Patents

Literature

39results about How to "Easy stroke adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

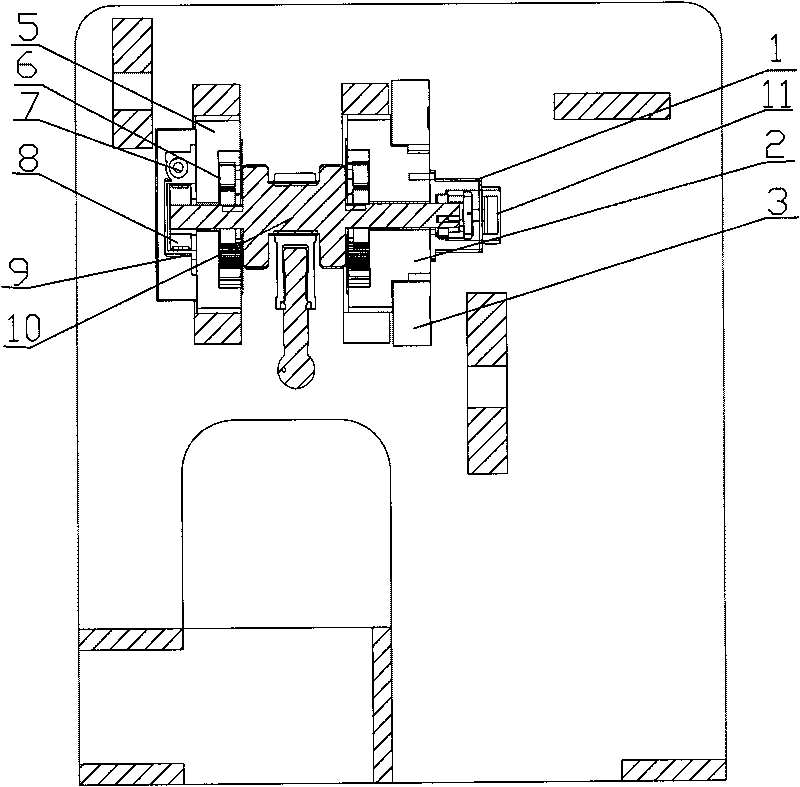

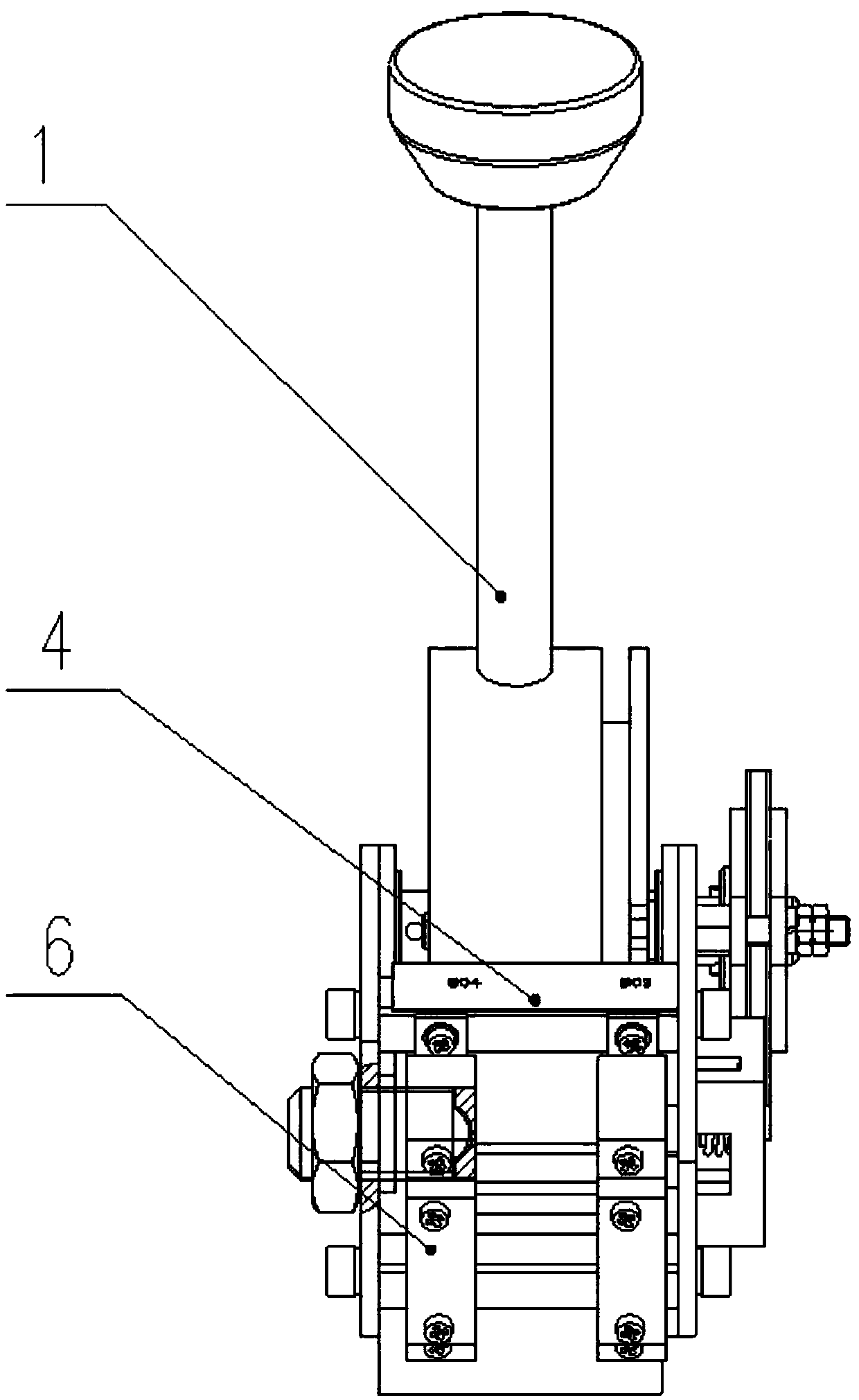

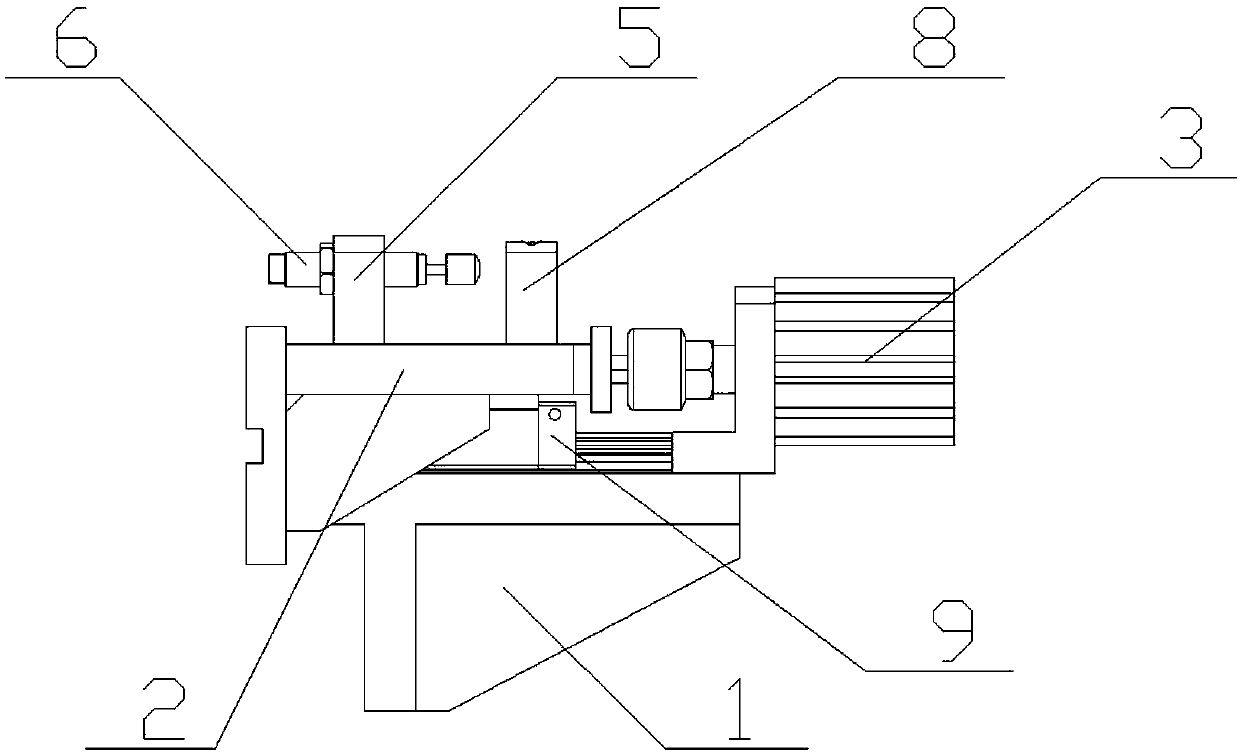

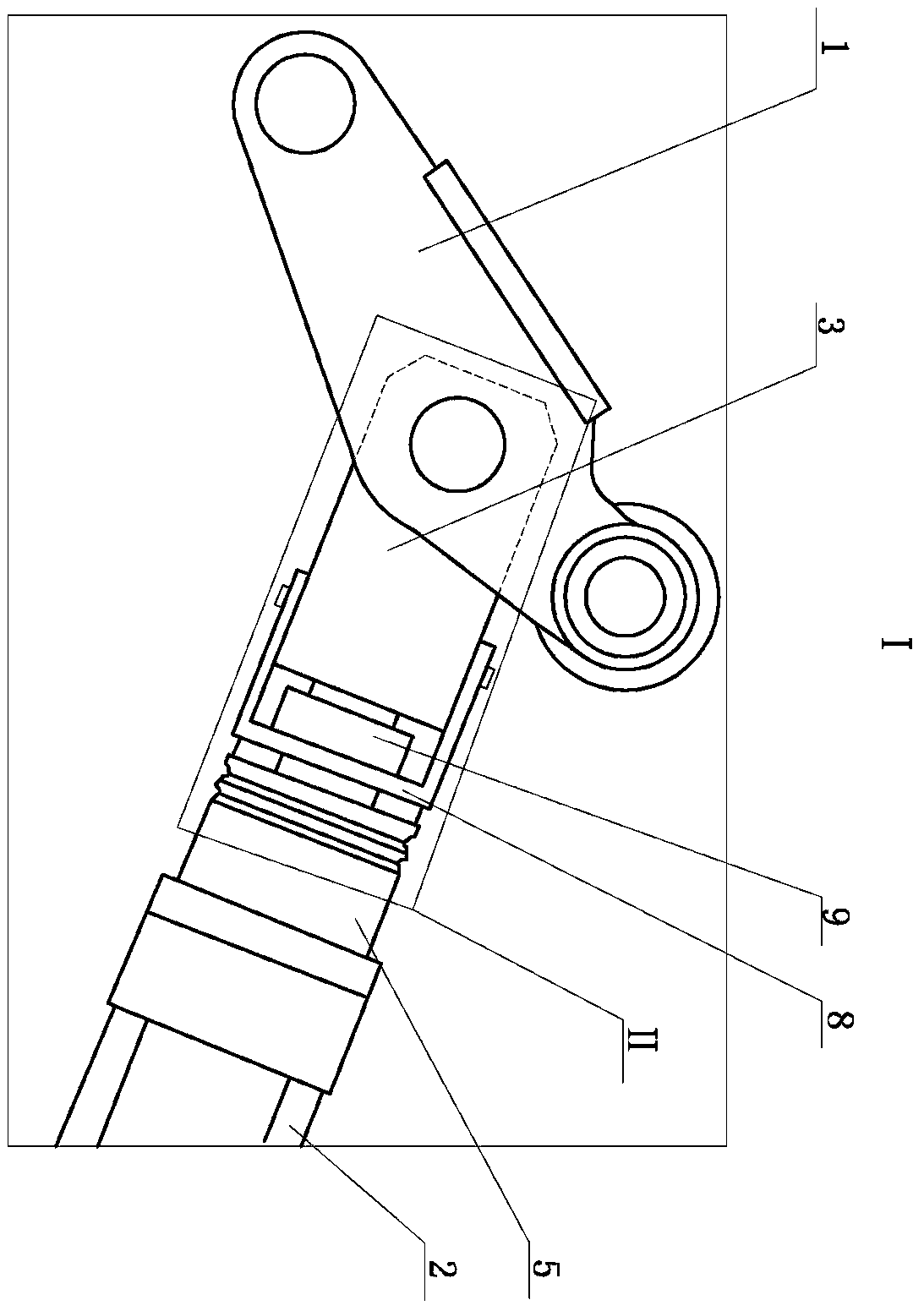

Quick clamping device

InactiveCN101829972ASimple structureReduce size requirementsWork holdersScrew threadBiomedical engineering

The invention discloses a quick clamping device, which comprises a press block, a clamp body, a clamping screw, an anti-rotating pin, a handle, a mandril, a spring, a gland and a positioning pin, wherein the clamping screw is in threaded connection with the clamp body; the right end of the clamping screw is provided with the handle; the mandril is in clearance fit with the clamping screw; the anti-rotating pin can prevent the rotation of the clamping screw; the other side of an anti-rotating bolt on the clamping screw is provided with the positioning pin for preventing the backward movement of the mandril; and the spring and the gland are arranged between the anti-rotating pin and the positioning pin; and the head of the mandril is provided with the swing smooth-surfaced press block or groove-surfaced press block. The quick clamping device has the advantages of simple structure, low requirements on size and accuracy, quick clamping, convenient and fast travel adjustment, and the like.

