Patents

Literature

32results about How to "Meet tension requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

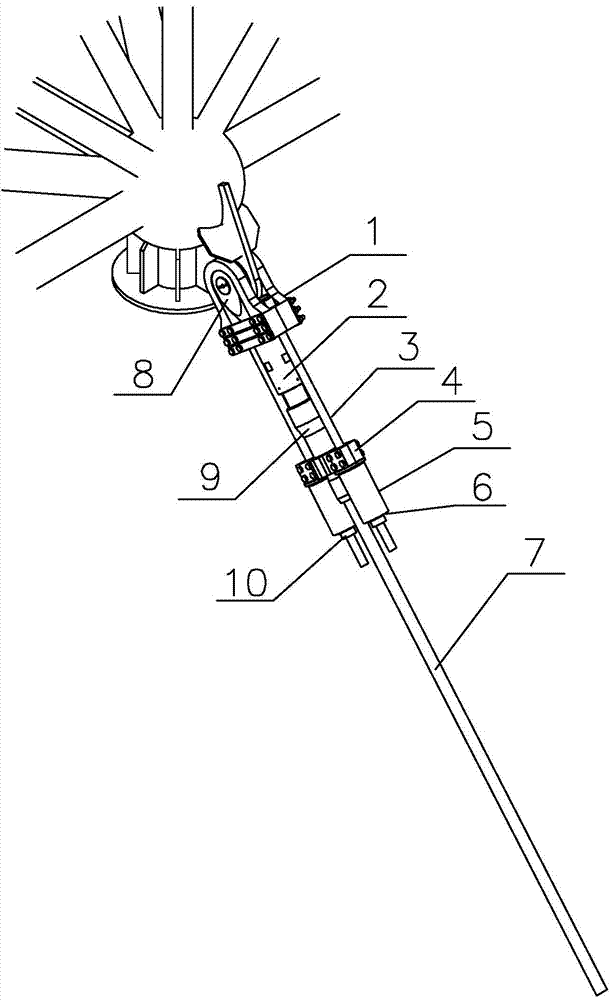

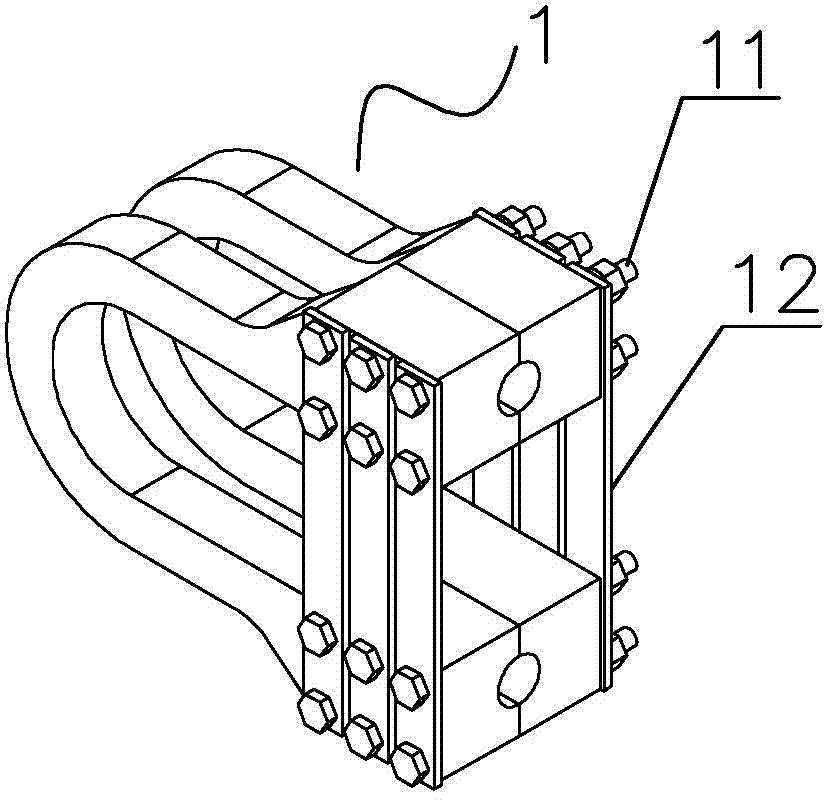

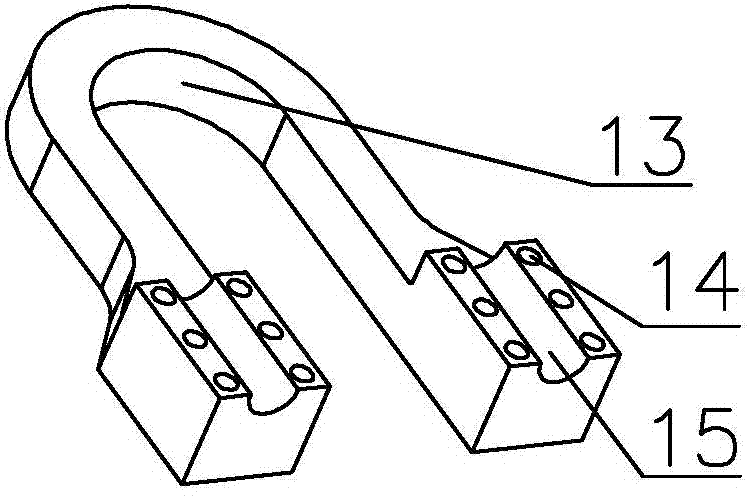

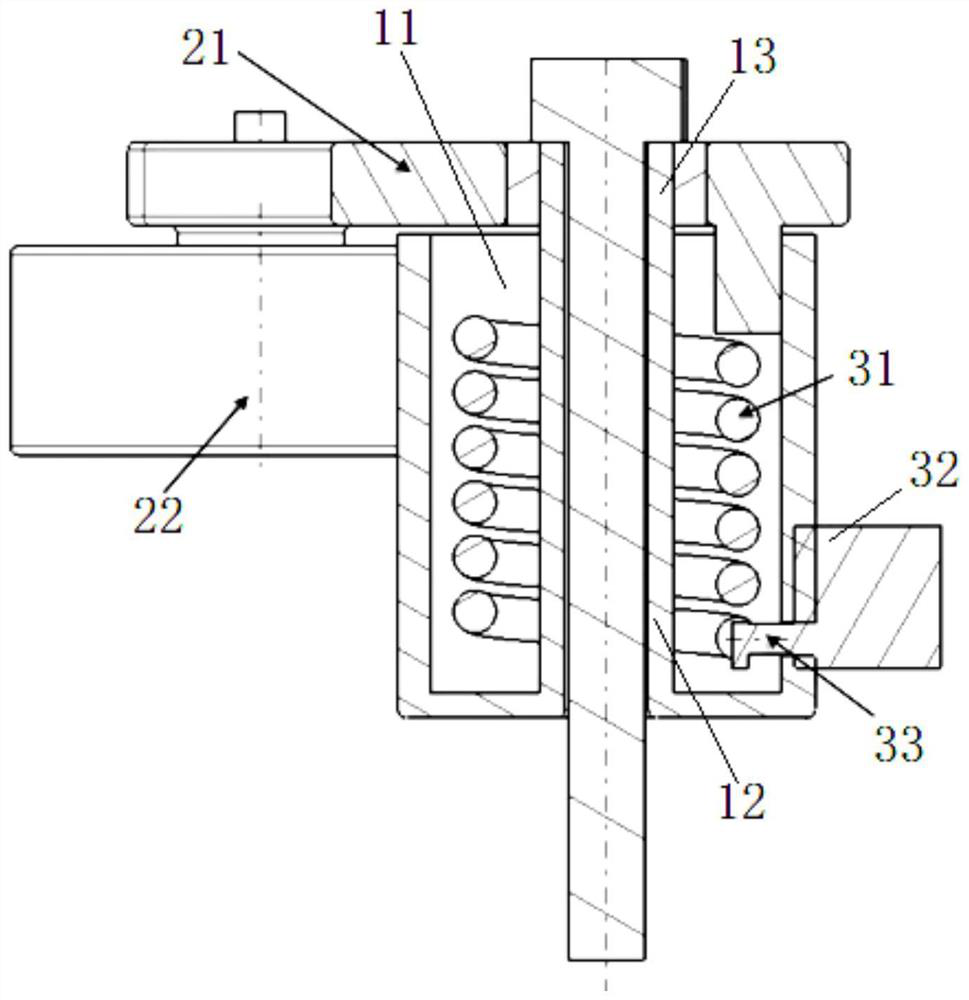

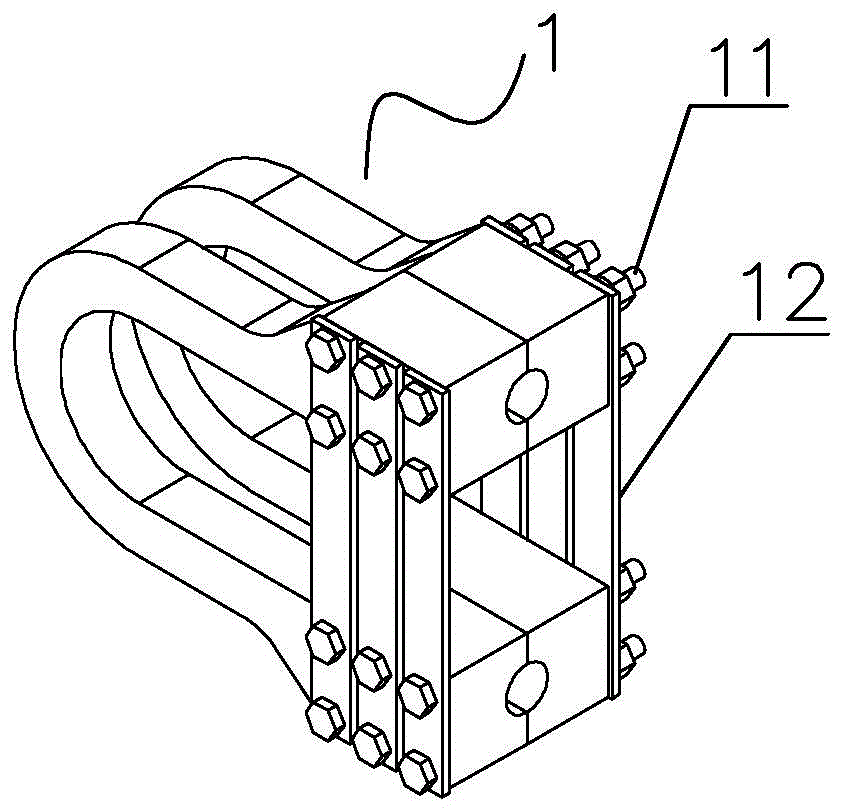

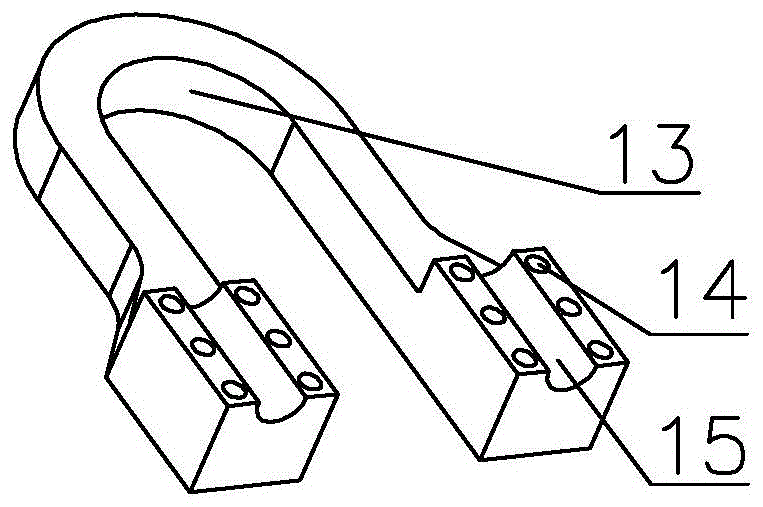

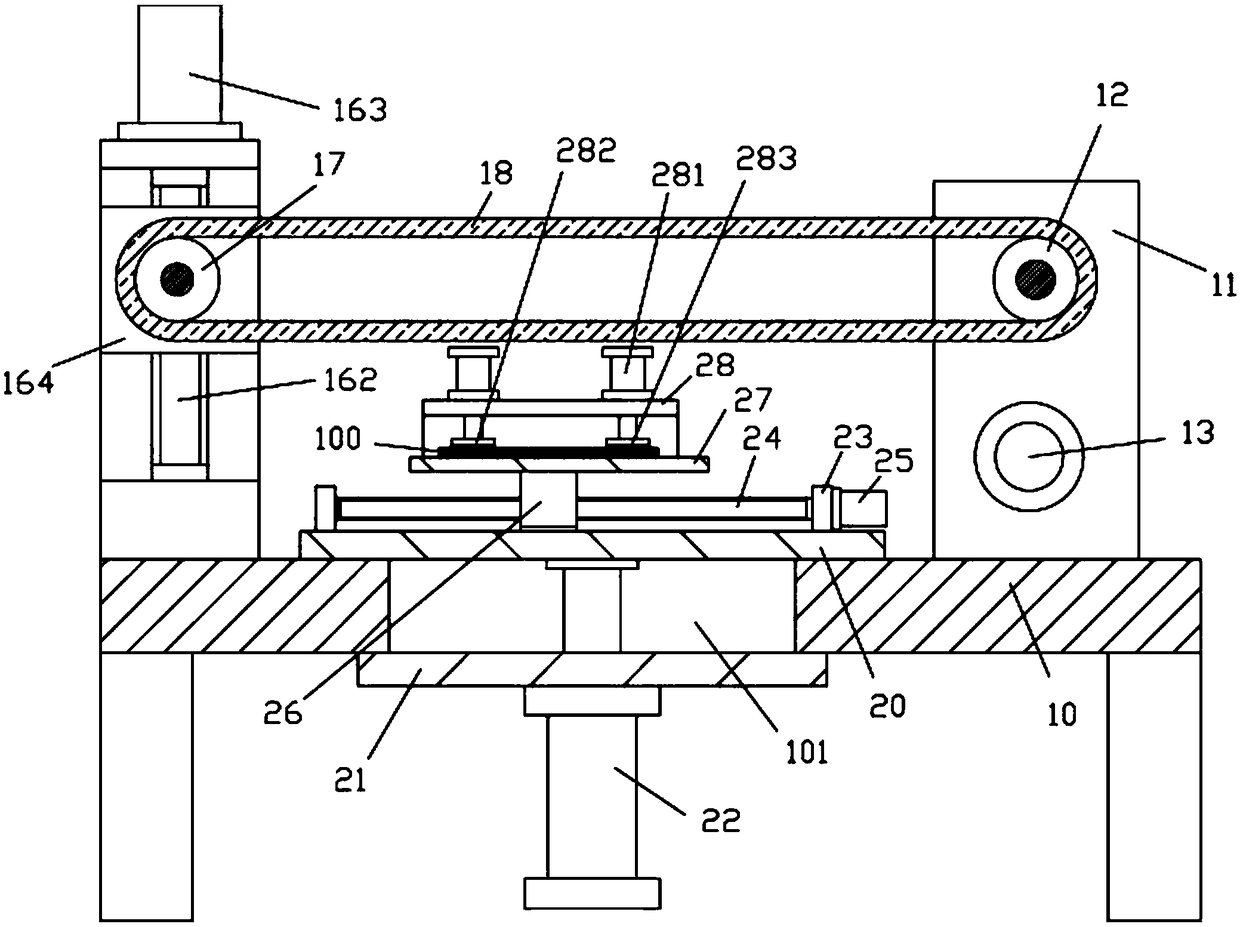

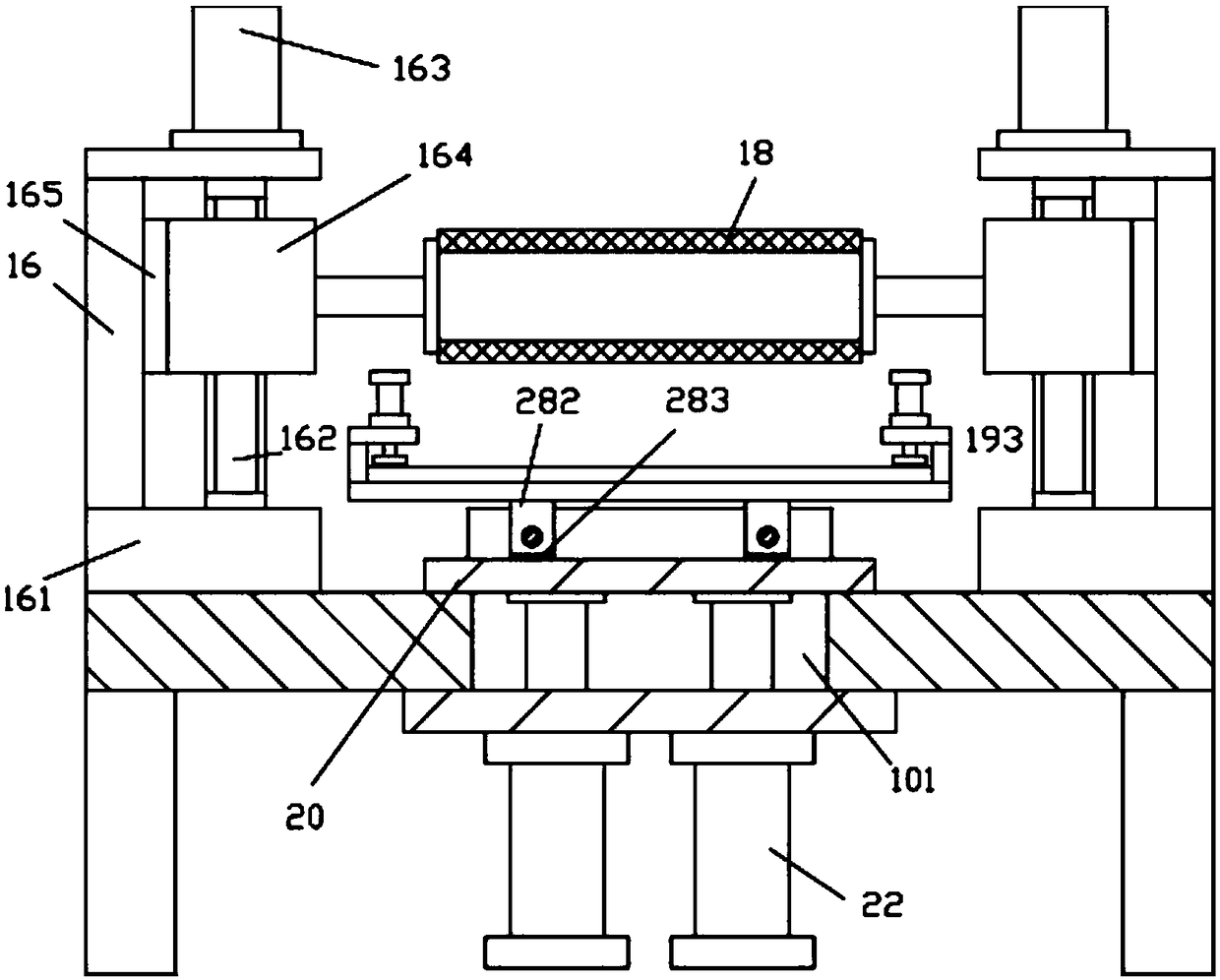

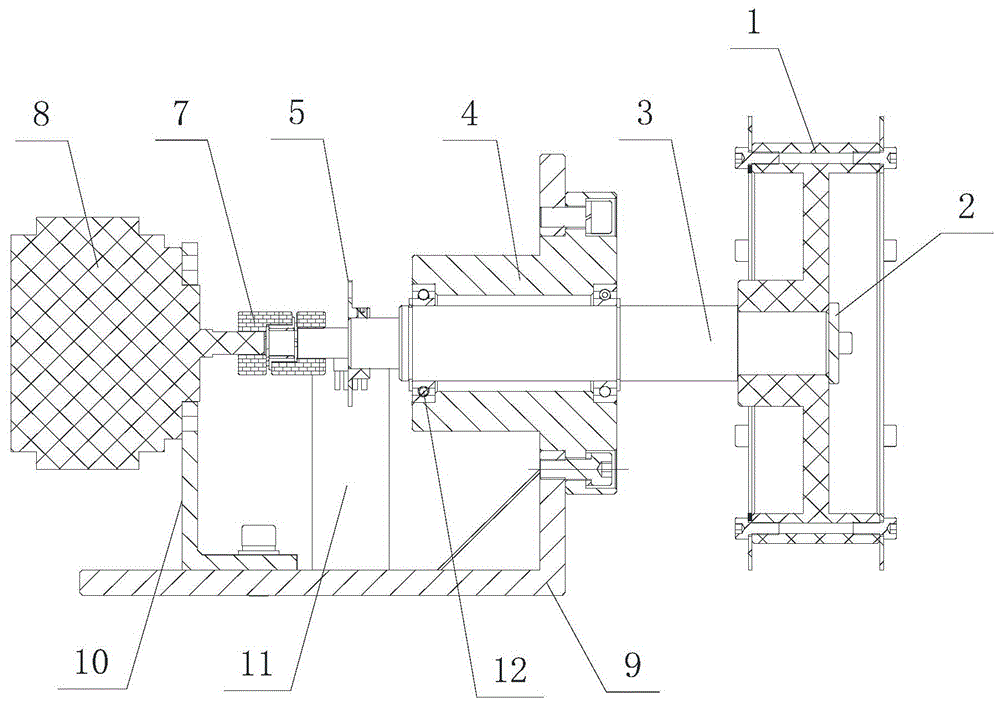

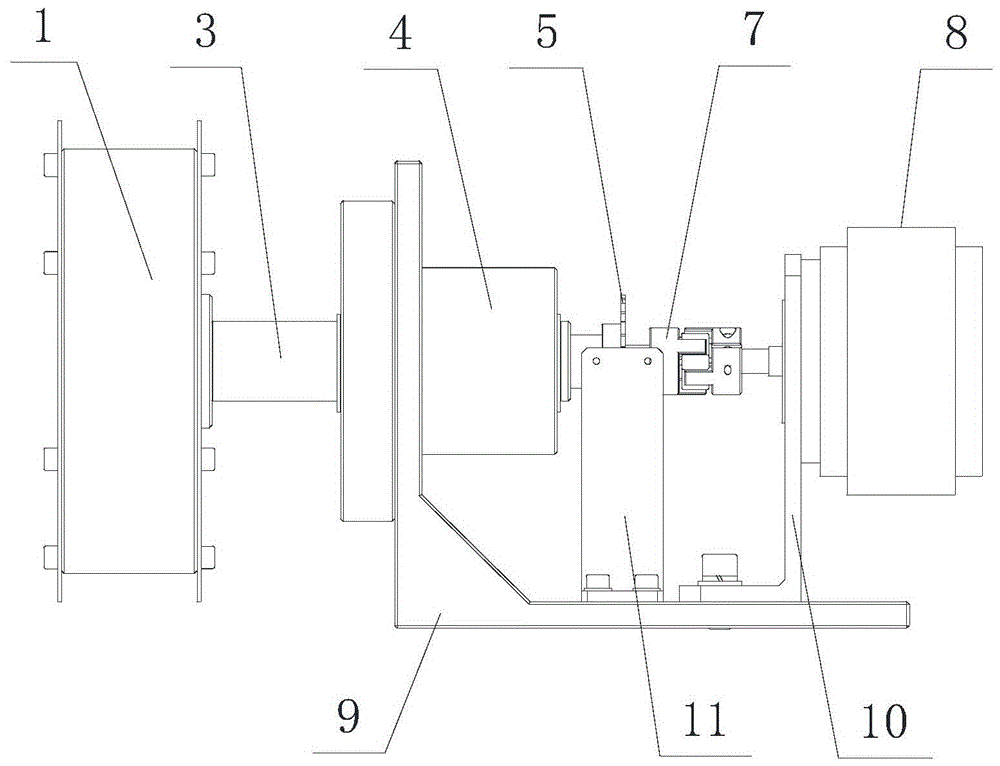

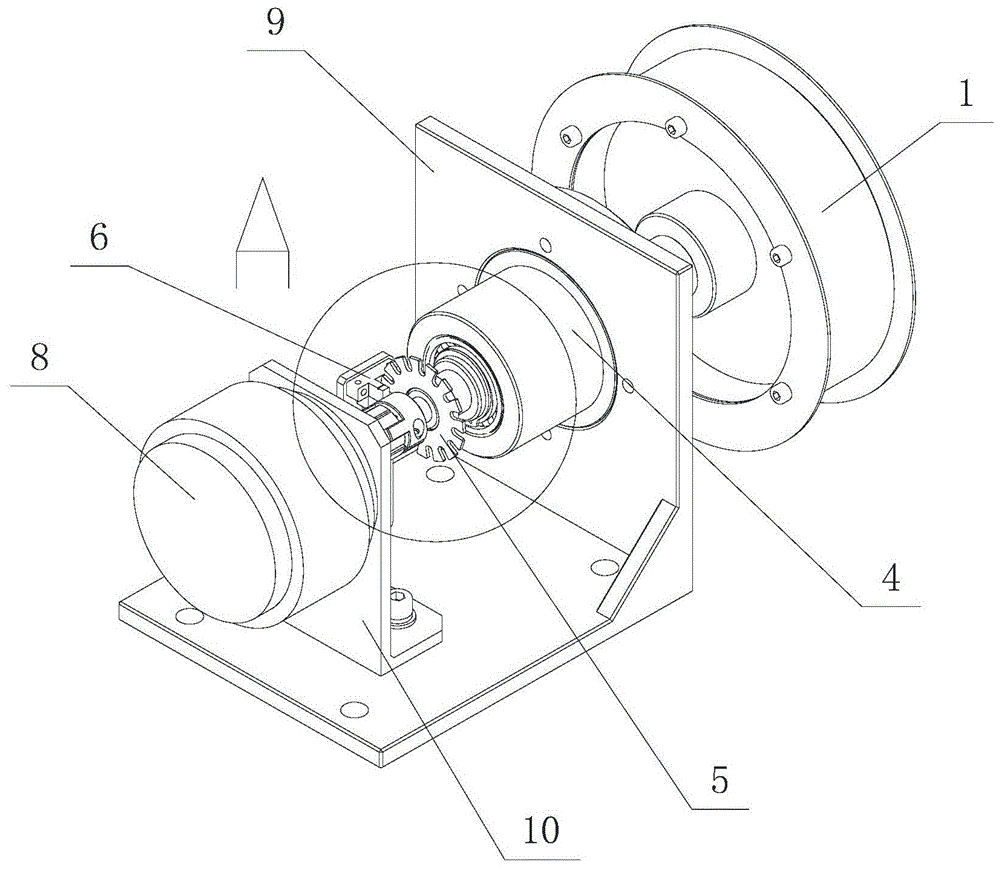

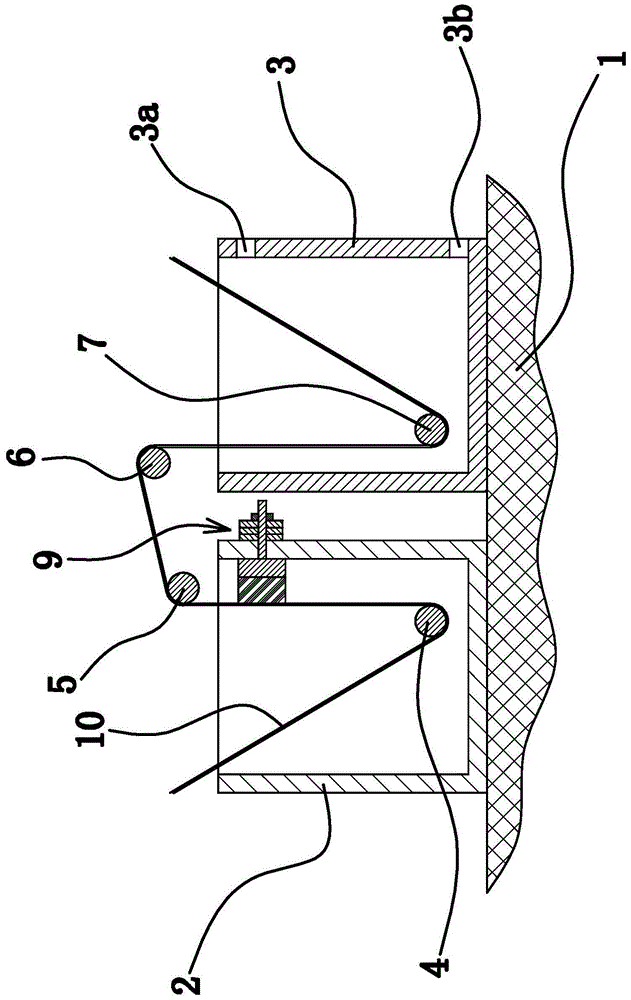

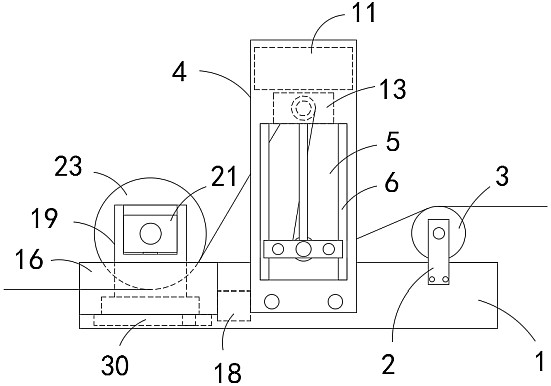

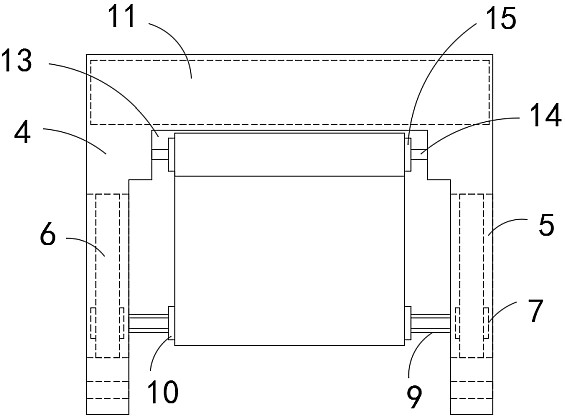

Device assembly for tensioning fork ear type stay rope or steel pull rod and tensioning construction method of device assembly

