Middle arranged tension device

A technology of tension device and tension roller, which is applied in other manufacturing equipment/tools, textiles and papermaking, warping machines, etc. It can solve problems such as difficult control, uneven tension of single yarn, large fluctuations in tension of sliver and sheet yarn, etc. To achieve the effect of meeting the tension requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

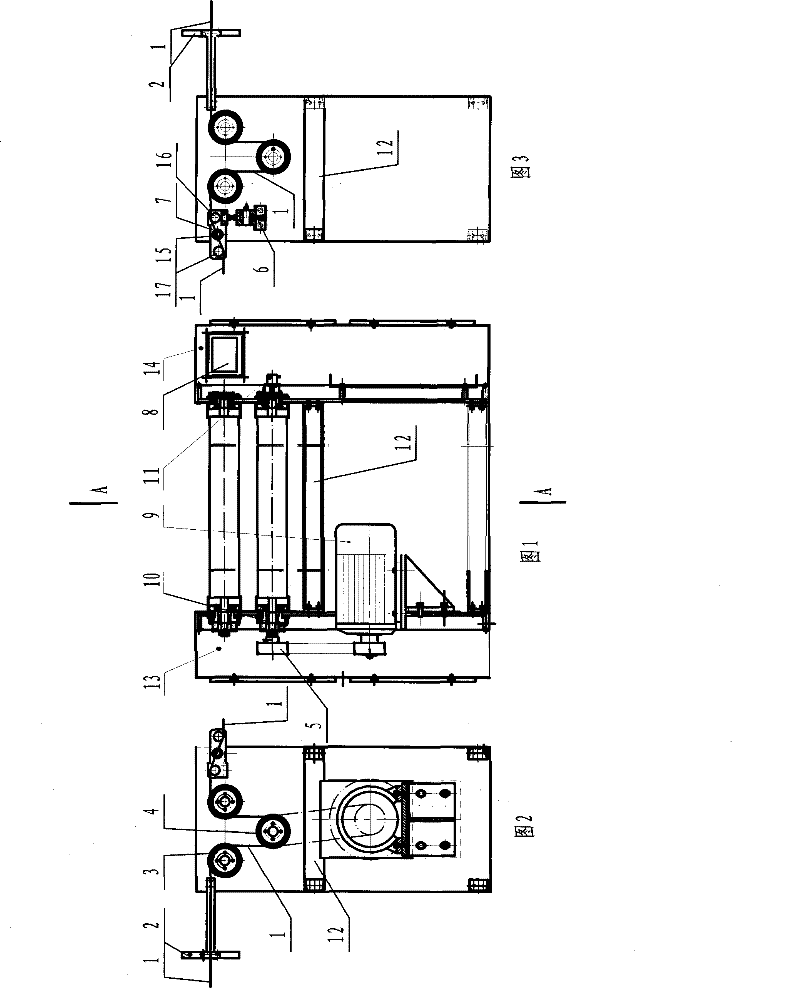

[0014] Describe the present invention in detail below in conjunction with accompanying drawing:

[0015] like Figure 1-3 Shown, this tensioning device comprises motor 9, left box body 13, right box body 14, support beam 12, yarn 1, steel reed 2, guide roller 3, tension roller 4; The support arms are respectively fixed on the inner side of the yarn 1 input port of the left box body 13 and the right box body 14 wallboards; On the wallboard, the left box body 13 and the right box body 14 are connected by support beams 12 to form a whole. Motor 9 axles are connected with the rotating shaft of tension roller 4 one ends by synchronous pulley 5 and synchronous belt. Electromagnetic brakes 10 are respectively provided at one end of the two guide rollers 3 and the tension roller 4; a rotary encoder 11 is also arranged at the other end of the tension roller 4.

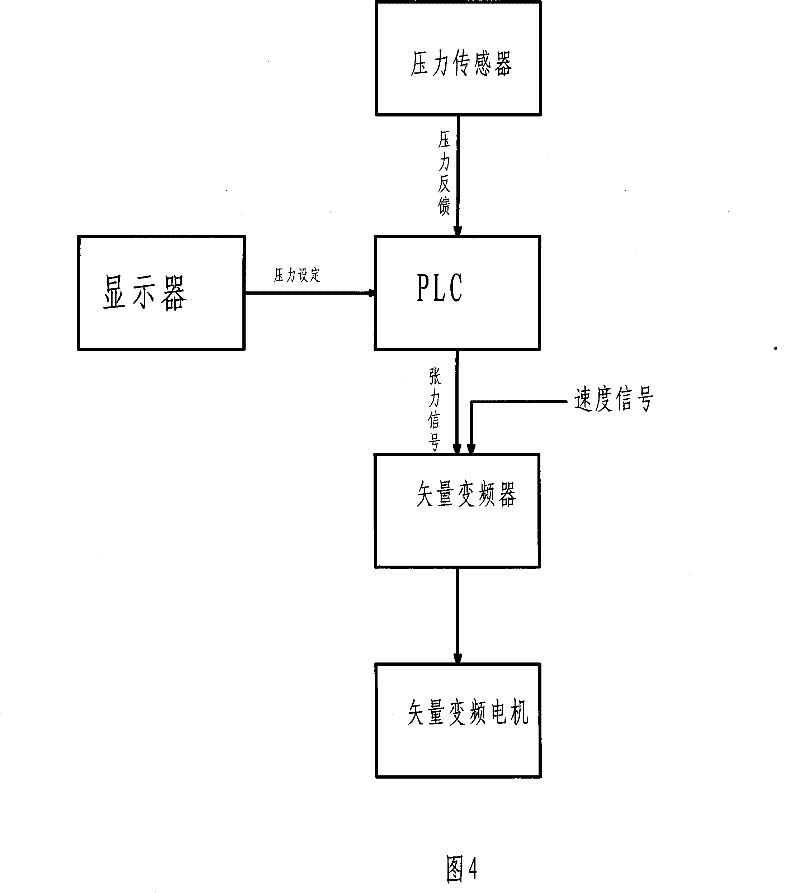

[0016] Motor 9 is a vector frequency conversion motor that can be electrically connected with the automatic speed control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com