Owner:CITIC DICASTAL

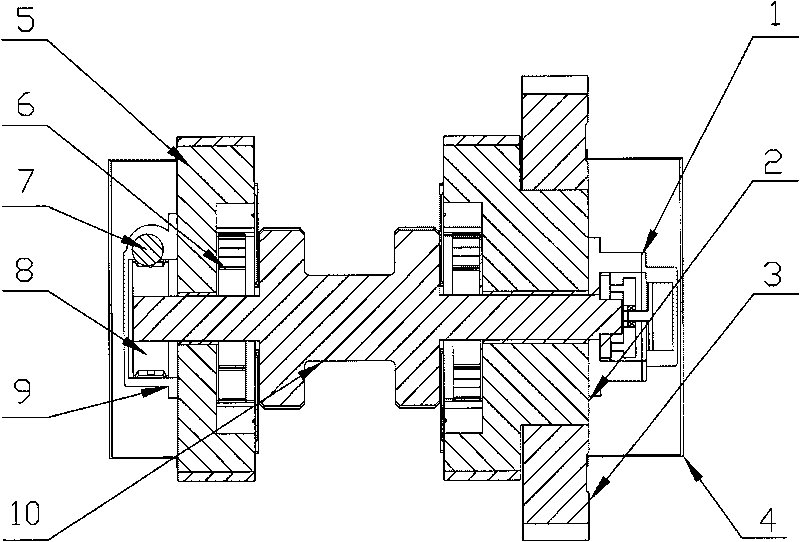

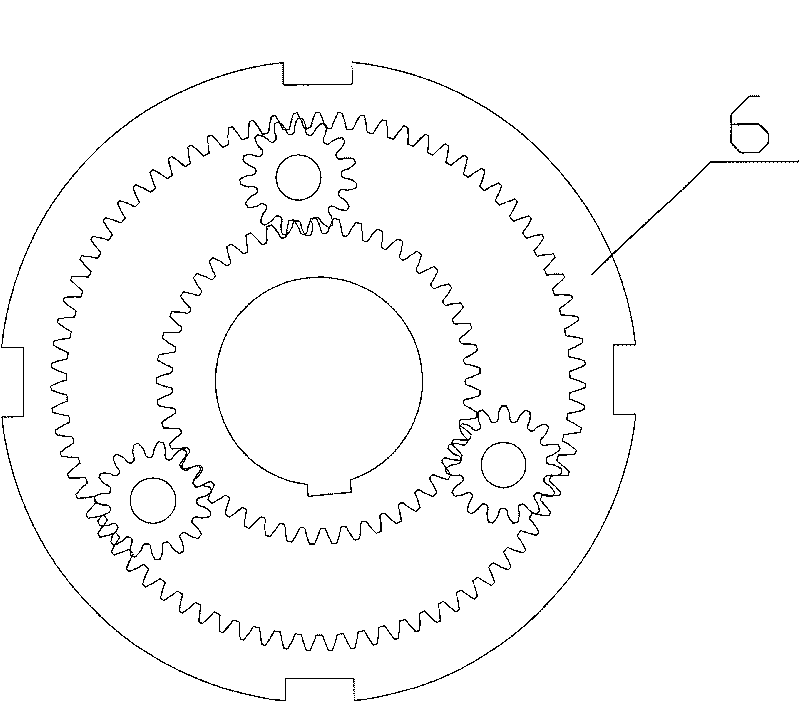

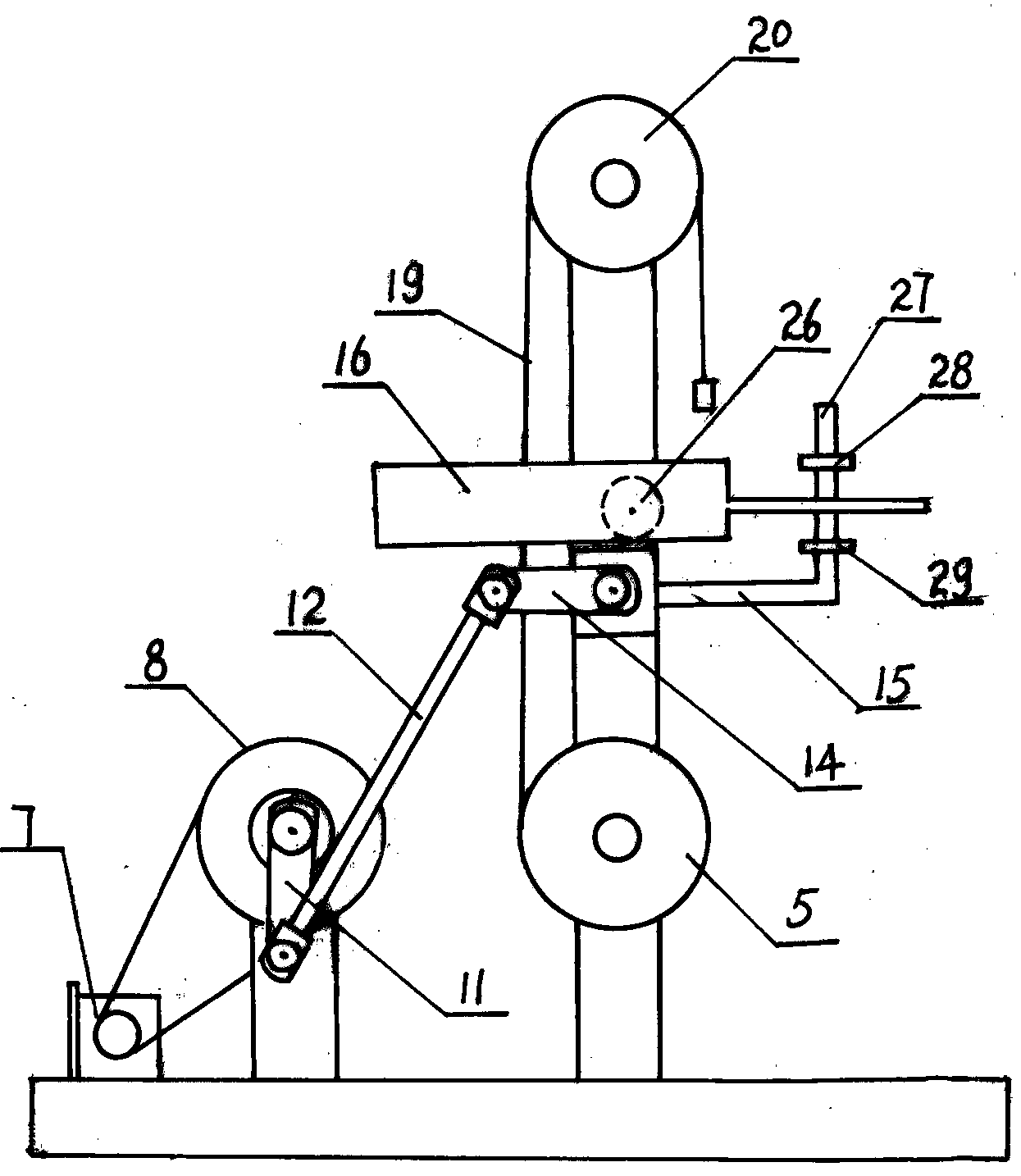

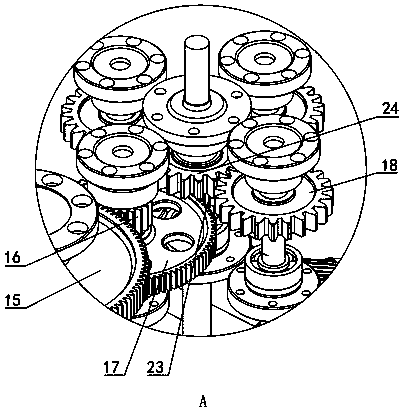

Stroke automatic adjusting device for press machine

The invention relates to a stroke automatic adjusting device for a press machine, belonging to the technical field of press machines. The device is characterized in that eccentric sleeves are sleeved and fixed at two ends of a crank; a planet gear mechanism is arranged in each eccentric sleeve; two ends of the crank are respectively provided with a locking mechanism and a self-locking worm and worm gear adjusting mechanism. The device is provided with two eccentric centers, one is an eccentric center of the crank itself, while the other is the eccentric center of a combining bush of an external gear ring, wherein the eccentric center of the combining bush of the external gear ring is fixed, rotation of the crank can change the distance between the two eccentric centers which is the eccentricity of a slider mechanism when the gear rotates, namely half of a slide stroke, so that different eccentricities can be obtained by rotating the crank structure inside. The device has reasonable structure, convenient stroke adjustment and reliable self locking, realizes automatic adjustability, effort saving, accuracy and reliable locking, is stable, greatly contributes to improve the manufacture technical range of the press machine, and has strong practicality and economy.