ActiveCN104847122ASimple designCompact structureBuilding material handlingClassical mechanicsStructural engineering

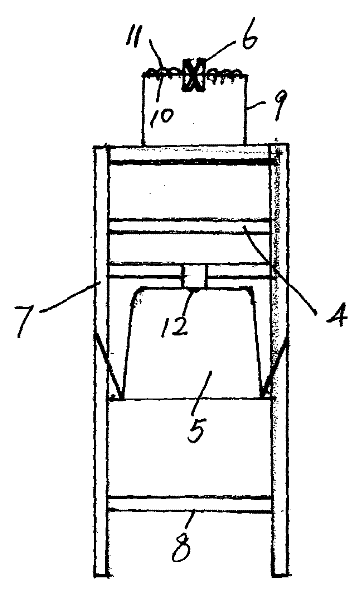

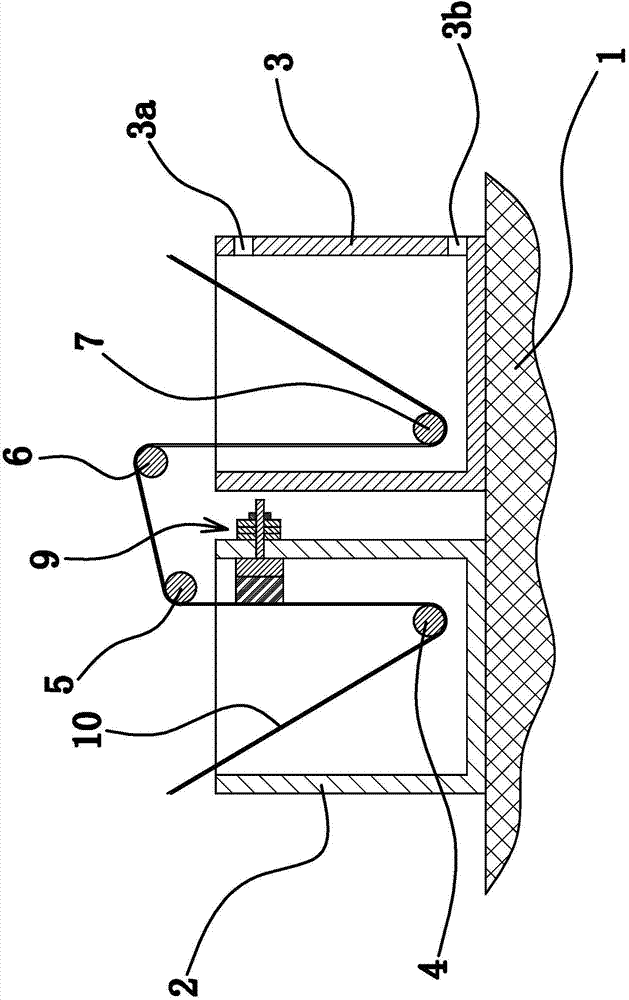

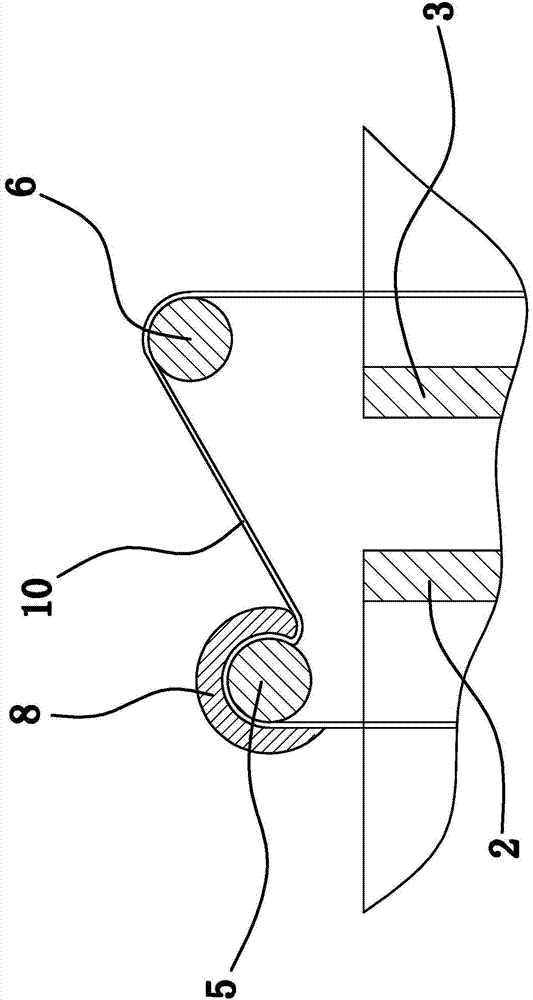

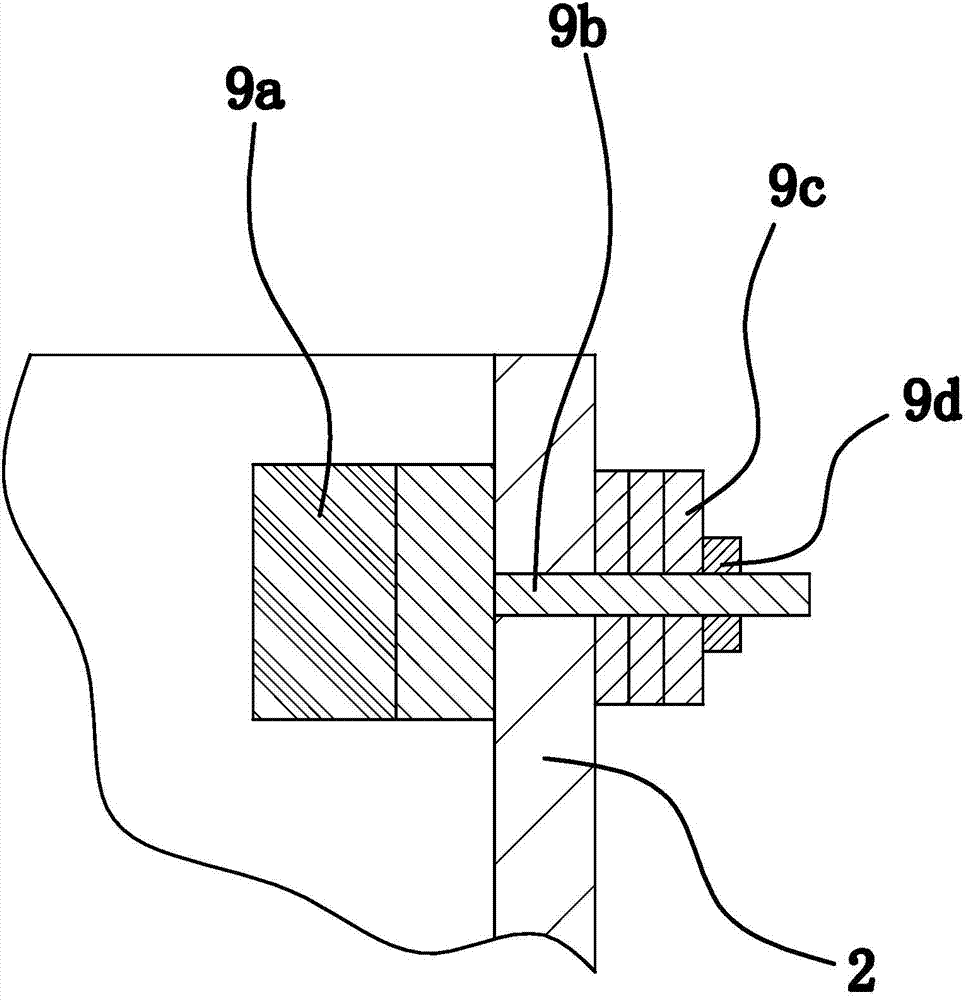

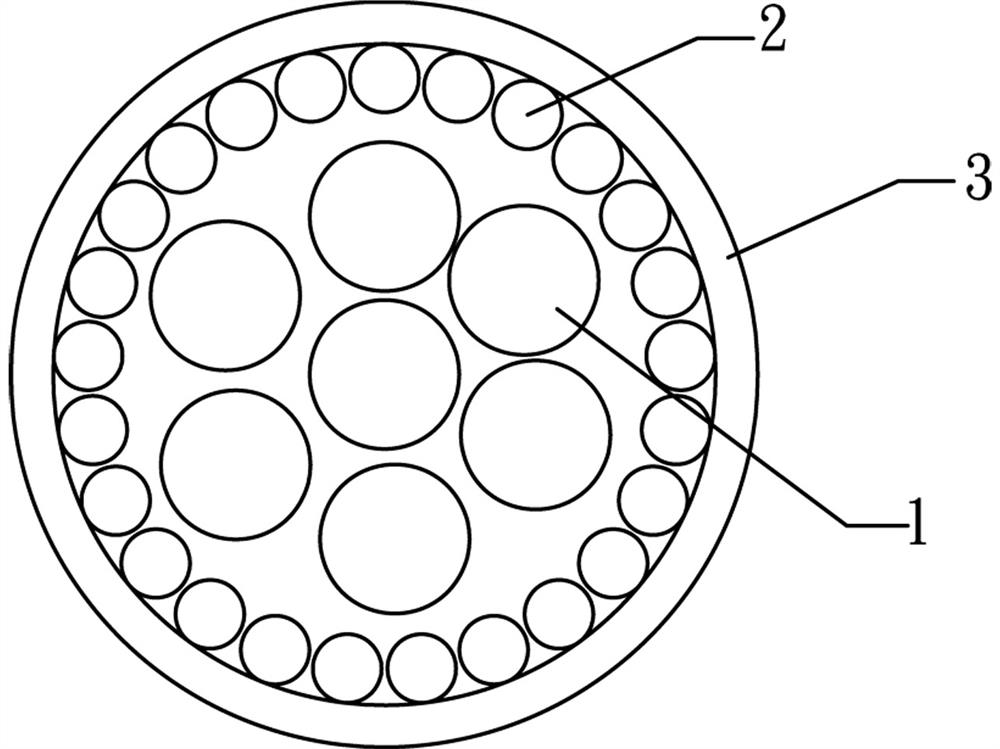

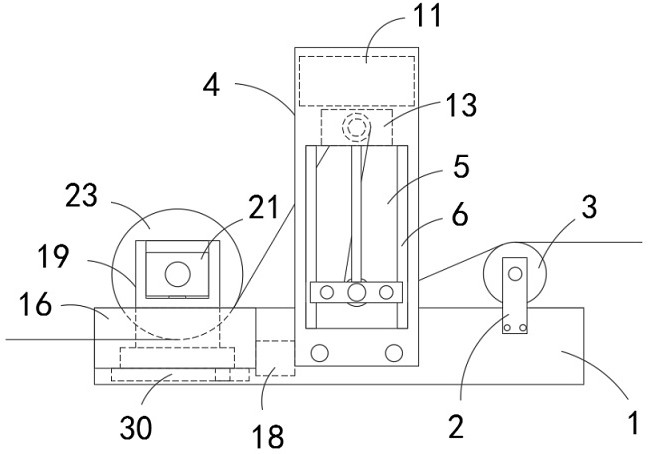

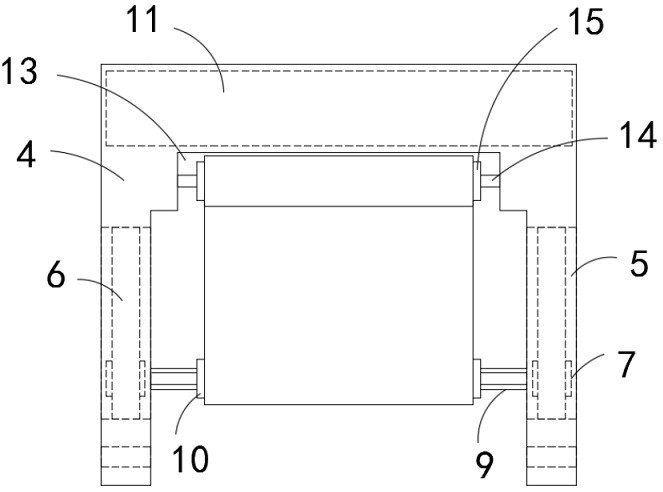

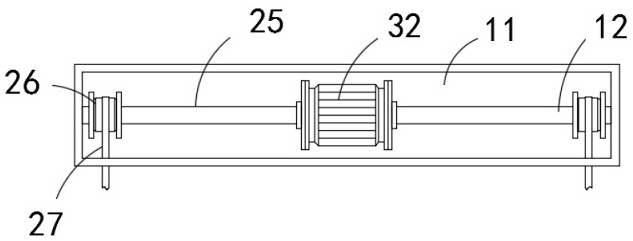

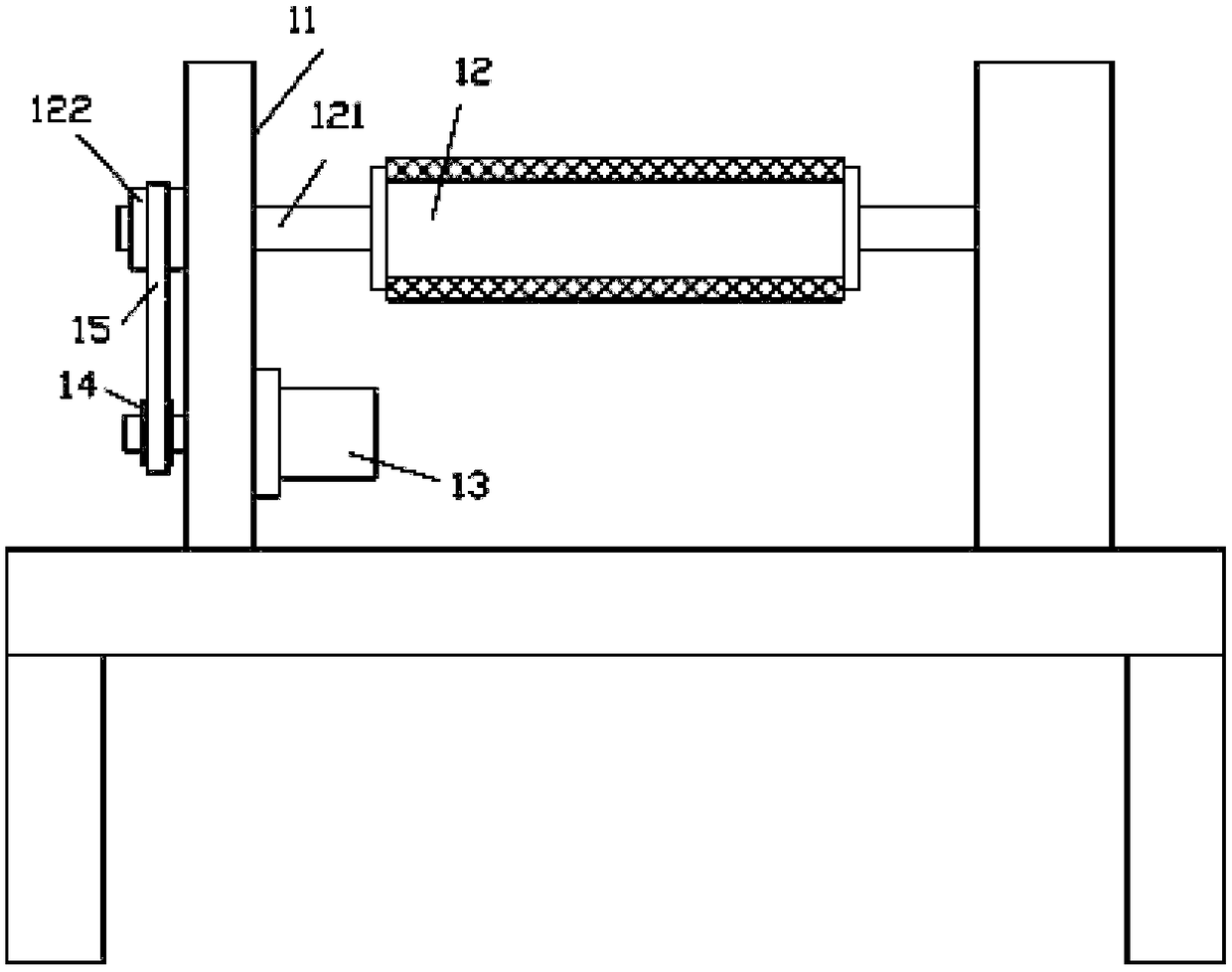

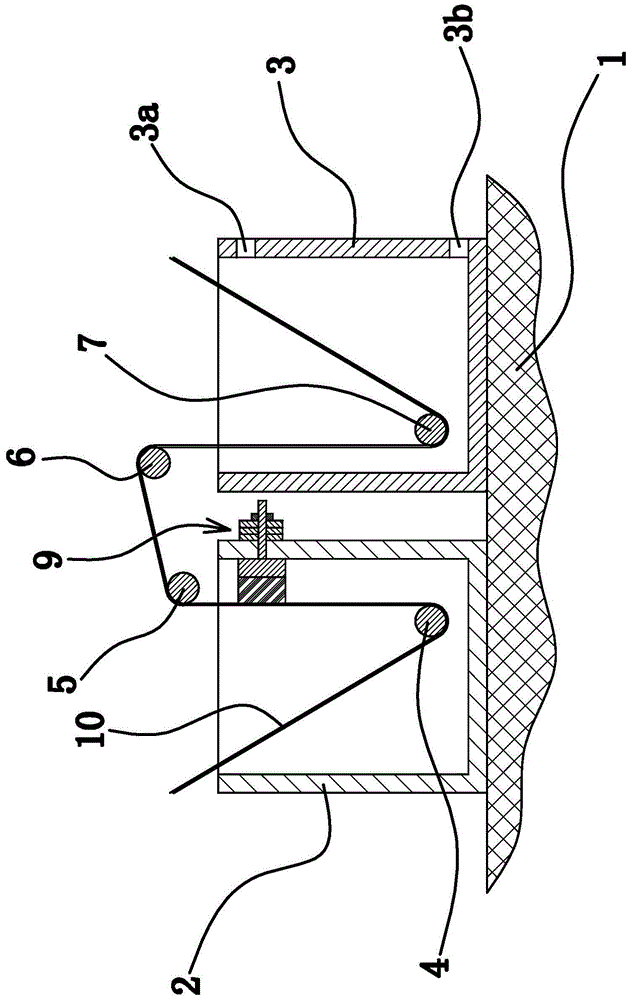

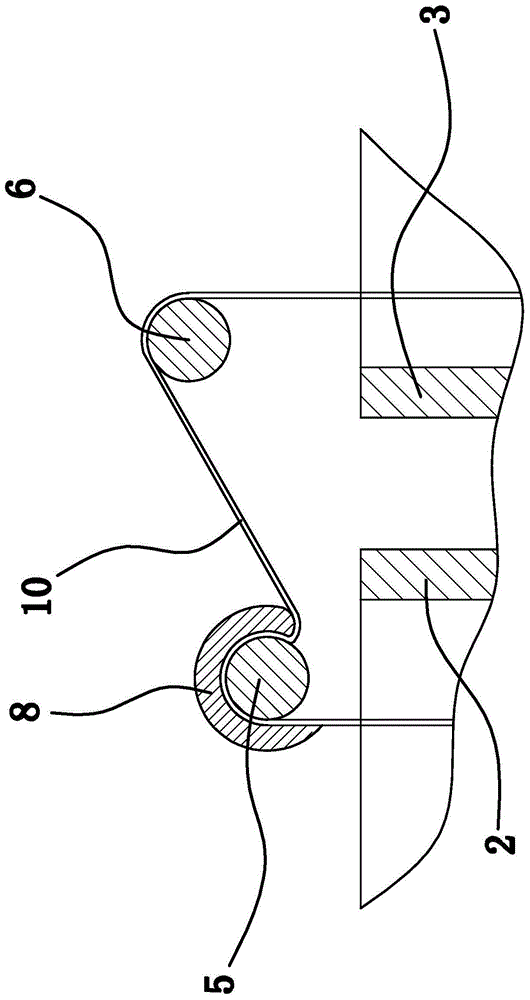

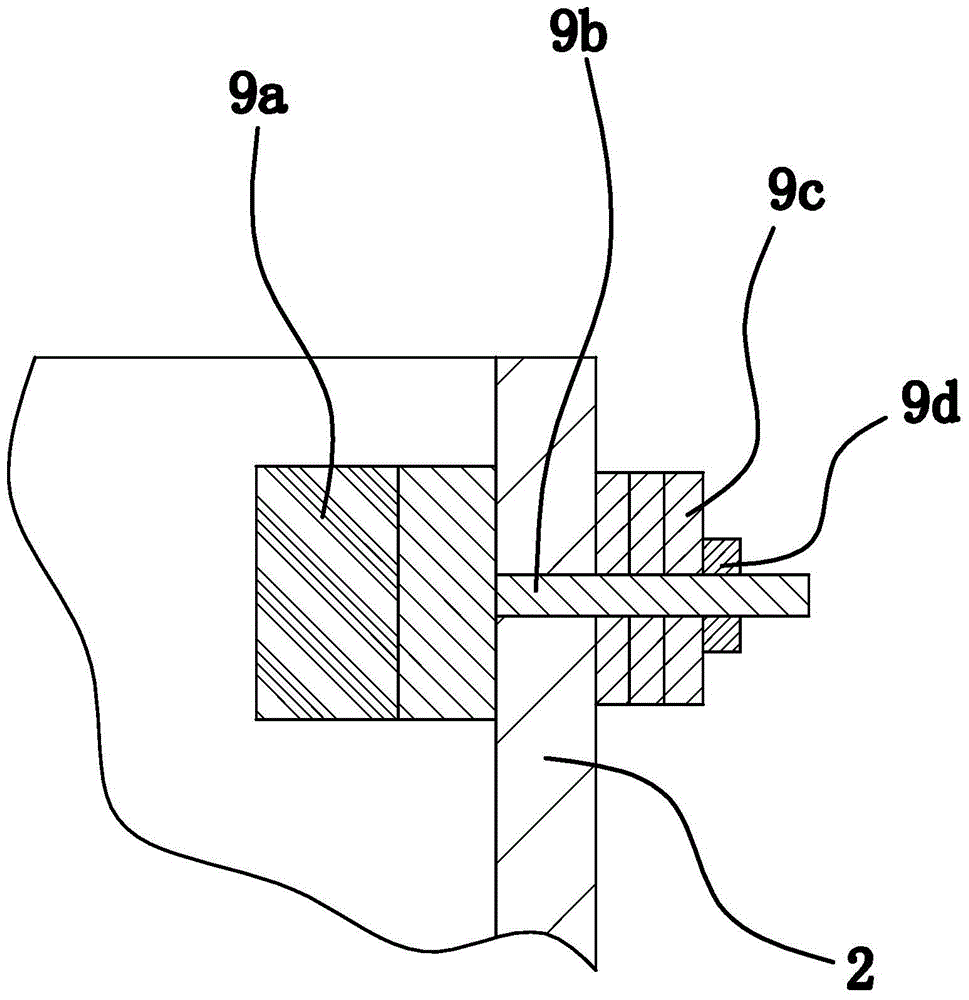

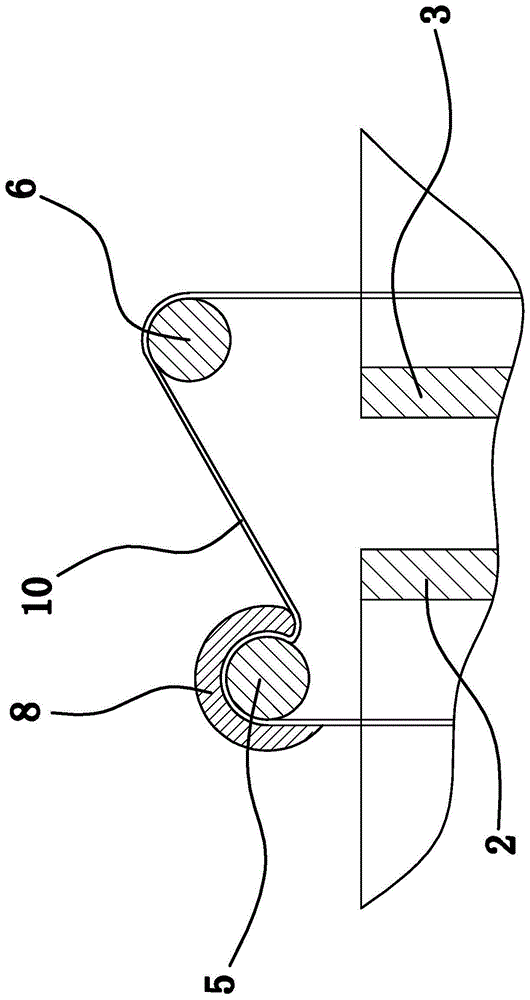

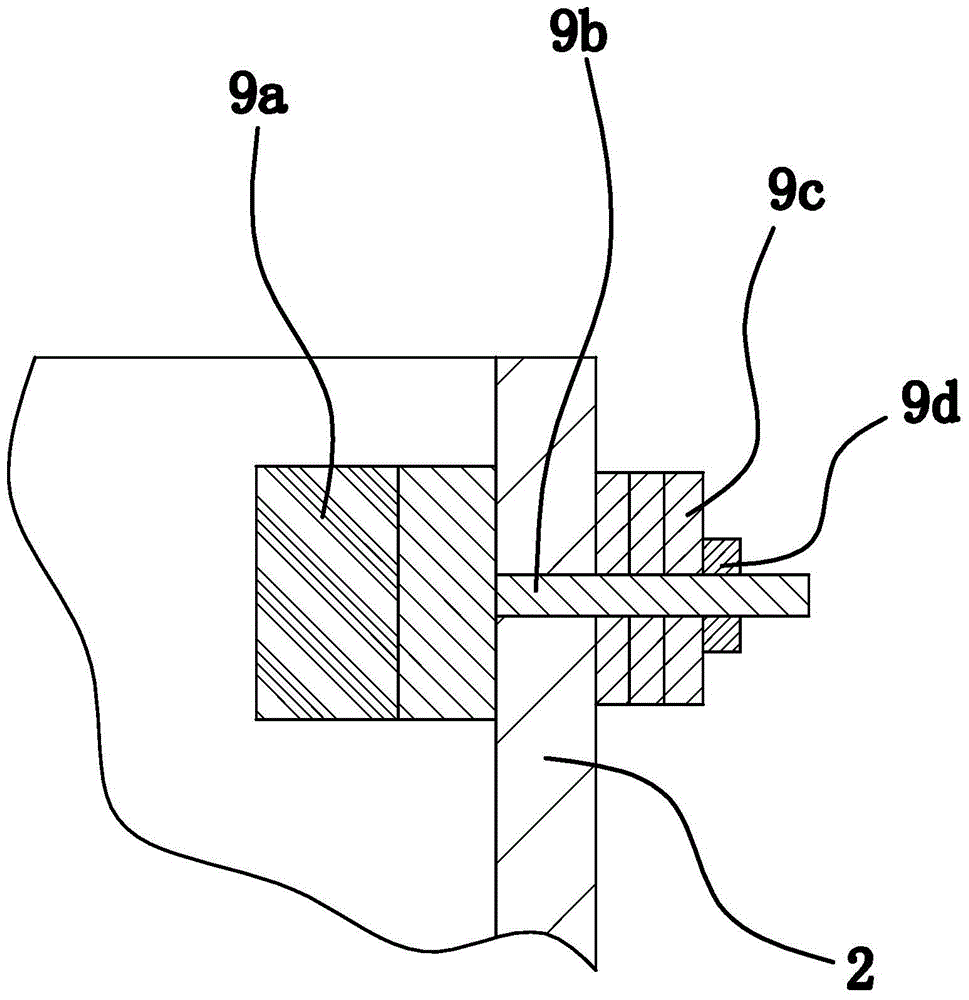

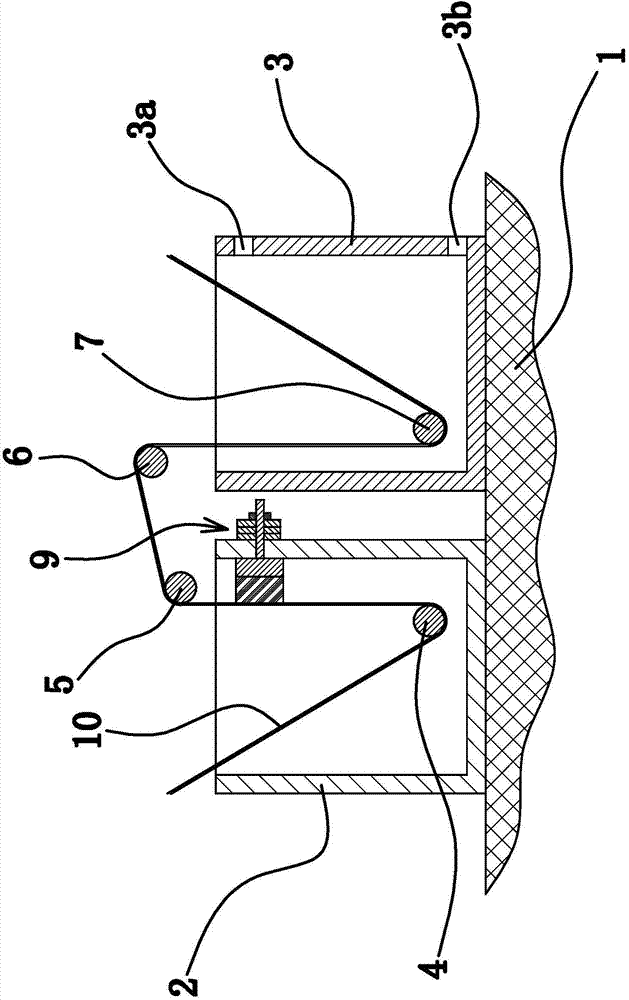

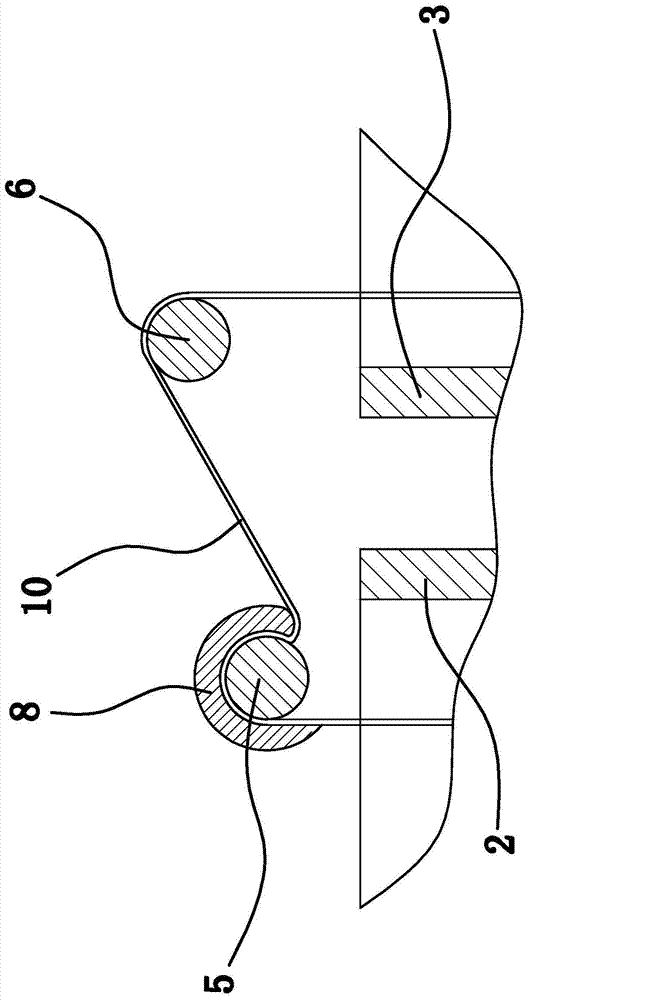

The invention provides a device assembly for tensioning a fork ear type stay rope or a steel pull rod. The device assembly comprises a counter-force rack, a tensioning rod, a carrying pole beam and a jack; the counter-force rack is of a similar U-shaped structure and divided into two pieces; the opening of the U-shaped structure is designed into a step shape, and a bolt holes and a tensioning rod semicircular groove I to allow the tensioning rod to pass through are formed in the step; the carrying pole beam is of a split two-half structure, and the stay rope or the steel pull rod is capable of passing through the middle of the split two-half structure, and tensioning rod semicircular grooves II for mounting the tensioning rod are formed on the two sides of the split two-half structure; when the device assembly is applied to tensioning construction, the two pieces of the counter-force rack are mounted on the two sides of the fork ear of the fork ear type stay rope or the steel pull rod and are integrated by use of a bolt and a connecting plate; the two-half carrying pole beam is mounted on the extension cylinder end of the fork ear type stay rope or the steel pull rod and fixed by use of a bolt; the tensioning rod is put through the carrying pole beam and the counter-force rack, and anchored by use of a fixing nut at one end of the counter-force rack; the jack and a base plate are mounted on the other end of the tensioning rod and the other end of the tensioning rod is anchored by use of a tensioning nut; the device assembly is good in safety and high in universality in tensioning construction.

