Tension mechanism for hot galvanizing colorful coating plate production

A tensioning mechanism and hot-dip galvanizing technology, applied in the direction of coiling strips, thin material handling, transportation and packaging, etc., can solve the problems of up and down shaking, affecting product quality, easy sagging, etc., and achieve the effect of convenient tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

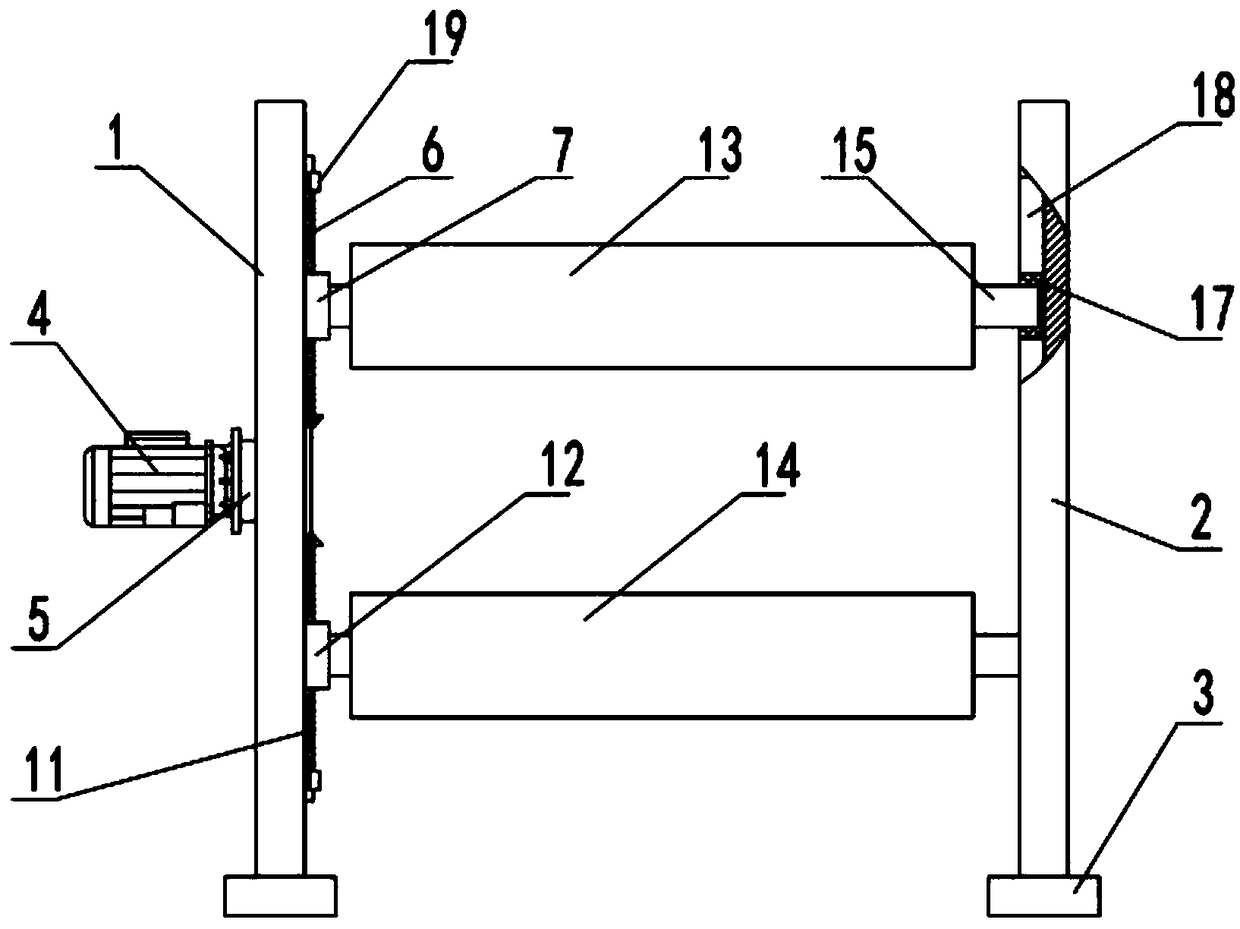

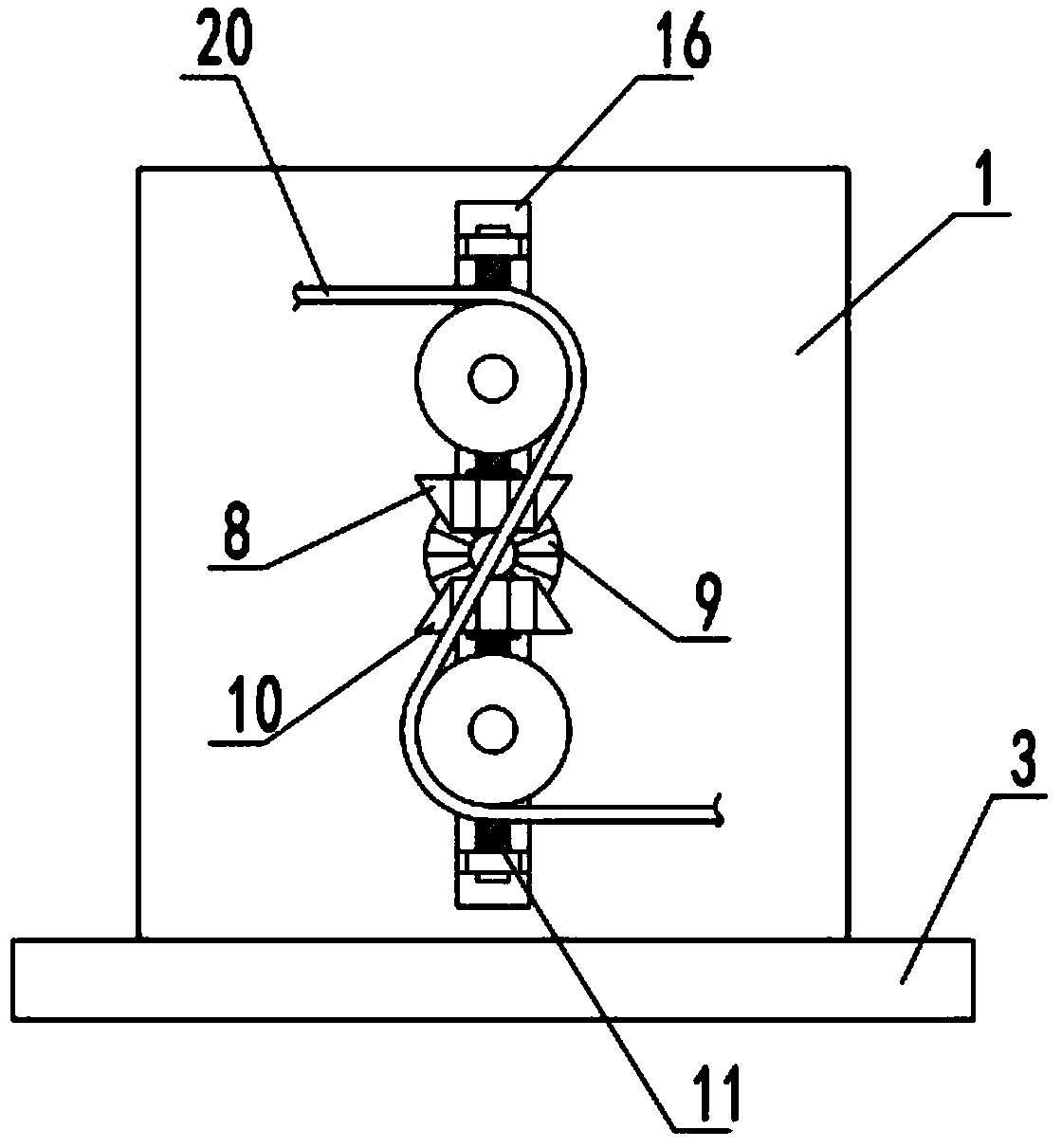

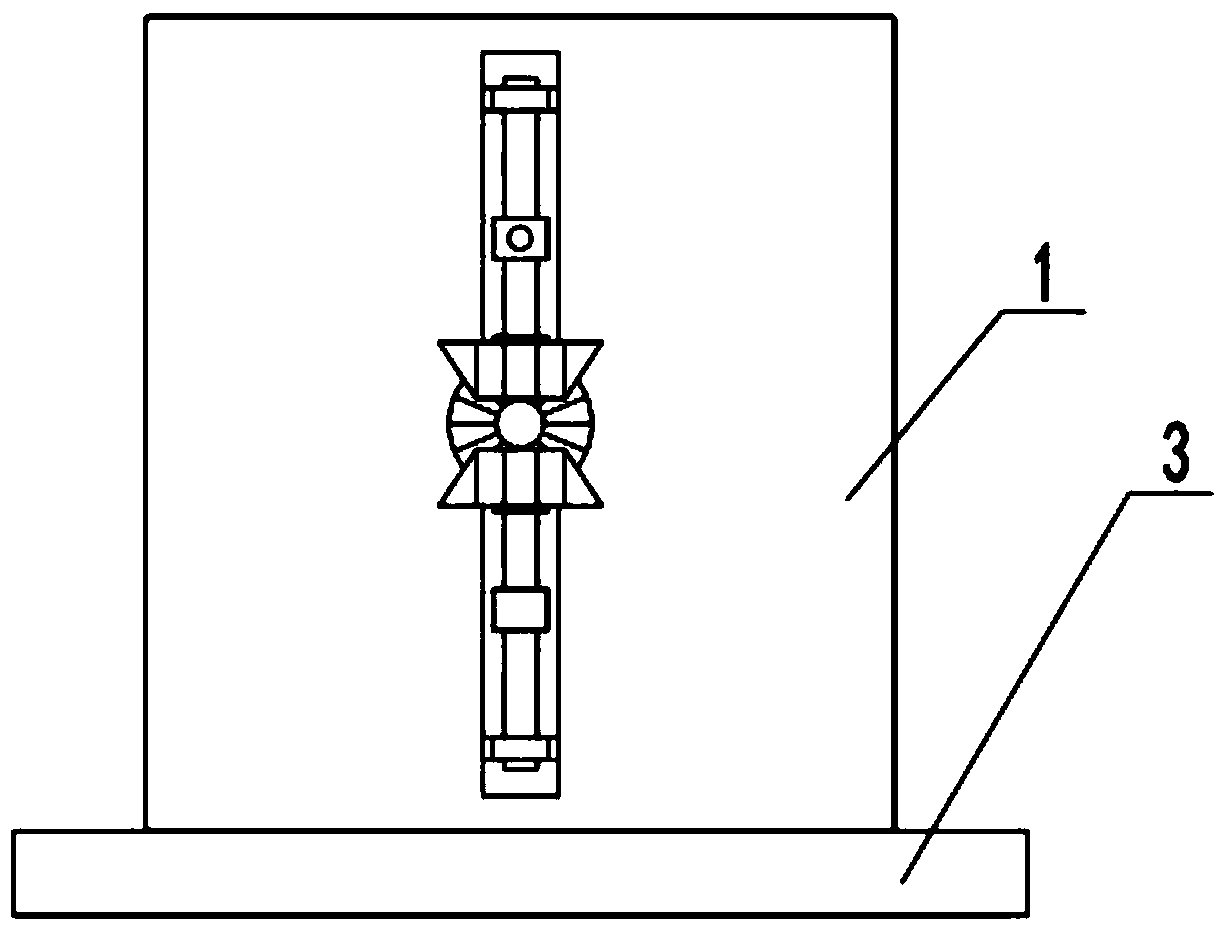

[0018] see Figure 1~3 , in an embodiment of the present invention, a tension mechanism for hot-dip galvanized color-coated sheet production, including a left side plate 1, a right side plate 2, a base 3, a reduction motor 4, a guide roller 13 and a guide roller 2 14, The left