Owner:YANGLI GRP CORP LTD

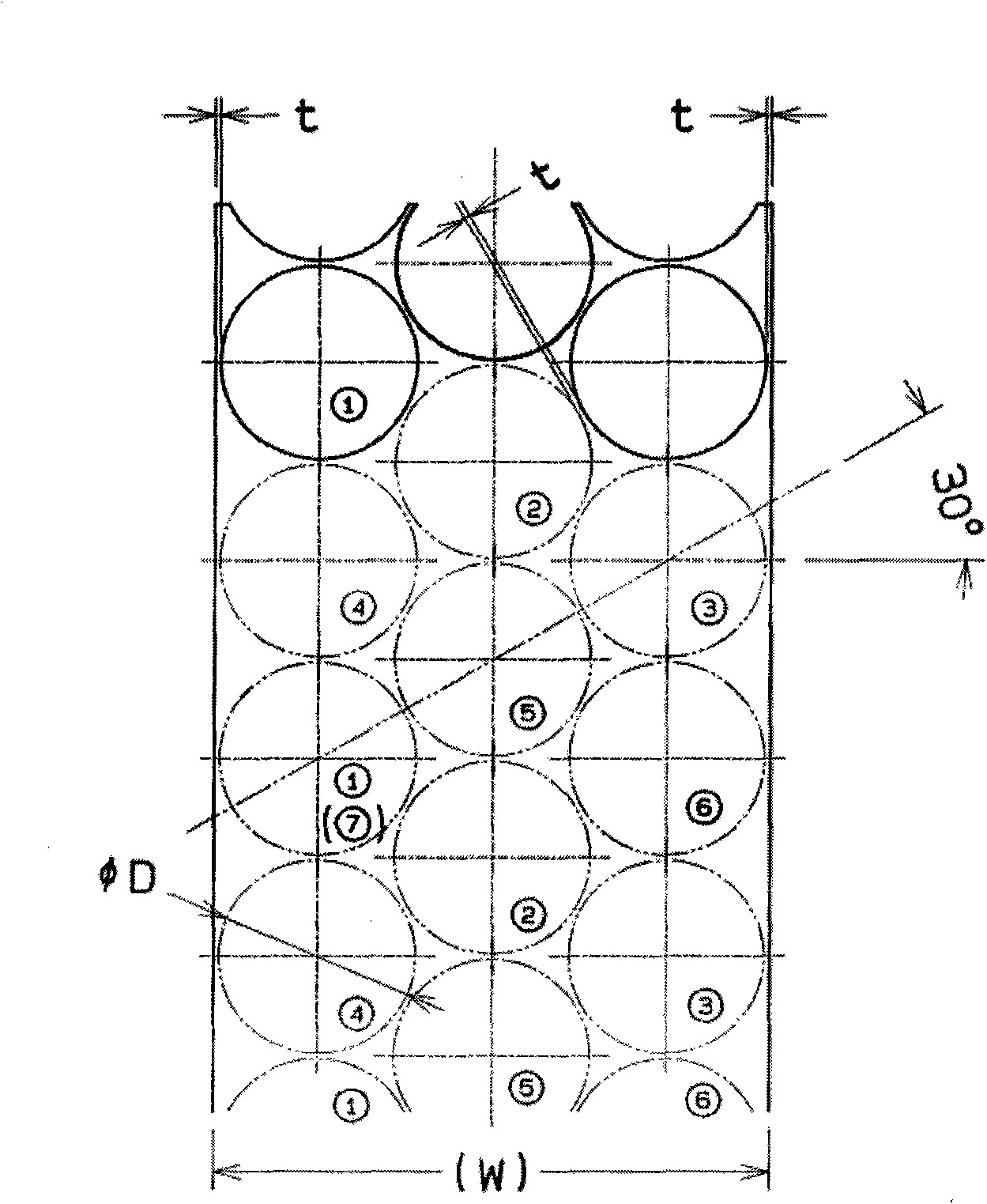

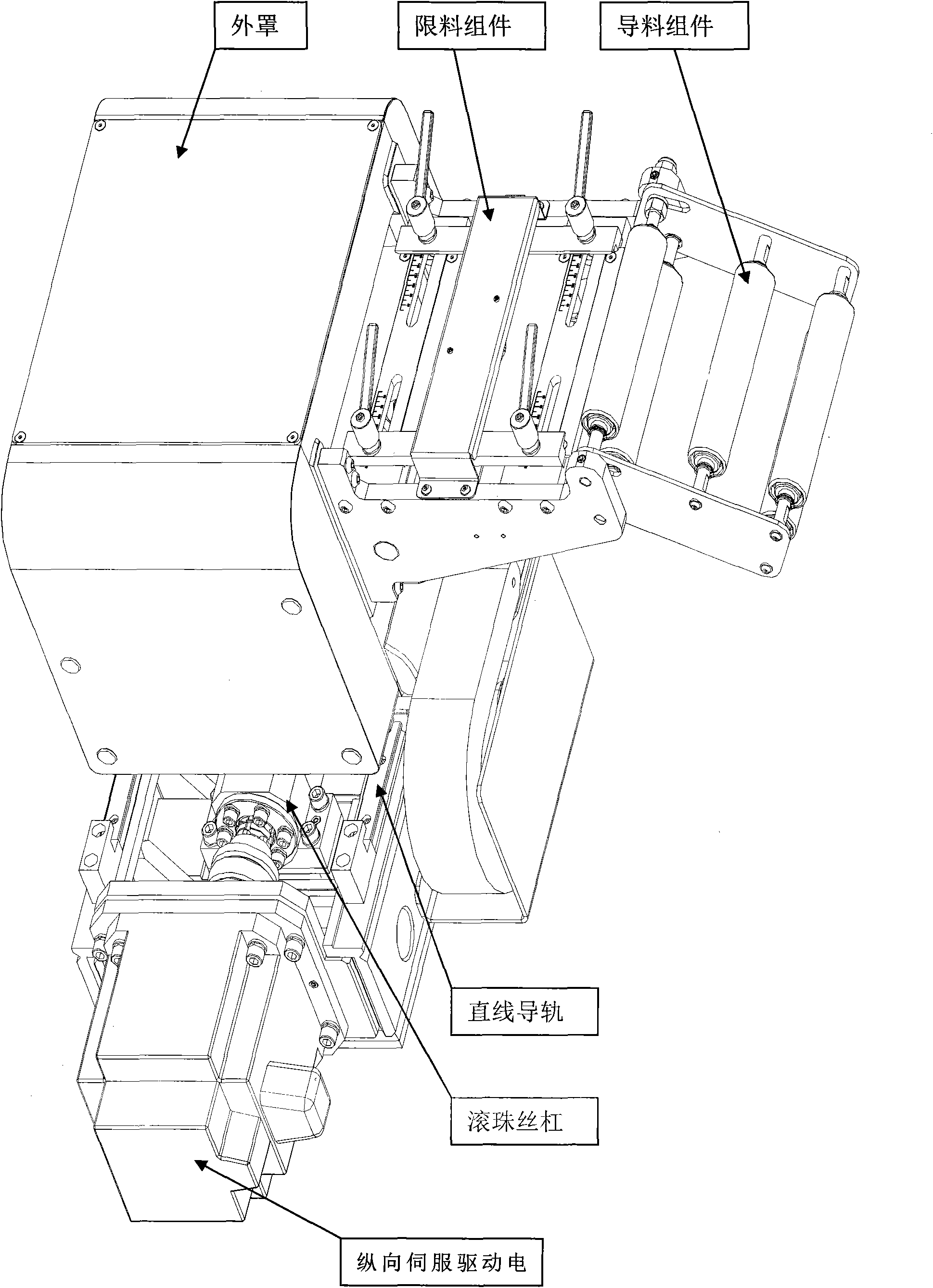

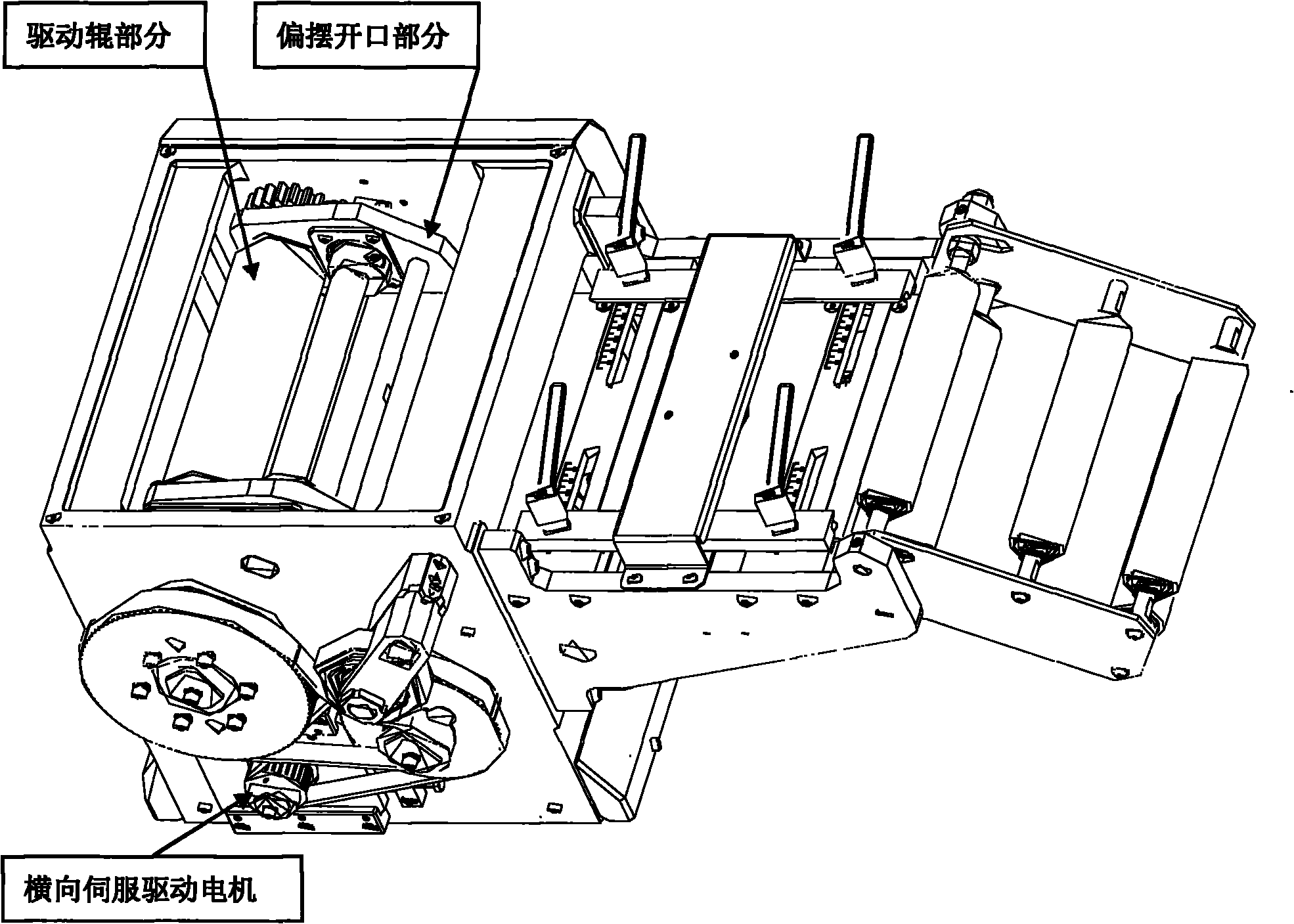

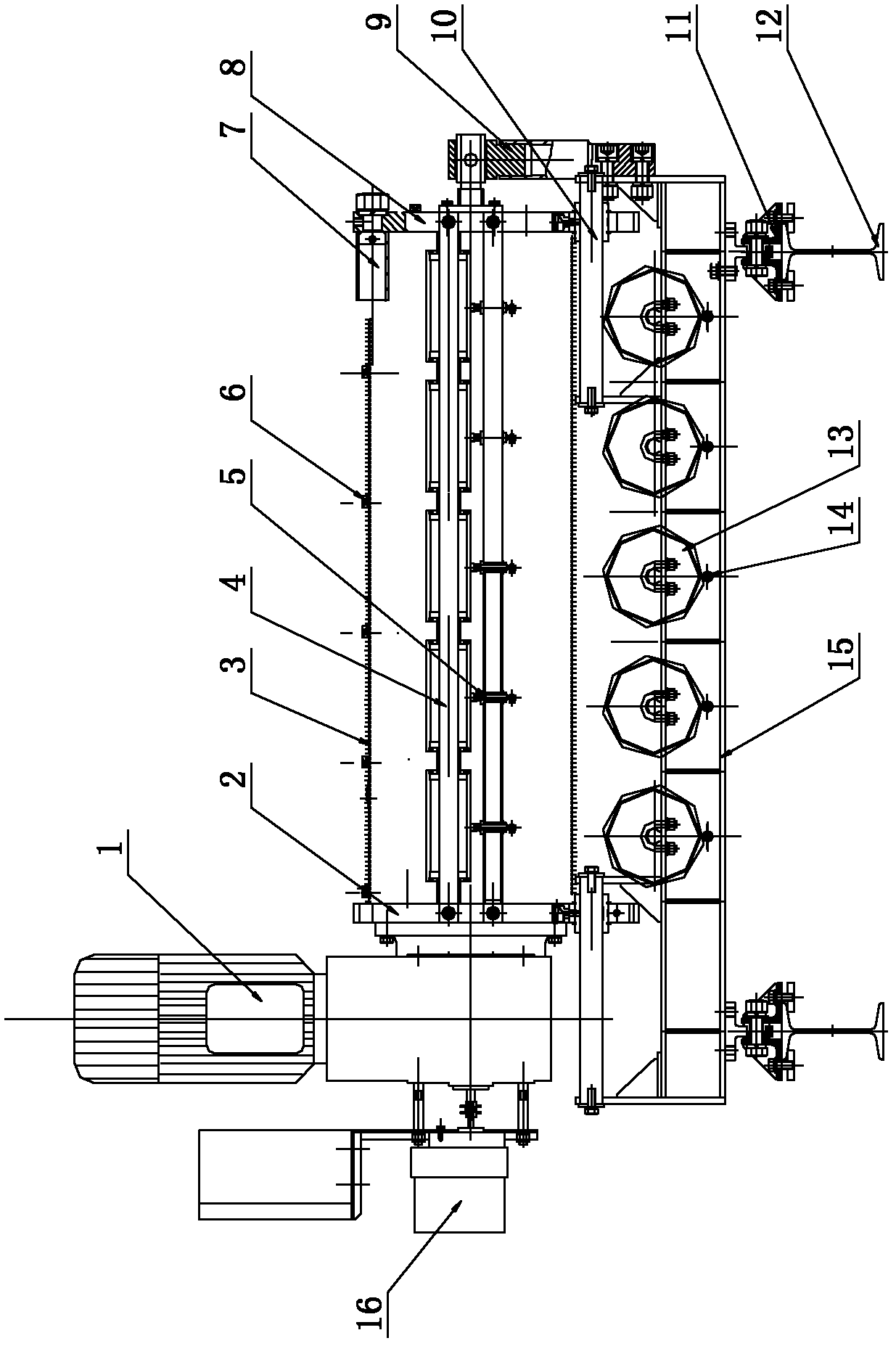

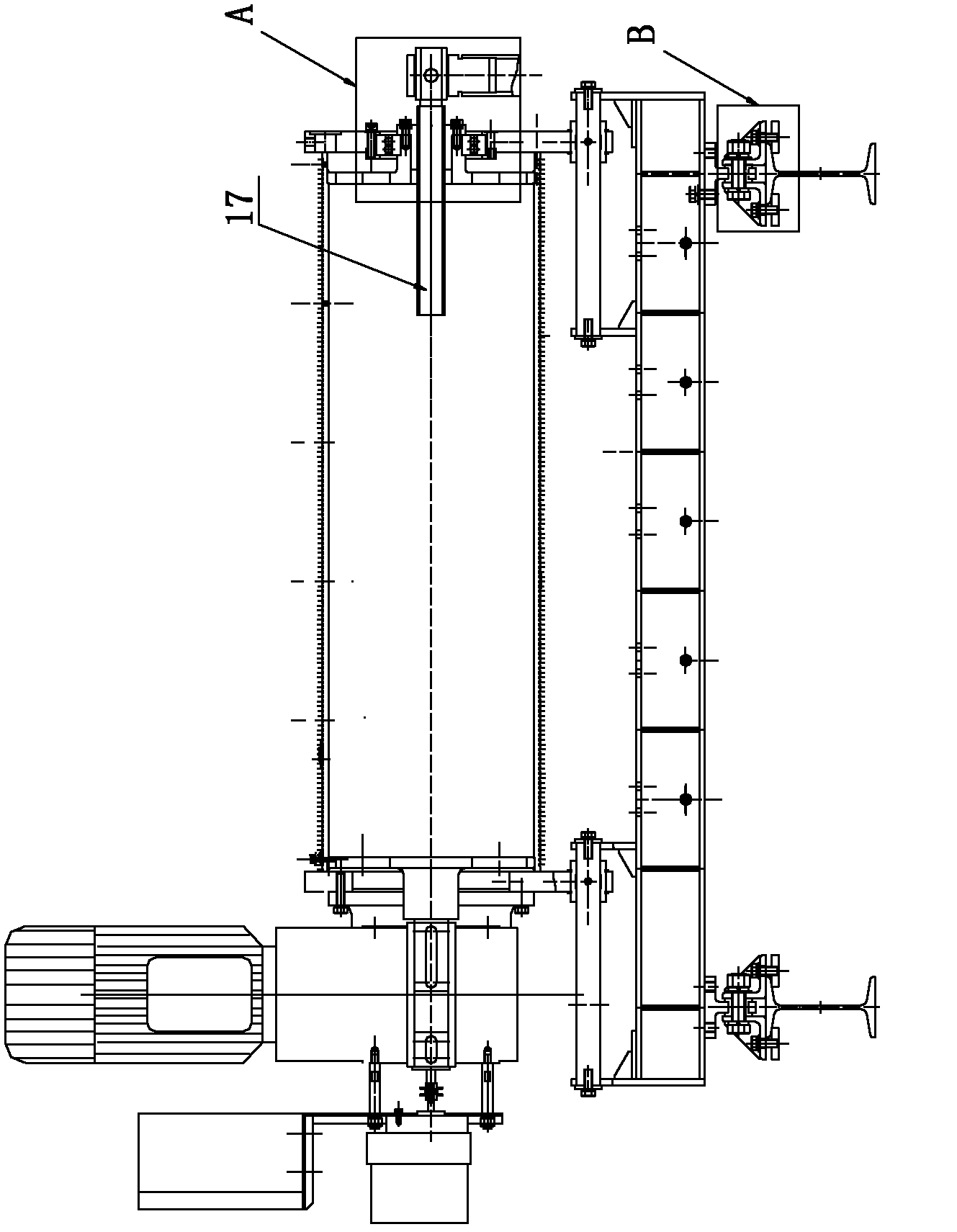

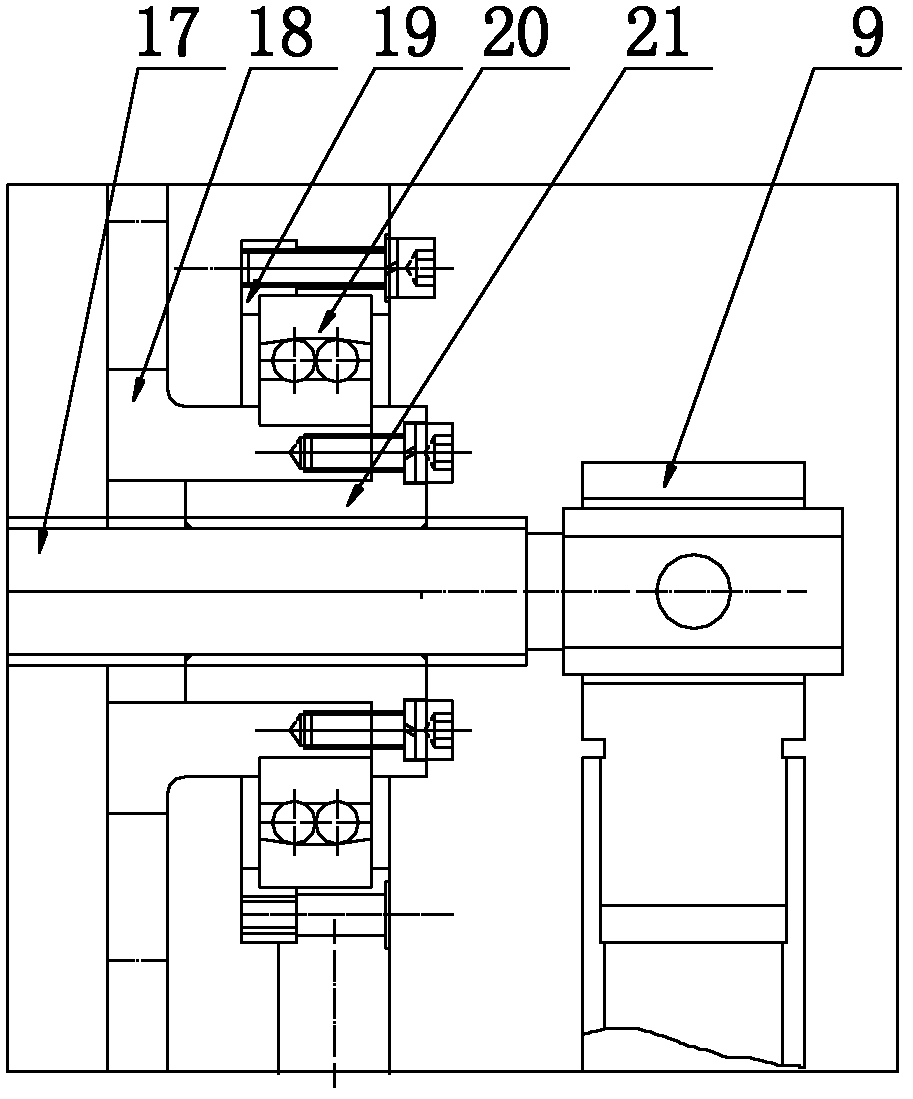

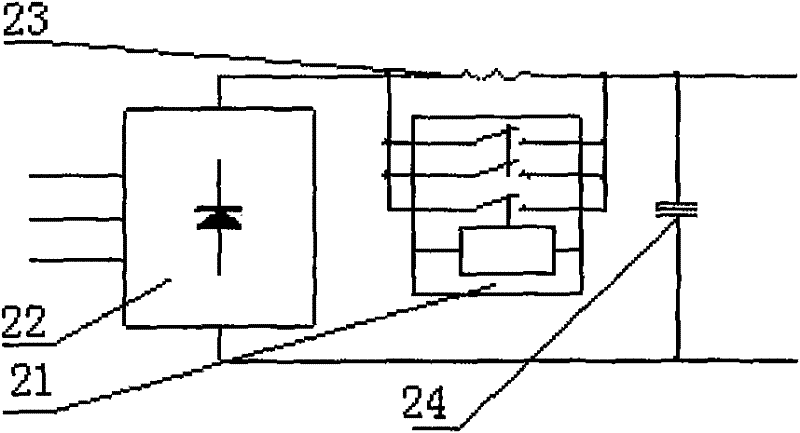

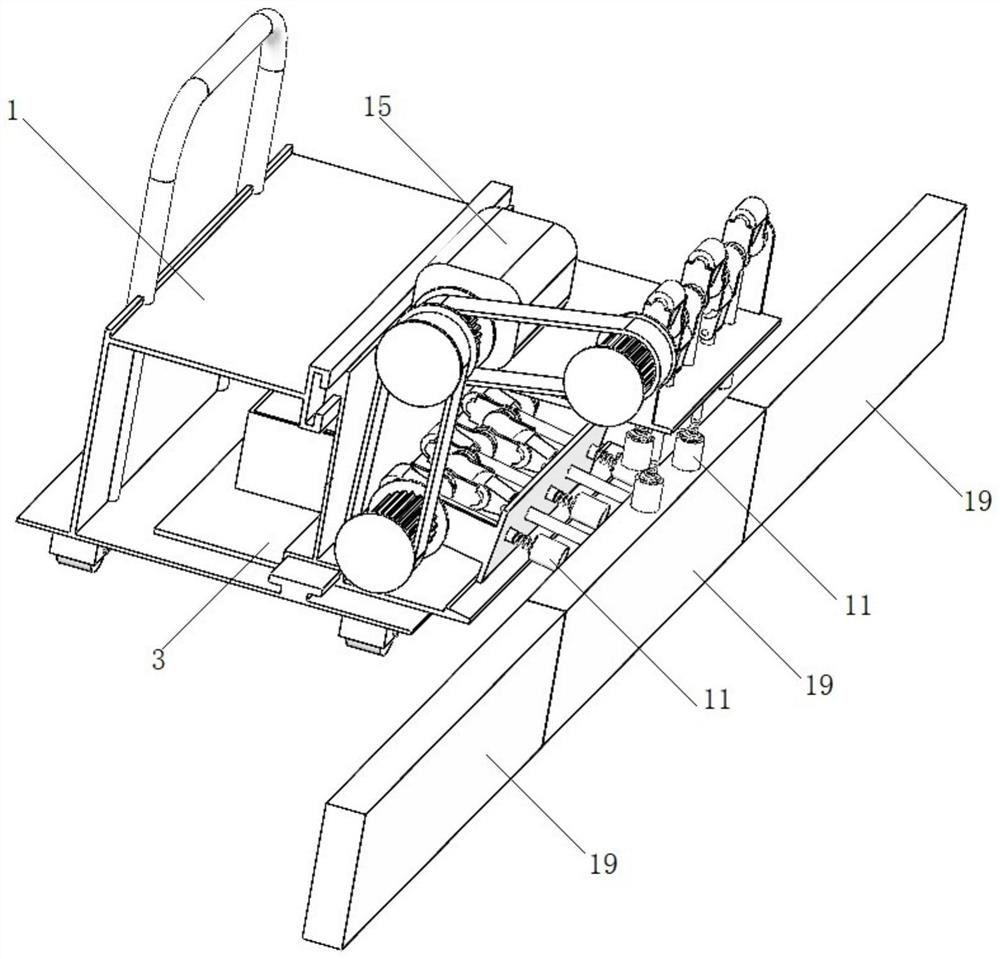

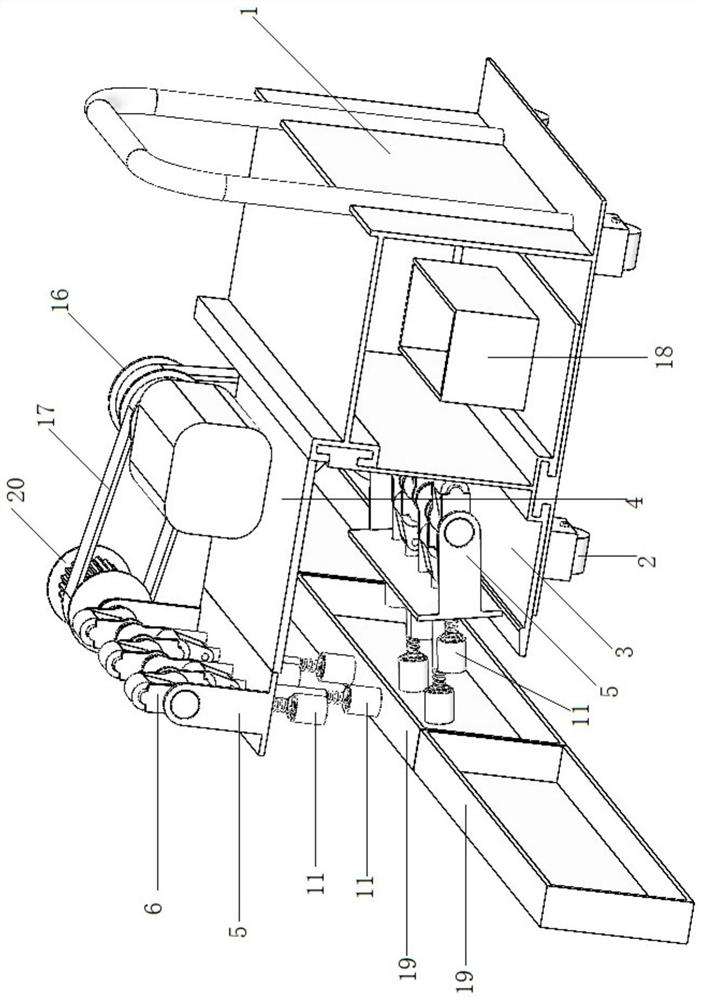

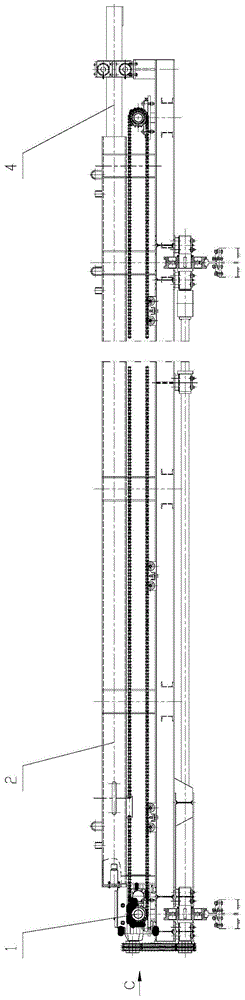

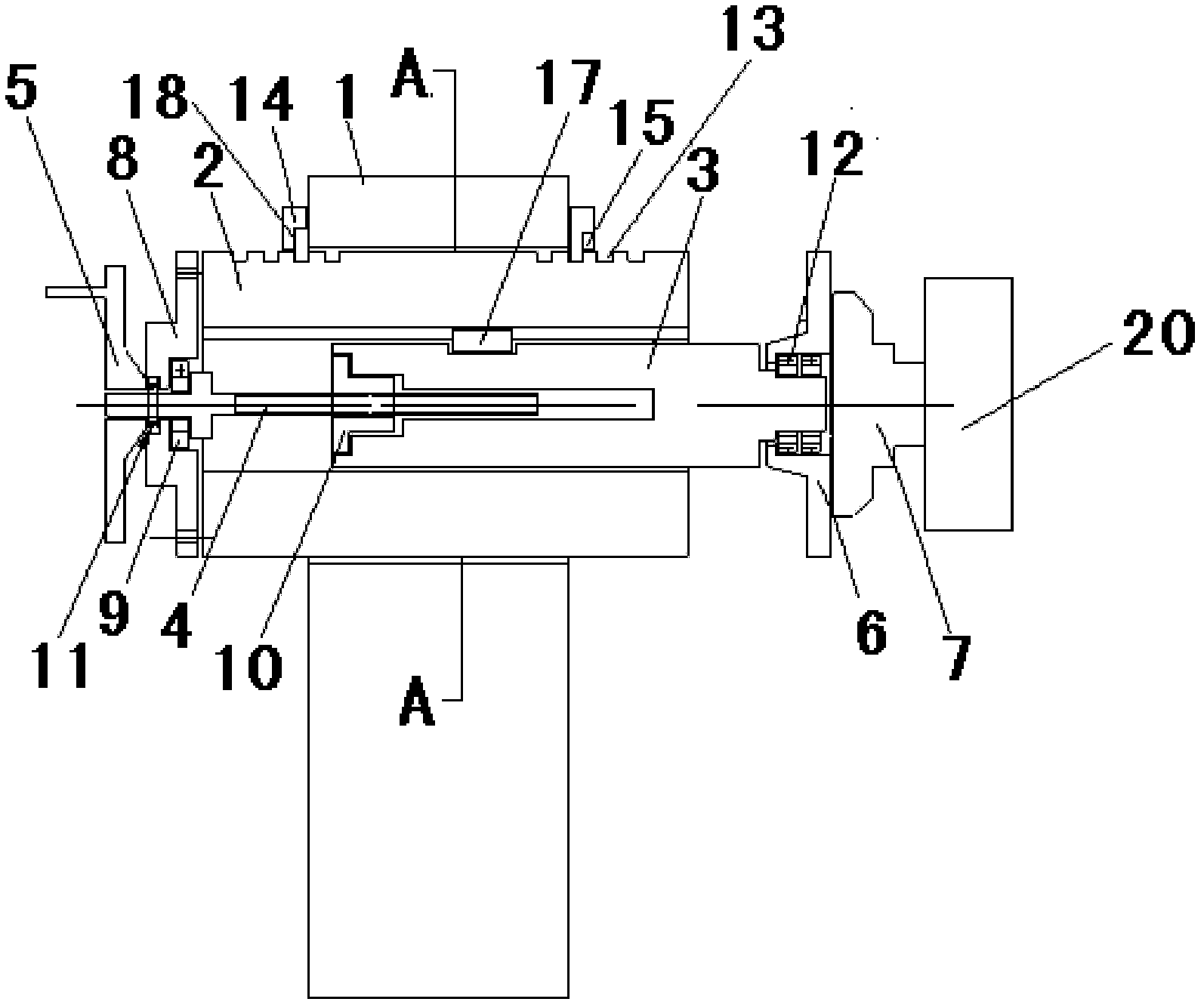

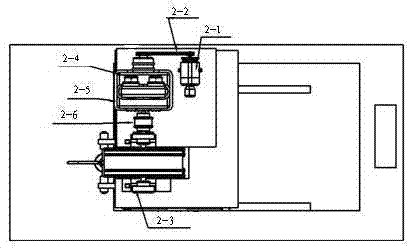

Bidirectional servo feeding machine