Owner:LIUZHOU OVM ENG

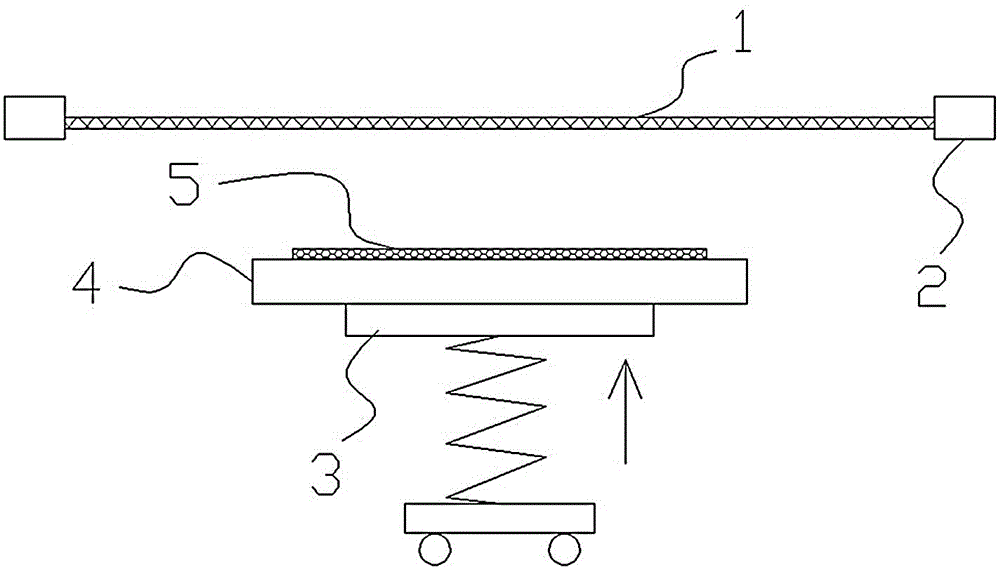

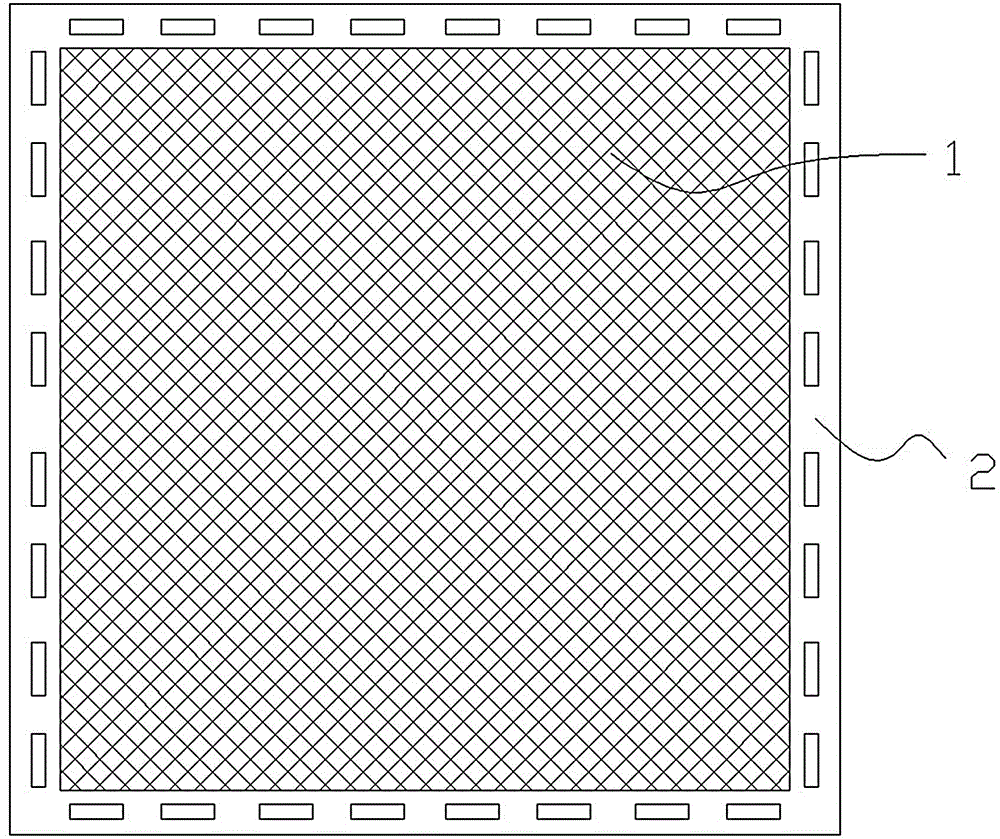

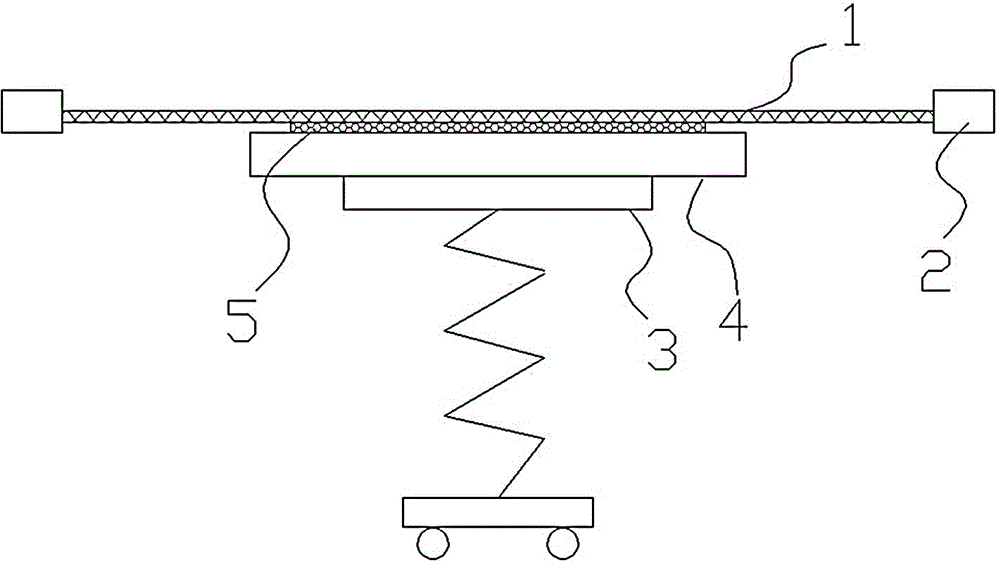

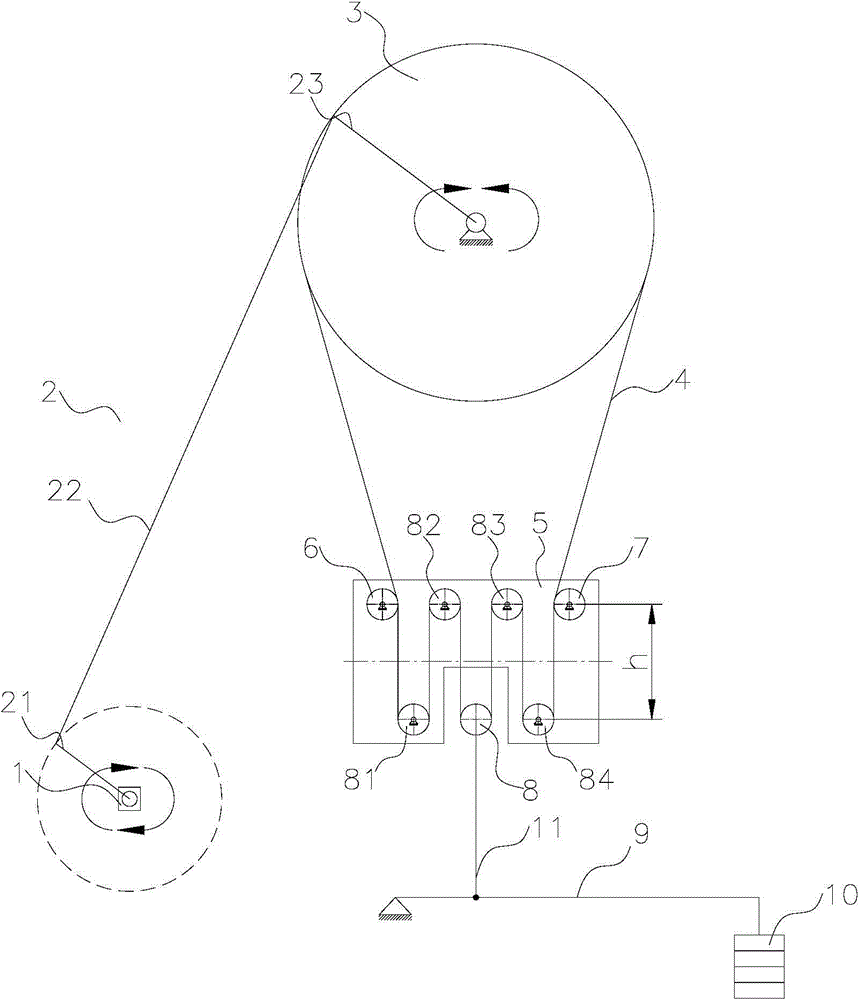

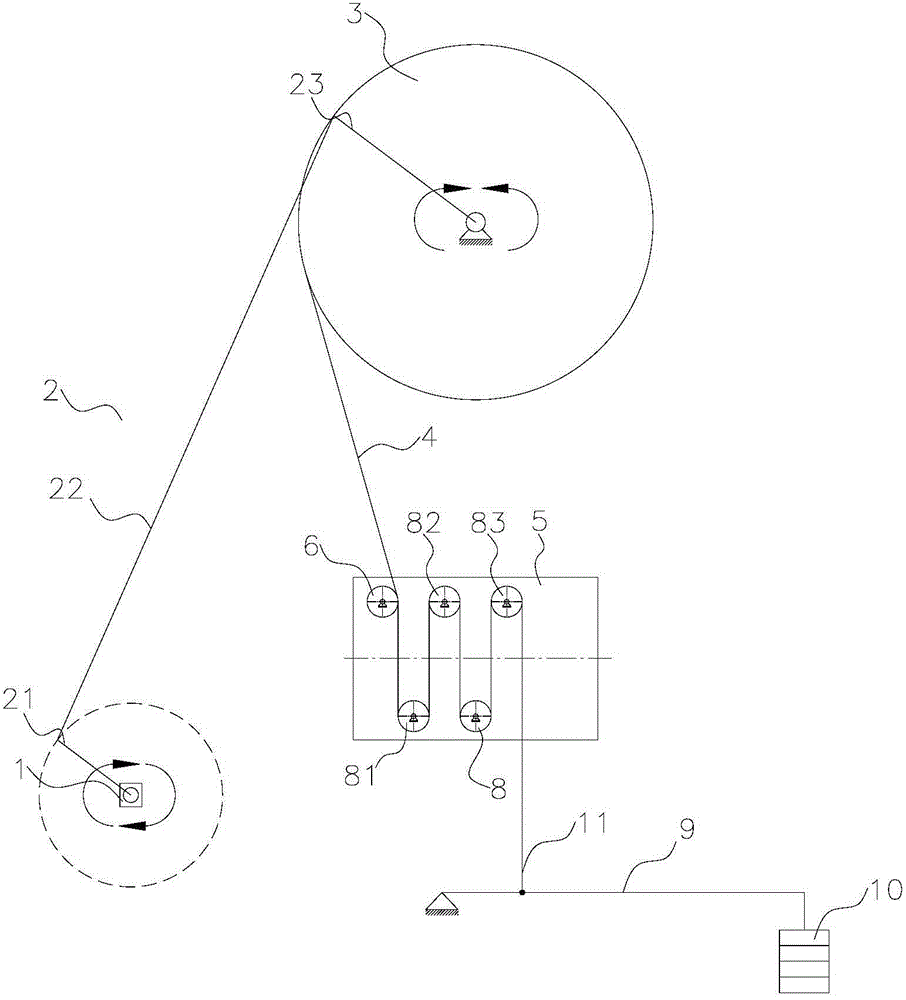

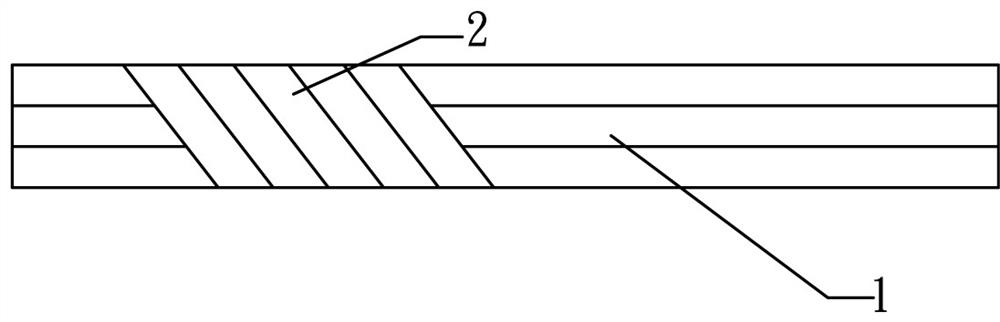

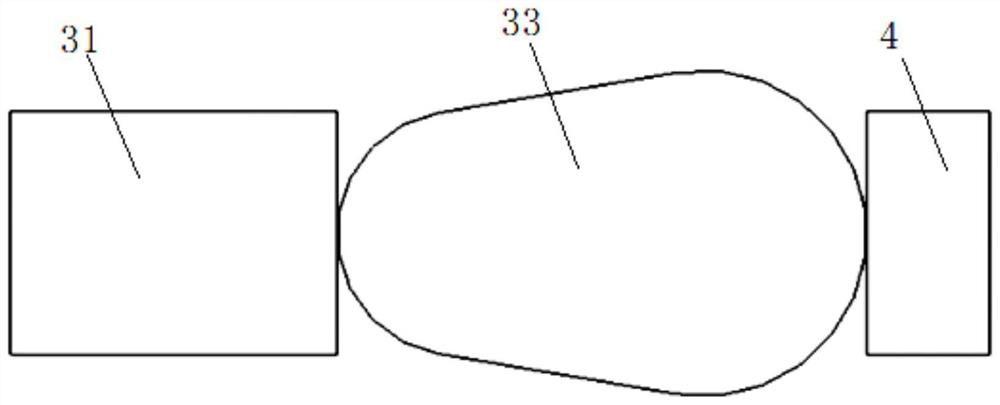

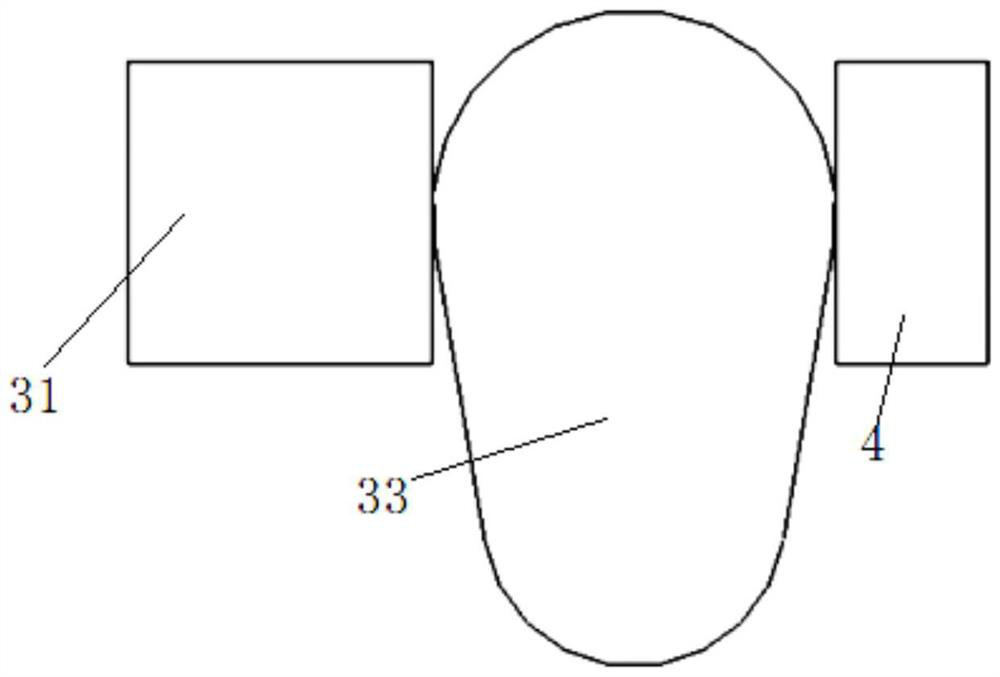

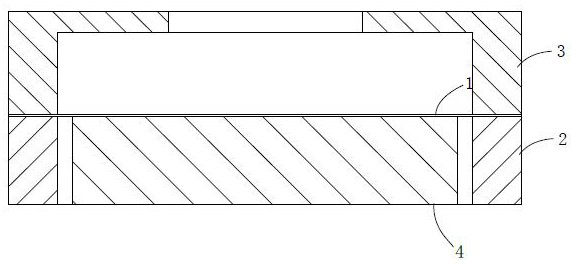

Manufacturing method for composite silk screen printing plate

InactiveCN104669777AMeet tension requirementsEasy to operateScreen printersForme preparationScreen printingPolyester

The invention discloses a manufacturing method for a composite silk screen printing plate. The manufacturing method comprises the following steps: a) cutting a steel wire screen into a required dimension; b) putting a horizontal supporting plate on a hydraulic lifting platform, and flatly putting the cut steel wire screen on the center of the supporting plate; c) moving the hydraulic lifting platform on which the steel wire screen is placed to the center of a screen stretcher and operating the hydraulic lifting platform to enable the plane of the supporting plate to be lower than a screen stretching surface of the screen stretcher; d) getting and fixing a polyester screen on the screen stretcher to perform stretching operation; e) lifting the hydraulic lifting platform to enable the steel wire screen to contact with the polyester screen; f) splicing the steel wire screen with the polyester screen; g) trimming the superposed polyester screen to obtain a composite wire screen; h) performing stretching operation on the composite wire screen; i) replacing a plate frame; j) splicing the polyester screen with the plate frame; k) removing the excessive polyester screen outside the plate frame to obtain a required composite silk screen printing plate. The manufacturing method is simple to operate, low in cost and capable of completing the manufacturing only through the hydraulic lifting platform and the screen stretcher.

