000BRealize up and down displacementReasonable structureSolid materialEngineeringSprocket

A lifting mechanism comprises a base. A driving sprocket is mounted in the base, a support is arranged on the lower portion of the base, a driven sprocket is mounted on the support, and the driving sprocket is in meshed transmission with the driven sprocket via a first chain, so that a vertically arranged chain transmission mechanism is formed; a first connector and a second connector are respectively mounted on chain links on two sides of the first chain by fasteners; a first cylinder is mounted at the bottom of the base, and a first piston rod of the first cylinder is connected with the first connector; a second cylinder is mounted on the support, and a second piston rod of the second cylinder is connected with the second connector; a slide groove framework which is parallel to the vertically arranged chain transmission mechanism is arranged on one side of the support, rollers are mounted in the slide groove framework, a bracket capable of sliding along the slide groove framework is connected onto the slide groove framework, and a compaction plate is mounted on the upper portion of the bracket; and a fixed pulley is arranged on one side of the driving sprocket, the driving sprocket is meshed with the fixed pulley via a second chain, and the second chain at one end of the fixed pulley is connected with the compaction plate by a fastener. The lifting mechanism has the advantages of reliability in operation and high precision.

Owner:M & J MACHINERY ENGINEER

A 3D printer with a rotating self-coloring structure

ActiveCN108312541BRealize up and down displacementAchieve forward and backward displacementManufacturing driving meansAdditive manufacturing with liquidsComputer printingEngineering

Owner:WANGYUN WUHAN 3D TECH CO LTD

A curing room for recycled concrete test blocks

ActiveCN112497462BLower the altitudeEasy accessCeramic shaping apparatusArchitectural engineeringStructural engineering

This application relates to a curing room for recycled concrete test blocks, which includes a curing room with an open side and a curing door covered on the opening. The inner wall of the curing room is provided with a humidifying component. For the maintenance boards arranged horizontally, the maintenance room is provided with a lifting assembly that drives several maintenance boards to move up and down sequentially, and the maintenance room is provided with a supporting assembly that fixes the maintenance boards moved to the designated positions. In the present application, the lifting component is driven to move downwards to reduce the height of the curing plate, which is convenient for staff to put and take concrete test blocks on the curing plate, and reduces the workload of the staff.

Owner:深圳市汇基砼混凝土有限公司

A wet slurry sample placement device and its control method

InactiveCN103487311BThe result of whiteness test is accurateSimple structurePreparing sample for investigationElectricityMicrocontroller

Owner:GUANGDONG DONGGUAN QUALITY SUPERVISION TESTING CENT

High-voltage transmission line ground wire operation device

ActiveCN113394710AAchieve supportRealize up and down displacementApparatus for overhead lines/cablesCircular discElectric machine

The invention discloses a high-voltage transmission line ground wire operation device which comprises a machine body, a positioning block is welded to the outer wall of the machine body, a push cylinder is installed at the front end of the machine body, an air cylinder body is hinged to one end of the push cylinder, a push rod is installed at the telescopic end of the air cylinder body, and a hinge joint is hinged to the top end of the push rod. A vertical column is welded to the other end of the hinge joint, a motor is installed at the top end of the vertical column, and pneumatic supporting legs are welded to the lower portion of the outer wall of the vertical column. According to the high-voltage power transmission line ground wire operation device, an electric push rod is controlled to operate to drive a lower mounting disc to ascend and descend, and when the lower mounting disc ascends, a hinged swing rod and a movable claw hinged through a hinge piece are driven to contract; and the disc connected to the inner side part of the movable claw can gather all the soil into the formed hole, so that the soil backfilling operation after drilling is realized.

Owner:启晗电力建设集团有限公司

Overhead line insulator decontamination device

ActiveCN106076941BEnsure personal safetySave human effortCleaning using liquidsApparatus for overhead lines/cablesArchitectural engineering

The invention relates to a cleaning device for insulators of electric lines. The cleaning device is characterized by comprising a cleaning module, a lifting module, a walking module, a water pipe box, a water tank and a water pump, wherein the cleaning module is fixed to the walking module by virtue of the lifting module, the water pipe box, the water tank and the water pump are all fixed to the walking module, and the water pipe box is connected with the water tank by virtue of the water pump; the cleaning module comprises a cleaning arm, a nozzle, a sliding block, a screw-nut mechanism, a guide rail, guide rail brackets and a workbench; a workbench water outlet is formed in the workbench, the guide rail brackets are arranged on the outer side of the workbench water outlet, the guide rail is fixed to the guide rail brackets by virtue of screws, a connecting frame is horizontally connected between the two adjacent guide rail brackets, the screw-nut mechanism is fixed to the outer side of the middle of the connecting frame along a vertical direction, and the screw-nut mechanism comprises a screw connecting plate, a screw nut, a screw, bearing seats, a coupling and a stepping motor; the stepping motor is connected with screw by virtue of the coupling, and the bearing seats sleeve both ends of the screw.

