Elevator traction steel belt testing method and device

A technology of traction steel belt and elevator traction, which is applied in the field of elevators, can solve the problems of complex measurement mechanism, difficult measurement, low efficiency, etc., and achieve the effect of intuitive load force and improved test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

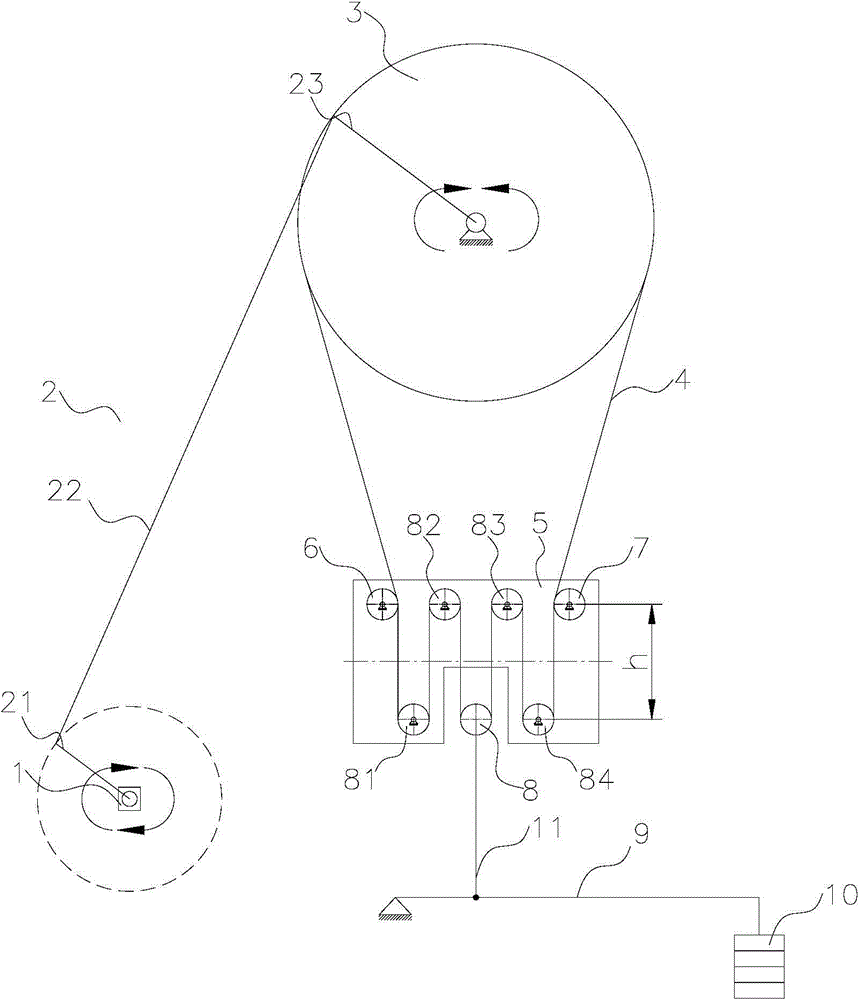

[0026] In this example, if figure 1 As shown, the device includes: a motor 1 . A crank rocker mechanism 2 linked with the motor 1 . The driving wheel 3 is connected with the crank rocker mechanism 2, so that the rotation of the motor is converted into the reciprocating rotation of the driving wheel, thereby driving the traction steel belt 4 to be tested to reciprocate. Five pulleys 81, 82, 8, 83, 84 are located below the drive pulley 3, arranged in waves in two rows and installed on the pulley mounting plate 5, wherein the pulley 8 in the middle is a movable pulley, and the others are fixed pulleys. pulley. The pulley mounting plate 5 is provided with a plurality of pulley mounting holes, and the pulley mounting holes are vertical elongated holes for adjusting the vertical position of the pulley. Wrap angle adjustment wheels 6, 7 are respectively arranged on both sides of the pulleys 81, 84 to ensure that the wrap angle of the pulleys on the outermost two sides is 180°. Th...