Owner:凯盛科技股份有限公司 +1

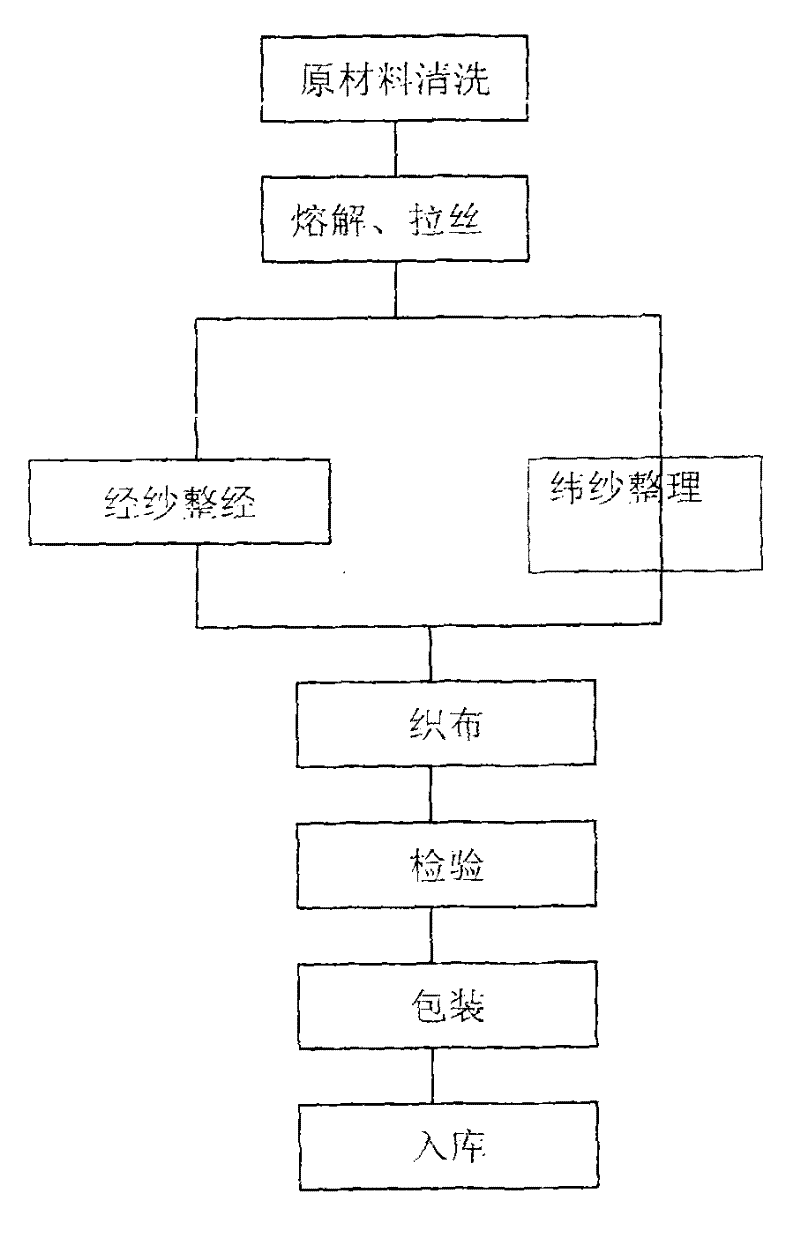

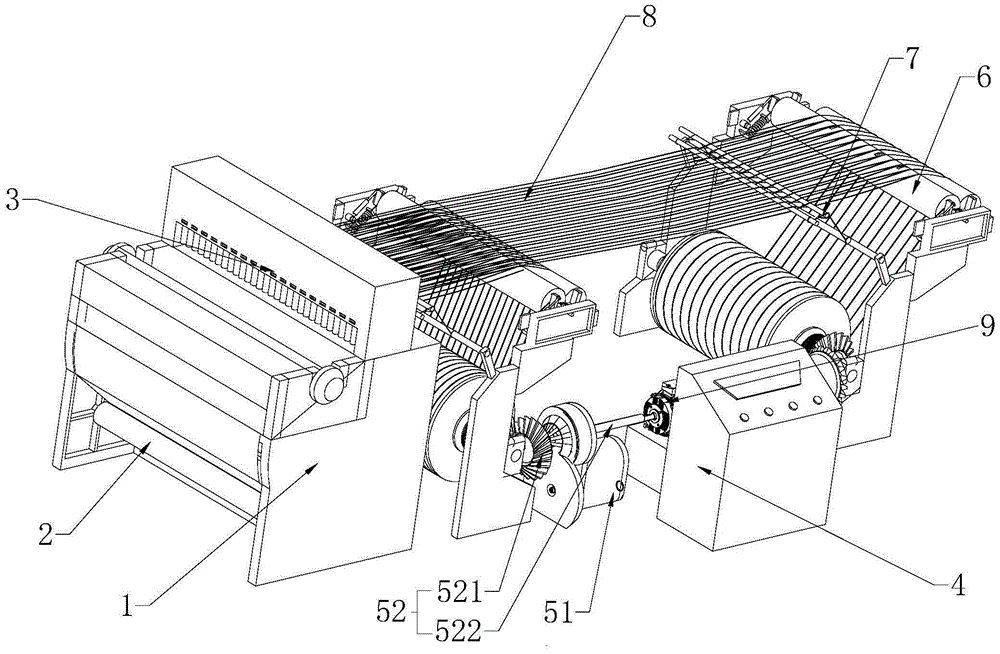

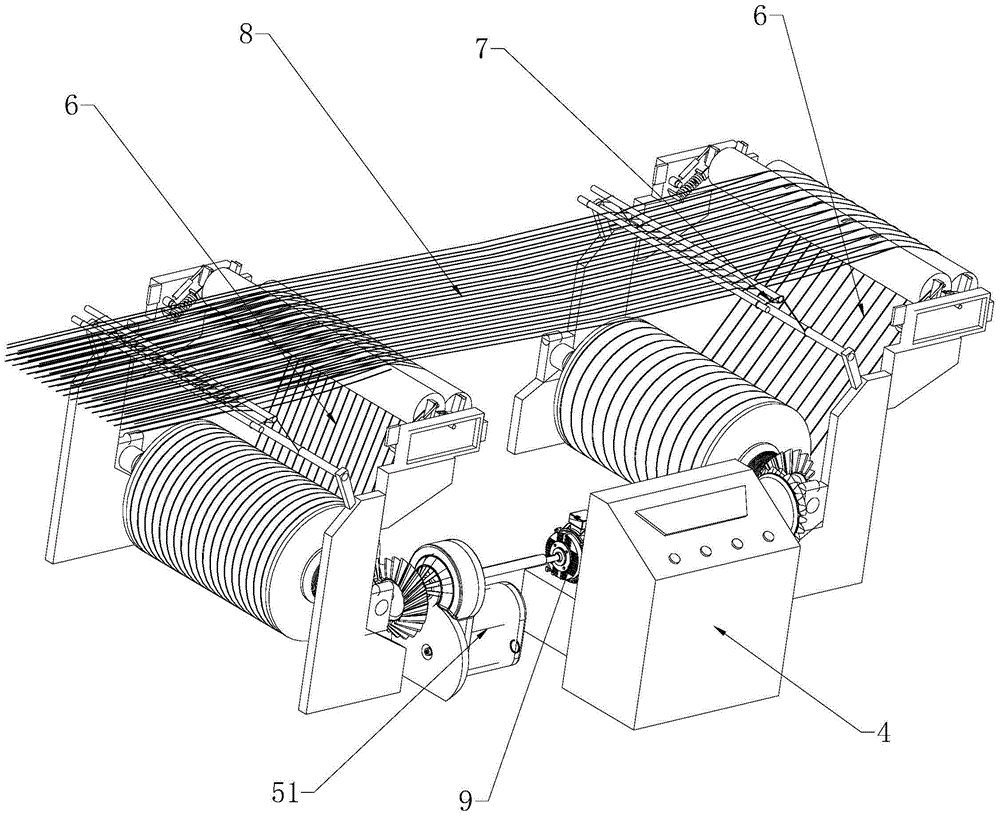

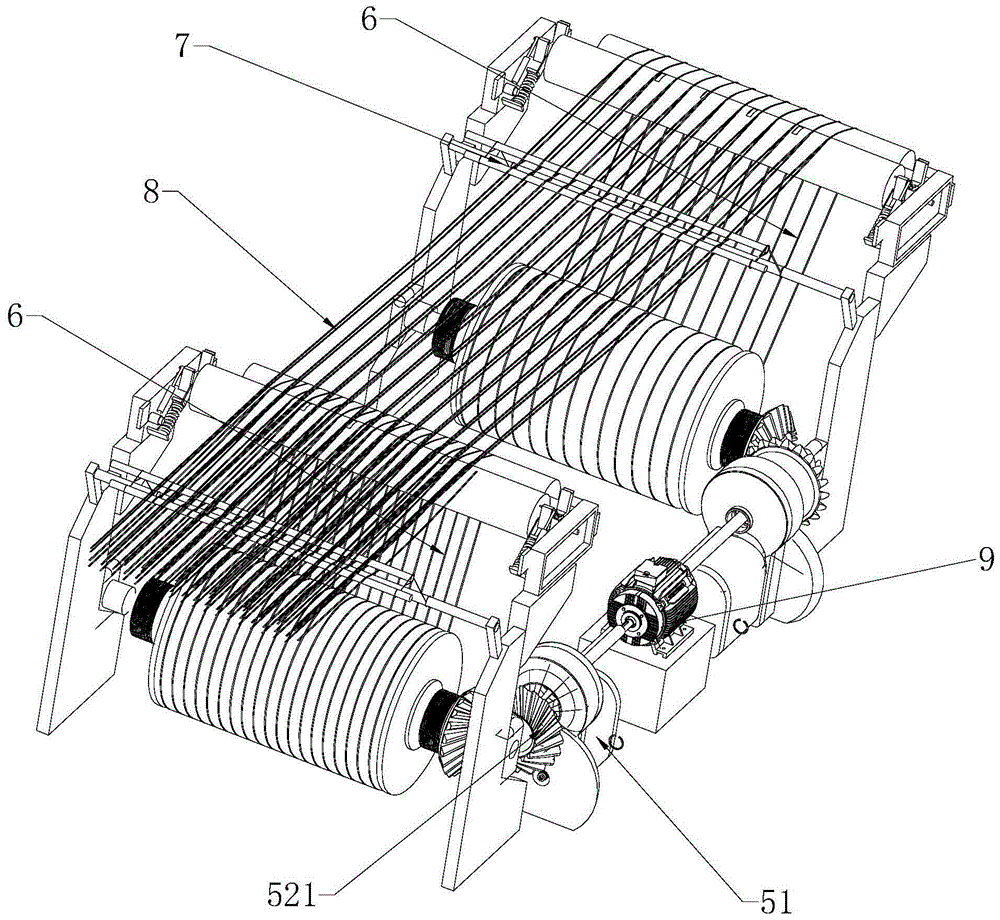

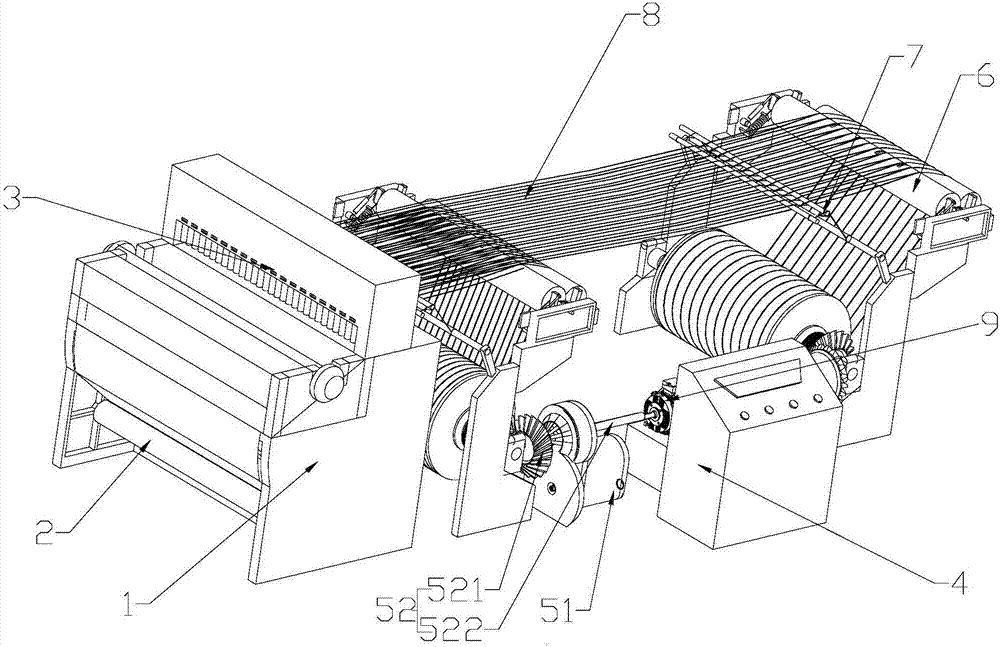

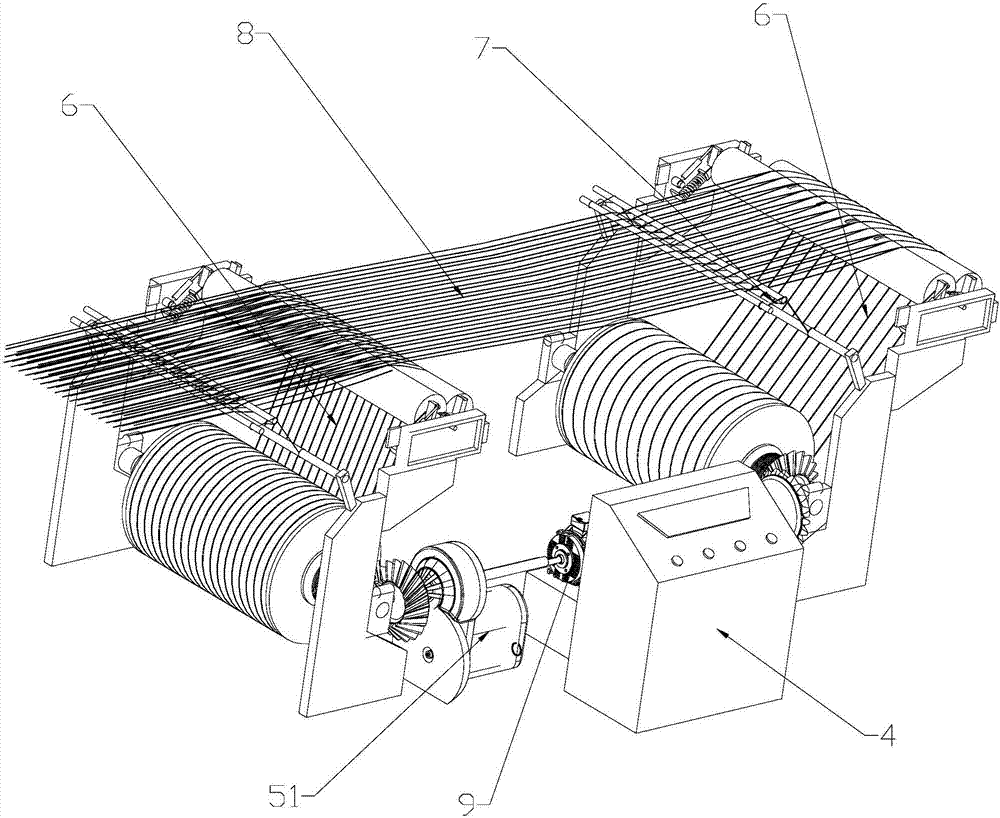

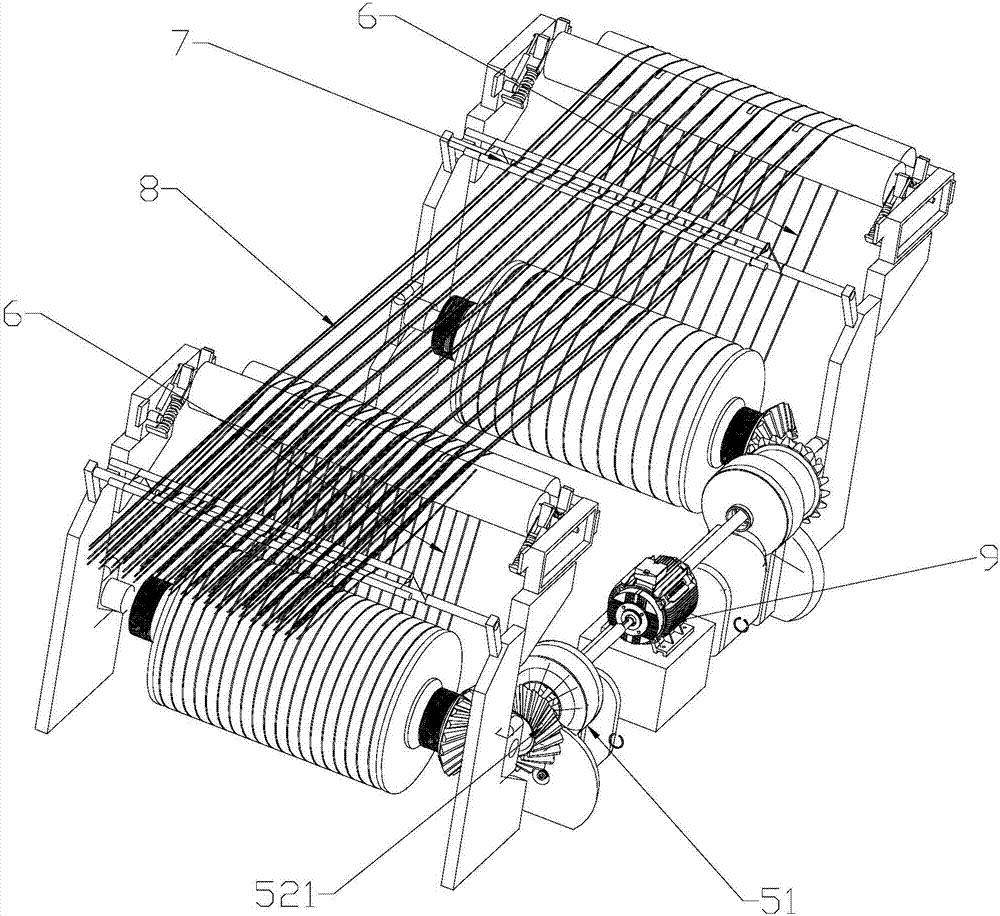

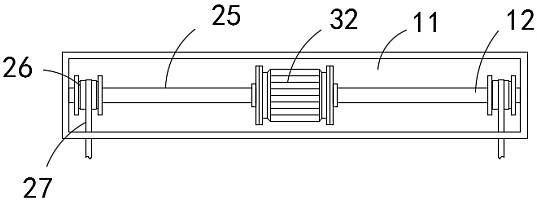

Glass fiber weaving process and special equipment thereof

InactiveCN101748546AAvoid wear and tearAvoid harmLoomsOther manufacturing equipments/toolsFiberGlass fiber

The invention discloses a glass fiber weaving process and special equipment thereof. The technological process is finished through procedures of cleaning, melting, wire drawing, warp yarn warping, weft yarn finishing, weaving, check and warehousing on raw materials. The special equipment is a warping tensioner and a weft yarn introduction device. When the process is adopted to manufacture a glass fabric, procedures of unwinding and twisting are removed from a finishing process of weft yarns, and a stranding procedure is removed from a finishing process of weft yarns so as to enable glass precursor fibers not to generate friction with equipment of unwinding, twisting and stranding, avoid abrasion and hurt to the glass precursor fibers, guarantee the tensile strength of the glass precursor fibers, enhance the product quality and the production efficiency and save the energy consumption and the product cost.

Owner:黄新春

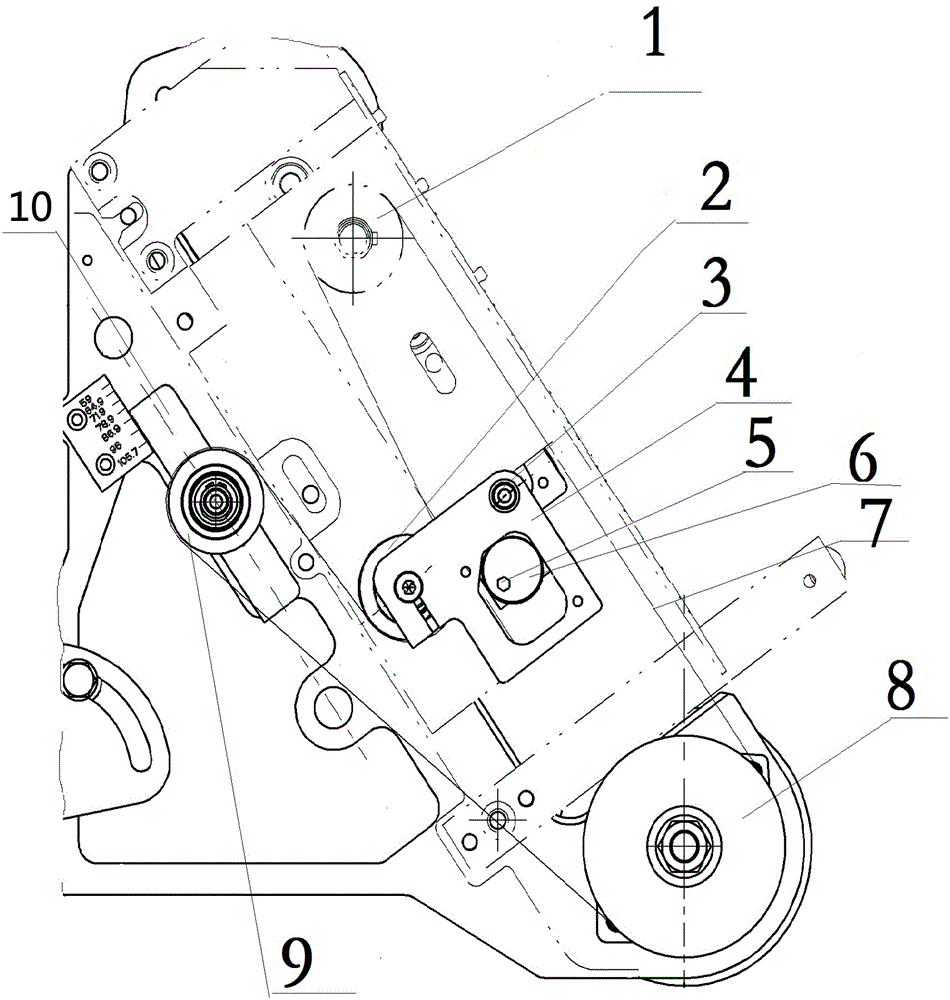

Let-off mechanism, rapier loom comprising same, and control method for let-off mechanism

The invention discloses a let-off mechanism, a rapier loom comprising the same, and a control method for the let-off mechanism. Compared with the prior art using individual control technology, the link between let-off mechanisms is enhanced; certain rotation speed ratios are provided for all let-off rollers through setting a transmission ratio for a speed changer; during a let-off process, intermediate driving values of the speeds of the multiple let-off rollers are obtained through the detection performed by sensors and the calculation performed by a controller, the mean value of the multiple intermediate driving values is worked out, and the rotation speed change of a driving motor is controlled according to the mean value; the improvement of the accuracy and stability of the rotation speed change is facilitated; the rotation speed change directions of the let-off rollers are the same all the time, so that the uniformity of the change tendencies of warp yarns on all the let-off rollers is facilitated; and the reduction of the influence, caused by the rotation speed change of the driving motor, on the instant tension of the warp yarns can be facilitated through a step of calculating the intermediate driving values and a step of calculating the result driving value, so that the stability of the tension of the warp yarns can be guaranteed and the tension tends to reach a preset value of the controller.

Owner:HANGZHOU HUASHUI FABRICS

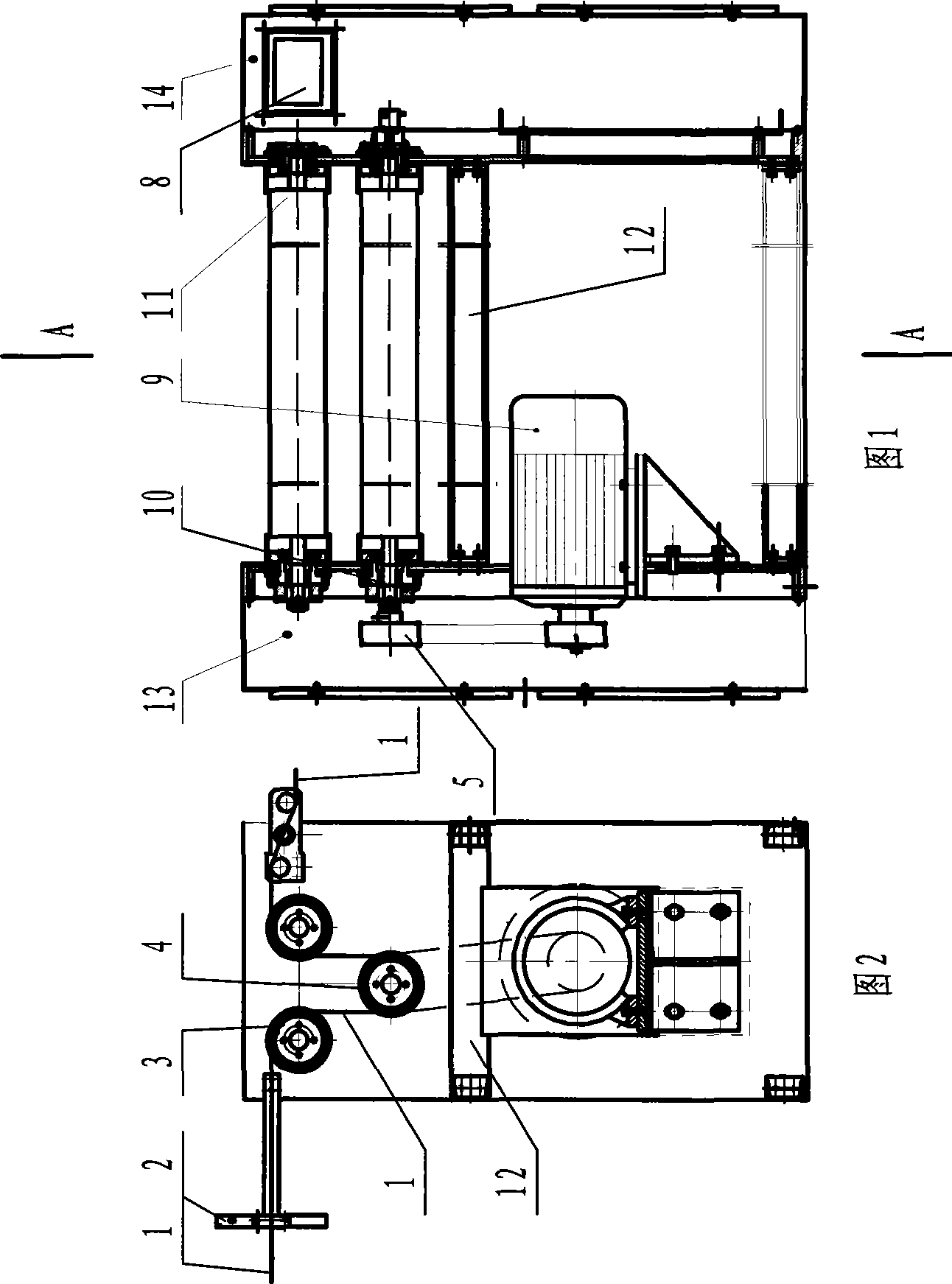

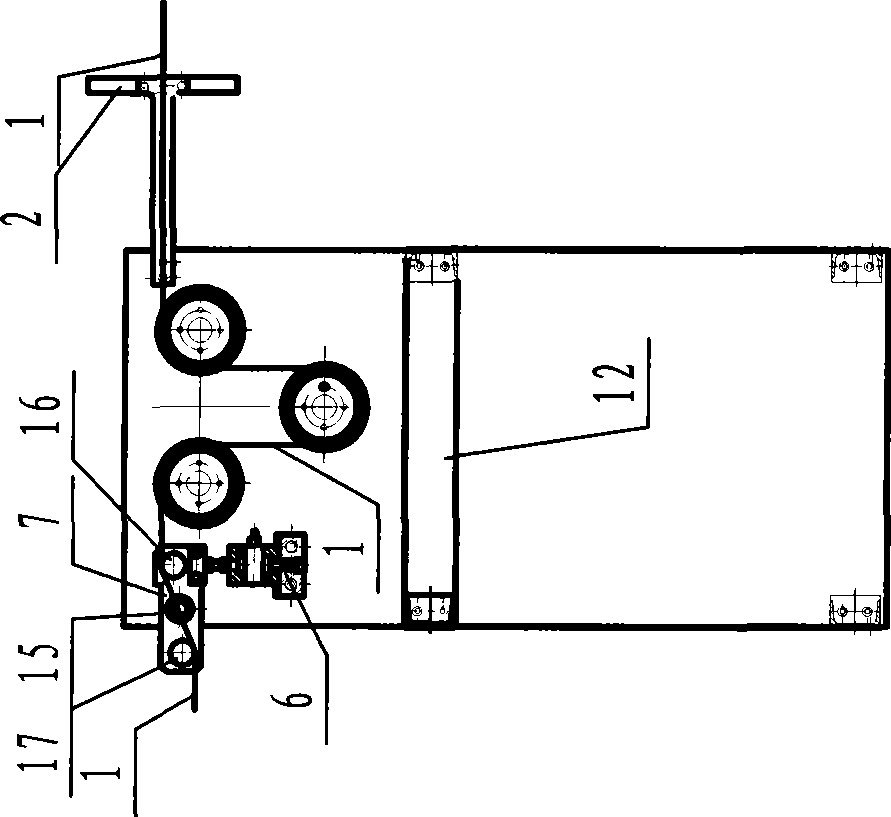

Elevator traction steel belt testing method and device

InactiveCN104444675AMeet tension requirementsImprove test efficiencyElevatorsMaterial strength using repeated/pulsating forcesTest efficiencyDrive wheel

The invention discloses an elevator traction steel belt testing method and device. The front side and the back side of a traction steel belt to be tested sequentially pass through two or more belt wheels, certain load force is applied to the traction steel belt to be tested through a counter weight mechanism, a driving wheel is driven through a power source and a transmission mechanism so that the traction steel belt to be tested can be driven to continuously move along the belt wheels, when a certain point of the traction steel belt to be tested passes through one belt wheel each time, bending testing is completed once, and therefore finally, the traction steel belt to be tested with bend testing performed for needed times can be obtained. According to the method and device, testing efficiency is improved, when the power source rotates once, bending testing is performed on the front side and / or the back side of the traction steel belt to be tested at least twice, testing efficiency is greatly improved, the front side and the back side can be tested at the same time, the testing condition can more approach the real using environment, the load force is directly applied to the traction steel belt to be tested through the counter weight mechanism, the magnitude of the load force can be more visualized, and the requirement for tension of the traction steel belt within different ranges can also be met.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

