Manual adjustable tension wire tightening mechanism

A wire-tightening and tensioning technology, which is used in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of insufficient uniform tension, high cost, and small adjustment of electrode wire, so as to achieve a simple and practical design structure and improve Productivity, flexible use of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

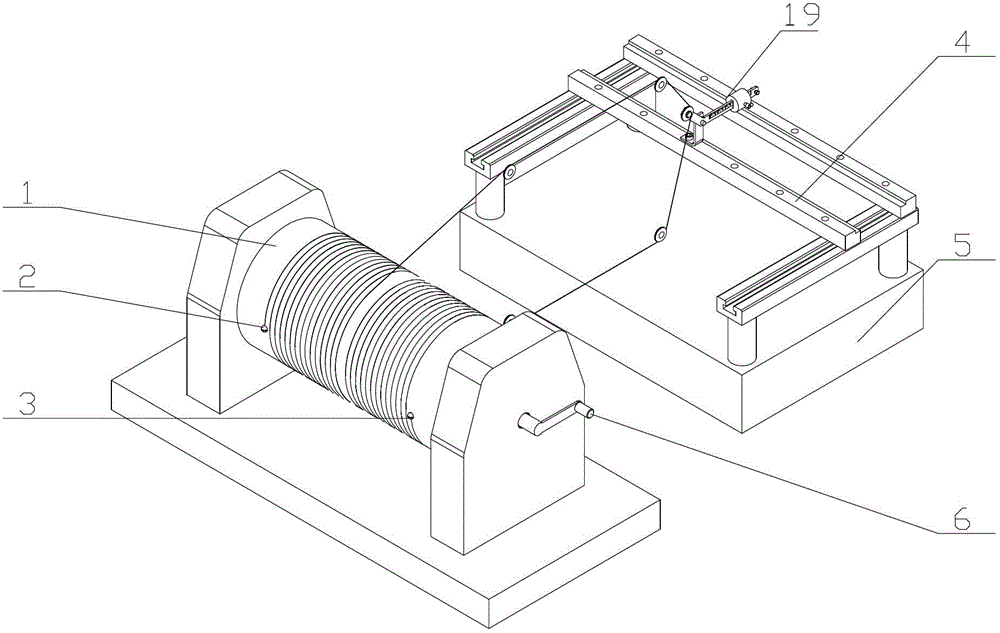

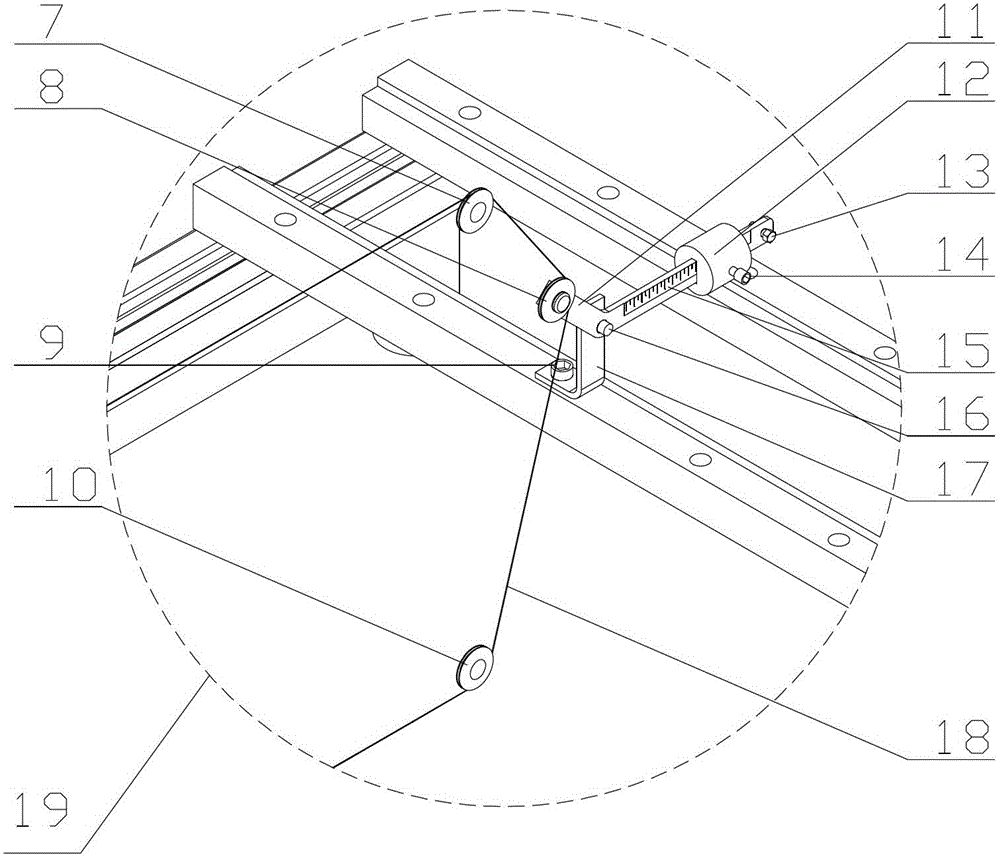

[0015] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0016] A manually adjustable tension wire tightening mechanism, the manual adjustable tension wire tightening mechanism includes a wire drum 1, an electrode wire 18, an upper guide wheel 7, a lower guide wheel 10, a workbench 5, a beam 4, and a wire tightening device 19. One end of the electrode wire 18 is wound on the wire drum 1 and fixed on the left end of the wire drum 1, and the other end of the electrode wire 18 passes through the upper guide wheel 7, the tightening wire device 19 and the lower guide wheel 10, and then is wound on the wire drum 1 and fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com