Cloth chute device for cloth machine

A technology for distributing chute and distributing machine, applied in the direction of supply device, manufacturing tools, etc., which can solve the problems of high manufacturing cost, many failures, complicated lifting of the upper and lower mechanism of the distributing machine outlet, etc., and achieves low manufacturing cost, low failure rate and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

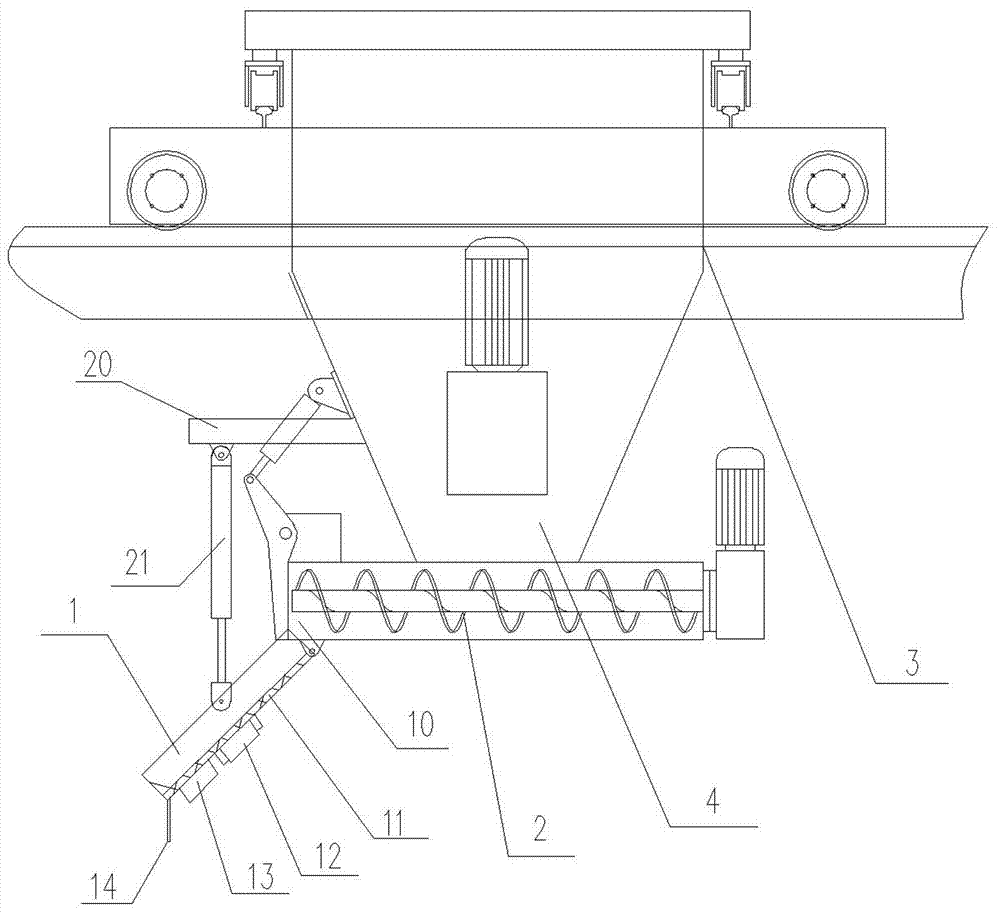

[0031] Example one: such as figure 1 As shown, at the bottom of the cloth hopper 4 of the cloth machine 3, there is a twisting cage feeding device 2, and the left side of the twisting cage feeding device 2 is a cloth outlet 10. The present invention includes a cloth chute 1 hinged to the bottom of the cloth outlet 10 and one end installed at The other end of the cloth machine 3 is connected with the cloth chute 1 and is used to drive the cloth chute 1 to swing along the hinge point.

[0032] The shape of the distributing chute 1 can be a cylinder, a rectangular tube, a cone-shaped tube, a semi-circular groove, a U-shaped groove and a flat plate.

