Anti-reversing device for air conditioning heat exchanger core L-shaped bending machine

A heat exchanger and bending machine technology, applied in the direction of heat exchange equipment, etc., can solve the problems of difficult to meet product quality requirements, unsatisfactory product qualification rate, no fin protection, etc., to improve quality and qualified rate, The effect of saving production costs and avoiding film rewinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

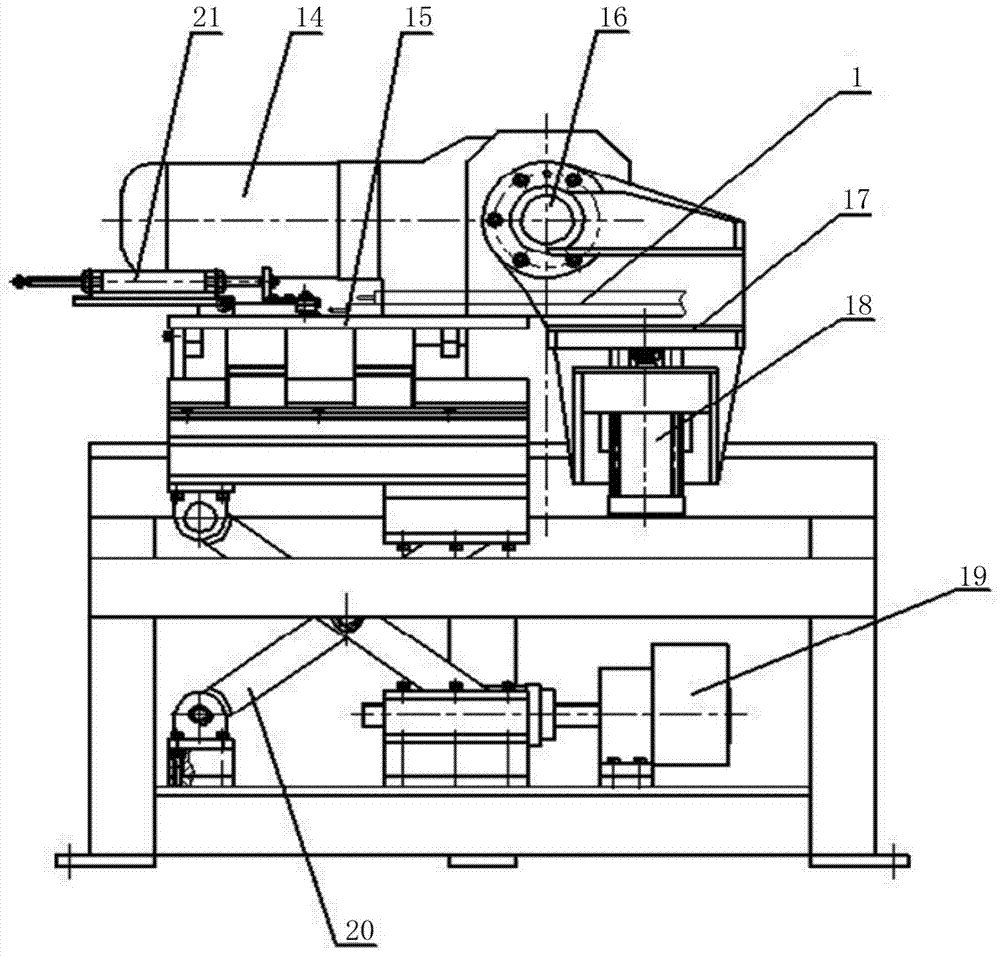

[0014] The invention provides an anti-reversal device for an L-shaped bending machine for the core body of an air-conditioning heat exchanger. The installation position on the L-shaped bending machine is as follows: image 3 shown.