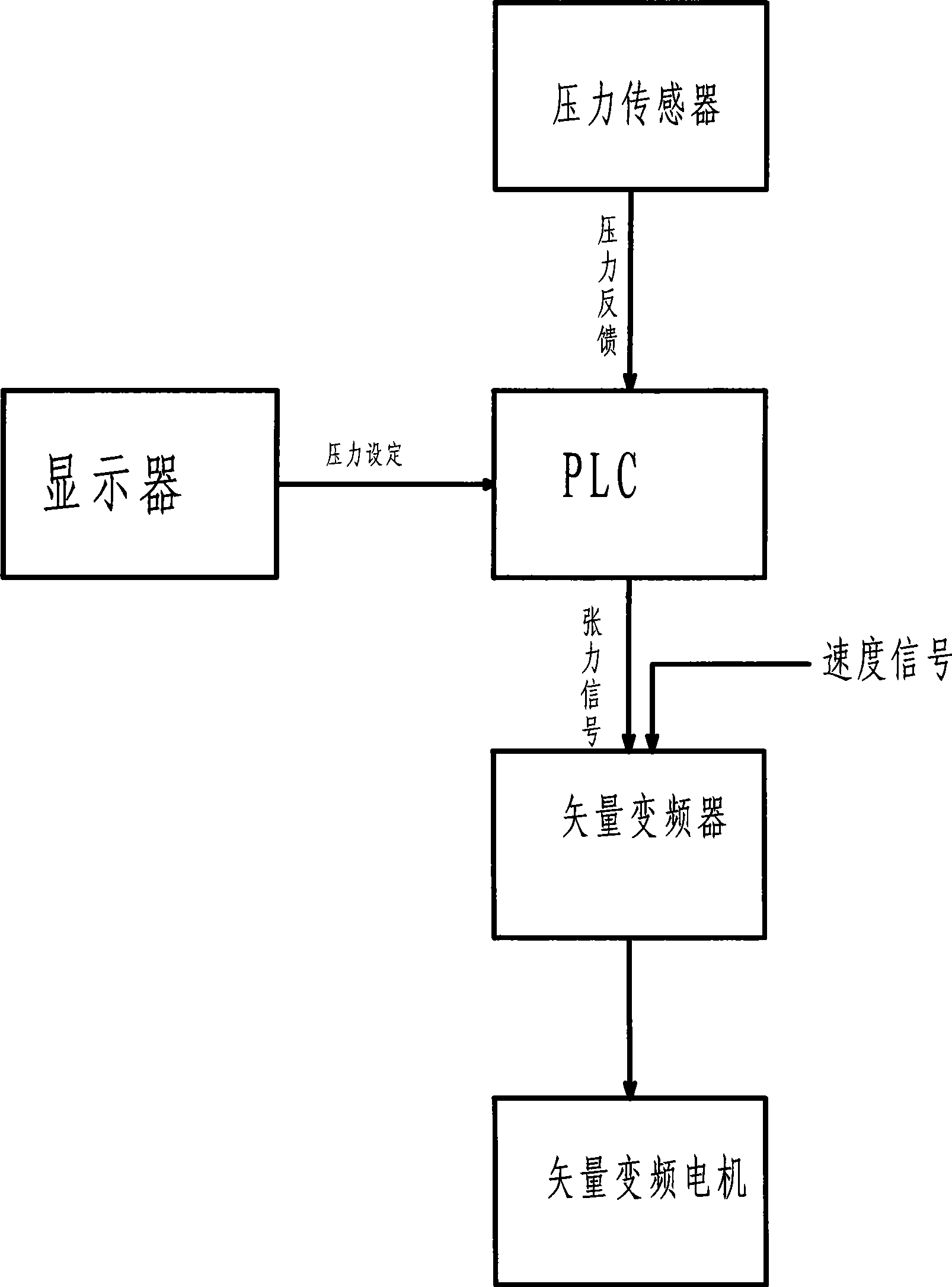

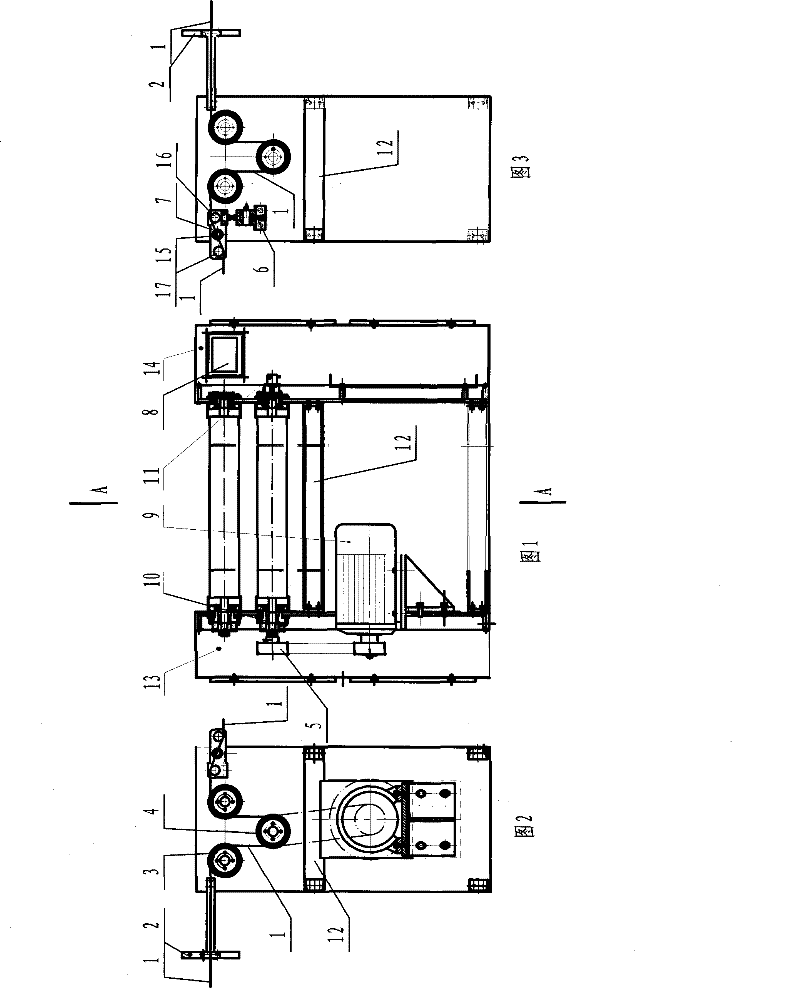

Middle arranged tension device

InactiveCN101469475ARealize closed-loop controlMeet tension requirementsWarping machinesOther manufacturing equipments/toolsAutomatic controlLoop control

The invention relates to a center disposed tension device of a warping machine, which is characterized in that: the motor is a vector frequency control motor electrically connected with an automatic control device for controlling rotation speed of let-off tension roller; the tension roller is disposed on bottom portion between two yarn guide rollers; pins are disposed on inner surface of the yarn outlet on the wall of the left box body and the right box body respectively, two connection plates are movably engaged with pins through a central hole, both ends of the tension rod (a) and the tension rod (b) are attached on both sides of the pin engaged with central holes of two connection plates; a pressure sensor contact is disposed on inner surface wall of left or right box body, which is in contact with the bottom side of the tension rod (a) axle neck permanently. The center disposed tension device makes the yarn form a wrapping angle through the yarn guidance roller, the tension roller, and the yarn guidance roller, makes the yarn and the yarn guidance roller generates adhesion, implements closed-loop control to the yarn tension through on-line detection of the pressure sensor, and satisfies needed tension requirements in the warping process.

Owner:射阳县中意纺织机械制造有限公司

Warp loom yarn tension compensating device

InactiveCN101899745ATension increases or decreases in timeTension increases or decreasesWarp knittingAgricultural engineeringFuel tank

The invention discloses a warp loom yarn tension compensating device which comprises a transmission main shaft, a tension bar, a tension sheet, an eccentric shaft, a connecting rod, a swing sleeve and a transmission mechanism, wherein the transmission main shaft is installed in the oil tank of a warp loom; the tension bar is installed on the frame of the warp loom; the tension sheet is installed on the tension bar; the eccentric shaft, the connecting rod and the swing sleeve are rotatablely installed on the frame of the warp loom; the transmission mechanism is arranged between the transmission main shaft and the eccentric shaft; one end of the swing sleeve is fixedly connected with the tension bar, and the other end of the swing sleeve is rotatablely connected with the upper end of the connecting rod; the lower end of the connecting rod is rotatablely connected with one end of the eccentric shaft, and the eccentric shaft is driven to rotate by the transmission main shaft; and the transmission mechanism can be composed of a driving synchronizing wheel fixedly arranged on the transmission main shaft, a driven synchronizing wheel fixedly arranged on the eccentric shaft, a middle transition synchronizing wheel rotatablely installed on the oil tank and synchronizing belts arranged between every two synchronizing wheels. When the yarn is woven to form loops, the invention can compensate the yarn tension in time, so that the yarn tension is kept consistent. The invention is suitable for popularization in warp looms.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

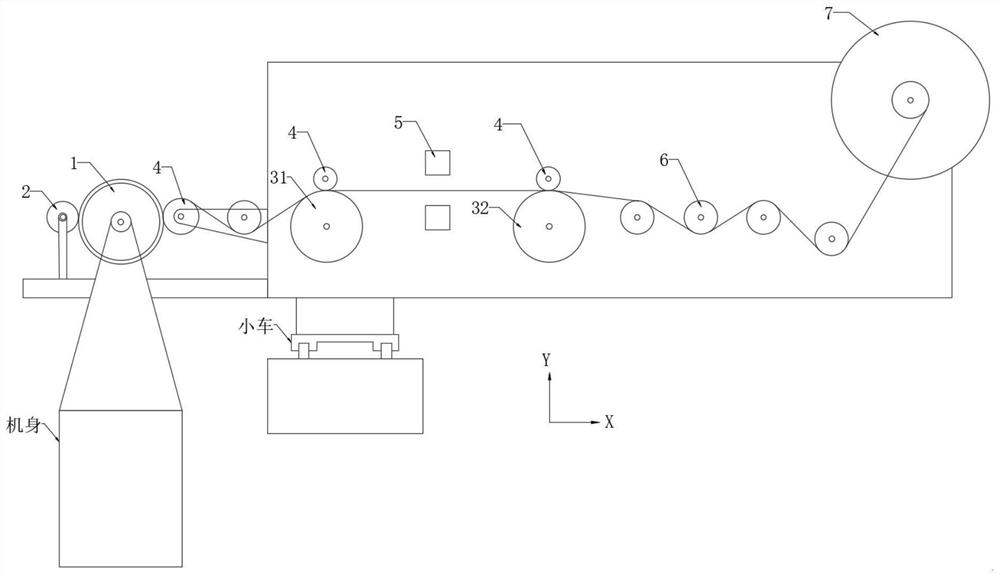

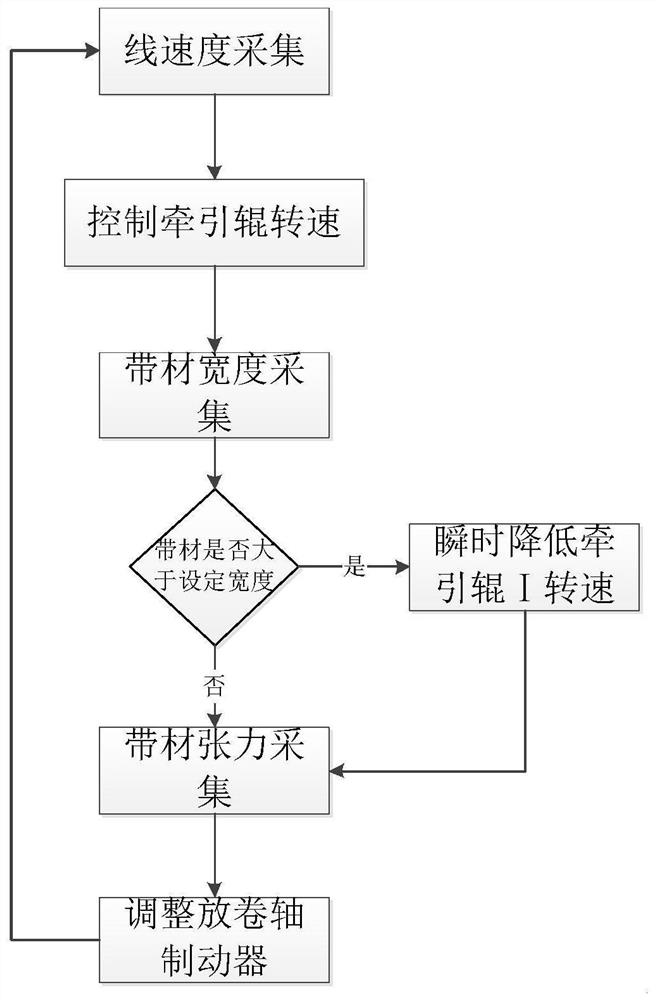

Strip winding device, strip winding method and numerical control winding machine

The invention relates to the technical field of composite material automatic formation, in particular to a strip winding device. The strip winding device comprises a mandrel, a velometer, a traction assembly, press rolls, a width sensor and an unwinding shaft. The traction assembly comprises a first traction roller and a second traction roller. The mandrel, the first traction roller, the second traction roller and the unwinding shaft are sequentially arranged. The velometer makes contact with the mandrel, the width sensor is arranged between the first traction roller and the second traction roller, and the mandrel, the first traction roller and the second traction roller are respectively provided with the press rolls. The invention further provides a strip winding method and a numerical control winding machine thereof. According to the strip winding device, because the width sensor and the traction assembly are arranged at the near end of the strip winding mandrel, a deformed strip isadjusted and then enters the mandrel, the measures of monitoring on a middle conveying line of the strip can be greatly lessened, the device is simplified, and the efficiency is improved.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

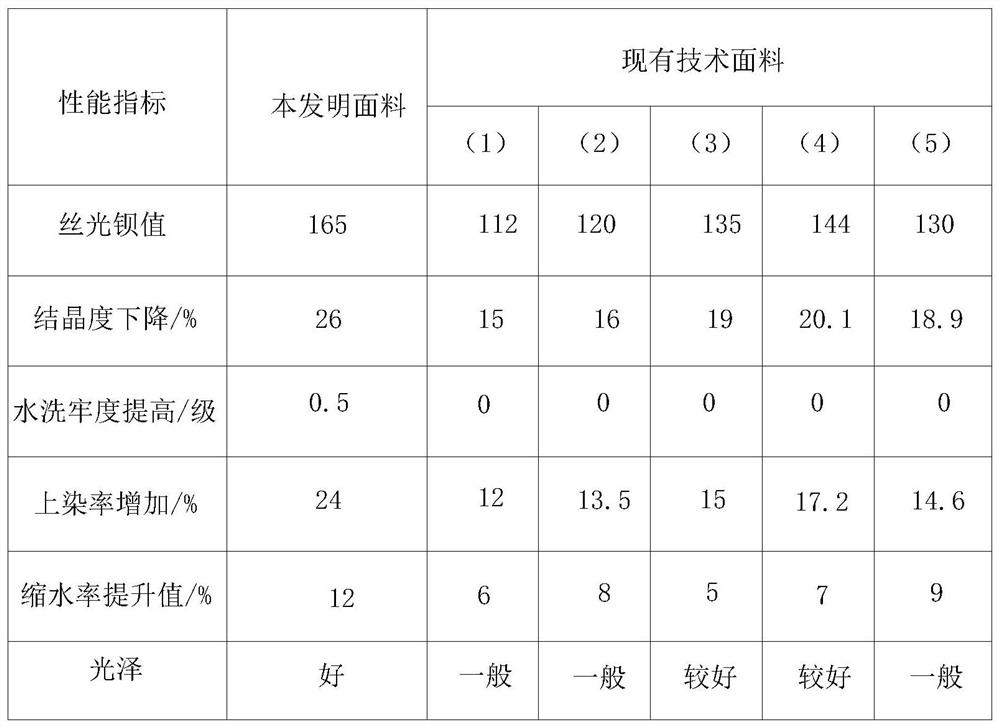

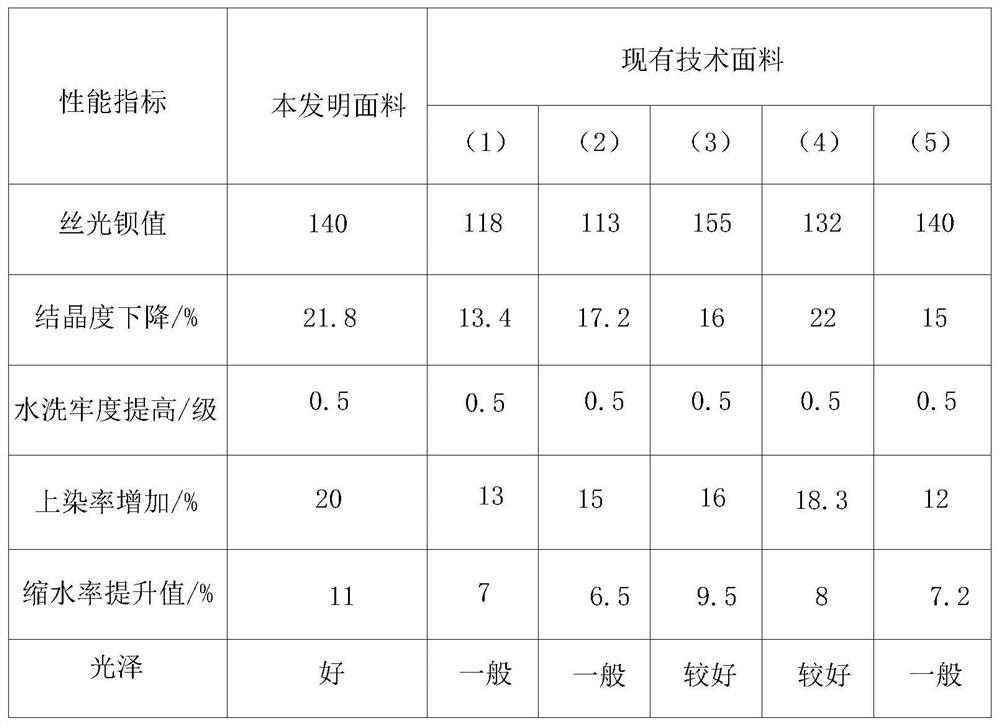

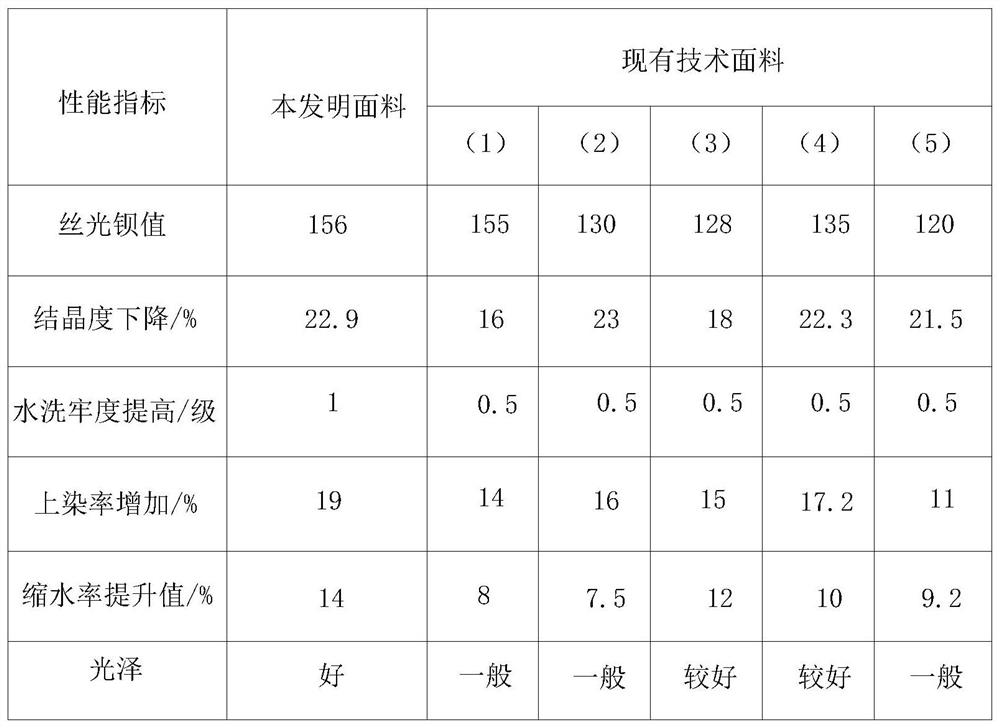

Crystal cotton three-mercerized fabric and processing method thereof

PendingCN113355825AMeet tension requirementsImprove yieldMercerising of yarns/threads/filamentsMercerising of indefinite length fabricsYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a crystal cotton three-mercerized fabric and a processing method thereof. Fibers are subjected to liquid alkali or liquid ammonia tension mercerization and then are processed into yarns under conventional procedures, and finished mercerized yarns are prepared through procedures of singeing, reeling, mercerizing, dyeing, setting and the like. The mercerized yarns produced by the method are uniform in mercerizing, full in color and good in dyeing effect. By a mercerizing device, the fabric automatically passes through a caustic soda solution and clear water, so that the fabric keeps certain tension all the time, the tension requirement of fabric mercerizing is met, the softness is improved, and the finished product rate of the fabric can be effectively improved; and the yarns only need to be mercerized once after fiber mercerizing, so that two times of reeling, drying and rewinding are avoided, the production and processing cost is saved, and the yarn loss is reduced.

Owner:HONGDOU GROUP WUXI YUANDONG CLOTHING

A let-off mechanism, a rapier loom including the let-off mechanism, and a control method

The invention discloses a warp let-off mechanism, a rapier loom including the warp let-off mechanism and a control method. Compared with the individual control in the prior art, the connection between each warp let-off mechanism is strengthened. Transmission ratio, given a certain speed ratio between the let-off rollers, during the let-off process, the intermediate drive values of the respective speeds of multiple let-off rollers are obtained through sensor detection and controller calculation, and the average value of the multiple intermediate drive values is calculated Finally, controlling the speed change of the drive motor is beneficial to improve the accuracy and stability of the speed change. Since the direction of the speed change of each let-off roller is kept consistent, it is conducive to the trend of the warp tension change on each let-off roller to tend to be consistent. Through calculation The two steps of the intermediate drive value and the result drive value are beneficial to reduce the influence of the speed change of the drive motor on the instantaneous tension of the warp yarn, so as to ensure that the warp yarn tension is stable and tends to the preset value of the controller.

Owner:HANGZHOU HUASHUI FABRICS

Processing method for cotton crimp bead fabric and treatment device used in processing method

ActiveCN104711864AMeet tension requirementsImprove yieldMercerising of indefinite length fabricsHeating/cooling textile fabricsMaterials preparationPulp and paper industry

The invention provides a processing method for a cotton crimp bead fabric, belongs to the technical field of machinery, and solves a problem of poor hand feel of an existing fabric. The processing method for the cotton crimp bead fabric comprises the following steps: A, material preparation; B, fabric weaving; C, fabric mercerization; D, shaping. A treatment device for fabric mercerization comprises a bracket, and further comprises a caustic soda container, a clear water container and transitional rollers, wherein the transitional rollers include a transitional roller I, a transitional roller II and a transitional roller III; upper parts of both the caustic soda container and the clear water container are open, and the bottom of each of the caustic soda container and the clear water container is fixedly connected to the bracket; the transitional roller I is connected in the caustic soda container; the transitional roller II is connected to the bracket and positioned at the upper parts of the caustic soda container and the clear water container; the transitional roller III is connected in the clear water container. The method is easy to implement. The device is high in finished product rate.

Owner:ZHEJIANG YANA TEXTILE

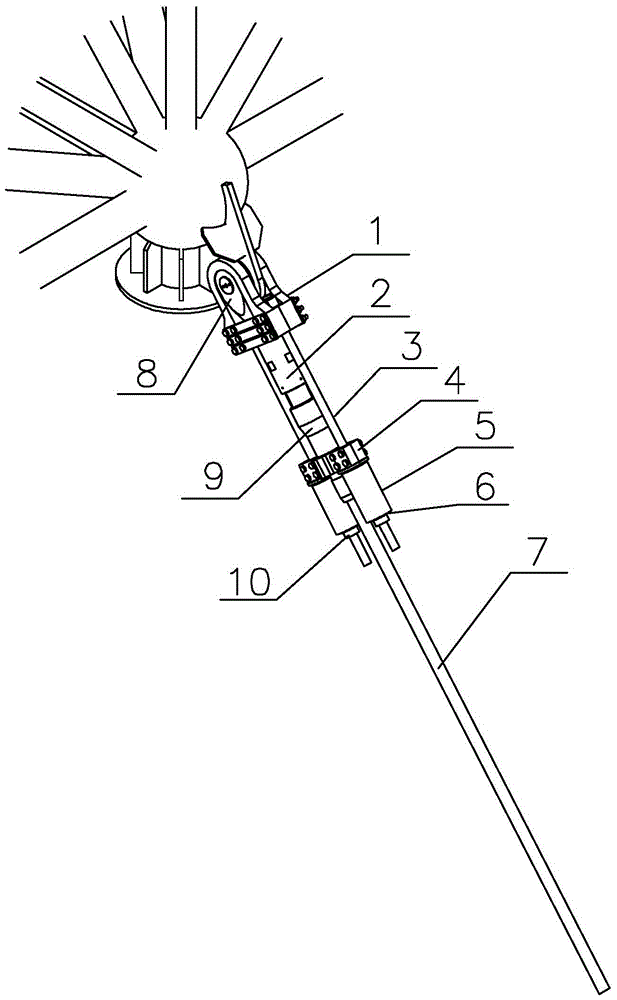

Easily degradable collagen thread and preparation method thereof

InactiveCN112402686APromote absorptionMeet tension requirementsSuture equipmentsFiberPolymer science

The invention relates to an easily degradable collagen thread. The easily degradable collagen thread comprises an inner layer of collagen fiber silk threads, a plurality of outer layers of collagen fiber silk threads and a sericin layer, wherein the outer layers of collagen fiber silk threads are parallel to one another and spirally wound on the surface of the inner layer of collagen fiber silk threads to form an outer layer, and the sericin layer is arranged on the surface of the outer layer. The invention further provides a preparation method of the easily degradable collagen thread. The easily degradable collagen thread has the following beneficial effects that the requirement for tension during sewing is met, and the inner layer of collagen fiber silk threads, the outer layers of collagen fiber silk threads and the sericin layer are all made of materials which can be absorbed by a human body, so that the easily degradable collagen thread is conveniently absorbed by a patient; meanwhile, the suture thread has the advantages of no irritation, no toxic or side effect and no scar at the stitch of the suture thread after healing.