[0033] The inner side wall of the distributing chute 1 is provided with a polymer polymer plate 11, and the polymer polymer plate 11 can effectively reduce the friction force from the inner side wall of the distributing chute 1 on the material during the discharging process.

[0034] A vibrating motor 12 is arranged on the outer side wall o...

Embodiment 2

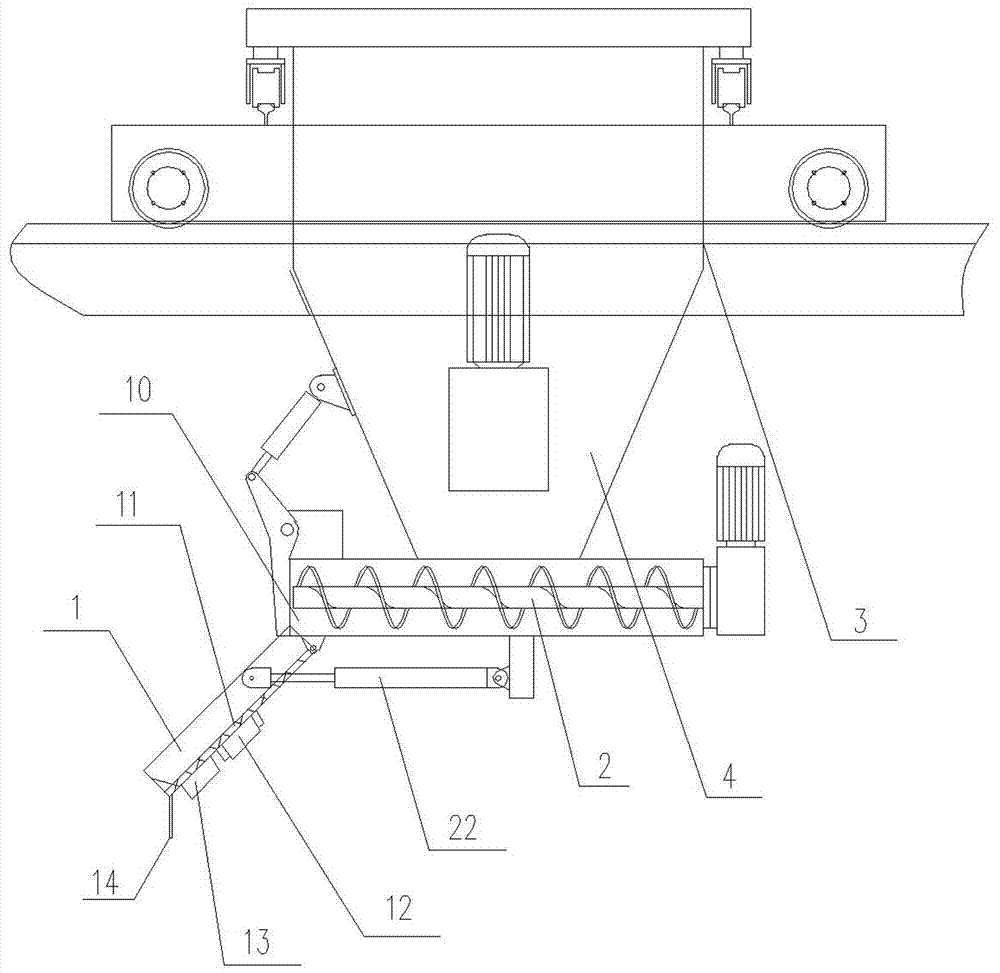

[0038] Embodiment two: such as figure 2 As shown, on the basis of Embodiment 1, the structure of the driving device is changed without the other structure. The driving device includes a pusher whose one end is hinged with the bottom of the cloth machine 3 and the other end is hinged with the surface or side of the cloth chute 1. The second rod 22; the second push rod 22 can be a hydraulic push rod or an electric push rod. The push rod 22 pushes its piston to move axially and drives the cloth chute 1 to swing around its hinge point with the outlet 10 of the cloth machine, and then the outlet end of the cloth chute 1 is displaced up and down, that is, the cloth The height of the outlet end of the chute 1 changes, and the operation can be adjusted according to the actual situation to realize the production of concrete parts of different thicknesses.

