Film manufacturing process

A manufacturing process and film technology, applied in the field of film production equipment, to achieve the effect of avoiding rewinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments.

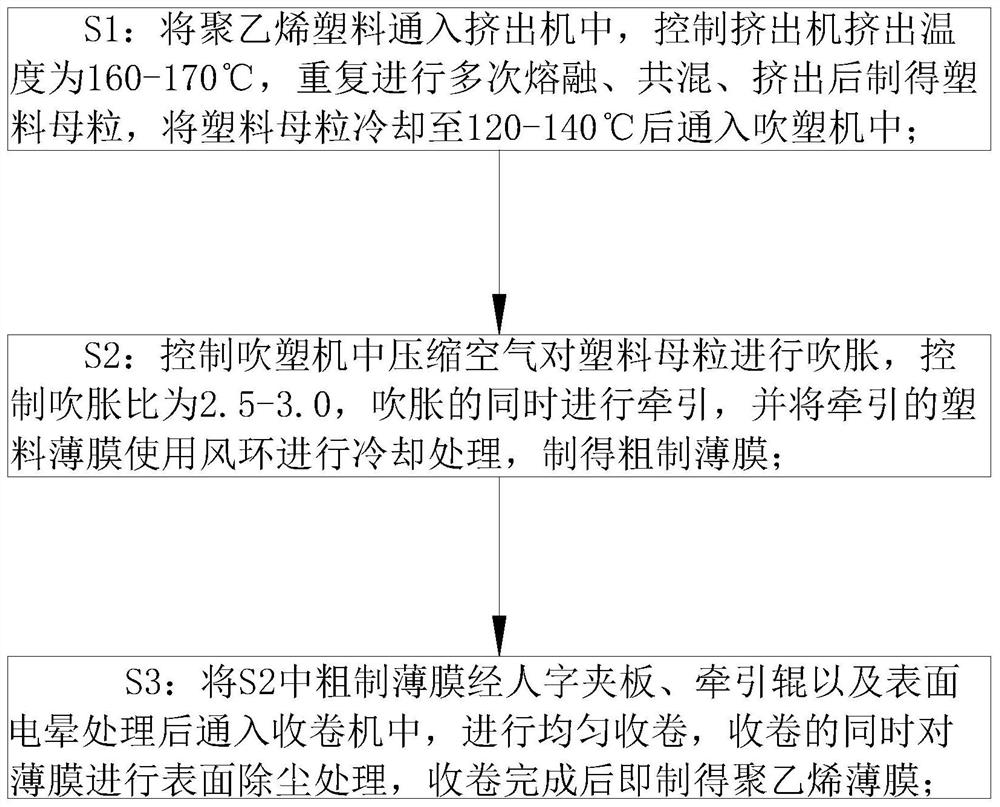

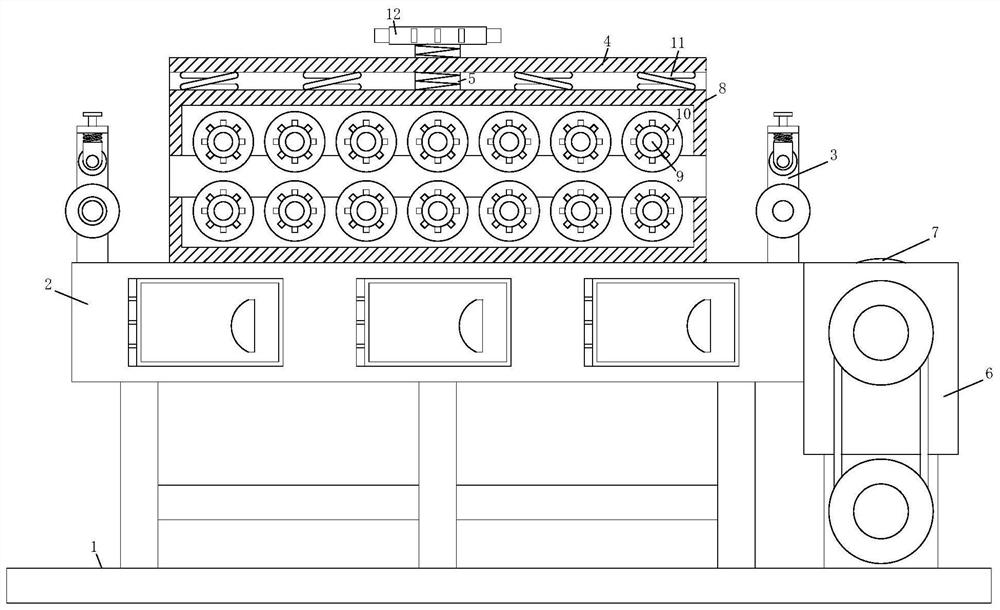

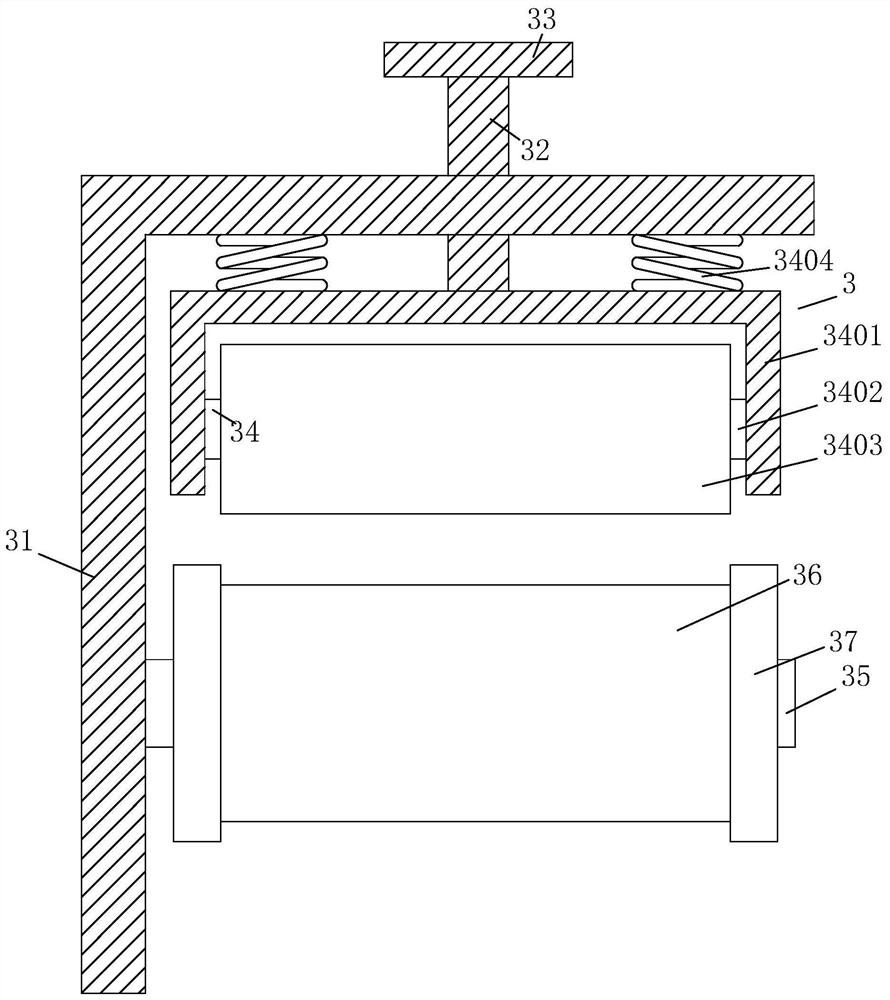

[0031] Such as Figure 1-Figure 8 As shown, a thin film manufacturing process according to the present invention includes the following steps:

[0032] S1: Feed polyethylene plastic into the extruder, control the extruder temperature to 160-170℃, repeat the melting, blending, and extruding for many times to prepare the plastic masterbatch, and cool the plastic masterbatch to Pass into the blow molding machine after 120-140℃;

[0033] S2: Control the compressed air in the blow molding machine to inflate the plastic masterbatch, control the inflation ratio to 2.5-3.0, carry out traction while inflating, and use the air ring to cool the hauled plastic film to obtain a rough film;

[0034] S3: Pass the rough film in S2 into the winder after undergoing ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com