Strip winding device, strip winding method and numerical control winding machine

A technology of winding device and winding machine, which is applied in the field of automatic molding of composite materials, can solve the problems of unsightly appearance of winding products, uneven thickness of products, and inability to realize stable control of cloth deformation, so as to reduce monitoring measures and ensure winding The effect of quality, structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

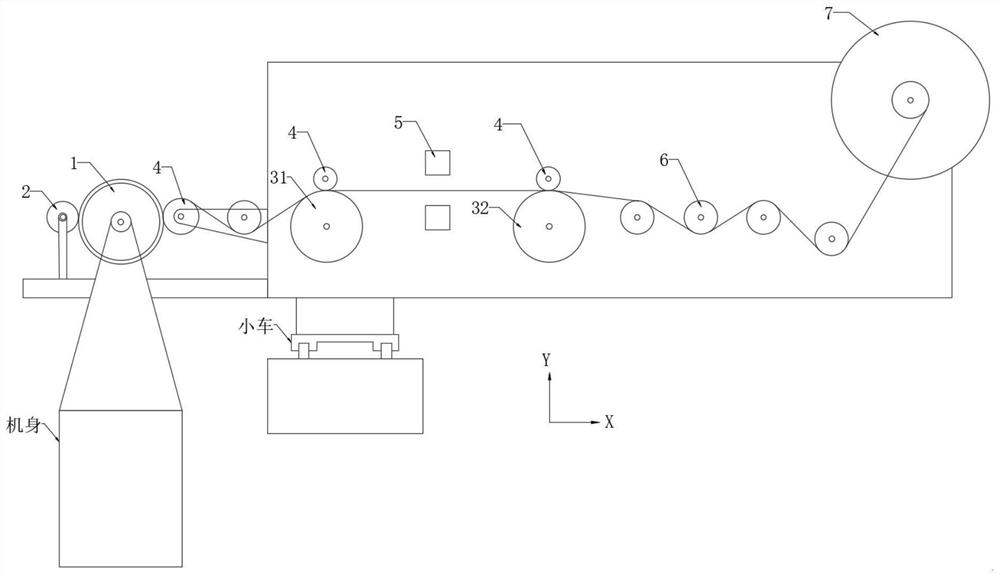

[0031] Such as Figure 1-2 As shown, the present invention provides a winding device based on a numerically controlled winding machine, including a mandrel 1 , a speedometer 2 , a traction assembly 3 , a pressing roller 4 , a width sensor 5 and an unwinding shaft 7 . The mandrel 1 acts as a winding power shaft, and the strip is wound on it through its regular rotation. Velocimeter 2 is used to measure the linear speed of the strip. The traction assembly 3 is used as an active traction device for adjusting the linear velocity of the strip to realize the adjustment of the deformation of the strip, mainly the adjustment of the width of the strip. The pressure roller 4 is used in cooperation with the mandrel 1 and the traction assembly 3, and the pressure roller 4 is also provided in other parts of the strip winding transmission route. The width sensor 5 is used to measure the time width of the acquisition strip. Unwind reel 7 in order to supply strip. specifically:

[0032] ...

Embodiment 2

[0039] Such as Figure 1-2 As shown, this embodiment 2 is a strip winding method based on a numerically controlled winding machine formed on the basis of embodiment 1, which specifically includes the following steps:

[0040] S1, select the strip, preset the winding parameters of the strip, and start the operation program. The strip winding parameters include winding tension, spindle speed, strip deformation, strip width minimum deviation response value, and speed difference between the first pulling roller 31 and the second pulling roller 32 . Wherein preferably, the minimum deviation response value of the strip width is 1-3 mm, particularly preferably 2 mm.

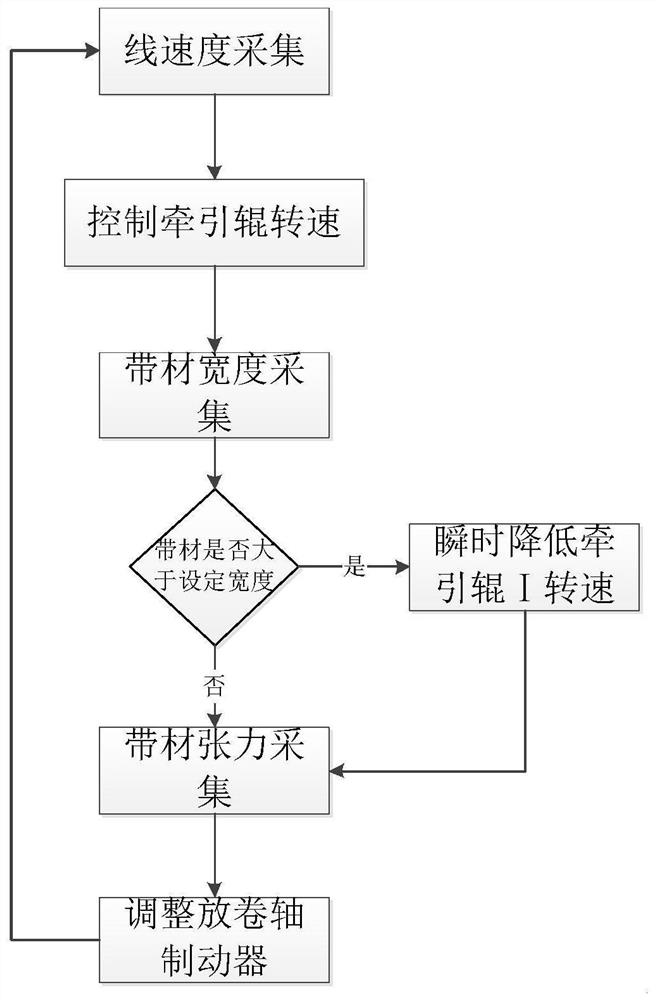

[0041] S2, measuring and maintaining the linear velocity: obtain the linear velocity of the strip through the speedometer 2, and adjust the rotational speeds of the first pulling roller 31 and the second pulling roller 32 to be consistent with the linear velocity of the strip.

[0042]S3, strip deformation control: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com