Owner:SHANXIAN HUAYU SUTURE PROD CO LTD

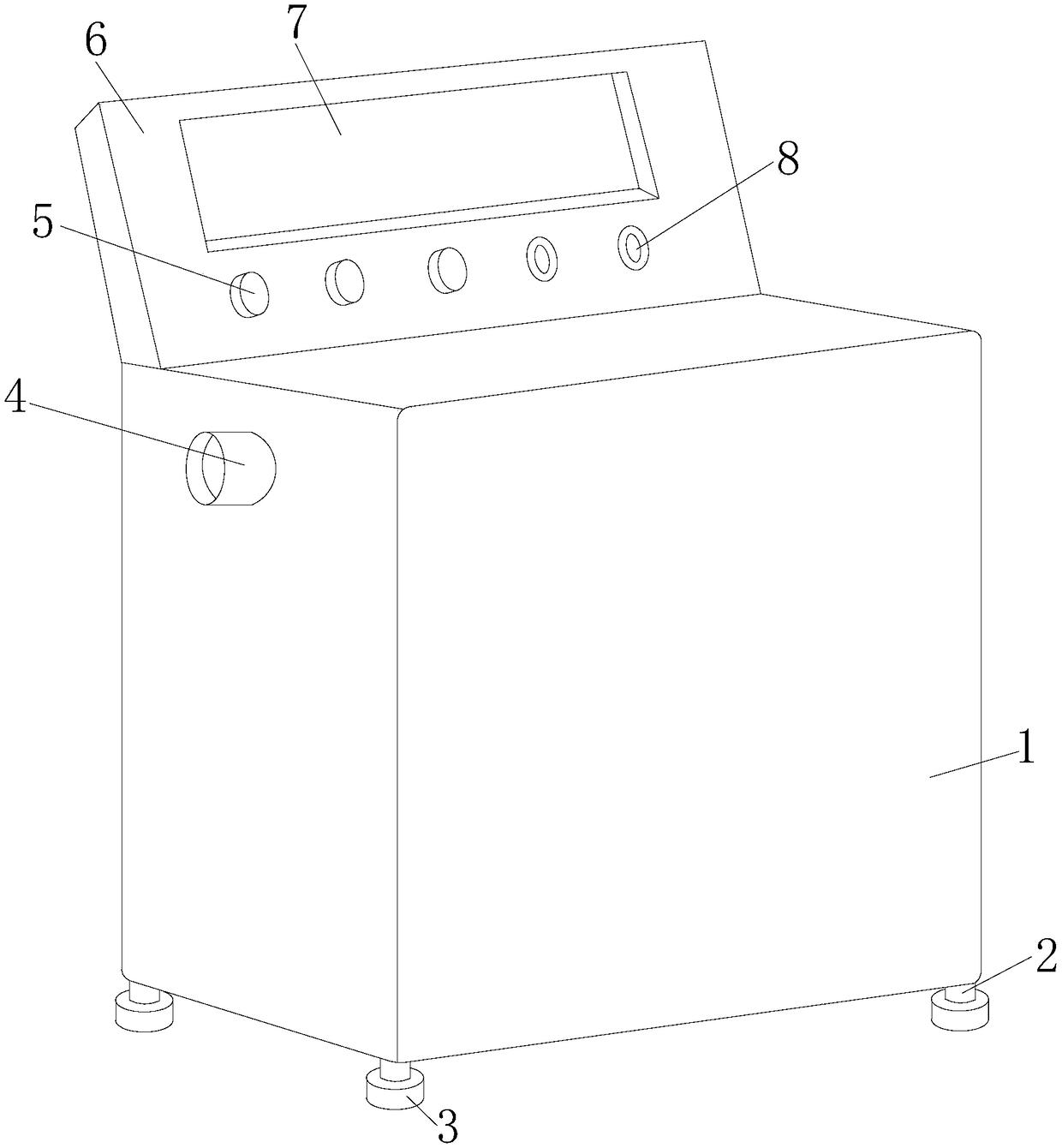

Weft yarn cutting mechanism of warp knitting machine

The invention discloses a weft yarn cutting mechanism of a warp knitting machine. The weft yarn cutting mechanism comprises a weft yarn cutting box, four connecting posts, an anti-slip bottom foot, afeeding pipe, a control panel, a control box, a display screen and an indicating lamp, wherein the four connecting posts are arranged at the lower surface of the weft yarn cutting box. The weft yarn cutting mechanism of the warp knitting machine has the advantages that the weft yarn cutting box consists of a collecting device, an assistance cutting mechanism, a tension regulating device, a coolingdevice, a starting device, a rotating mechanism and a traction device; the weft yarns can be effectively and flatly dragged and pulled into a conveying guide rail for cutting during the weft yarn guiding; the effect of improving the weft yarn quality is achieved; meanwhile, before the weft yarn cutting, the weft yarn can be abutted to the set cutting position; the tension requirement of the weftyarn can be met; the cutting treatment can be performed, so that the weft yarns maintain certain tension; the winding generated by the weft yarns in the fast yarn conveying an cutting process due to looseness can be prevented.

Owner:FOSHAN KEYI AUTOMATION TECH CO LTD

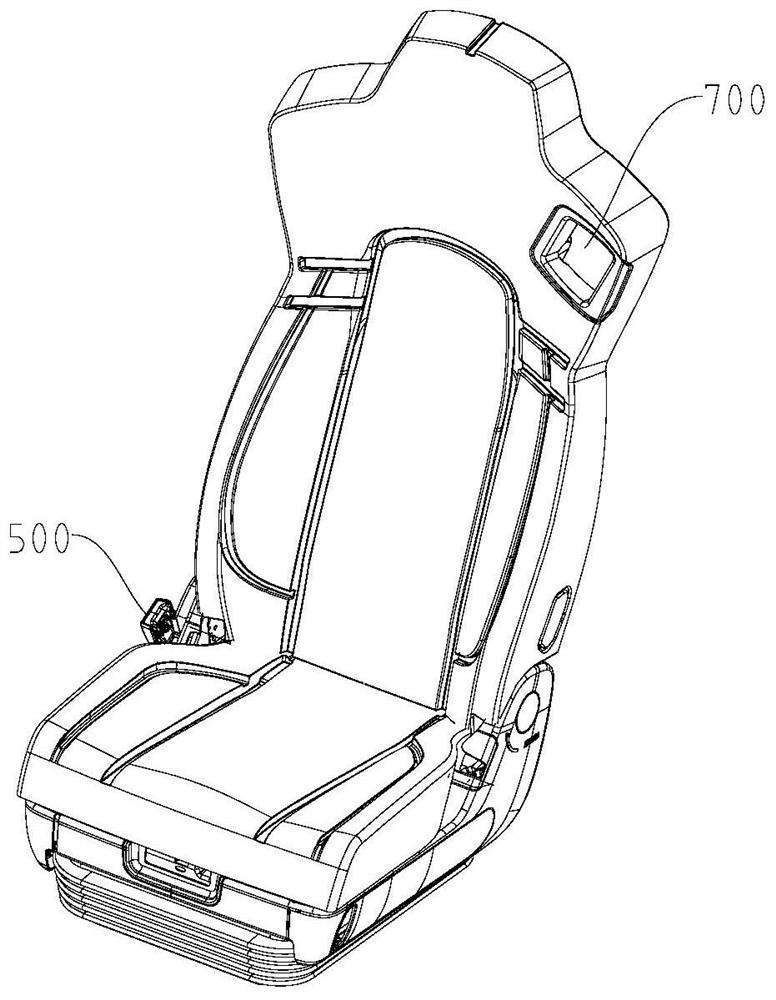

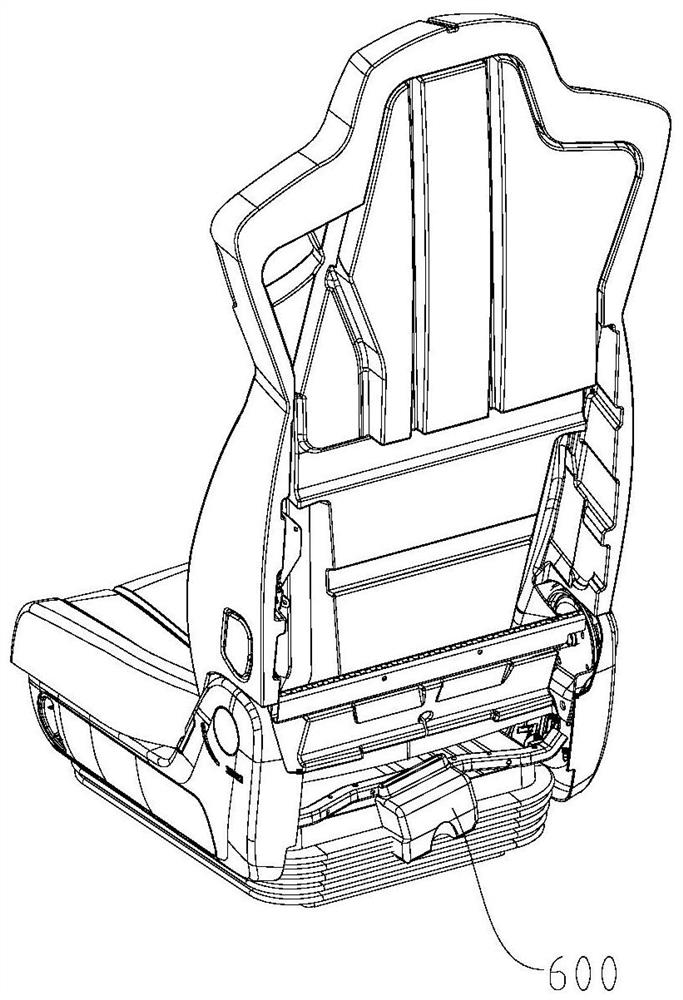

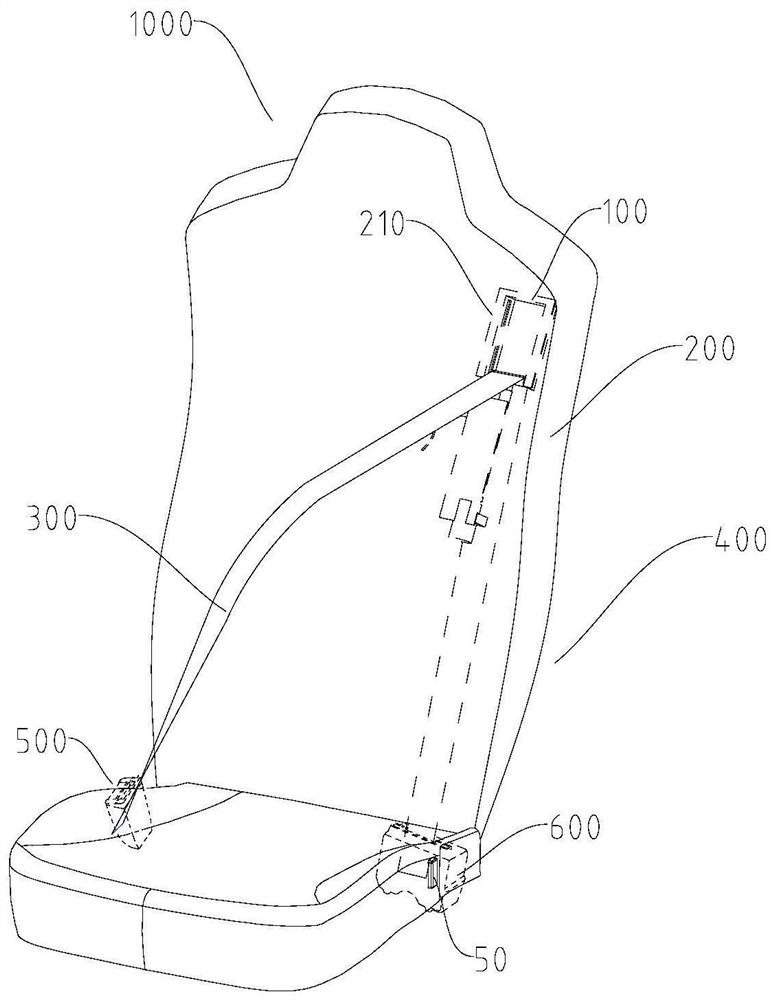

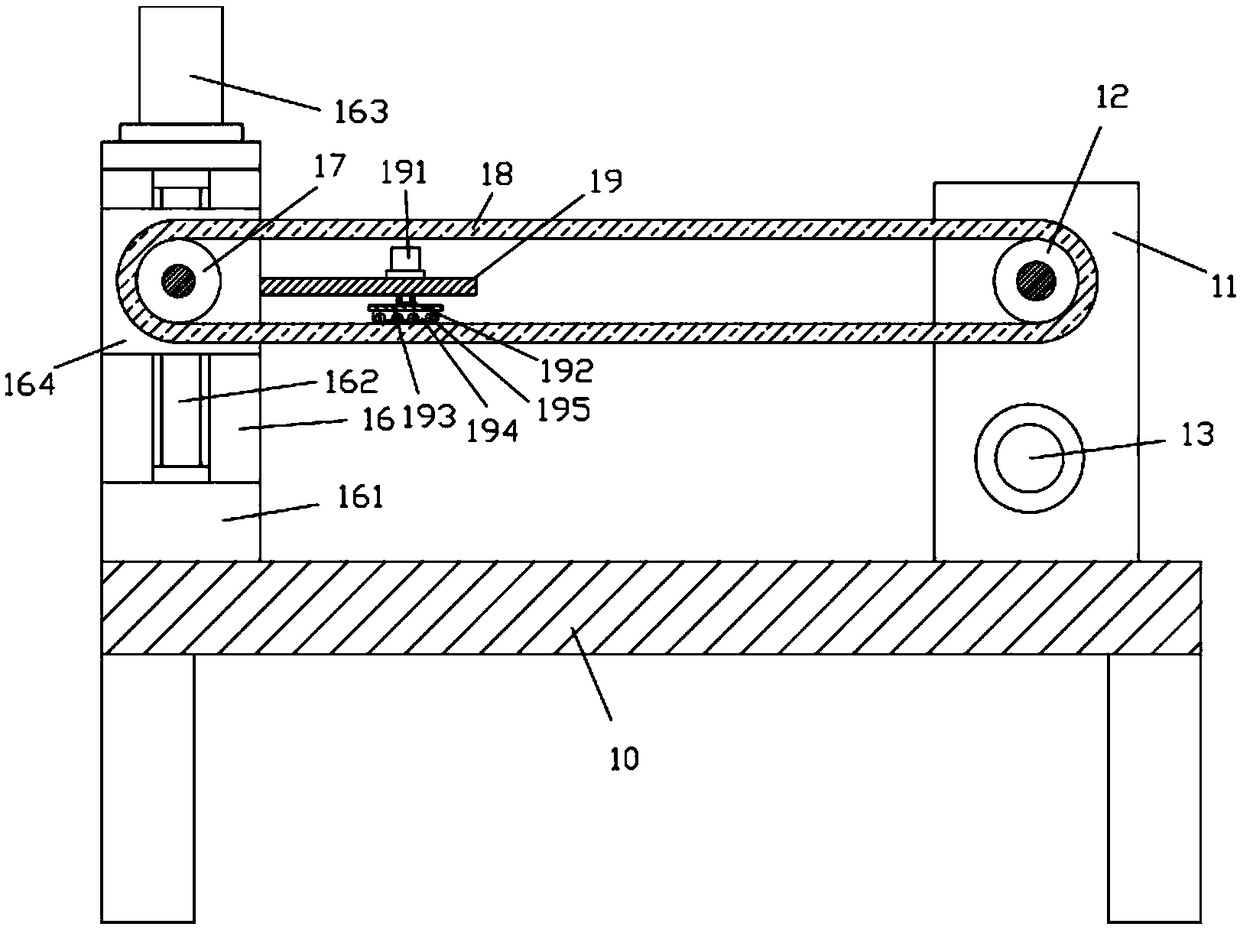

Safety belt height adjusting device, safety belt height adjusting method, seat and vehicle

ActiveCN113581124AMeet tension requirementsAvoid tighteningBelt anchoring devicesWearing seat beltControl theory

The invention relates to a safety belt height adjusting device, a safety belt height adjusting method, a seat and a vehicle. The safety belt height adjusting device comprises a fixed part, a movable part and a locking structure, the fixed part is used for being installed on a seat backrest, the movable part is movably connected to the fixed part in the first direction so as to be used for adjusting the height position of a safety belt from a leading-out point of the seat backrest, the locking structure is used for locking the movable part on the fixed part in the first direction, the locking structure comprises a locking piece and an electromagnet, and the locking piece locks or unlocks the movable part by controlling the power-on and power-off of the electromagnet. According to the safety belt height adjusting device, the safety belt can be led out from different height positions of the seat backrest, the tension requirements of passengers with different heights and body types for tying the safety belt are met, the body is prevented from being tightened by the safety belt, and the riding comfort can be improved.

Owner:BYD CO LTD +1

Wood product belt type grinding machine

InactiveCN108818239AMeet tension requirementsPrevent prolapseBelt grinding machinesEngineeringDrive motor

The invention discloses a wood product belt type grinding machine. The wood product belt type grinding machine comprises a rack, wherein main supporting plates are fixed at the front and the rear of the right top surface of a carrier plate of the rack; articulated shaft parts at the two ends of a main driving roller are articulated with the two main supporting plates; one of the articulated shaftparts extends out of the corresponding main supporting plate, and a transmission wheel is fixed to the articulated shaft part; a driving motor is fixed to the inner side wall of the lower part of eachmain supporting plate; an output shaft of the driving motor passes through the main supporting plate, and a driving wheel is fixed on the output shaft; a transmission belt is tensioned on the driving wheel and the transmission wheel; adjusting supporting plates are fixed at the front and the rear of the left top surface of the carrier plate of the rack; and supporting plates are fixed to the upper parts and lower parts of opposite wall surfaces of the two adjusting supporting plates. The wood product belt type grinding machine can adjust the tension degree of a grinding belt by adjusting theheight of the transmission roller; meanwhile, the height of a tension roller arranged at the middle can be finely adjusted so as to meet the tension requirements of the grinding belt, thereby ensuring the grinding effect, preventing the grinding belt from coming off and ensuring the normal operation of equipment.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

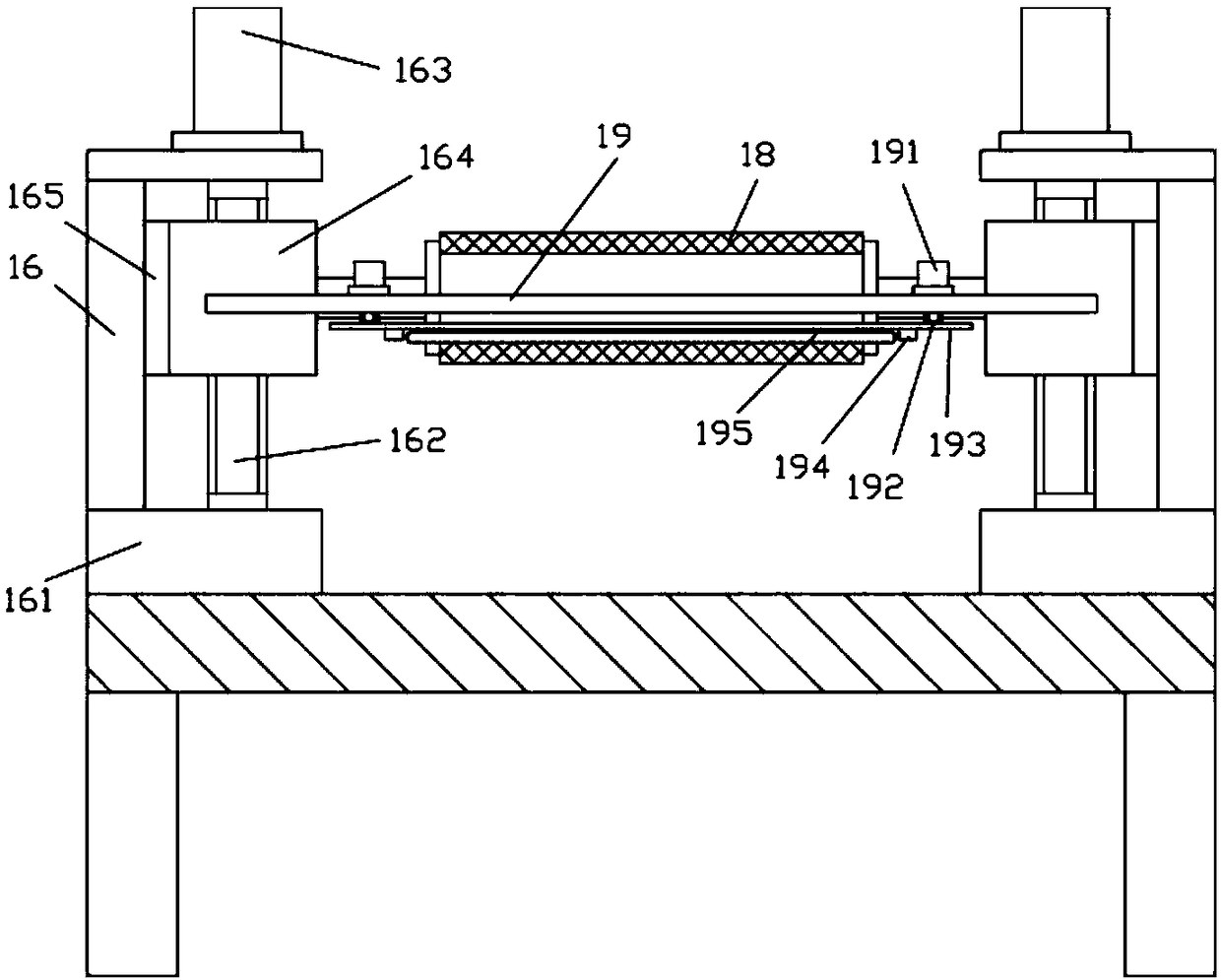

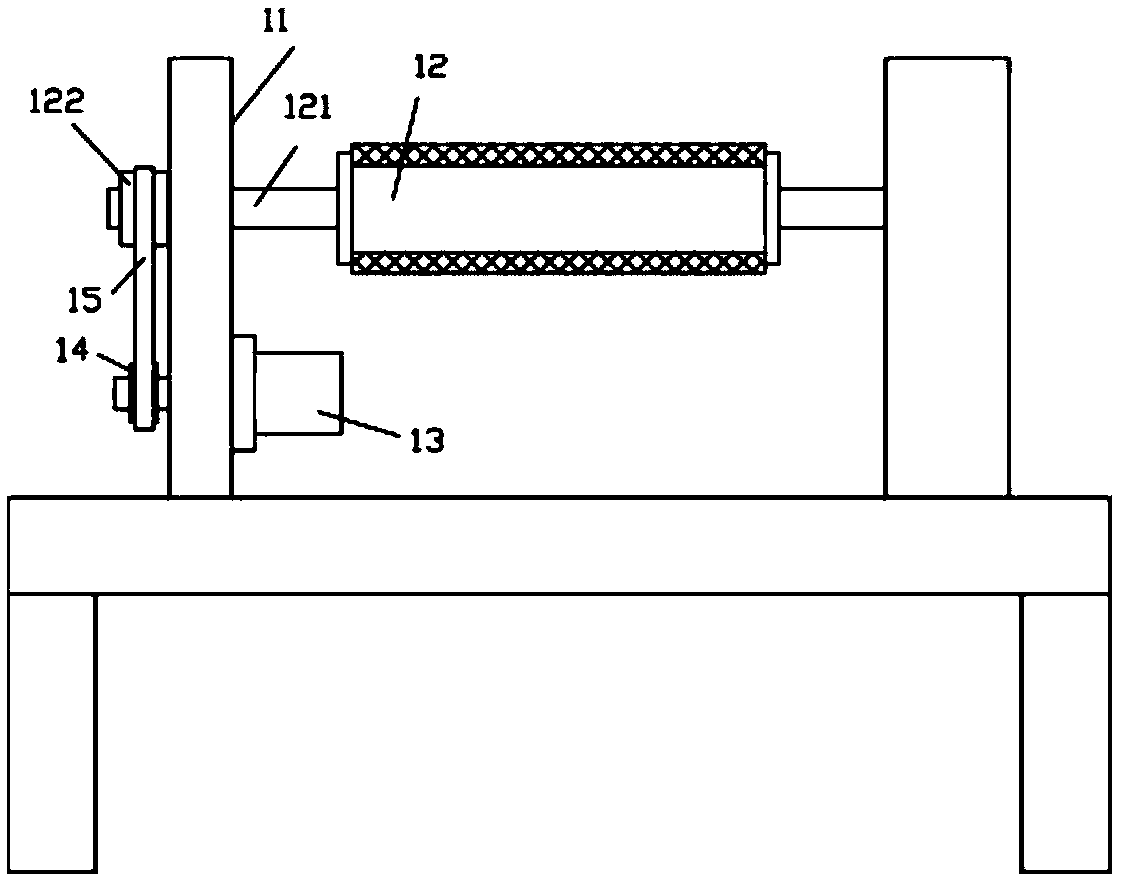

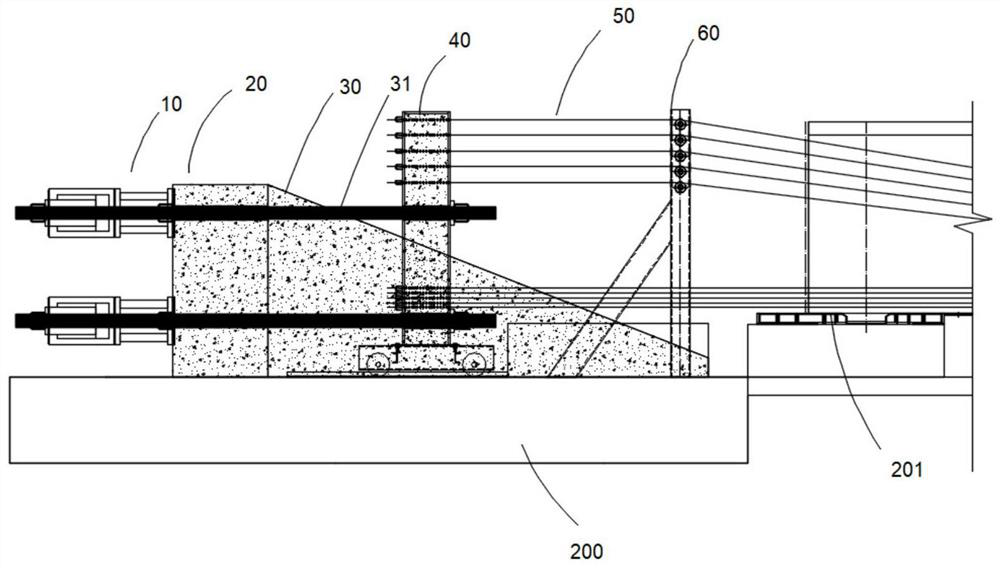

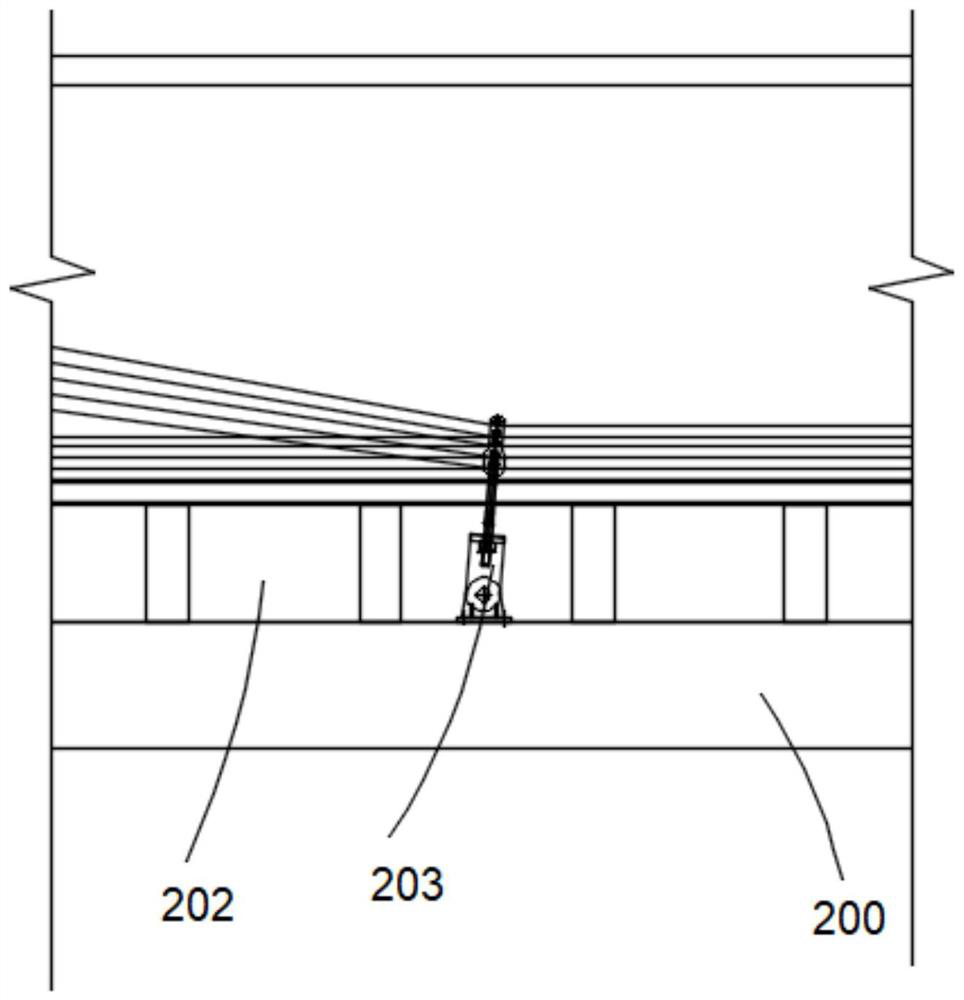

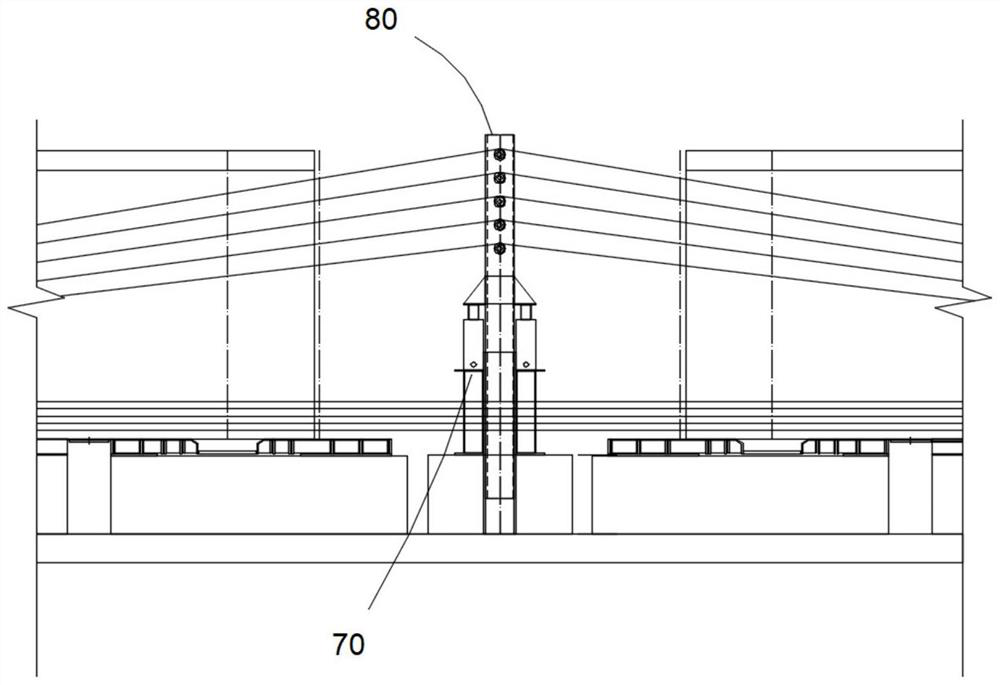

Pre-tensioning method precast beam tensioning concrete reaction wall

PendingCN114704099AMeet tension requirementsSolve the pretension tensionBuilding material handlingBogiePull force