side plate 1 and the right side plate 2 are opposite in position, and the bottoms of the left side plate 1 and the right side plate 2 are all fixed on the base 3, and the left side plate 1 is provided with a mounting groove 16, and the middle part of the mounting groove 16 is The active bevel gear 9 is installed at the position, and the active bevel gear 9 is connected with the reduction motor 4 through the coupling 5, and the rotation of the active bevel gear 9 is driven by the reduction motor 4, and the upper and lower positions of the active bevel gear 9 are respectively provided with gears for meshing transmission with it. Bevel gear 1 8 and bevel gear 2 10, bevel gear 1 8 and bevel gear 2 10 are fix...

Embodiment 2

[0022] On the basis of Embodiment 1, in order to make the two ends of the guide roller 13 and the guide roller 14 move synchronously in this embodiment, or the movement of the guide roller 13 and the guide roller 2 14 is smoother, in the middle shaft A linear bearing 17 is installed between the shaft end of 15 and the slide groove 18 .

[0023] Further, the base 3 is fixed on the ground or an external mechanism through anchor bolts, and its position can be adjusted according to actual usage conditions.

[0024] In order to prevent the deviation phenomenon of the galvanized strip 20 during movement, both ends of the first guide roller 13 and the second guide roller 14 are provided with 90-degree baffles, that is, the cross-sections of the first guide roller 13 and the second guide roller 14 It is in the shape of "工", which has a certain deviation-correcting effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com