Energy-saving and environment-friendly plastic cold pelletizing system

An energy-saving and environmentally-friendly plastic technology, which is applied in the direction of drying solid materials, drying solid materials without heating, and filtering and sieving, can solve the problems of shortening the life of the granulator, high energy consumption, and production concepts that do not conform to energy-saving and environmental protection, and achieve The effect of avoiding overlapping bonding and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

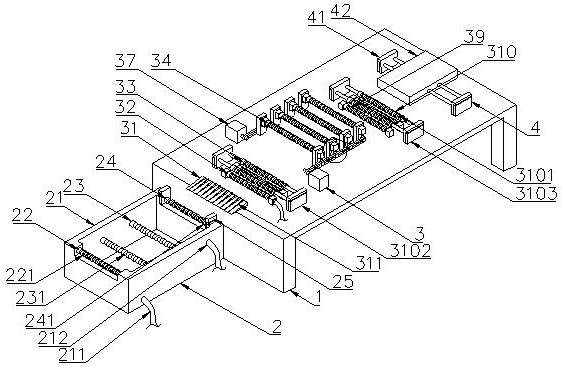

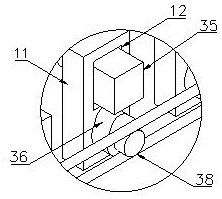

[0025] For a clearer representation, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] see figure 1 and figure 2 As shown, an energy-saving and environment-friendly plastic cold pelletizing system of the present invention includes a frame and a water-cooling mechanism, a screening mechanism and a pelletizing mechanism sequentially arranged on the frame along the first direction;

[0027] The water-cooling mechanism includes a water-cooling box, a separation roller, a first guide roller and a draining roller. The water-cooling box is arranged on one side of the machine. The inside of the water-cooling box is hollow and open at the top. water, the side wall of the water-cooled box is respectively provided with an inlet pipe and an outlet pipe connected with the inner cavity of the water-cooled box; Above, the separation roller, the first guide roller and the drain roller are all perpendicular to the first direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com