InactiveCN101869950AIncrease profitLow costMetal-working feeding devicesPositioning devicesAviationPunch press

The invention provides a bidirectional servo feeding machine which is matched with a punching machine in punching industry. The feeding machine is connected with the punching machine through an electric appliance control signal to automatically feed punching steel coils both in a transverse direction (the advancing direction of the coils) and a longitudinal direction (perpendicular to the advancing direction of the coils). The invention is widely used in the punching field of metal part manufacturing in automobiles, electronics, aviation and other fast developing industries at present. The feeding machine comprises an electric control box, a transverse servo drive motor, a drive roller part, a deflection opening part, a material guiding assembly, a material limiting assembly, a longitudinal servo drive motor, a linear guide rail, a ball screw part and a housing (see Figure 2). The invention adopts the servo drive motors, so that the transverse stroke and longitudinal stroke are convenient to be adjusted, and the feeding precision and resetting precision can be controlled within + / -0.05 mm. The number of rows or sections of the longitudinal stroke can be determined according to the width of material and size of produced components, and can be 2, 3, 4, 5, 6,...,N rows (sections). The invention can overcome the present situation of material wasting since the punched surplus material (single row porous shape) has a large area and can not be utilized when a single-direction feeding machine feeds quantitive material in one direction. The invention greatly enhances the material utilization ratio, reduces the absolute usage amounts of steel, reduces the number of reloading after the coils are used up, enhances the production efficiency and lowers the production cost.

