Processing method and treatment device for environmental fabric

A processing method and fabric technology, applied in the processing of textile materials, fiber processing, textile and other directions, can solve the problems of different degrees of mercerization, increased hairiness, different alkali soaking, etc., achieve the best feel and stiffness, reduce the use cost, The effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The processing method of this environment-friendly fabric comprises the following steps:

[0057] A. Material preparation: Nylon and rayon are selected.

[0058] B. fabric weaving: the above-mentioned nylon and rayon are woven into a rough fabric, and in step B, nylon accounts for 62% of the entire fabric, and the rayon accounts for 38% of the entire fabric.

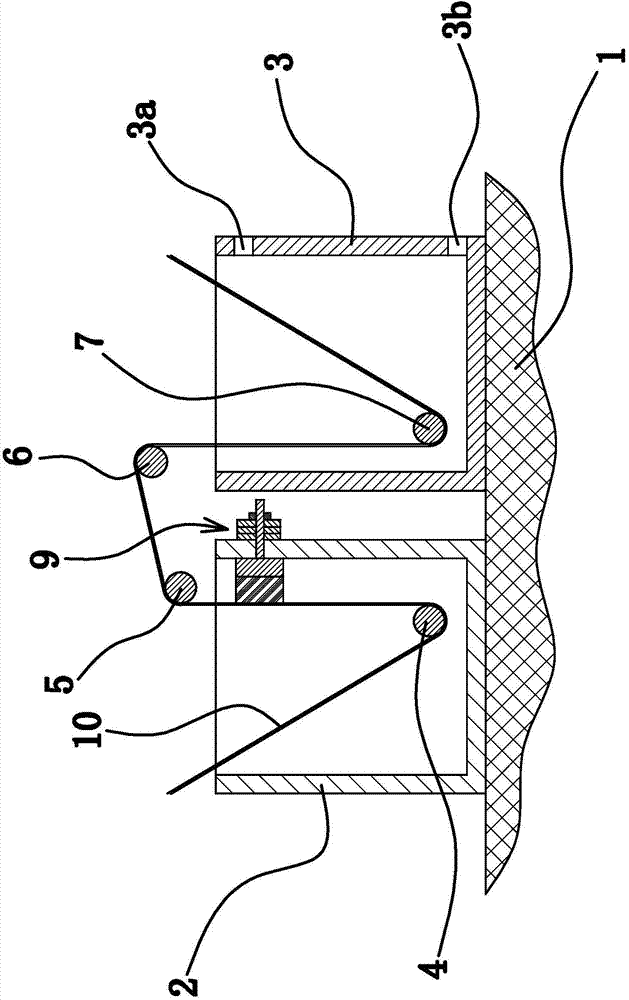

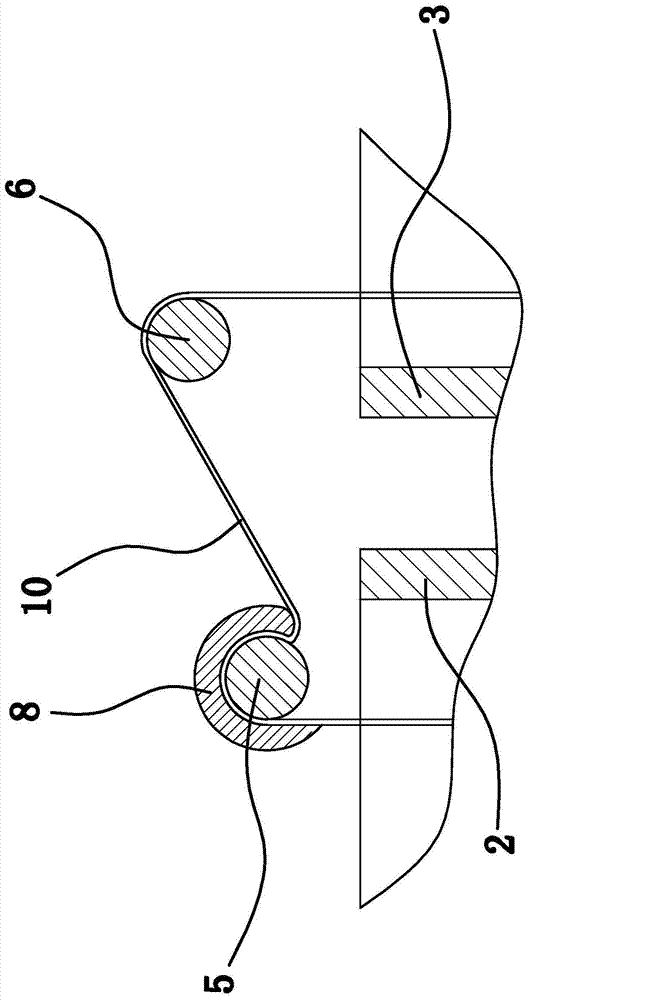

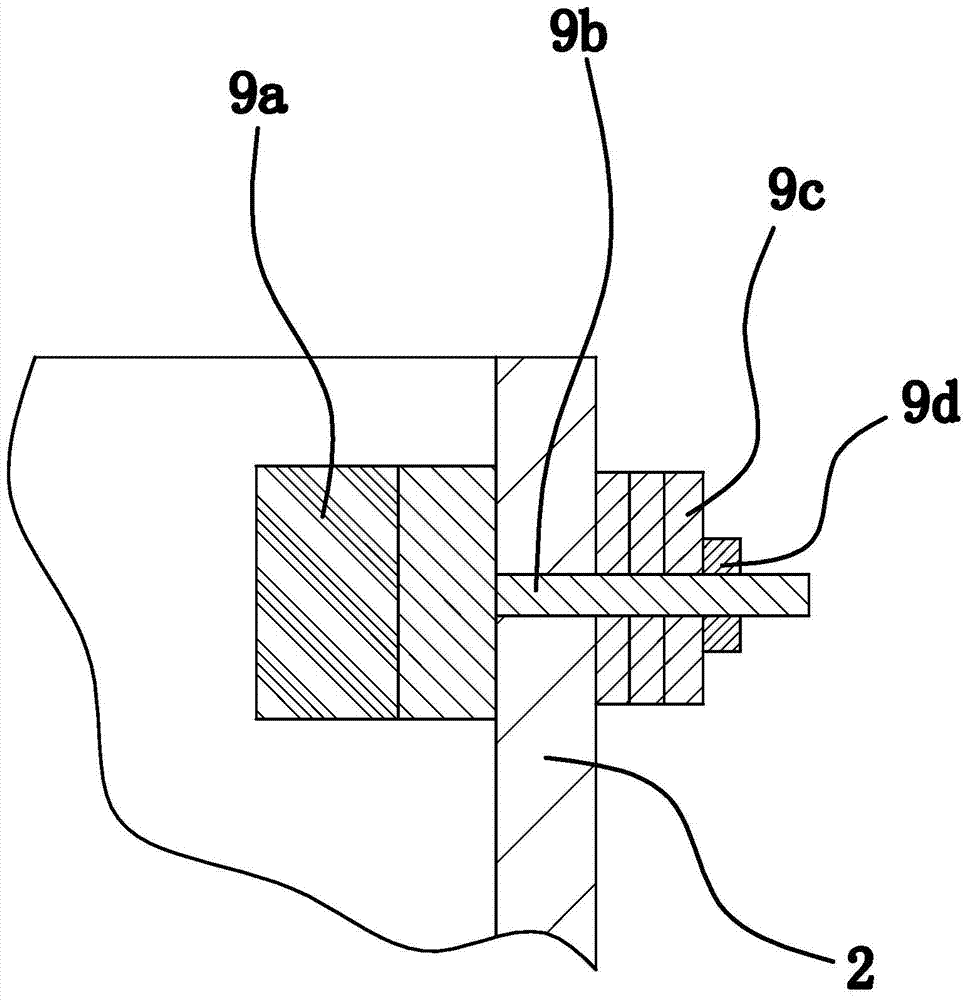

[0059] C. Fabric mercerizing: mercerizing the rough fabric. Specifically, the fabric is first tensioned, then the tensioned fabric is treated with a concentrated caustic soda solution, and then the caustic soda is washed away while the fabric is still under tension.

[0060] The concentration of liquid alkali is 26 degrees Baume, the temperature of liquid alkali is 15°C, the time of mercerizing alkali dipping is 120s, the stretching length is 1%, the temperature of hot water washing is 60°C, and the time of hot water washing is 40s.

[0061] D. Shaping: Pass the mercerized fabric through a baking oven with an in...

Embodiment 2

[0083] The processing method of this environment-friendly fabric comprises the following steps:

[0084] A. Material preparation: Nylon and rayon are selected.

