Let-off mechanism, rapier loom comprising same, and control method for let-off mechanism

A warp let-off mechanism and warp let-off technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of inconvenient installation and adjustment, large overall quality, no connection, etc., improve accuracy and stability, and avoid mutual entanglement , Guaranteed directional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

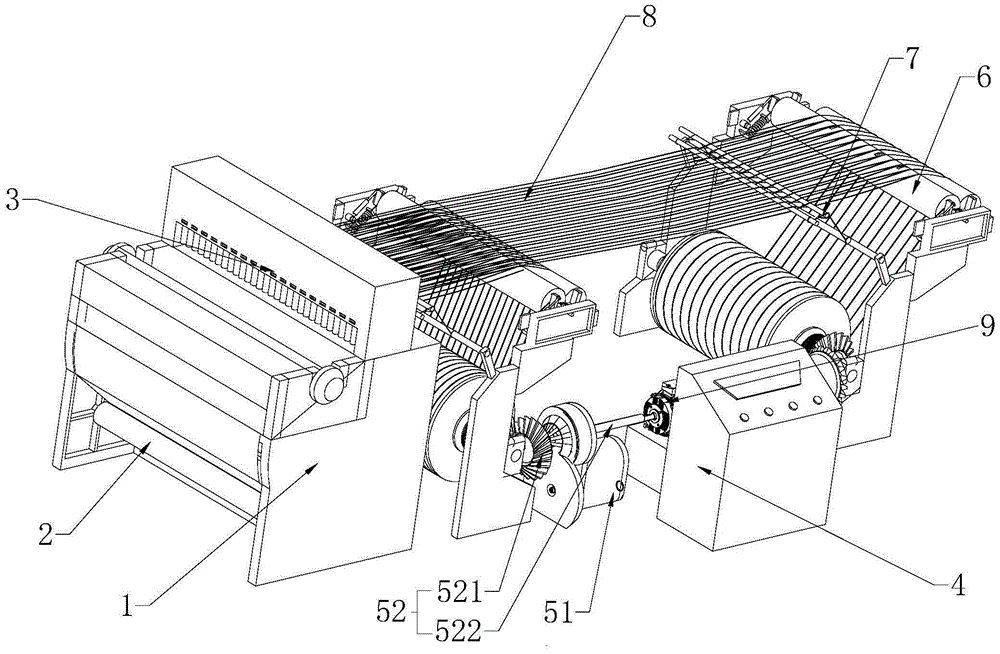

[0046] refer to Figure 2 to Figure 10 The present invention will be further described.

