Synchronous driving type automatic charging pile

An automatic charging and synchronous driving technology, which is applied in electric vehicle charging technology, charging stations, electric vehicles, etc., can solve the problems of ineffective line management, long charging lines, thick and difficult to manage, etc., to achieve convenient and smooth delivery or Winding storage, novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

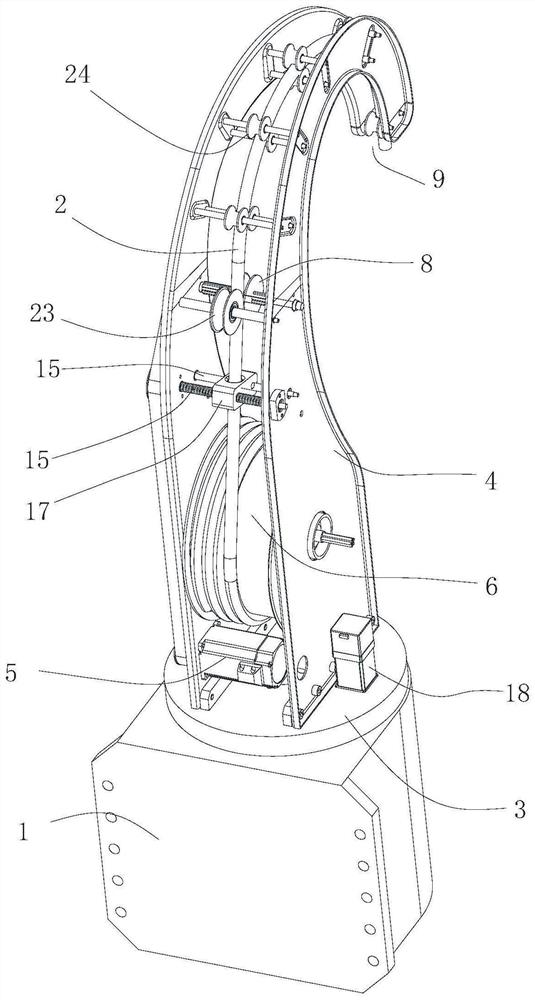

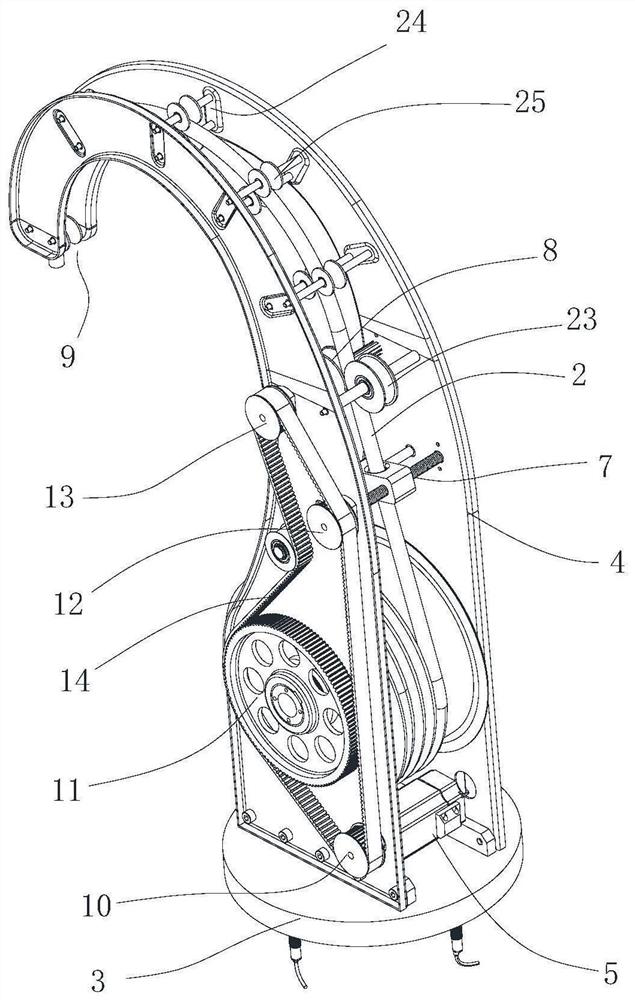

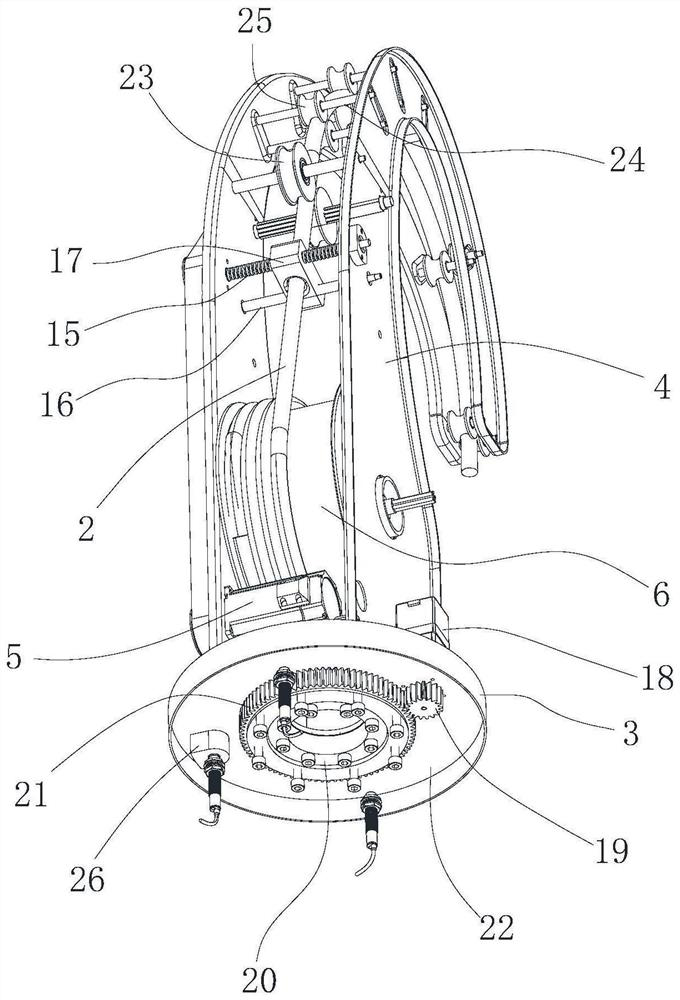

[0029] A synchronously driven automatic charging pile, such as Figure 1 to Figure 3 As shown, it includes a base 1, a charging cable 2, a rotating platform 3 mounted on the base 1 and a hanging arm 4 installed on the base 1; Wire winding wheel 6, synchronous transmission assembly, wire management assembly 7 and friction wheel 8;

[0030] The take-up and pay-off drive member 5 is installed on the hanging arm 4, the take-up winding wheel 6 is rotatably arranged on the end of the hanging arm 4 close to the turning table 3, and the end of the hanging arm 4 away from the turning table 3 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com