The invention discloses a pre-tensioning method precast beam tensioning concrete reaction wall which comprises a side jack, a reaction wall body, ear walls, a pull rod, an anchoring vehicle, a plurality of steel strands, a bogie, a vertical jack, a main bogie and a concrete bearing platform foundation, the rear end of the reaction wall body is connected with the two ear walls, one end of each steel strand is fixed to the anchoring vehicle, and the other end of each steel strand is fixed to the pull rod. The vertical jack is fixed to the concrete bearing platform foundation and drives the main bogie to move up and down so as to provide pulling force of the steel strand, and the reaction wall and the lug wall are fixed to the concrete bearing platform foundation. According to the device, through cooperation of the reaction wall, the lug wall, the pull rod, the anchoring vehicle, the steel strands, the bogie and the vertical jack, the vertical jack is driven to conduct tension transmission, the anchoring vehicle is tensioned to meet the tensioning requirement, the device is applied to tensioning construction of a pre-tensioning method precast beam, and the problems that the pre-tensioning force is large, and safety is insufficient are solved.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG +2

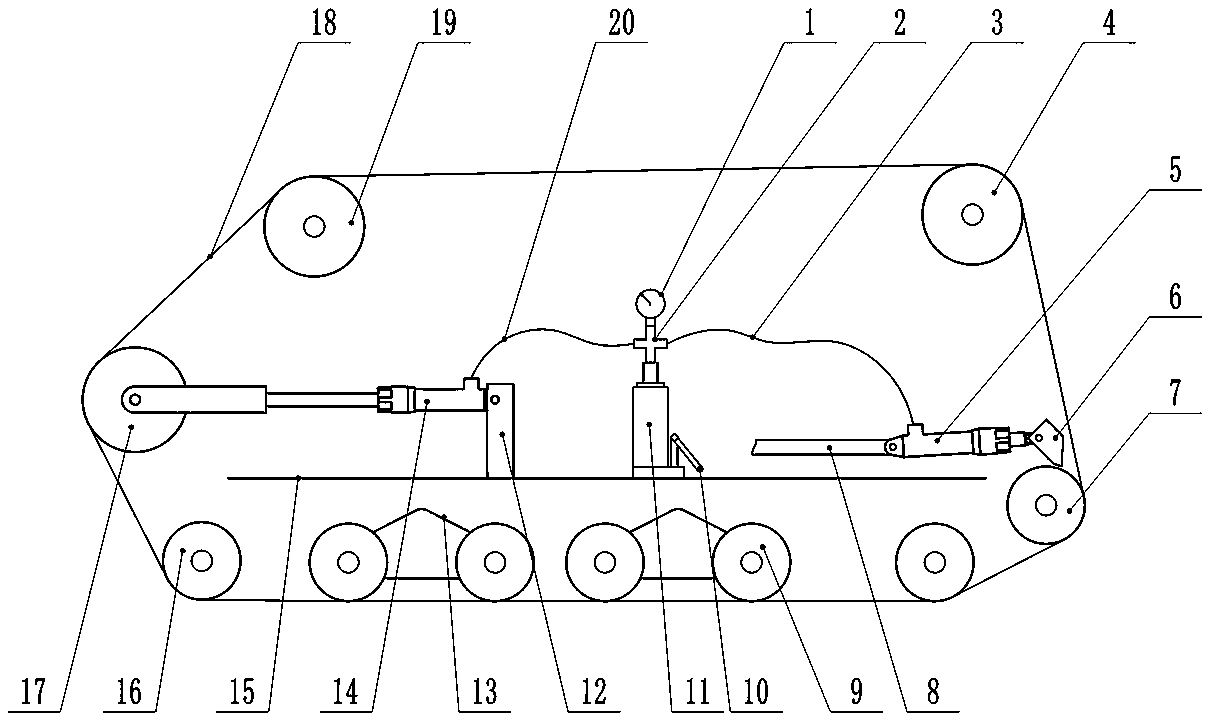

Rubber crawler hydraulic tensioning device with oil-charging and pressurizing functions for mountain crawler tractor

InactiveCN109533065AMeet tension requirementsResolve slackEndless track vehiclesHydraulic cylinderDual function

The invention discloses a rubber crawler hydraulic tensioning device with oil-charging and pressurizing functions for a mountain crawler tractor. The device comprises a hydraulic oil meter, a four-wayjoint, a rear cylinder oil pipe, a rear hydraulic oil cylinder, a rear hydraulic cylinder fixing frame, a pressure-reinforcing operation handle, an oil-charging and pressure-reinforcing device, a front hydraulic cylinder fixing frame, a front hydraulic cylinder and a front cylinder oil pipe; four outlets of the four-way joint are connected with the oil-charging and pressure-reinforcing device, the hydraulic oil meter, one end of the front cylinder oil pipe and one end of the rear cylinder oil pipe respectively; a piston rod of the front hydraulic cylinder is connected with a guiding wheel, alug of the hydraulic cylinder is connected with the front hydraulic cylinder fixing frame, a piston rod of the rear hydraulic oil cylinder is connected with the rear hydraulic cylinder fixing frame, and a lug is connected with a main connecting rod. The rubber crawler hydraulic tensioning device with the oil-charging and pressurizing functions for the mountain crawler tractor has the advantages that tensioning requirements of a rubber crawler of the mountain crawler tractor can be met, it is ensured that the rubber crawler does not fall off when the tractor walks, thereby achieving the dual functions of cushioning and tensioning, achieving the oil-charging and pressure-reinforcing functions, and effectively solving the problem of crawler looseness caused by oil line leakage.

Owner:NORTHWEST A & F UNIV

Tensioner, front end wheel train system and vehicle

The invention discloses a tensioner, a front end wheel train system and a vehicle, and solves the technical problems that in the prior art, due to the fact that the tension of a system belt is too high, all accessories are abraded, the belt is abraded, the friction loss of the system is increased, and then the oil consumption level of an engine is influenced, the tensioner comprises a base, a rotation driving mechanism and a tensioning assembly; wherein. The base is provided with a mounting cavity; the tensioning assembly is rotationally arranged on the base; the rotation driving mechanism comprises a force transmission piece, a power piece and a cam driven by the power piece to rotate. The force transmission piece and the cam are rotationally arranged in the mounting cavity, and the power piece is connected to the base; the force transmission piece is provided with a first contact part acting on the cam and a second contact part acting on the tensioning assembly, so that the cam drives the force transmission piece and the tensioning assembly to rotate in the circumferential direction of the force transmission piece, the requirement adjustment of the belt tension is achieved, the tension needed under different working conditions is adapted and matched, and the purposes of reducing the friction work of an engine and reducing the oil consumption of the engine are achieved.

Owner:DONGFENG MOTOR GRP

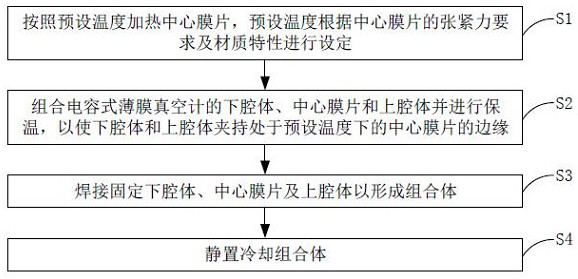

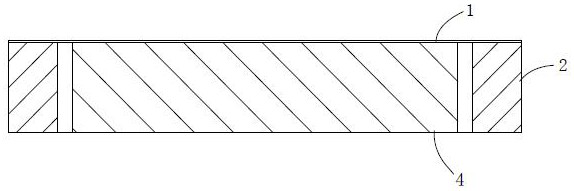

Thin film welding method of capacitive thin film vacuum gauge

ActiveCN114571125AEasy to produceMeet the tensionWelding/cutting auxillary devicesAuxillary welding devicesMeasuring instrumentThin membrane

The invention relates to the technical field of measuring instruments, and particularly discloses a thin film welding method for a capacitive thin film vacuum gauge, which comprises the following steps of: heating a central diaphragm according to a preset temperature, and setting the preset temperature according to the tension requirement and the material characteristic of the central diaphragm; combining a lower cavity, a central diaphragm and an upper cavity of the capacitive film vacuum gauge, and carrying out heat preservation, so that the lower cavity and the upper cavity clamp the edge of the central diaphragm at a preset temperature; welding and fixing the lower cavity, the central diaphragm and the upper cavity to form a combined body; standing and cooling the assembly; according to the method, the heated central diaphragm is welded by utilizing the characteristic of thermal expansion and cold contraction of the central diaphragm, so that the central diaphragm in the standing and cooling combined body has the tensile force meeting the tensile force requirement, the tensioning treatment of tensioning equipment is omitted, the central diaphragm meets the processing quality requirement of the capacitive film vacuum gauge, and the processing efficiency of the capacitive film vacuum gauge is improved. And the product percent of pass is effectively improved.

Owner:JIHUA LAB

Belt tensioning device for combing machine

The invention relates to a belt tension device of a carding machine. The belt tension device comprises a fixing wallboard, a small belt pulley, a large belt pulley and a tension pulley support. The tension pulley support is positioned between the small belt pulley and the large belt pulley, a fixing plate is arranged below the support, a rotating pin penetrates through the tension pulley support and the fixing plate to be connected with the fixing wallboard, an eccentric wheel is mounted inside an elongated slot of the tension pulley support, an inner hexagonal groove on the eccentric wheel is matched with an eccentric wheel rotating pin on the fixing plate, a tension belt pulley positioned between the fixing wallboard and the tension pulley support is fixed via a bolt, and an additional belt pulley is positioned on the left upper side of the tension pulley support and is fixed onto the fixing wallboard. The belt tension device has the advantages that belt transmission in narrow tension belt pulley accommodating space can be realized, the belt tension device is simple in structure, and the large belt pulley can be replaced at any time as needed, so that tensioning requirements can be met.

Owner:JINGWEI TEXTILE MASCH CO LTD

Middle arranged tension device

InactiveCN101469475BRealize closed-loop controlMeet tension requirementsWarping machinesOther manufacturing equipments/toolsAutomatic controlLoop control

The invention relates to a center disposed tension device of a warping machine, which is characterized in that: the motor is a vector frequency control motor electrically connected with an automatic control device for controlling rotation speed of let-off tension roller; the tension roller is disposed on bottom portion between two yarn guide rollers; pins are disposed on inner surface of the yarnoutlet on the wall of the left box body and the right box body respectively, two connection plates are movably engaged with pins through a central hole, both ends of the tension rod (a) and the tension rod (b) are attached on both sides of the pin engaged with central holes of two connection plates; a pressure sensor contact is disposed on inner surface wall of left or right box body, which is incontact with the bottom side of the tension rod (a) axle neck permanently. The center disposed tension device makes the yarn form a wrapping angle through the yarn guidance roller, the tension roller, and the yarn guidance roller, makes the yarn and the yarn guidance roller generates adhesion, implements closed-loop control to the yarn tension through on-line detection of the pressure sensor, andsatisfies needed tension requirements in the warping process.

Owner:射阳县中意纺织机械制造有限公司

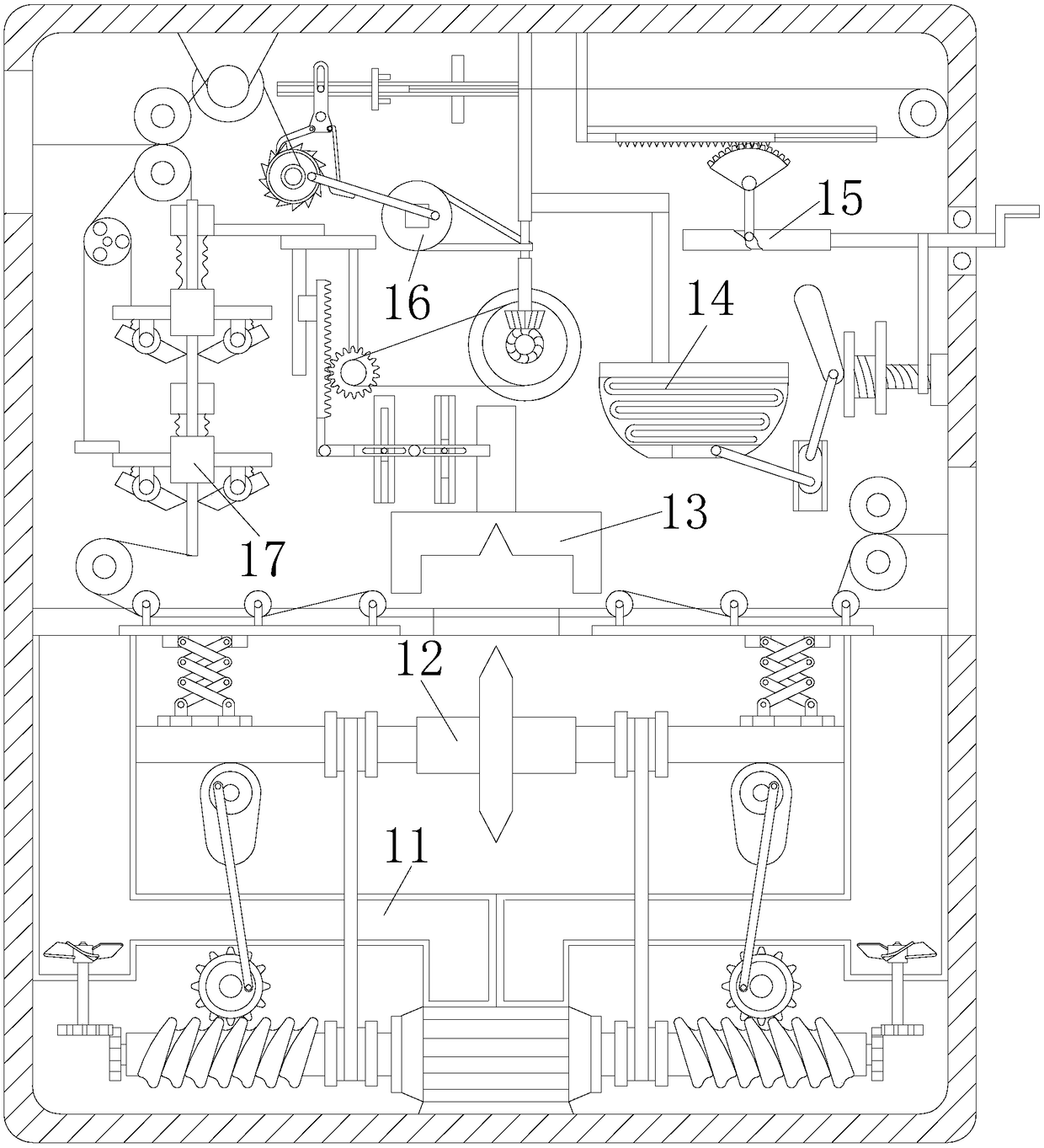

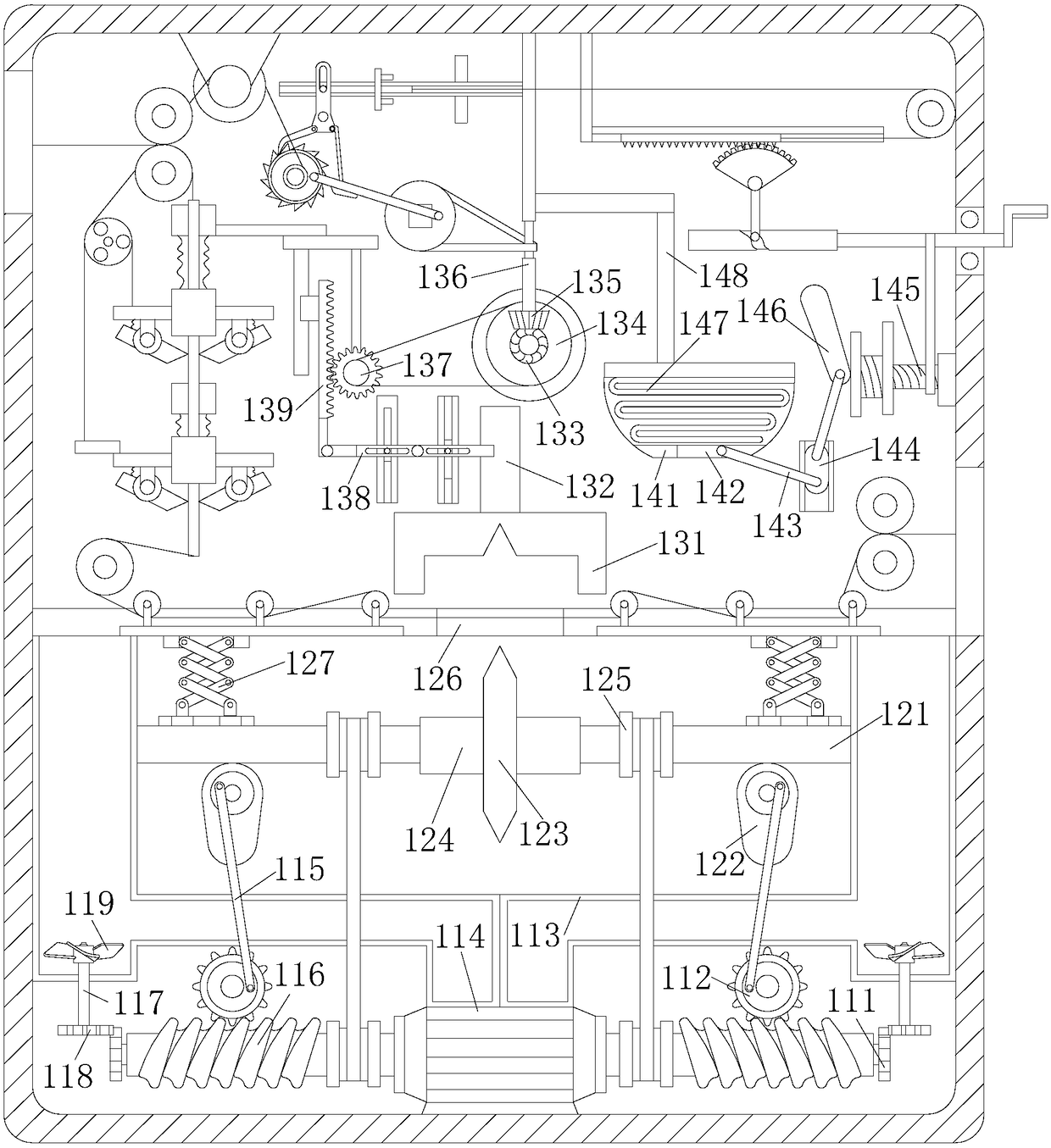

An integrated mechanical equipment for textile processing

ActiveCN109160377BSmooth motionAchieving tension adjustmentFilament handlingFunction indicatorsStructural engineeringMechanical equipment

The invention belongs to the technical field of textile processing, and particularly relates to an integrated mechanical equipment for textile processing. The equipment comprises a working table; vertical first supporting plates are fixedly connected to the front side wall and the rear side wall of the working table respectively, and a first rotating wheel is rotationally connected between the twofirst supporting plates; the top wall of the working table is fixedly connected to a gantry support, and two stand columns of the gantry support are fixedly connected to the front side wall and the rear side wall of the working table; rectangular openings are formed in the side walls of the two stand columns of the gantry support respectively, and strip-shaped limiting blocks are fixedly connected to the left inner wall and the right inner wall of each rectangular opening; and the two strip-shaped limiting blocks are in sliding connection with the same moving part, and sliding grooves which are connected to the strip-shaped limiting blocks in a sliding mode are formed in the left side wall and the right side wall of the moving part respectively. The equipment has the advantages that errors are small when the tension is adjusted, the working efficiency is high, damage to textiles is not easily caused, so that the use reliability is improved.