Embodiment 3

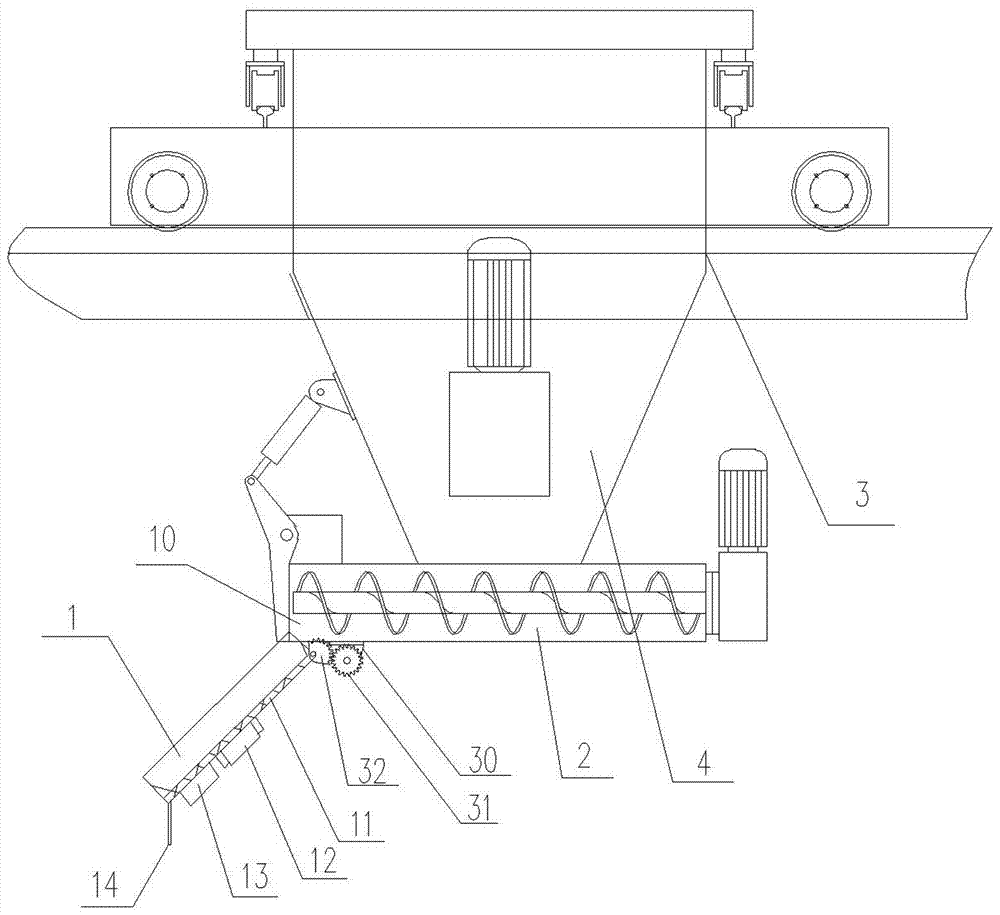

[0039] Example three: such as image 3 As shown, on the basis of Embodiment 1, the structure of the driving device is changed without the other structure. The driving device includes a motor 30 installed at the bottom of the cloth machine 3 and a drive shaft installed on the motor 30. The number gear 31 and the number two gear 32 meshed with the number one gear 31; the number two gear 32 is arranged on the distribution chute 1 and the distribution chute 1 can rotate with the number two gear 32. The motor drives the second gear 32 to rotate through the rotation of the first gear 31, and then the second gear 32 drives the cloth chute 1 hinged to the cloth outlet 10 of the cloth machine to swing, so that the outlet end of the cloth chute 1 Up and down displacement occurs, that is, the height of the outlet end of the distributing chute 1 changes, and adjustment operations can be performed according to actual conditions to realize the production of concrete parts of different thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com