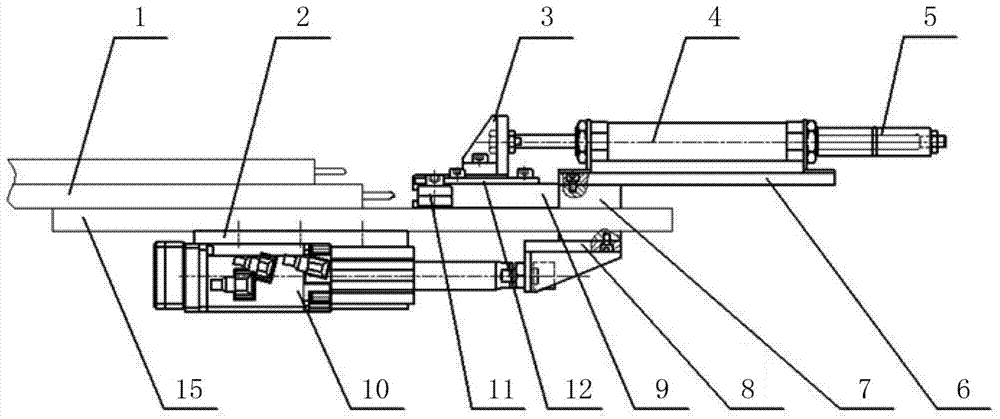

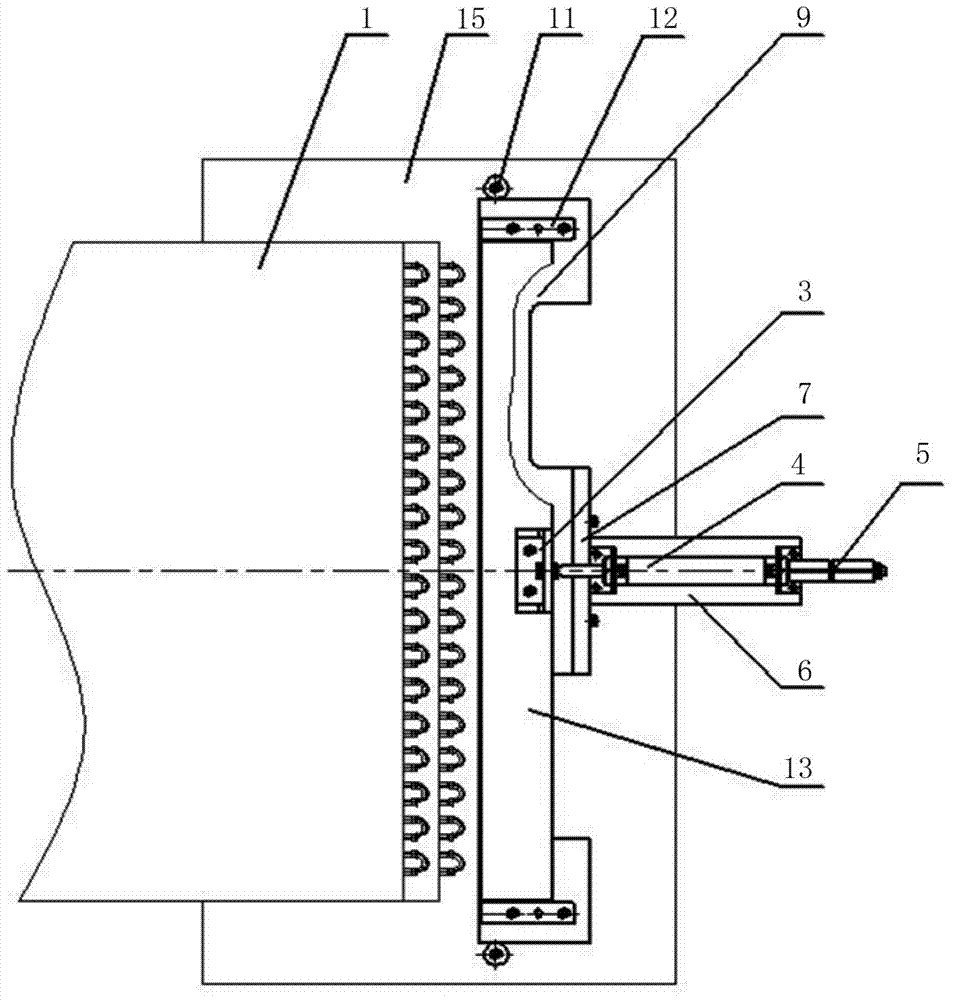

[0015] Such as Figure 1-Figure 4 As shown, the technical solution of the present invention can be realized in the following manner: the composition of the anti-reversal device 21 for an L-type bending machine includes an electric cylinder mounting seat 2, a cylinder connecting seat 3, a cylinder 4, a cylinder limit sleeve 5, and a cylinder installation Plate 6, connecting plate 7, electric cylinder connecting plate 8, lower plate 9, electric actuator 10, bearing 11, guide block 12 and upper plate 13. Among them, the electric cylinder mounting base 2 is fixed to the worktable 15 of the L-shaped bending machine through fasteners, the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com