Owner:福建省香江服饰科技有限公司

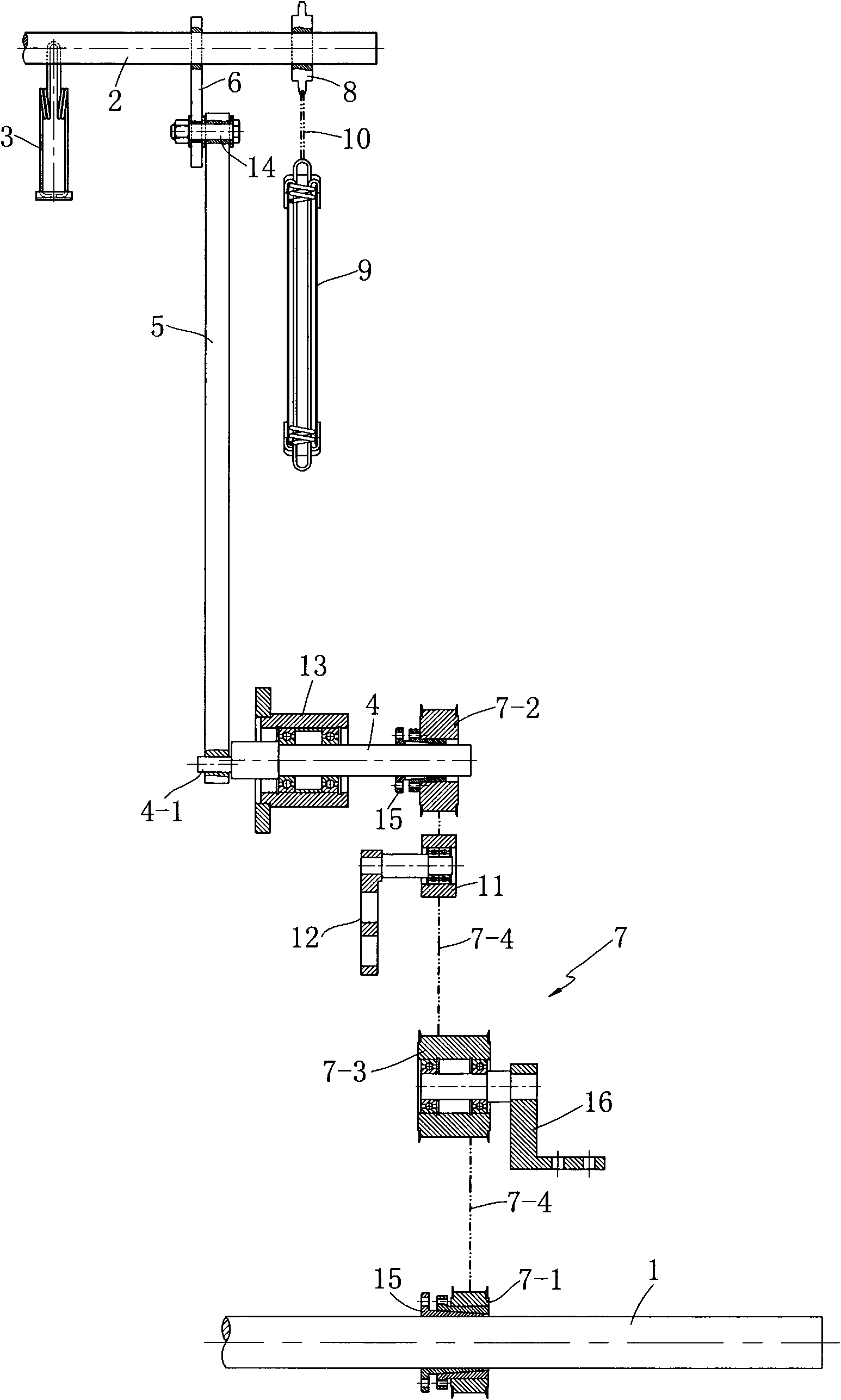

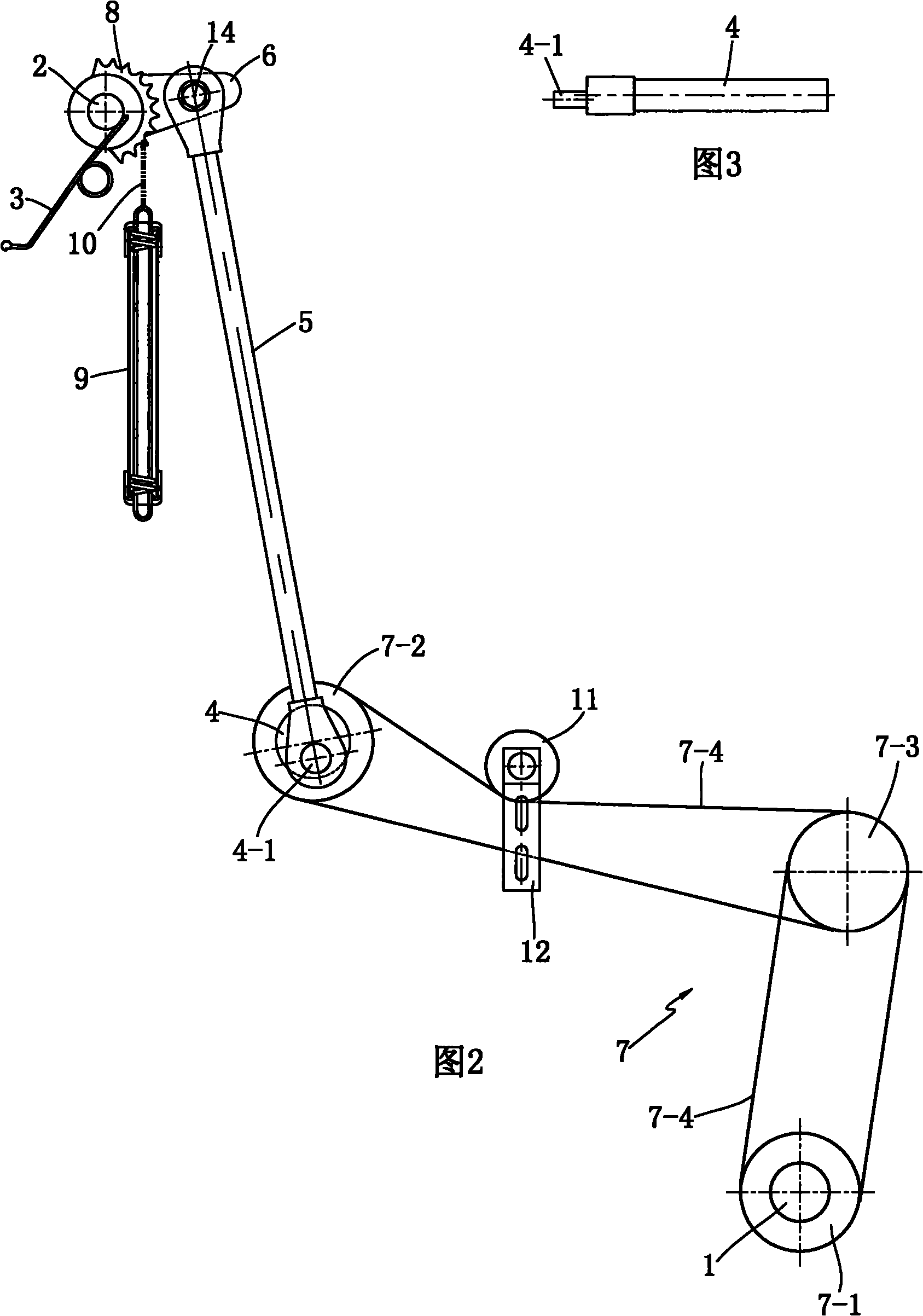

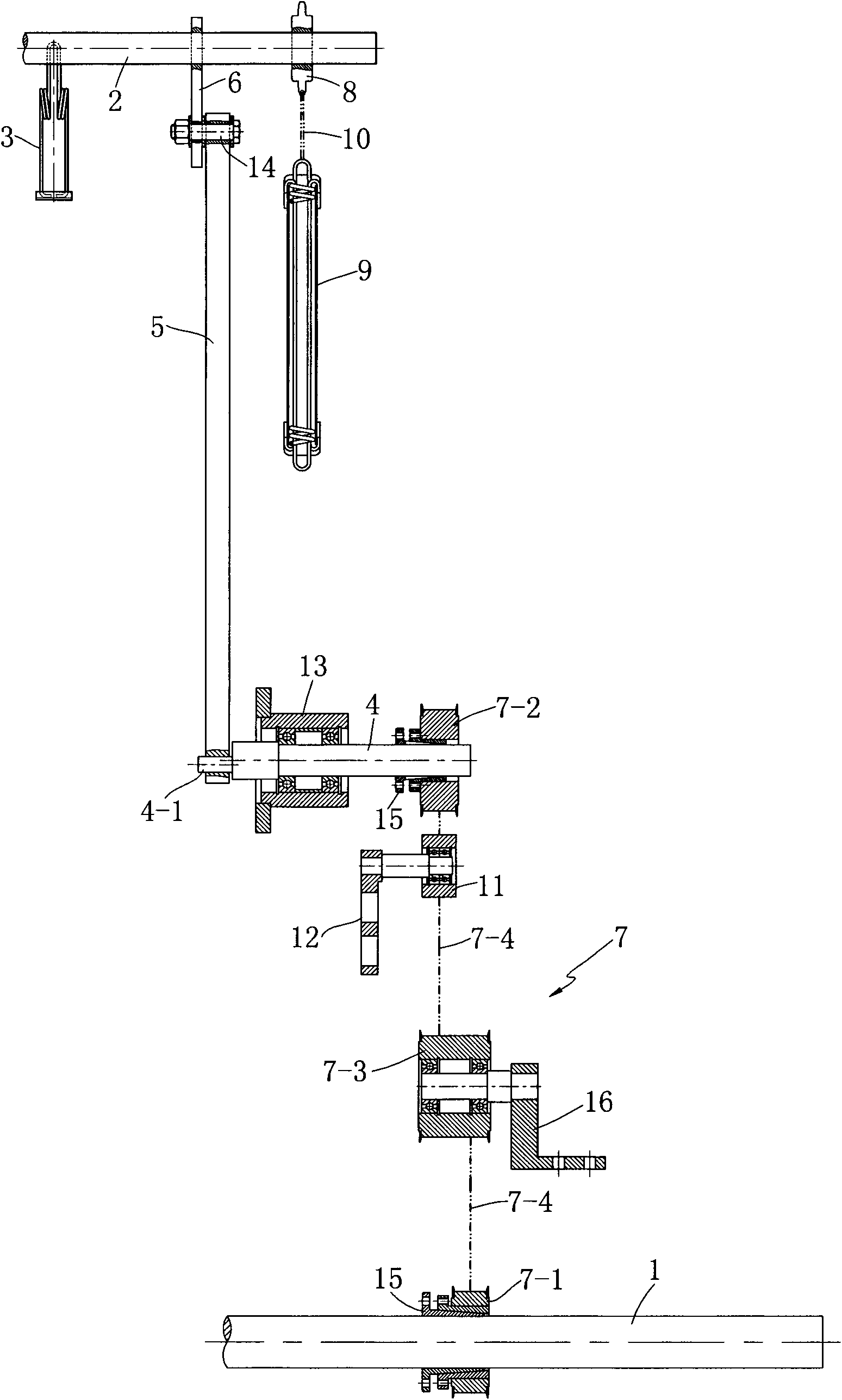

A device assembly and tensioning construction method for tensioning fork lug type cables or steel rods

ActiveCN104847122BSimple designCompact structureBuilding material handlingJackscrewArchitectural engineering

A device assembly for tensioning fork lug type cables or steel rods, including: reaction frame, tension rod, pole beam and jack, the reaction frame is similar to a "U"-shaped structure, divided into two pieces; " The opening of the U"-shaped structure is designed as a step shape, with bolt holes and semi-circular slots I for the tension rods to pass through the tension rods; Tie rods, with tension rod semicircular grooves II for installing tension rods on both sides; when it is used for tension construction, two pieces of reaction frames are respectively installed on both sides of the fork lugs of the fork lug type cable or steel tie rod, through bolts It is integrated with the connecting plate; the two halves of the pole beam are installed on the extension tube end of the fork ear cable or the steel rod, and are fixed by bolts; the tension rod passes through the pole beam and the reaction frame, and passes through the fixing nut at one end of the reaction frame For anchoring, the other end is installed with a jack and a backing plate and anchored by a tension nut. The device assembly is used for tension construction with good safety and strong versatility.

Owner:LIUZHOU OVM ENG

Automatic feeding belt sander for wooden products

InactiveCN108747732AMeet tension requirementsPrevent prolapseBelt grinding machinesSanderEngineering

The invention discloses an automatic feeding belt sander for wooden products. The automatic feeding belt sander for the wooden products includes a rack, and main support plates are fixed to the frontportion and rear portion of the right top surface of a top plate of the rack. Hinged shaft parts are arranged at both ends of a main driving roller and hinged to the two main support plates, and one of the hinged shaft parts extends out of the corresponding main support plate and is fixedly provided with a driving wheel. A center through groove is formed in the middle of the top plate of the rack,and a lifting plate is pressed against the top surface of the top plate of the rack and covers the center through groove. A lifting support plate is fixed to the bottom surface of the middle of the top plate of the rack, and a plurality of lifting cylinders are fixed to the bottom surface of the lifting support plate. According to the automatic feeding belt sander for the wooden products, the high and low positions of a drive roller can be adjusted to adjust the tensioning degree of a sanding belt to meet the tensioning requirements of the sanding belt, the sanding effect is ensured, the sanding belt is prevented from slipping, and the normal operation of the belt sander is ensured; and meanwhile, a board to be processed can be automatically clamped and fixed as well as automatically lifted and moved by the belt sander to achieve automatic sanding, the effect is good, and the degree of automation is high.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Processing method and processing device of cotton bead fabric

ActiveCN104711864BMeet tension requirementsImprove yieldMercerising of indefinite length fabricsHeating/cooling textile fabricsMaterials preparationPulp and paper industry

The invention provides a processing method for a cotton crimp bead fabric, belongs to the technical field of machinery, and solves a problem of poor hand feel of an existing fabric. The processing method for the cotton crimp bead fabric comprises the following steps: A, material preparation; B, fabric weaving; C, fabric mercerization; D, shaping. A treatment device for fabric mercerization comprises a bracket, and further comprises a caustic soda container, a clear water container and transitional rollers, wherein the transitional rollers include a transitional roller I, a transitional roller II and a transitional roller III; upper parts of both the caustic soda container and the clear water container are open, and the bottom of each of the caustic soda container and the clear water container is fixedly connected to the bracket; the transitional roller I is connected in the caustic soda container; the transitional roller II is connected to the bracket and positioned at the upper parts of the caustic soda container and the clear water container; the transitional roller III is connected in the clear water container. The method is easy to implement. The device is high in finished product rate.

Owner:ZHEJIANG YANA TEXTILE

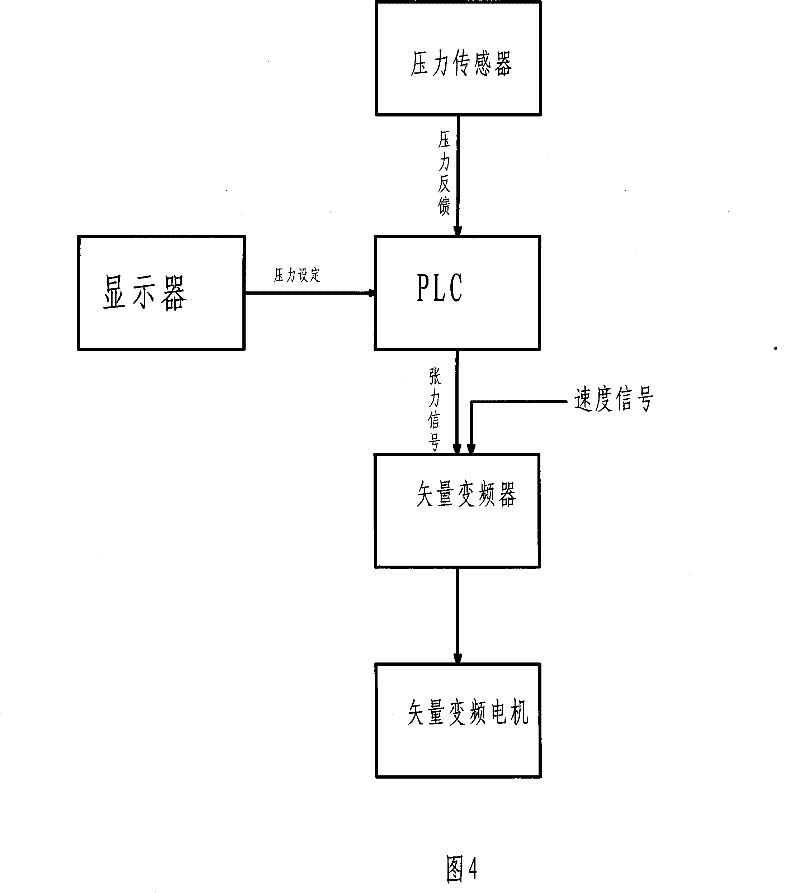

Tension Control Device

ActiveCN103587998BMeet tension requirementsAchieve tightnessWebs handlingElectrical controlEngineering

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

Improved processing method of cotton bead fabric and processing device thereof

ActiveCN104711863BMeet tension requirementsImprove yieldMercerising of indefinite length fabricsHeating/cooling textile fabricsPulp and paper industryCOTTON WOOL

The invention provides an improved processing method of a cotton lace fabric, belongs to the technical field of machinery and solves the problem of poor hand feeling of the existing fabrics. The processing method of the cotton lace fabric comprises the following steps: A, preparing materials; B, weaving the fabric; C, mercerizing the fabric; D, shaping. A fabric mercerizing device comprises a bracket, a caustic soda container, a clear water container and transitional rollers, wherein the transitional rollers comprise a transitional roller I, a transitional roller II and a transitional roller III; openings are formed in the tops of the caustic soda container and the clear water container; the bottoms of the caustic soda container and the clear water container are fixedly connected to the bracket; the transitional roller I is connected to the caustic soda container; the transitional roller II is connected to the bracket and is located above of the caustic soda container and the clear water container; the transitional roller III is connected to the clear water container. The method is easy to implement; by the adoption of the equipment used in the method, the rate of finished products is high.

Owner:ZHEJIANG YANA TEXTILE

Processing method and treatment device for environmental fabric

InactiveCN104711795AFeel goodGood crispnessMercerising of indefinite length fabricsFibre typesMaterials preparationEnvironmental engineering

The invention provides a processing method for environmental fabric, and belongs to the technical field of machinery. The processing method solves the problem that existing fabric is poor in hand feel. The processing method for environmental fabric comprises the following steps of A, material preparation, B, fabric weaving, C, fabric mercerizing, and D, sizing. A fabric mercerizing device comprises a support, a caustic soda container, a clear water container and transition rollers, wherein the transition rollers comprise the first transition roller, the second transition roller and the third transition roller; the upper portion of the caustic soda container and the upper portion of the clear water container are both provided with openings, the bottom of the caustic soda container and the bottom of the clear water container are both fixedly connected to the support, the first transition roller is connected into the caustic soda container, the second transition roller is connected to the support and located above the caustic soda container and the clear water container, and the third transition roller is connected into the clear water container. The method is easy to implement, and the yield is high through the device.

Owner:ZHEJIANG YANA TEXTILE

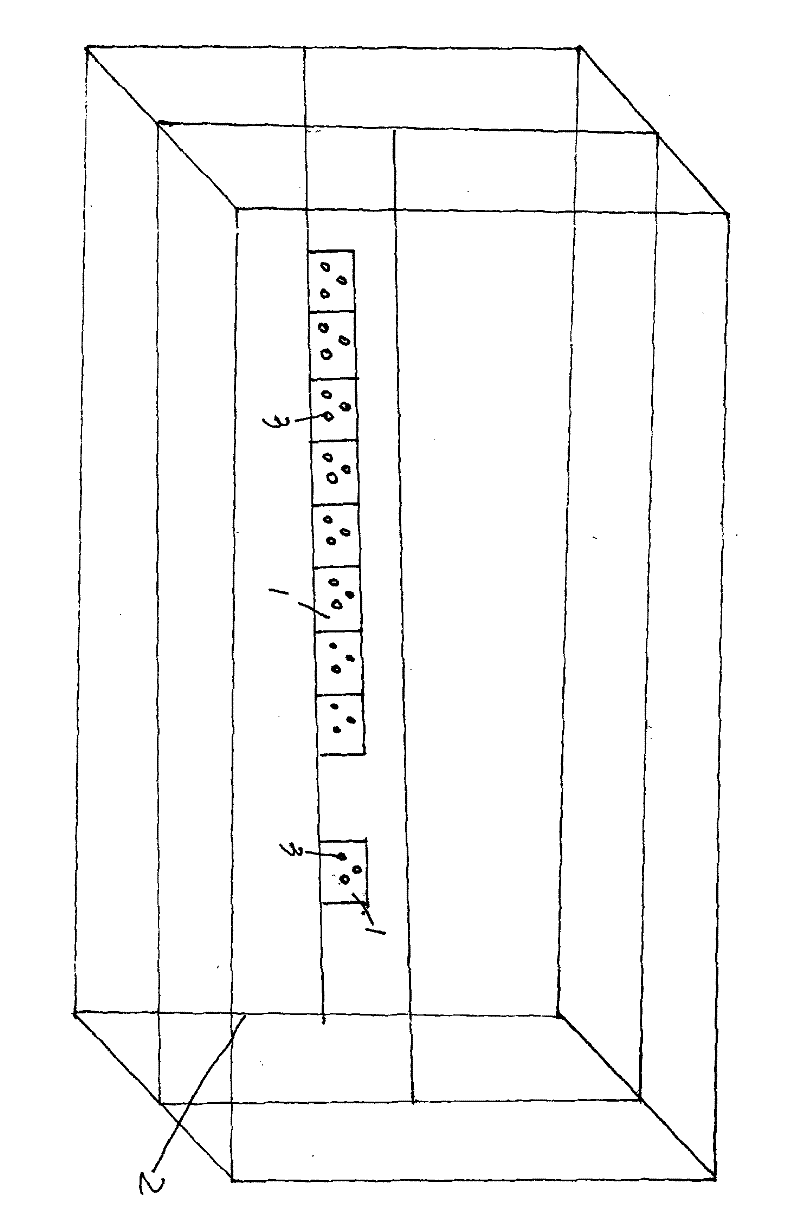

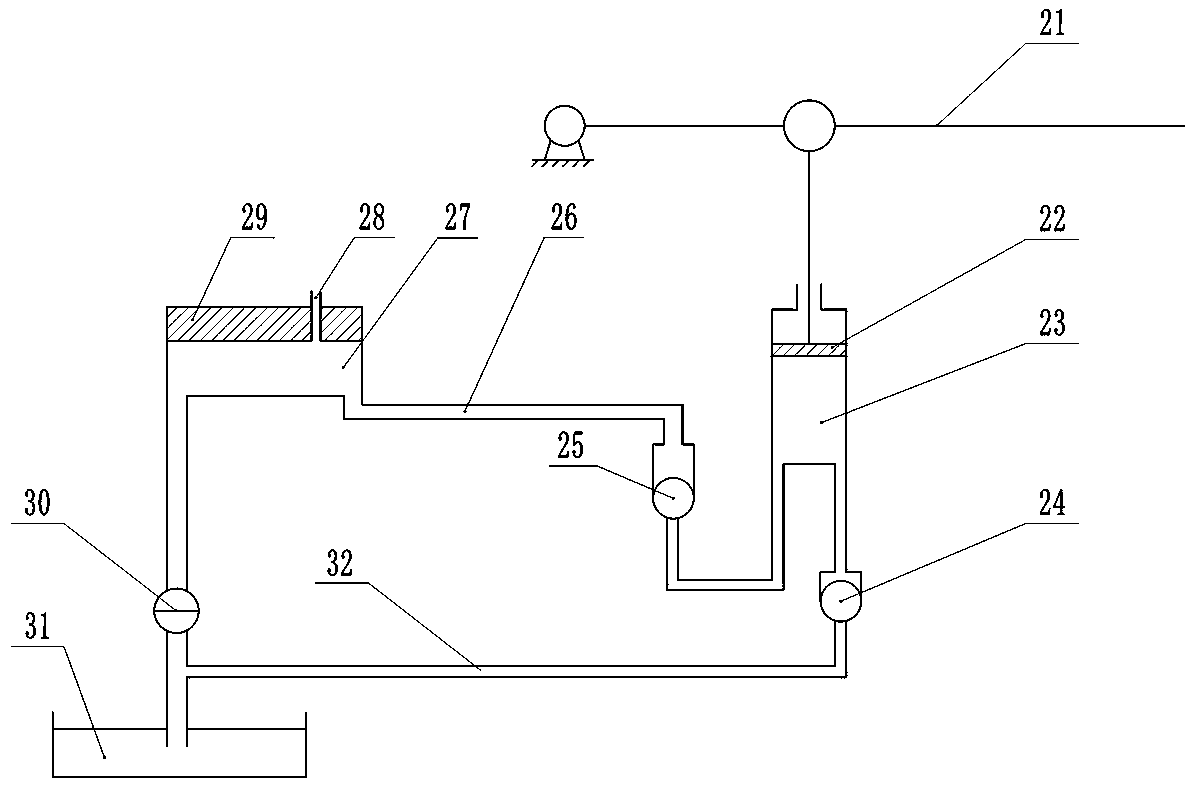

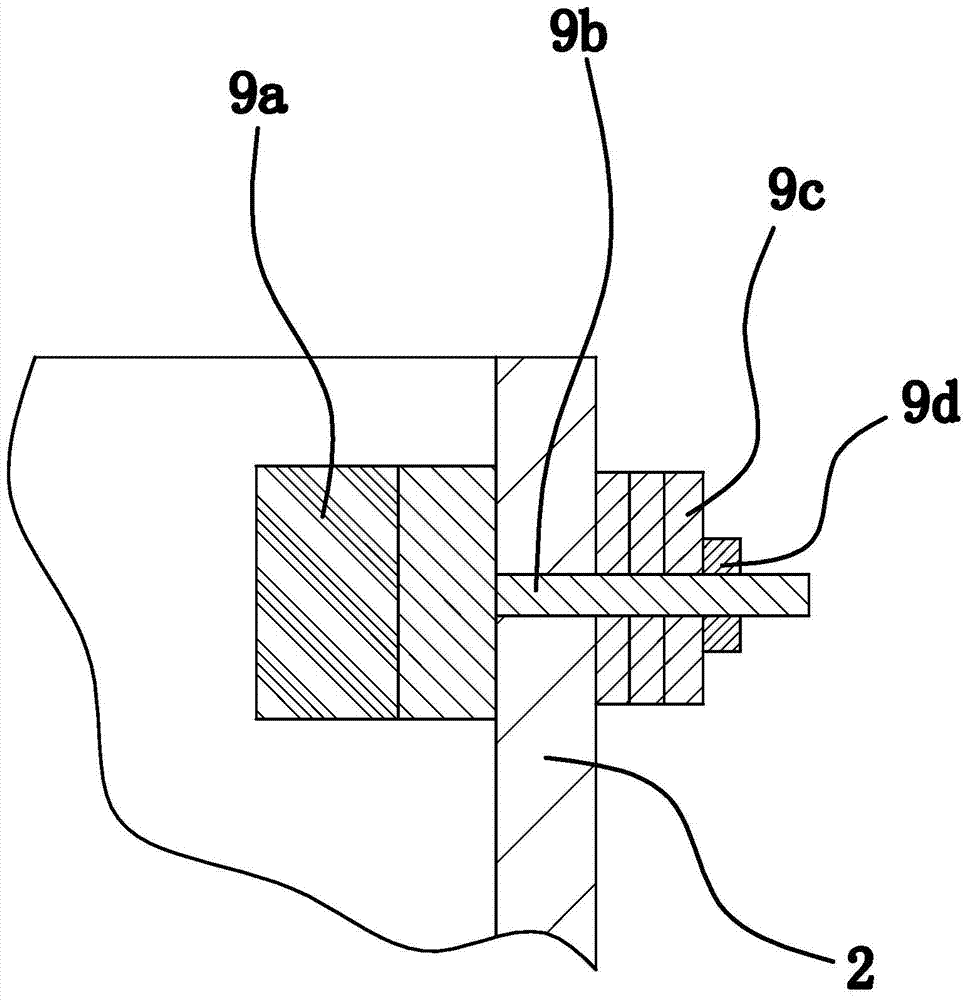

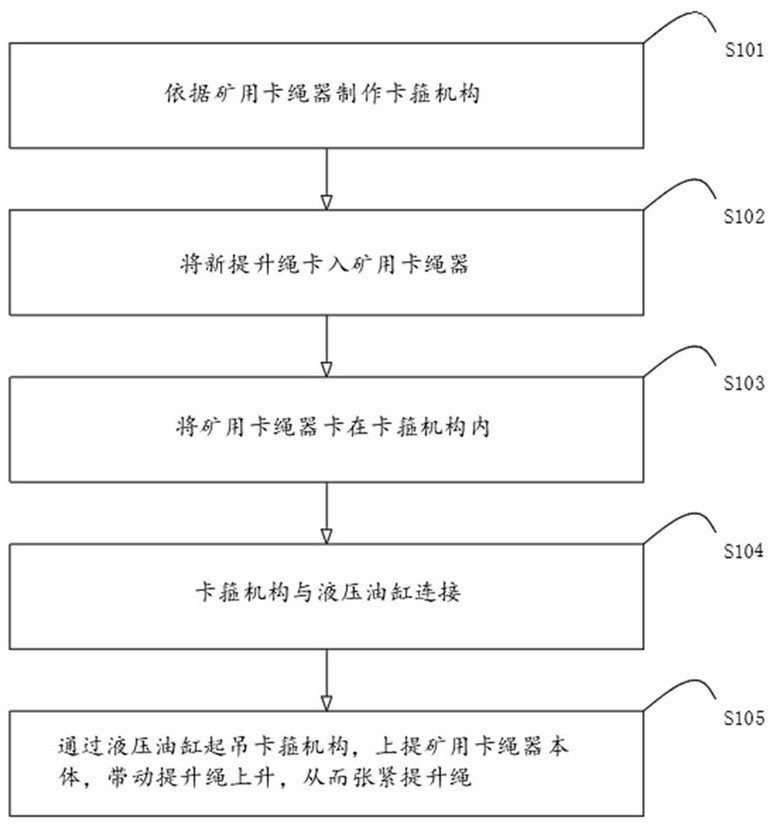

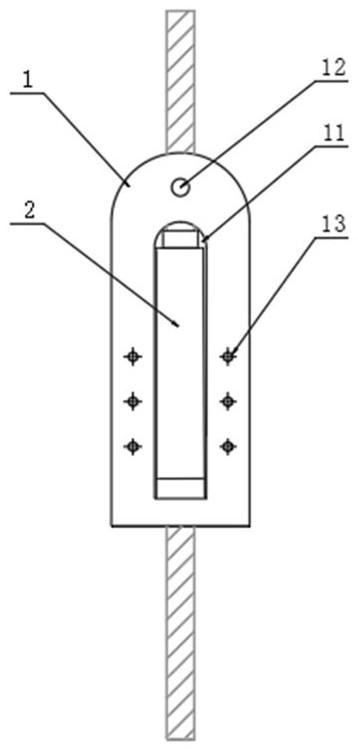

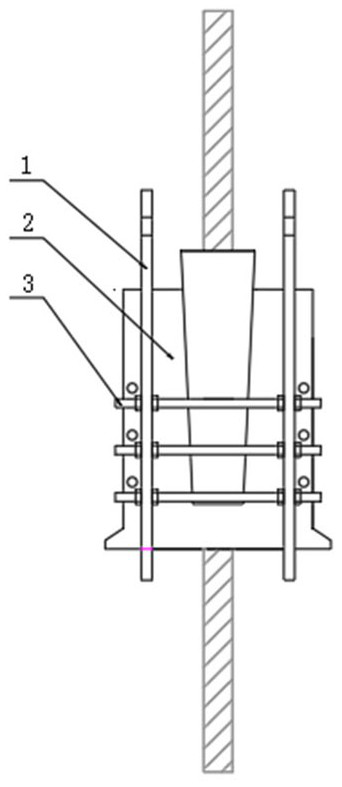

Construction method and system for tensioning vertical shaft hoisting rope

PendingCN114572799AUnique structureNovel structureElevatorsMine liftsHydraulic ramHydraulic pressure

The invention belongs to the technical field of mine construction, and particularly relates to a construction method and system for tensioning a vertical shaft hoisting rope. The embodiment of the invention discloses a construction method for tensioning a vertical shaft hoisting rope. The construction method comprises the following steps that a clamping mechanism is manufactured according to a mining rope clamping device; a new lifting rope is clamped through a mining rope clamping device; the mining rope clamping device is clamped in the clamping mechanism; the clamping mechanism is connected with the hydraulic oil cylinder; the clamping mechanism is lifted, the mining rope clamping device body is lifted, and the lifting rope is driven to ascend, so that the lifting rope is tensioned, the problem that the speed of tensioning a new lifting rope through a lifting system oil cylinder is low is solved, it is effectively guaranteed that rope replacement operation is safely and efficiently completed, meanwhile, the clamping mechanism is wide in application range, one clamping mechanism can be used for various types of mining rope clamping devices, and the clamping mechanism is suitable for various types of mining rope clamping devices. The use flexibility is high.

Owner:MECHANICAL & ELECTRICAL INSTALLATION ENG CO LTD OF CHINA COAL NO 3 CONSTR GRP CORP LTD +1

Integrated mechanical device for textile processing

InactiveCN111847059ASmooth motionAchieving tension adjustmentFunction indicatorsWebs handlingWorkbenchTextile processing

The invention belongs to the technical field of textile processing, and particularly relates to an integrated mechanical device for textile processing. The integrated mechanical device comprises a workbench, the front side wall and the rear side wall of the workbench are fixedly connected with vertical first supporting plates, and a first rotary wheel is rotationally connected between the two first supporting plates. The top wall of the workbench is fixedly connected with a gantry bracket, and two stand columns of the gantry bracket are fixedly connected with the front side wall and the rear side wall of the workbench. Rectangular openings are formed in the side walls of the two stand columns of the gantry bracket, and the left inner walls and the right inner walls of the rectangular openings are fixedly connected with strip-shaped limiting blocks. The same movable part is slidably connected between the two strip-shaped limiting blocks of each rectangular opening, and sliding grooves in sliding connection with the strip-shaped limiting blocks are formed in the left side walls and the right side walls of the movable parts. The integrated mechanical device has the advantages that when tension is adjusted, the error is small, the work efficiency is high, textiles are not likely to be damaged, and therefore the use reliability of the integrated mechanical device is improved.

Owner:巴红宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com