Tensioner, front end wheel train system and vehicle

A front-end gear train and tensioner technology, applied in the direction of belt/chain/gear, transmission device, mechanical equipment, etc., can solve the problems of increasing system friction loss, high system tension, affecting engine fuel consumption level, etc., to increase or decrease Effects of tension, fast response, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

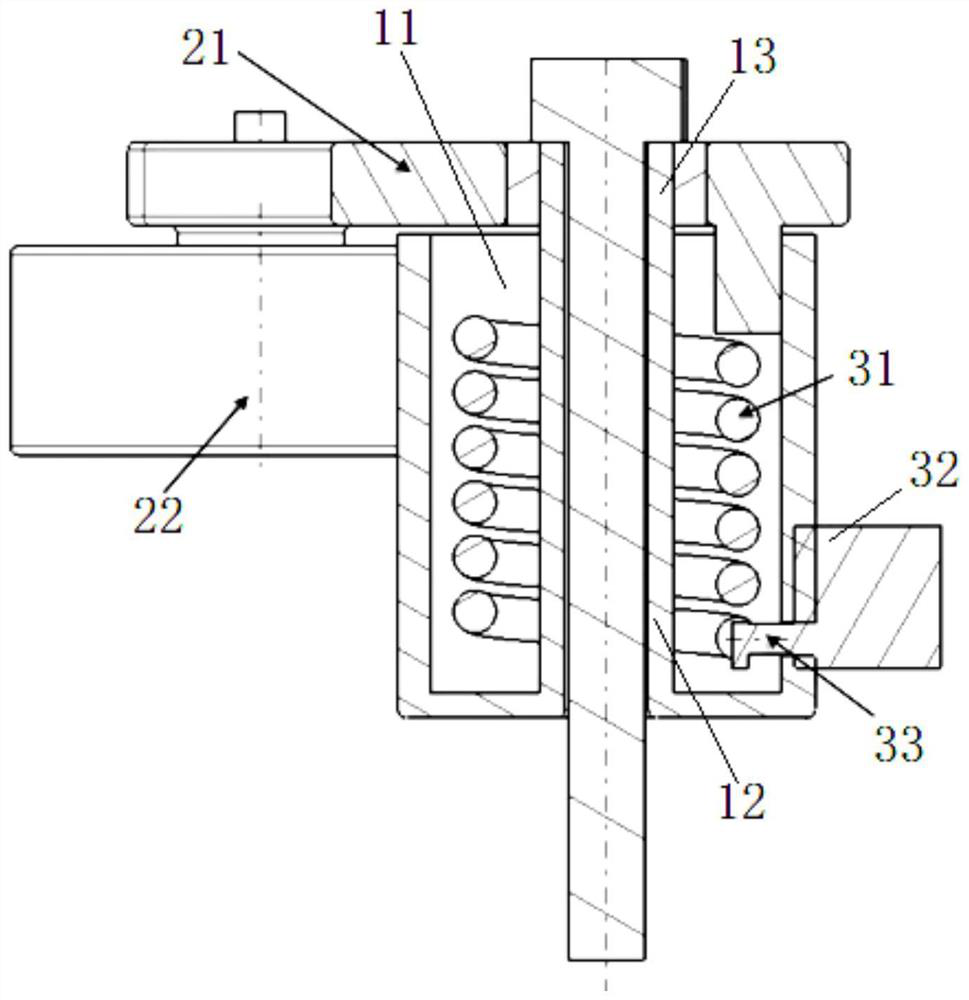

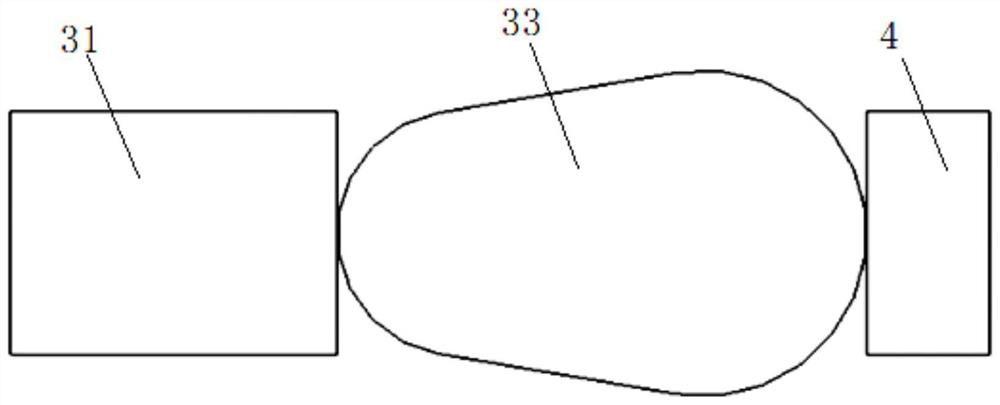

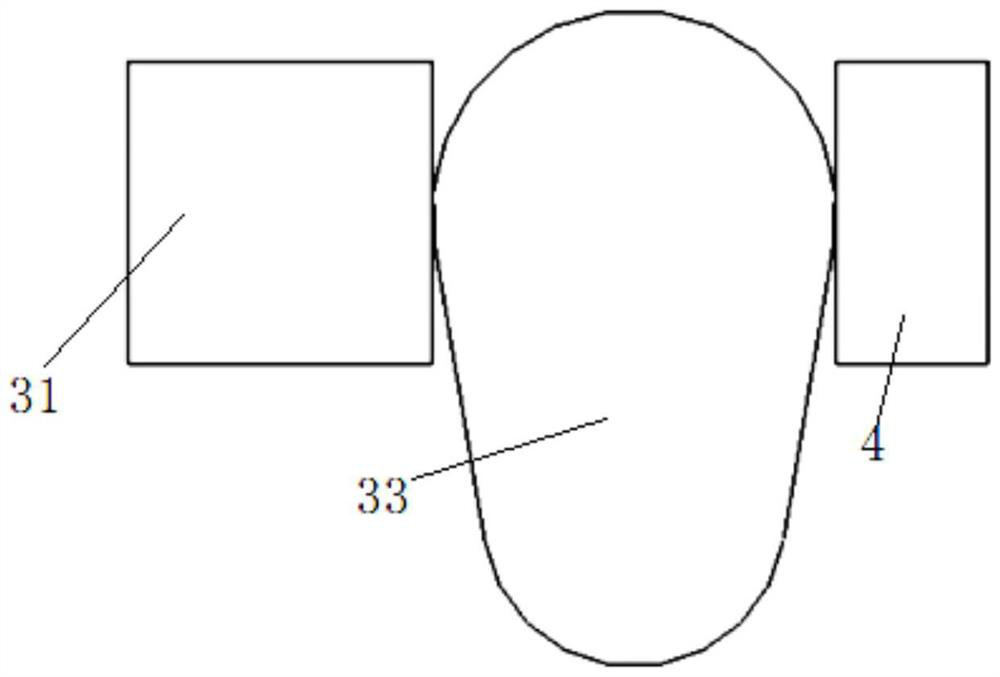

[0033] The tensioner provided in this embodiment includes a base, a rotating drive mechanism and a tensioning assembly. The base serves as a mounting base for the rotating driving mechanism and the tensioning assembly, and the rotating driving assembly provides driving power for the tensioning assembly to realize the tensioning assembly. One-way active rotation on the base. Wherein, the base has an installation cavity; the tensioning assembly is rotatably arranged on the base; the rotation driving mechanism includes a power member, a force transmission member and a cam driven to rotate by the power member; the power member is connected to the base The force transmission member and the cam are both rotatably arranged in the installation cavity of the base; the force transmission member is used for a first contact part that contacts with the cam and a second contact part that acts on the tensioning assembly. At the contact part, when the cam rotates along the rotation axis under...

Embodiment 2

