Sheet-material automatic positioning system

An automatic positioning and sheet material technology, which is applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as personal injury, unsafe operation process, and inability to guarantee the repeat positioning accuracy of sheet materials, so as to improve efficiency and repeat The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

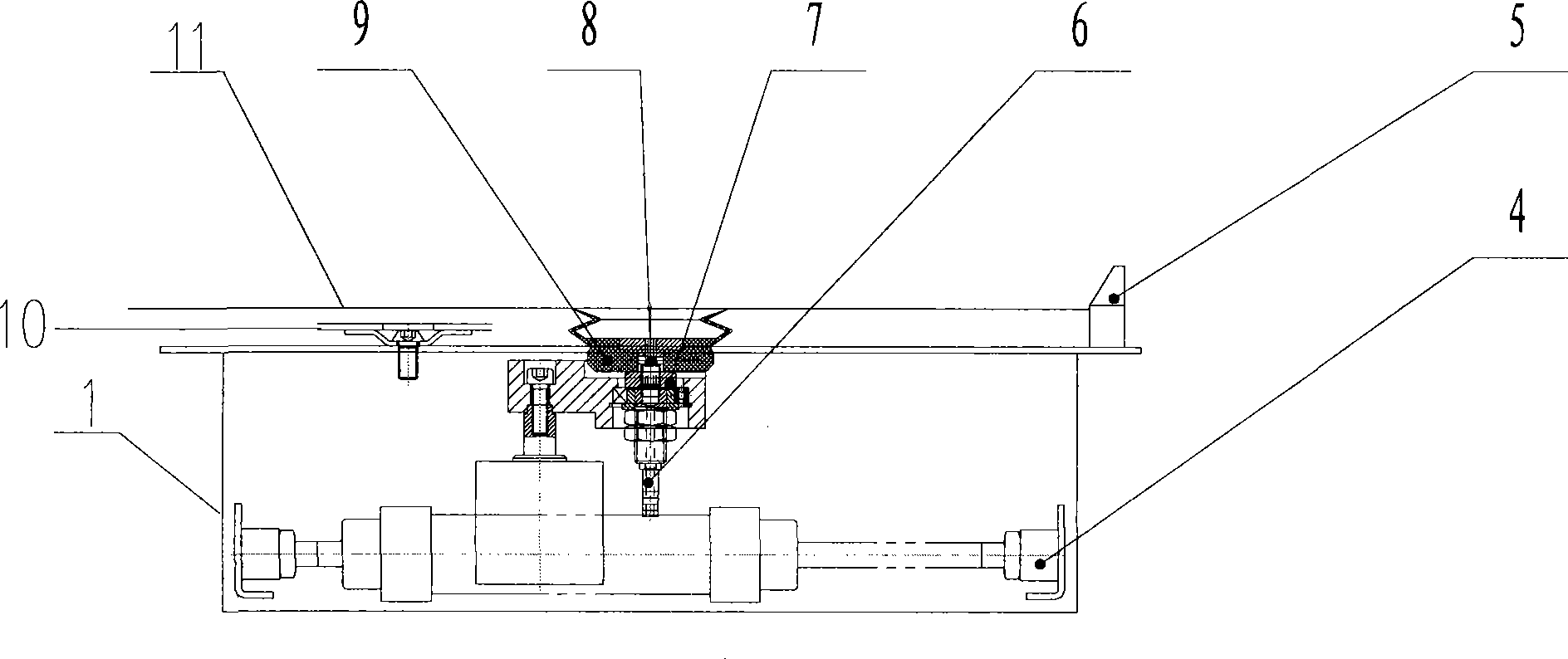

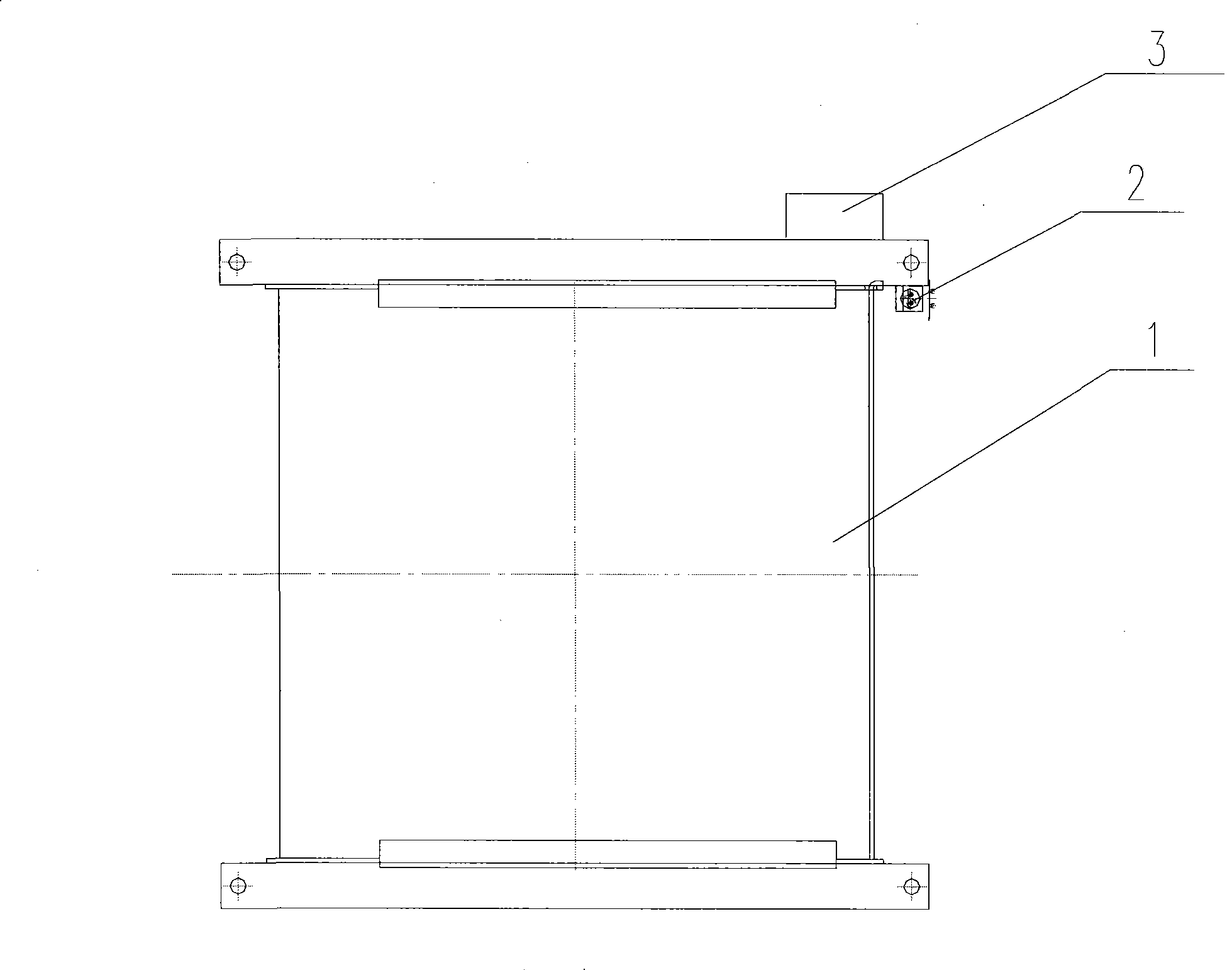