Owner:LEN SEIKI SHENZHEN

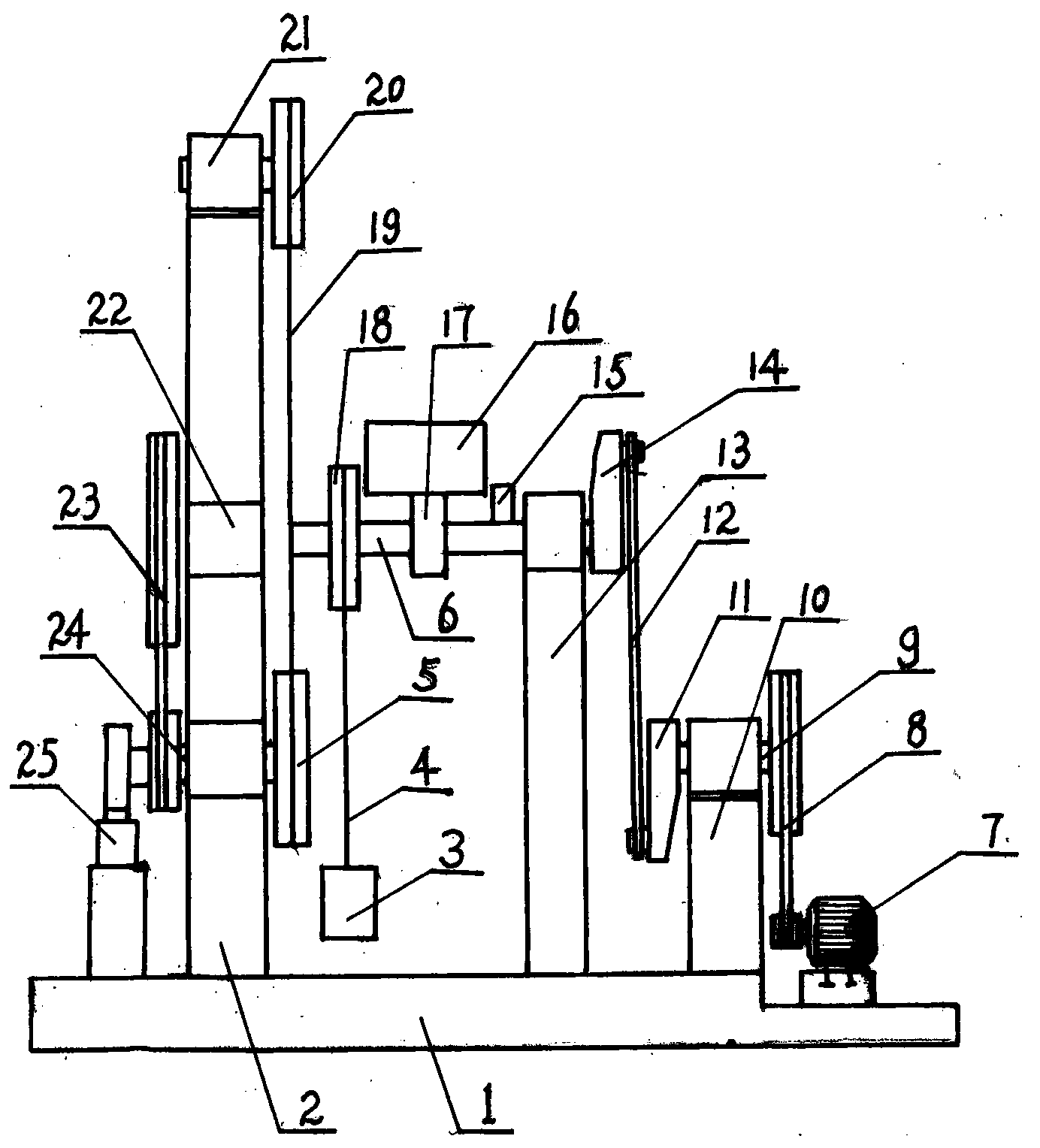

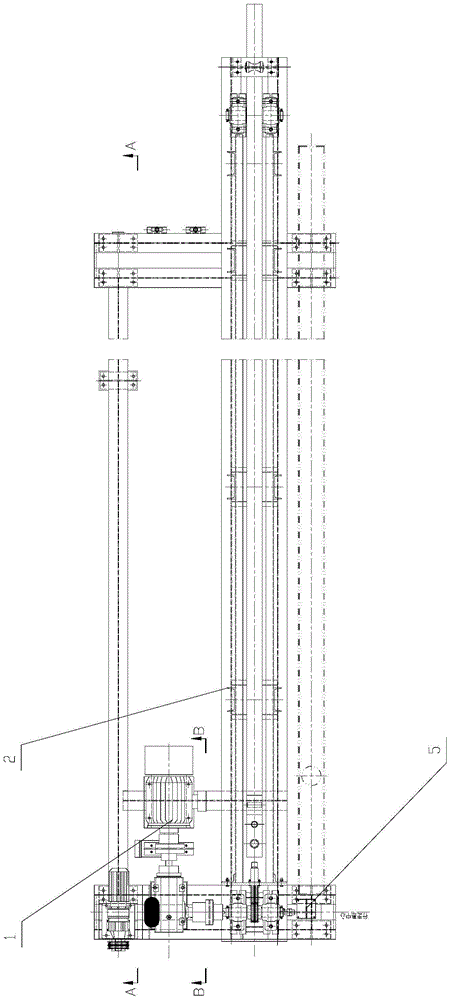

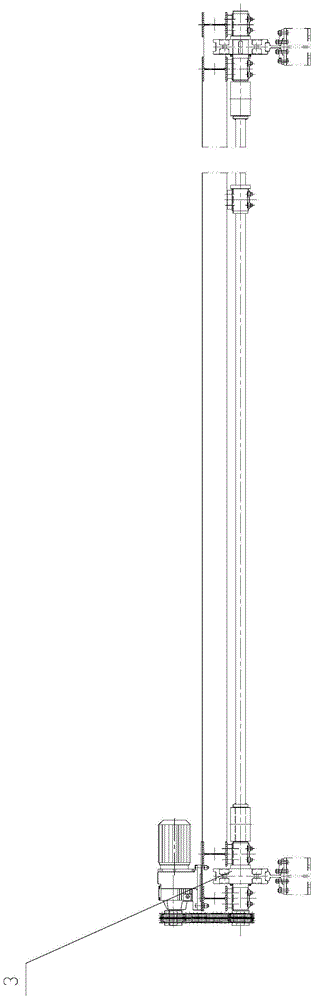

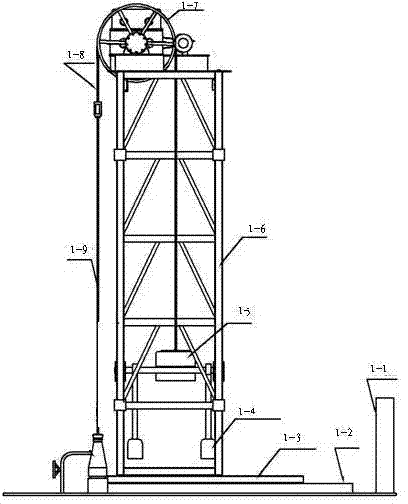

Multi-hoisting point two-dimensional transmission automatic rope arranging compound crane

InactiveCN102616692AReduce weightSave structure cost and equipment costWinding mechanismsEngineeringMotor drive

The invention relates to a multi-hoisting point two-dimensional transmission automatic rope arranging compound crane which comprises a base, a frame, a reducing brake motor and a rope arranging roller. The output shaft of the reducing brake motor drives the rope arranging roller to rotate; the crane is characterized in that two ends of the rope arranging roller are rotationally installed between two supporting wallboards; lower parts of the supporting wallboards are glidingly installed on sliding bars symmetrically installed at two ends of the upper part of the frame; a movable base plate is longitudinally and fixedly installed at one end of the frame; a horizontal screw penetrating through the inner part of the roller is fixedly installed on the movable base plate; the horizontal screw is matched with a nut installed at the axle center of the end part of the rope arranging roller; and a deflecting pulley group is installed on the frame at the lower part of the rope arranging roller. The crane integrates a boom machine and the deflecting pulley group into a whole, a motor drives a winding drum to drive a hoisting cable to lift weights, meanwhile, the horizontal movement of the winding drum is realized, and two-dimensional transmission mode is realized, so that automatic rope arranging function is realized during small-space and multi-angle installation, and meanwhile, the crane has the advantages of low cost, easiness in installation and high safety.

