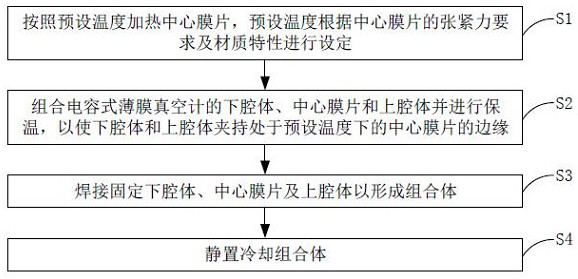

Thin film welding method of capacitive thin film vacuum gauge

A welding method and vacuum gauge technology, applied in the field of measuring instruments, can solve problems such as restricting product qualification rate, difficult to control tension force, and no technical solutions, so as to avoid randomness, improve product qualification rate, and simplify production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

Embodiment 2

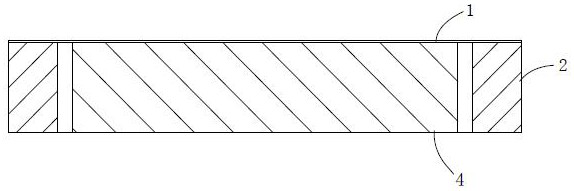

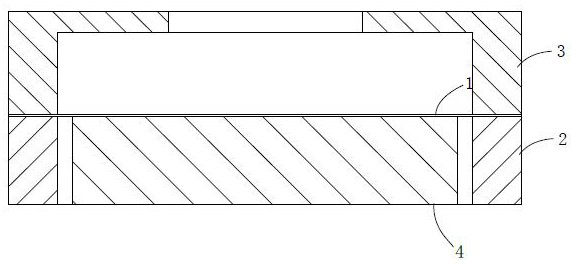

[0079] To sum up, the embodiments of the present application provide a film welding method for a capacitive film vacuum gauge, which utilizes the thermal expansion and cold contraction characteristics of the central diaphragm 1 to weld the heated central diaphragm 1, so that the static cooling is performed. The central diaphragm 1 in the latter assembly has a tensioning force that meets the requirements of the tensioning force, which avoids the tensioning treatment of the tensioning equipment, and also avoids the randomness caused by the stress coupling during the tensioning treatment and the welding treatment. It can make the central diaphragm 1 meet the processing quality requirements of the capacitive thin film vacuum gauge, effectively improve the product qualification rate, and simplify the production process of the capacitive thin film vacuum gauge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com