[0085] B. Fabric weaving: the above-mentioned nylon and rayon are woven into a blank fabric. In step B, nylon accounts for 73% of the entire fabric, and the rayon accounts for 27% of the entire fabric.

[0086] C. Fabric mercerizing: mercerizing the rough fabric. Specifically, the fabric is first tensioned, then the tensioned fabric is treated with a concentrated caustic soda solution, and then the caustic soda is washed away while the fabric is still under tension.

[0087] The concentration of liquid caustic soda is 30 degrees Baume, the temperature of liquid caustic soda is 25°C, the soaking time for mercerizing is 180s, the stretching length is 6%, the temperature of hot water washing is 80°C, and the time of hot water washing is 60s.

[0088] D. Shaping: Pass the mercerized fabric through an oven with an intern...

Embodiment 3

[0110] The processing method of this environment-friendly fabric comprises the following steps:

[0111] A. Material preparation: Nylon and rayon are selected.

[0112] B. Fabric weaving: the above-mentioned nylon and rayon are woven into a rough fabric. In step B, nylon accounts for 69% of the entire fabric, and the rayon accounts for 31% of the entire fabric.

[0113] C. Fabric mercerizing: mercerizing the rough fabric. Specifically, the fabric is first tensioned, then the tensioned fabric is treated with a concentrated caustic soda solution, and then the caustic soda is washed away while the fabric is still under tension.

[0114] The concentration of liquid caustic soda is 28 degrees Baume, the temperature of liquid caustic is 21°C, the time of mercerizing alkali dipping is 150s, the stretching length is 4%, the temperature of hot water washing is 70°C, and the time of hot water washing is 50s.

[0115] D. Shaping: Pass the mercerized fabric through a baking oven with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com