Bending method of air conditioning condenser and press brake

A technology of air-conditioning condenser and condenser, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration and liquefaction, etc., can solve the problems of easy rewinding of fins, large bending moment, rewinding, etc., and achieves low relative pressure, The effect of small bending moment and easy film rewinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

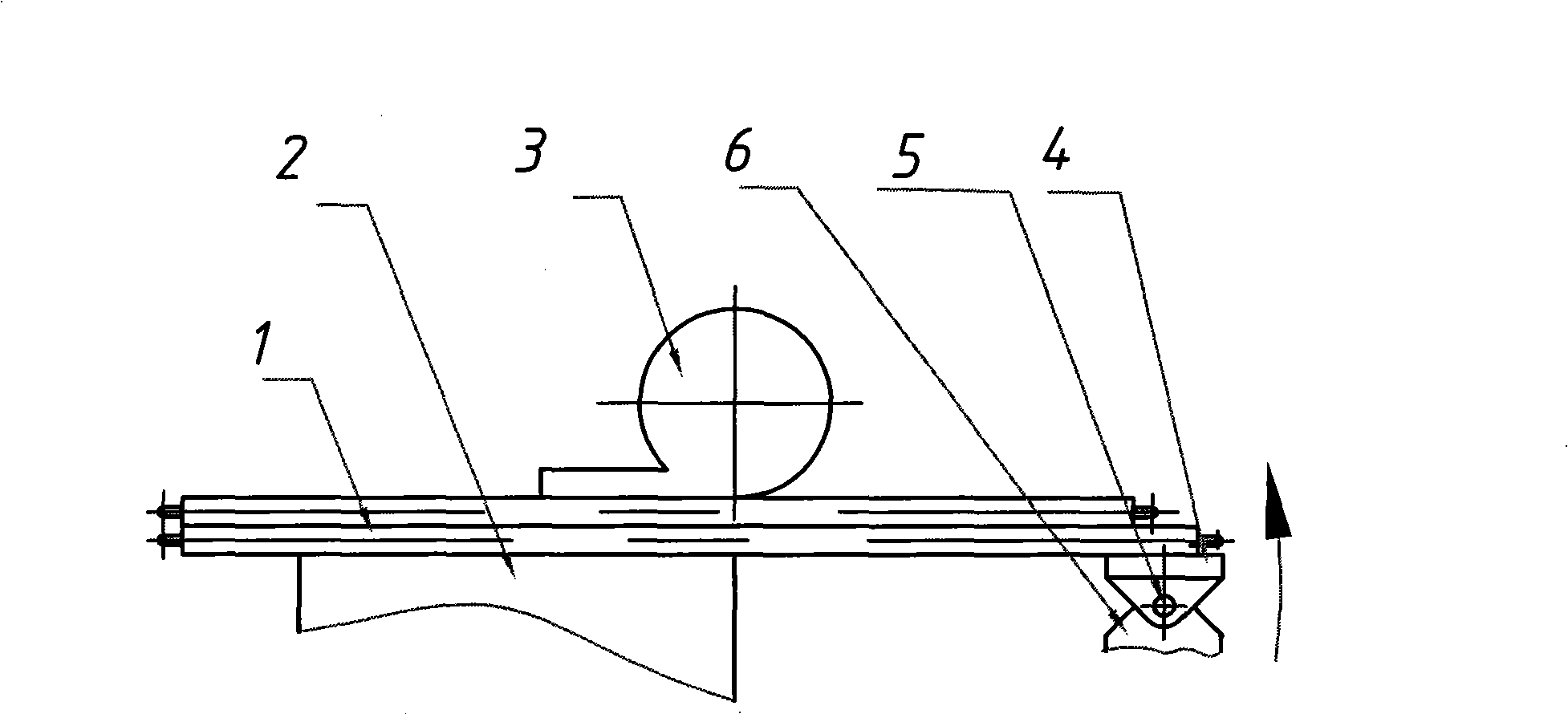