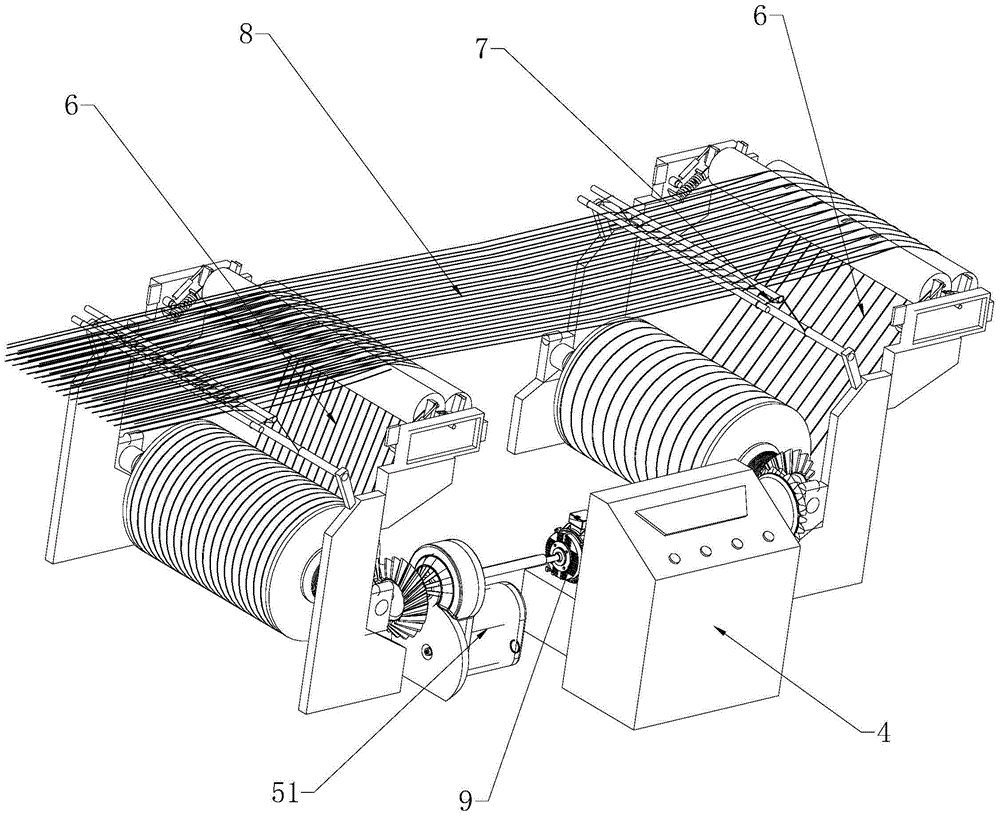

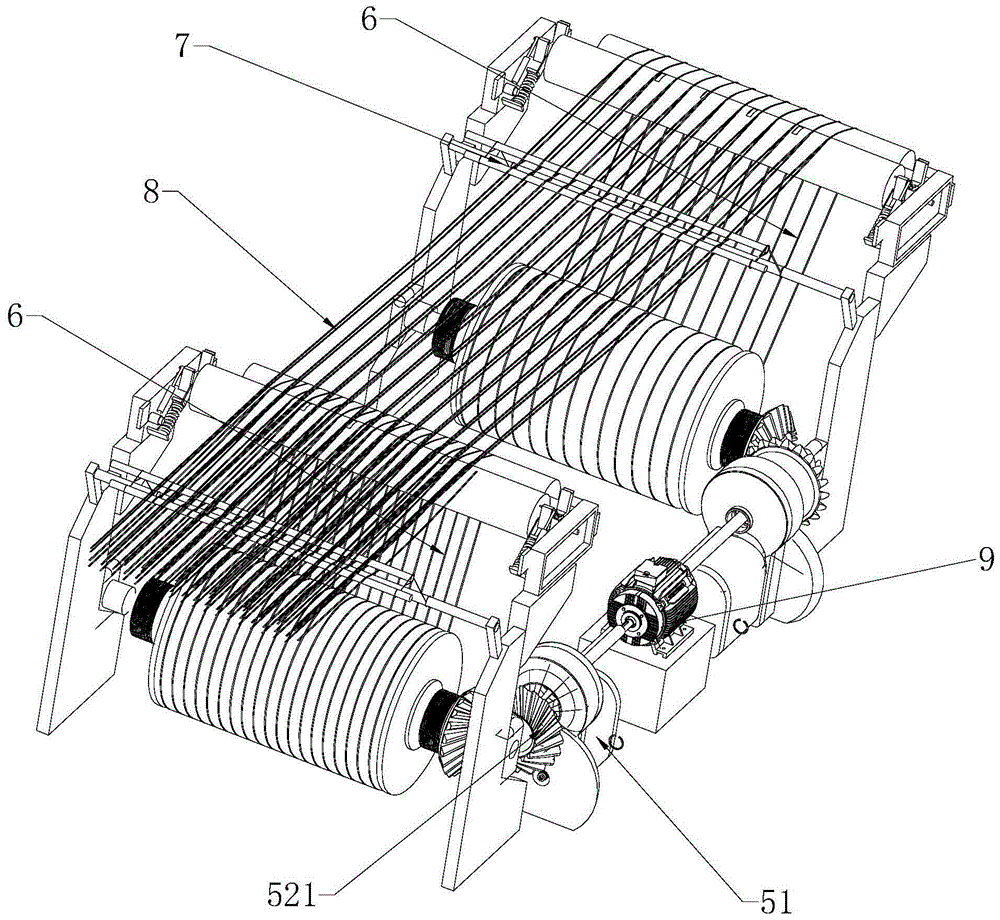

[0047] A warp let-off mechanism, comprising a controller 4 and at least two sets of warp let-off assemblies 6. In this embodiment, two sets of warp let-off assemblies 6 are selected, and the two sets of warp let-off assemblies 6 are arranged side by side in parallel. The warp assembly 6 all includes a warp let-off roller 11, a back beam 12, a dowel bar 13, left and right wall panels 10, and a tension detection unit 14, and the warp let-off roller 11, back beam 12, and dowel bar 13 are all fixed between the left and right wall panels 10 and Be arranged parallel to each other, when let-off, warp yarn 8 breaks away from the let-off roller 11 and passes through back rest 12 and dowel bar 13 successively, as Figure 8 As shown, the tension detection unit 14 includes a tension sensor 142 located on the dowel bar 13 and a tension spring 141 located at both ends of the dowel bar 13. One end of t...

Embodiment approach 1

[0049] Embodiment 1: A drive motor 9 is placed between two sets of let-off assemblies 6, the let-off assemblies 6 are divided into first and second let-off assemblies 6, and a speed changer is placed between the drive motor 9 and the first let-off assemblies 6. Box 51, one end of the drive motor 9 is connected to the gearbox 51 through a linkage rod 522, and the other end of the drive motor 9 is directly connected to the let-off roller 11 of the second let-off assembly 6 through a bevel gear set 521. The gearbox 51 and The let-off shafts on the first let-off assembly 6 are connected in transmission through a linkage rod 522 and a bevel gear set 521 .

Embodiment approach 2

[0050] Embodiment 2: A drive motor 9 is placed between two sets of let-off assemblies 6, and the let-off assemblies 6 are divided into first and second let-off assemblies 6. Between the drive motor 9 and the first let-off assembly 6 and the second let-off assembly A gearbox 51 is placed between the warp components 6, and the two ends of the drive motor 9 are respectively connected to two gearboxes 51 and connected through a linkage rod 522. The gearbox 51 and the warp let-off roller 11 are connected through a linkage rod 522 and a bevel gear set 521. Make drive connections.

[0051] Mode 1 and Mode 2 can both achieve the adjustment effect. Compared with Mode 1 and Mode 2, another gearbox 51 is needed, which saves cost, but the transmission ratio adjustment will also be limited accordingly. Considering the convenience of adjustment, Mode 2 is selected.

[0052] Such as Figure 9 As shown, the surface of each dowel bar 13 is provided with several grooves 131, the grooves 131 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com