Ripple runner sand washing moving bed sand filter and water treatment process thereof

A technology of sand filter and sand washer, which is applied in the field of corrugated channel sand washing moving bed sand filter and its water treatment process, can solve the problems of water quality deterioration, shorten the filtration cycle, increase the resistance of the filter layer, etc., and achieve pipeline and The valve is simple, realizes unmanned operation, and improves the effect of effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

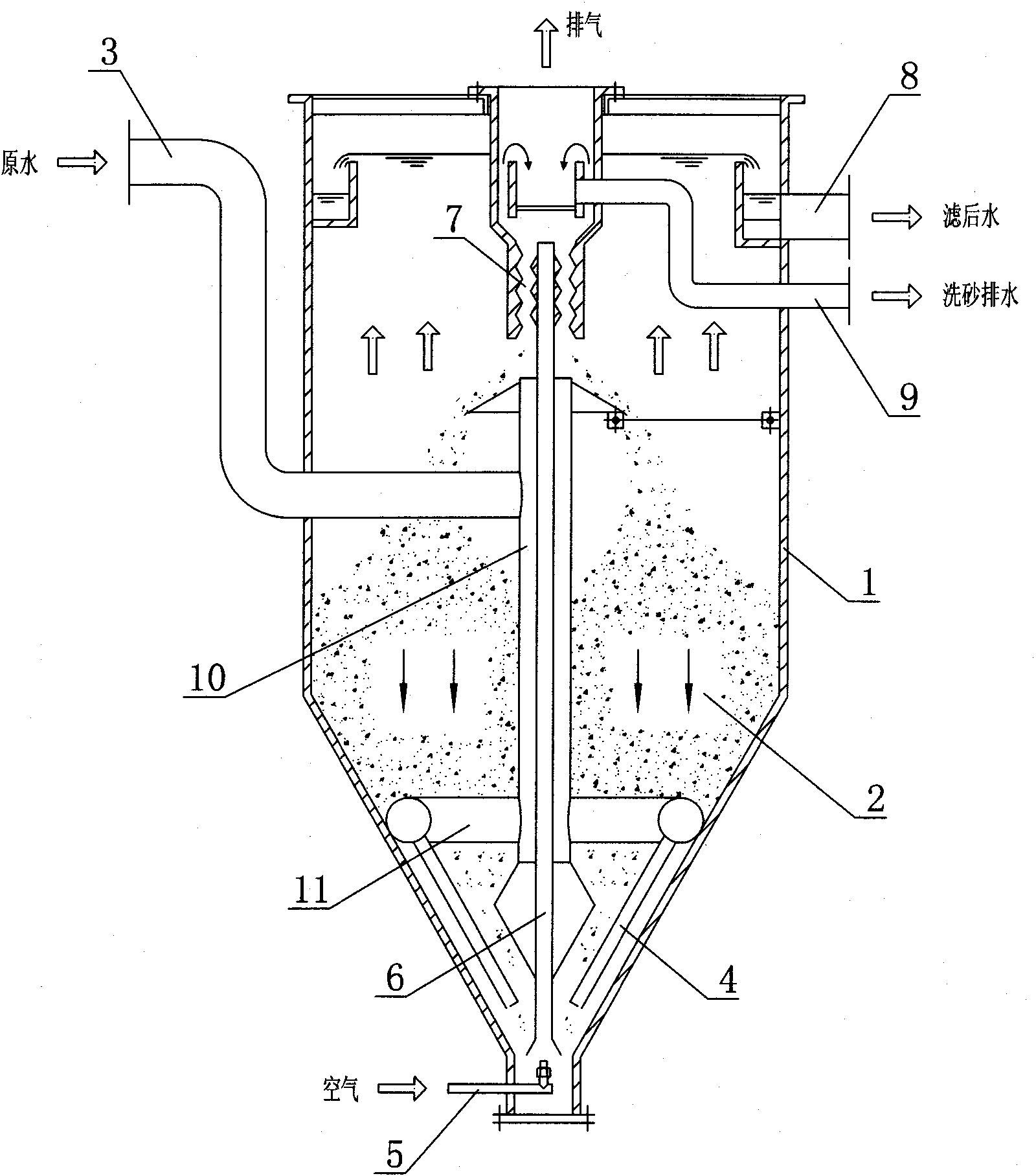

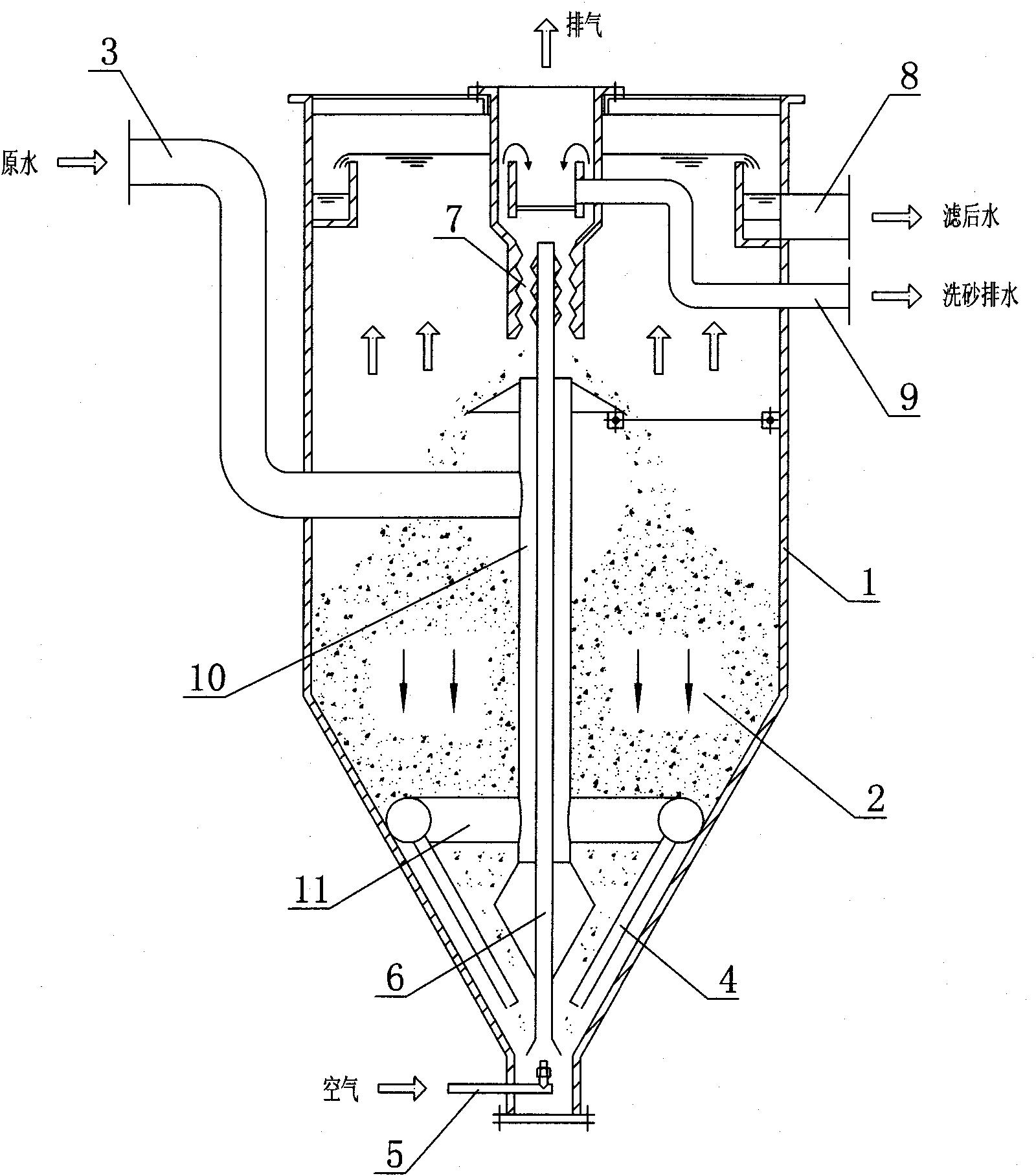

[0014] The corrugated channel sand washing moving bed sand filter and its water treatment process of the present invention are realized in this way, which will be described in detail below in conjunction with the accompanying drawings.

[0015] See figure 1 , the moving bed sand filter with corrugated channel sand washing of the present invention is composed of: sand filter shell 1, filter sand 2, water inlet pipe 3, water distribution branch pipe 4, air pipe 5, sand lifting pipe 6, corrugated channel sand washer 7. Outlet pipe 8, sand washing and drainage pipe 9, water inlet central standpipe 10 and water distribution ring pipe 11. The upper part of the sand filter outer shell 1 is cylindrical and the lower part is inverted cone. There is filter sand 2, and filter sand 2 is the main material for purifying and filtering raw water. The particle gradation of the sand filter material is selected according to the water quality of the raw water and the water quality requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com