A centralized control cabinet for pumping unit well site

A technology for pumping wells and control cabinets, which is applied in the field of control cabinets, can solve problems such as inconvenient management and automatic control, cumbersome stroke and stroke adjustment of pumping units, poor protection reliability, etc., and achieves convenient and economical maintenance. money, reduce the failure rate of power outages, and achieve the effect of unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

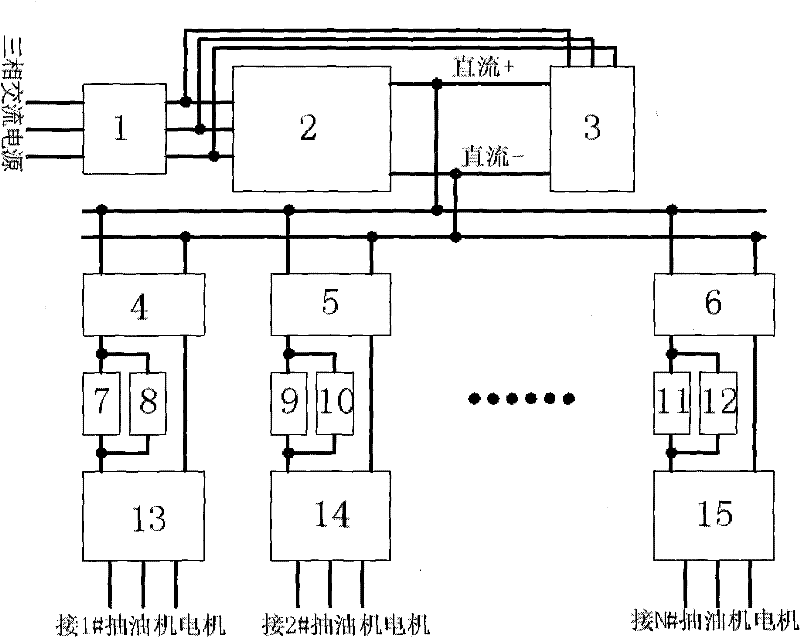

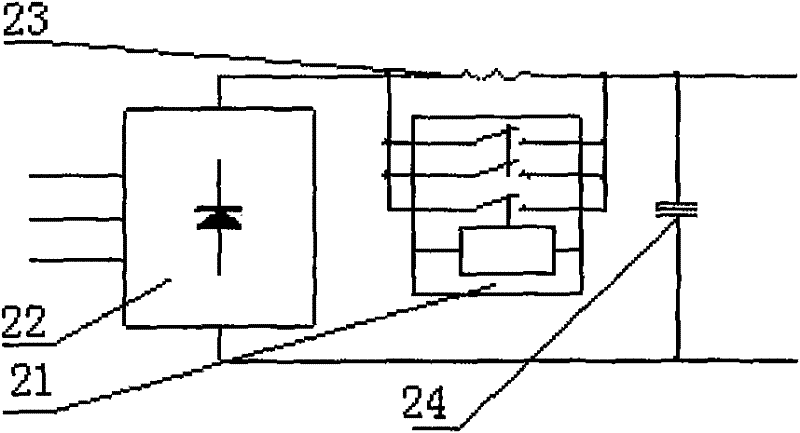

[0030] Such as figure 1 , figure 2 As shown, the pumping unit well site centralized control cabinet of the present invention mainly includes an air switch A 1, a soft start rectifier power supply 2, an energy feedback unit 3, and a sub-well inverter device, and the sub-well inverter device includes N inverter devices , including the first air switch 4, the second air switch 5, the Nth air switch 6, the first unipolar switch 7, the first resistor 8, the second unipolar switch 9, the second resistor 10, and the Nth unipolar switch 11 , the Nth resistor 12, the first inverter power supply 13, the second inverter power supply 14, the Nth inverter power supply 15, and the inverter power supply has a communication interface (RS485 or RS232 or USB). The soft-start rectifier power supply 2 can be selected from a WR-ZLDY type three-phase half-control or full-control rectifier circuit, or through a combination circuit of a three-phase rectifier bridge circuit 22, a resistor A 23, a sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com