[0045] Based on the same inventive concept, the present embodiment provides a front-end gear train system, including a crankshaft pulley, a compressor pulley, a water pump pulley, a generator pulley, and a crankshaft pulley, a compressor pulley, and a water pump. Belts for pulleys and generator pulleys. In order to realize the adjustment of the basic tension of the front-end gear train system to meet the tension requirements under different working conditions, in this embodiment, the front-end gear train system further includes the tensioner provided in Embodiment 1; The components act on the belt, and other unmentioned structures of the front-end gear train system may refer to the prior art, which will not be repeated in this embodiment.

[0046] The applicant found that in the existing traditional front-end gear train system, the position of the crankshaft, the compressor, the water pump, the generator, and the center point of the tensioner and the diameter of the pulley are...

Embodiment 3

[0050] Based on the same inventive concept, this embodiment also provides a vehicle, including the front-end wheel train system provided in Embodiment 2, which naturally has all the beneficial effects of the above-mentioned front-end wheel train system. The present invention does not specifically limit the type and type of the vehicle, and it can be any vehicle in the prior art, such as a family car, a passenger car, a truck, etc. For other undetailed structures of the vehicle, reference can be made to the relevant disclosures in the prior art , which is not explained here.

[0051] Taking the two-stage tension adjustment as an example, the adjustment control method of the vehicle in this embodiment is as follows:

[0052] The default state of the system is the low tension state. When the user requests the air conditioner to be turned on (press the air conditioner on button), the vehicle electronic control system receives the user's request command, and firstly sends the comma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com