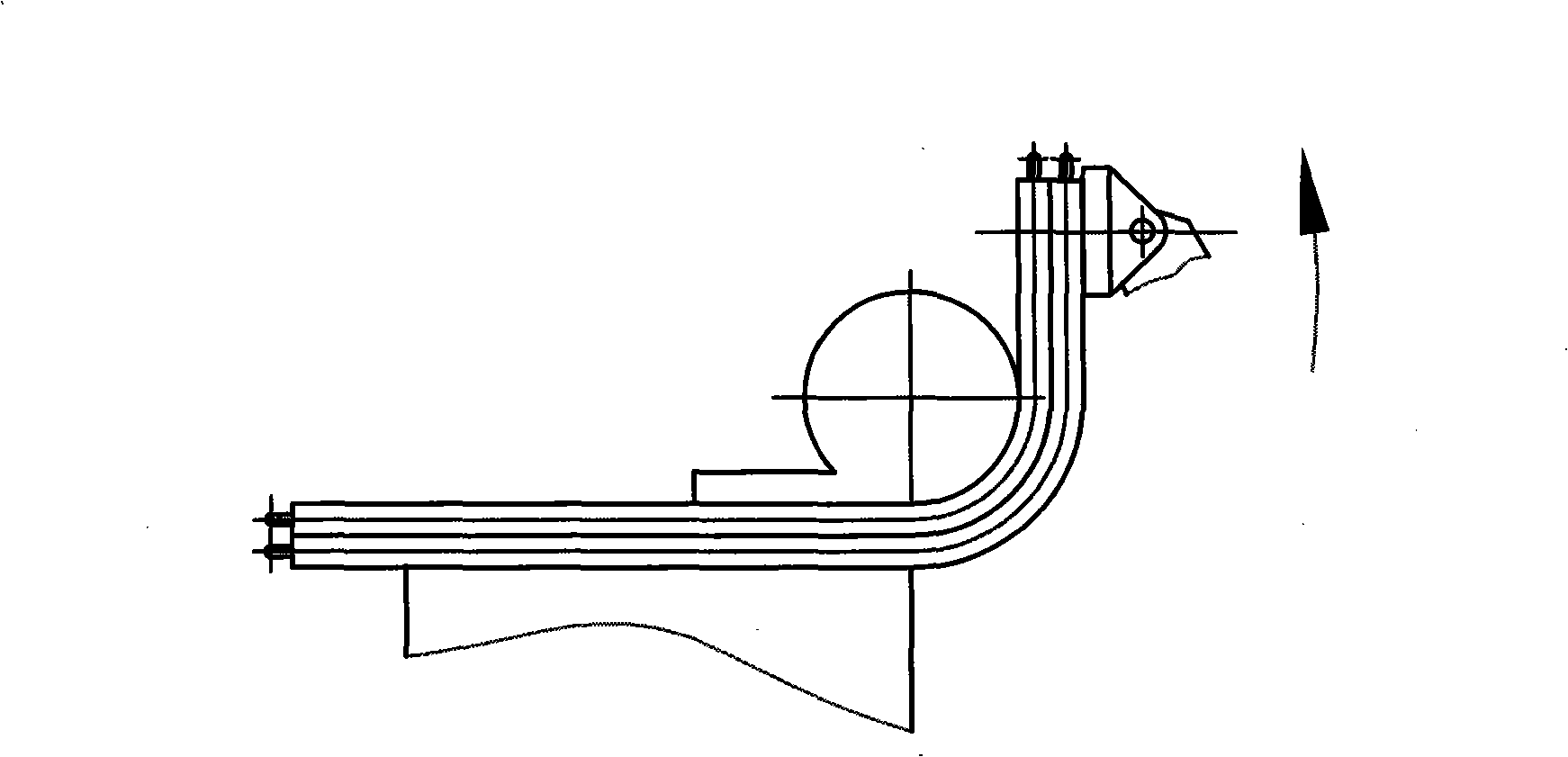

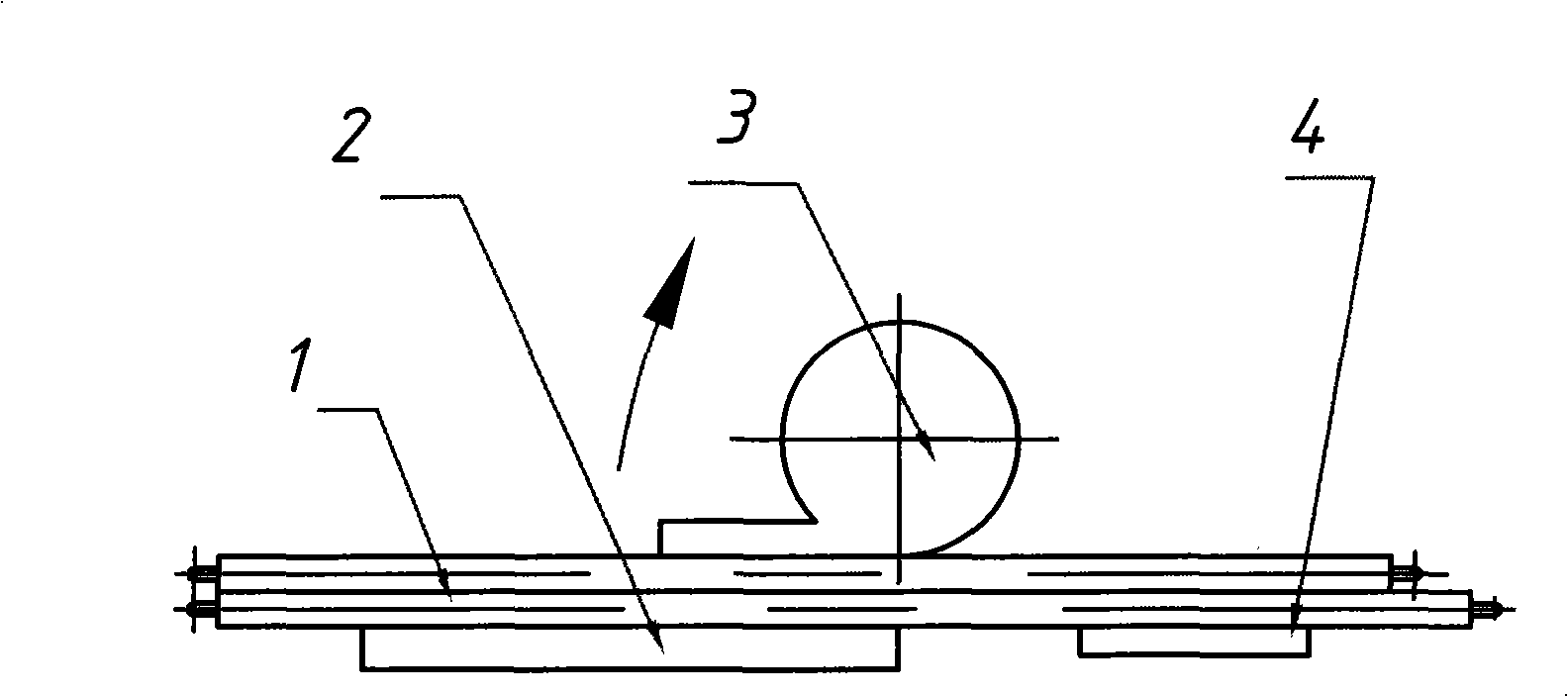

[0037] Such as Figure 5 As shown in the bending method of the air conditioner condenser, one side of the condenser plate 1 is pressed on the bending die 3 by the clamping frame 2, and the other side is supported by the bending plate 4, and the clamping frame 2 and the bending die 3 are controlled by the rotating mechanism (Fig. (not shown in) rotation, described bent plate 4 is moved horizontally by moving device, and its speed is equal to the linear velocity when the bottom condenser sheet turns around on the bending die.

[0038] When the bending machine is working, during the bending process of the condenser sheet 1, due to the moving speed of the bending plate 4 along the X direction and the linear speed of the bottommost condenser sheet turning around on the bending die, the rotation speed of the condenser sheet 1 The distance is equal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com