Owner:HEBEI UNIV OF TECH

A screen printing machine

ActiveCN110576674BAchieve displacementGood up and down abilityScreen printersPrinting pressConveyor belt

The invention discloses a screen printer. The screen printer comprises a net frame, a support frame, a conveyor and an electric linear guide rail, wherein a supporting plate used for supporting a conveyor belt is arranged on the supporting frame, the supporting plate is fixedly connected with the supporting frame, the conveyor is mounted on the support frame, the belt of the conveyor is clung to the supporting plate, a first connecting plate and a second connecting plate are arranged on the supporting frame, a first sliding guide rail and a second sliding guide rail are arranged on the front surface of the first connecting plate and the front surface of the second connecting plate respectively, clamps used for clamping the net frame is arranged on the first sliding guide rail and the second sliding guide rail, a net plate is arranged on the net frame, the net plate is located right above the supporting plate, the electric linear guide rail is mounted between the first connecting plateand the second connecting plate, and a scraping plate matched with the net plate is arranged on a slider of the electric linear guide rail. The screen printer can adjust the screen height so as to prevent the scraping plate from working under the condition of high load for a long time.

Owner:HUZHOU XINTIAN GREEN PACKAGE PRINTING CO LTD

Processing and spraying device for photocatalyst plate for indoor and outdoor decoration

InactiveCN112354733ARealize multi-angle adjustmentAchieve sprayingSpraying apparatusEngineeringStructural engineering

The invention discloses a processing and spraying device for photocatalyst plate for indoor and outdoor decoration. The device comprises a base table. Mounting columns are welded to the four corners of the base table correspondingly, a welding base is welded to the position, close to the right side, of the middle of the upper surface of the base table, a first rotating shaft mounting block is arranged on the outer side of the welding base, a reinforcing rib frame is welded to the middle of an inner frame of the base table, two second rotating shaft mounting blocks are mounted on the portion, close to the left, of the upper surface of the base table, and a rotating shaft is mounted between the opposite faces of the two second rotating shaft mounting blocks. According to the processing and spraying device for photocatalyst plate for indoor and outdoor decoration, a support is placed between two sliding blocks, specifically,sliding protruding blocks on the lower portion of the outer wallof the support are in sliding butt joint with notches formed in the outer sides of the sliding blocks so that the support can be limited, the bottom end of the support is located on the upper surfaceof a belt, and during belt transmission, the support can be driven to move.

Owner:杭州御诺装饰有限公司

Corrugated carton forming device

InactiveCN112060679AAchieve rotationAvoid bending over to takePaper-makingBox making operationsGear driveGear wheel

The invention relates to the technical field of corrugated carton production equipment, and discloses a corrugated carton forming device. The corrugated carton forming device comprises a rack, a conveying roller is fixedly installed in the rack, a power box is fixedly installed on the right side surface of the rack, a transverse rod is fixedly connected to the front surface of the rack, and a supporting frame is fixedly connected to the top face of the transverse rod. According to the corrugated carton forming device, a carrier plate can be adjusted up and down, and the bottom of the carrier plate is connected with a first movable rod sleeved with a first fixed sleeve, so that a second gear drives a first gear to rotate when a foot bar rotates, rotation of a threaded rod is achieved, a movable plate connected to the threaded rod in a threaded and sleeving mode moves to drive pressure oil to extrude the first movable rod, upward displacement of the carrier plate is finally achieved, thecarrier plate gradually moves upwards in the process that the number of the corrugated cartons is reduced, the corrugated carton on the uppermost portion is located at a feeding port all the time, workers are prevented from bending down to take the corrugated cartons, feeding efficiency is improved, and carton nailing efficiency is improved.

Owner:盐城大白杨彩印有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com