Embodiment 2

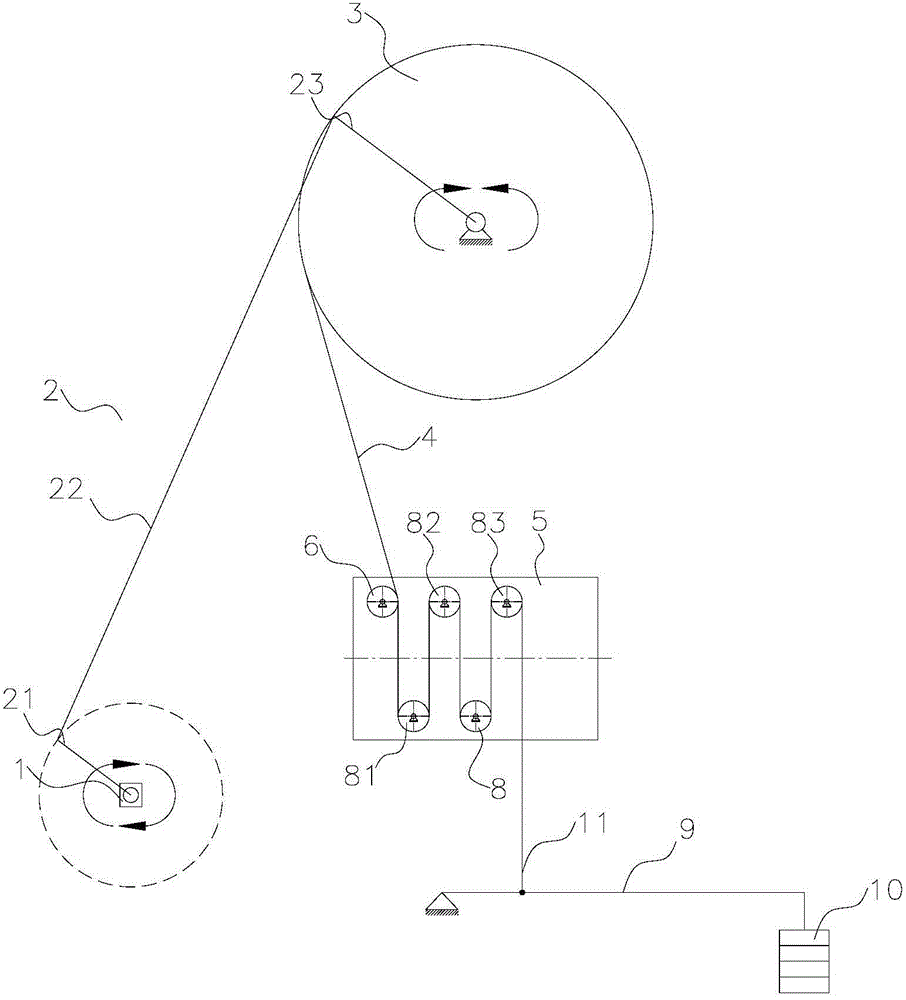

[0032] like figure 2 As shown, the driving wheel 3 is located above the pulleys 81 , 82 , 8 , 83 . Pulleys 81, 82, 8, and 83 are fixed pulleys, which are respectively installed on the vertical strip holes of the pulley mounting plate 5, and the outside of the pulley 81 is also provided with an angle adjustment wheel 6.

[0033] The traction steel belt 4 to be tested has a long strip structure, and the head end is fixed on the driving wheel 3. After the middle section passes through the wrapping angle adjustment wheel 6, the front and back sides go around the pulleys 81, 82, 8, 83 in sequence. The lead steel belt 4 bypasses the last pulley 83 from above, and the counterweight mechanism is directly fixed on the tail end of the lead steel belt 4 to be tested to apply a load force to it, including a lever 9 and a weight 10, and one end of the lever 9 is fixed , the other end is equipped with a weight 10, and the middle part is suspended on the tail end of the traction steel belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com