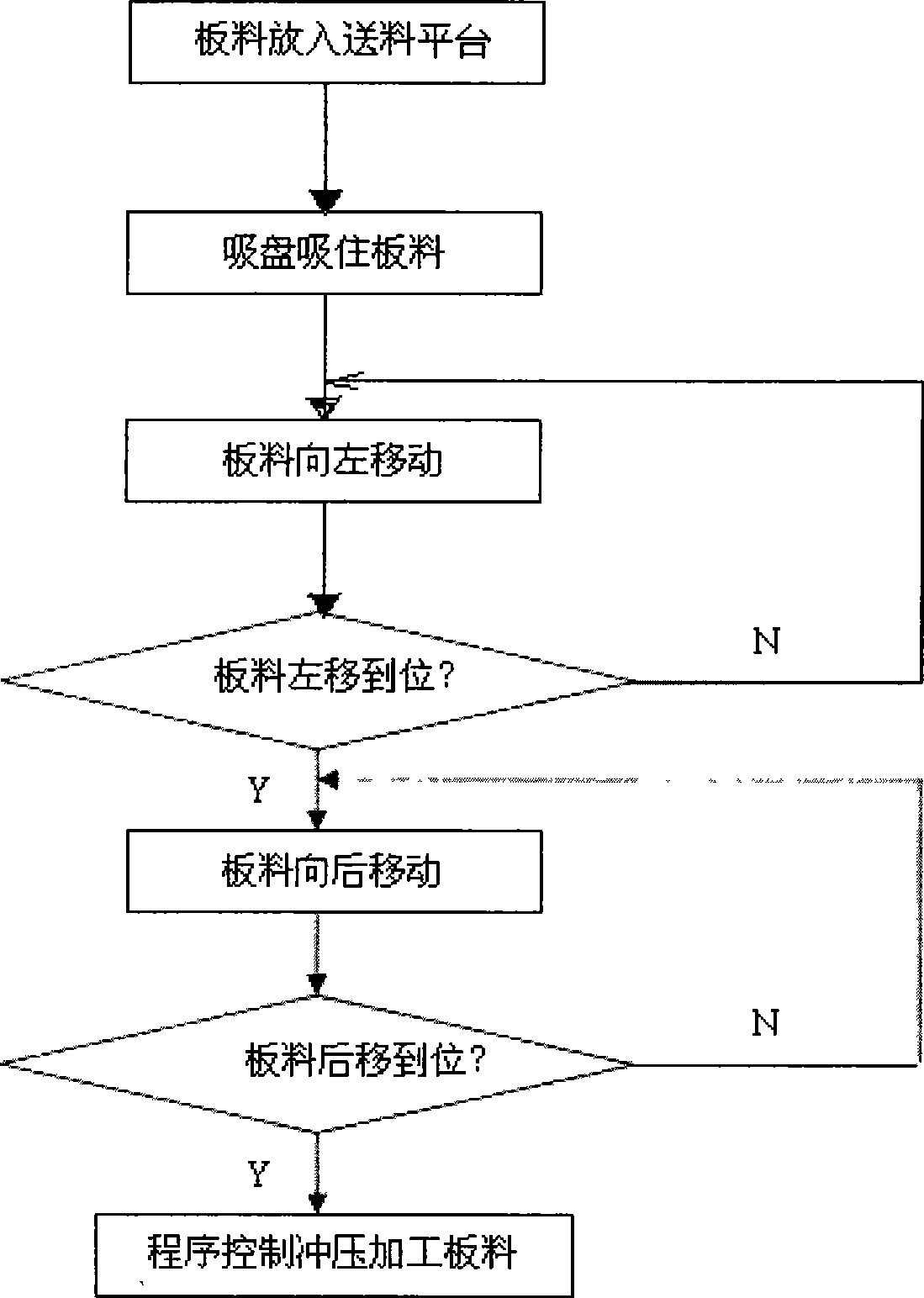

[0018] Such as figure 1 , figure 2 , Figure 4 As shown, a sheet metal automatic positioning system of the present invention is composed of a positioning machine base 1, a detection device 2, a solenoid valve 3, a biaxial cylinder 4, a positioning block 5, a suction cup adjustment mechanism 6, a sealing ring 7, an air suction Pipe 8, sucker 9, feeding platform 10 are formed.

[0019] Such as figure 1 , Figure 4 As shown, the biaxial cylinder 4 is composed of two cylinders, wherein the cylinder I21 is connected with the suction cup 9, the cylinder II22, and the solenoid valve II18 respectively, and the cylinder II22 is connected with the cylinder I21 and the solenoid valve I17 respectively.

[0020] Such as Figure 4 As shown, the solenoid valve 3 includes a solenoid valve I17, a solenoid valve II18, a solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com