Owner:马超

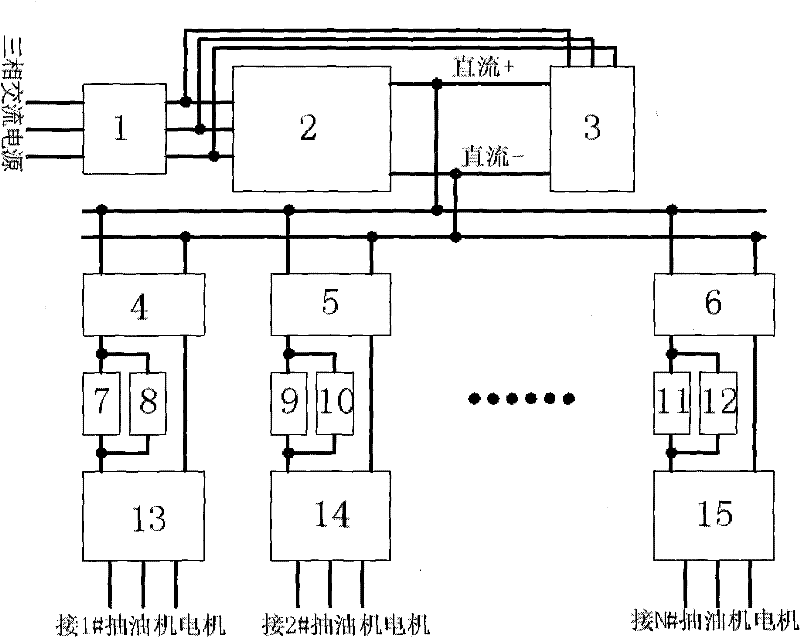

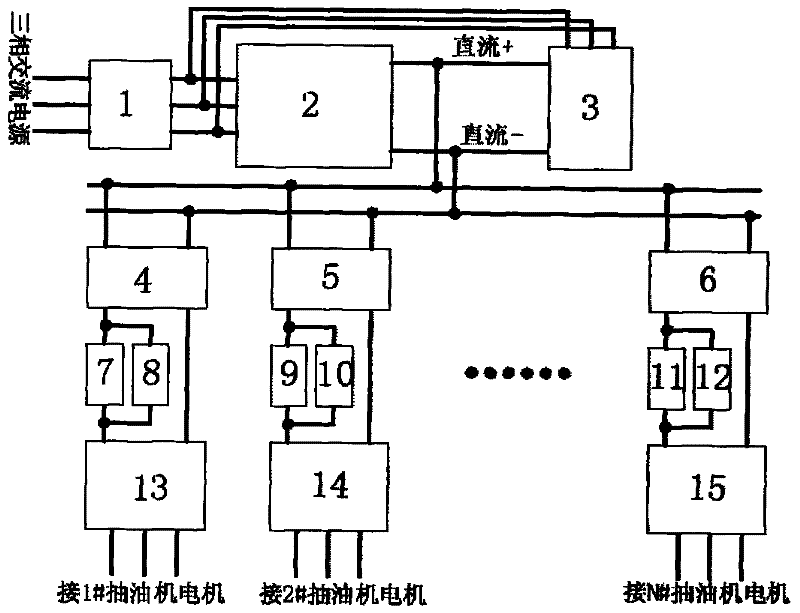

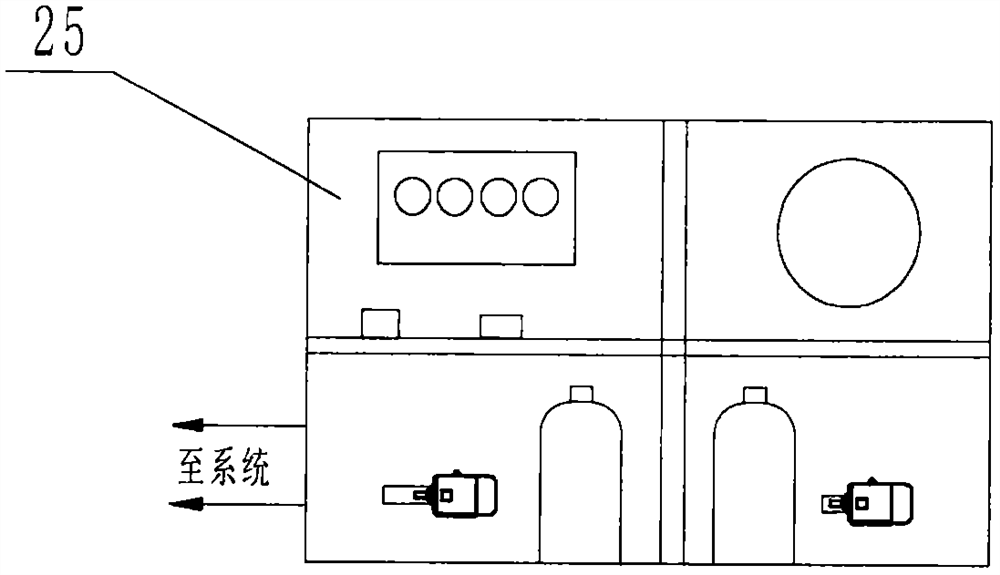

A centralized control cabinet for pumping unit well site

InactiveCN102299670AHigh power saving rateImprove reliabilityMultiple ac dynamo-electric motors controlFailure rateHigh rate

The invention relates to a centralized control cabinet for pumping unit well sites. The device includes an air switch A, a soft-start rectifier power supply, a sub-well inverter device, an energy feedback unit, and a housing. The air switch A, soft-start rectifier power supply, sub-well The well inverter device and the energy feedback unit are packaged in the shell, the split well inverter device includes N inverter devices, the air switch A is connected to the soft-start rectifier power supply, and the output of the soft-start rectifier power supply terminal is connected to the input terminal of the energy feedback unit, the output terminal of the energy feedback unit is connected between the air switch A and the soft-start rectifier power supply, and the input terminals of the N inverters are connected to the same bus, the The bus bar is connected to the DC output end of the soft-start rectifier power supply, and the output ends of the N inverters are respectively connected to the N pumping unit motors one by one. Compared with the prior art, the present invention has the advantages of high power saving rate, low failure rate of power grid failure, convenient and cost-saving maintenance, maintenance, and the like.

Owner:谭雪开

Compound balanced long-stroke oil pumping machine

InactiveCN102352740BIncreased balance factorImprove acceleration performanceFluid removalElectric machineDrive shaft

The invention relates to a compound balanced long-stroke oil pumping machine which comprises a base and a frame, wherein a transmission shaft is arranged on a support, a compound balancing mechanism is arranged at the middle part of the transmission shaft, one end of the transmission shaft is connected with a wheel train hanging rope mechanism through a belt transmission part, the other end of the transmission shaft is connected with a direction-changing driving mechanism, and the direction-changing driving mechanism comprises a driving motor, a drive shaft, a connecting rod and a pair of cranks connected with the connecting rod. Through the adoption of the compound balancing structure, the weight of a counterweight can be reduced greatly; furthermore, the rated power of a motor matched with the machine is small, the steel consumption can be reduced by above 35%, and the energy consumption during the using process can be reduced by above 50%. Simultaneously, the stroke and the stroke frequency are simple and convenient to adjust, the configuration of the mechanism does not need to be changed, and the machine has a larger range of application to different oil well states and changes of the oil well states.

Owner:陈宗武

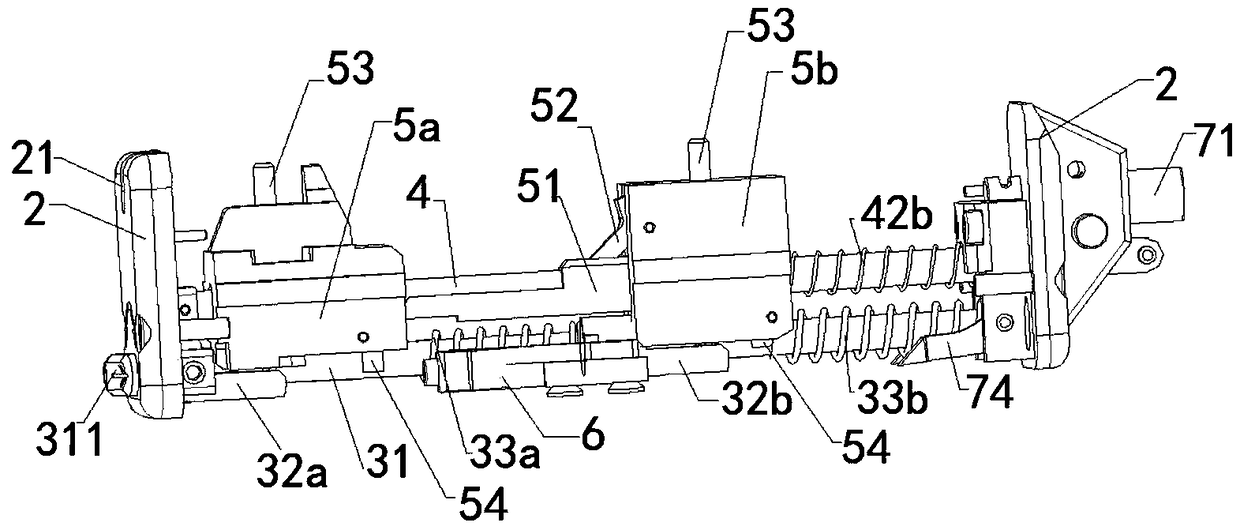

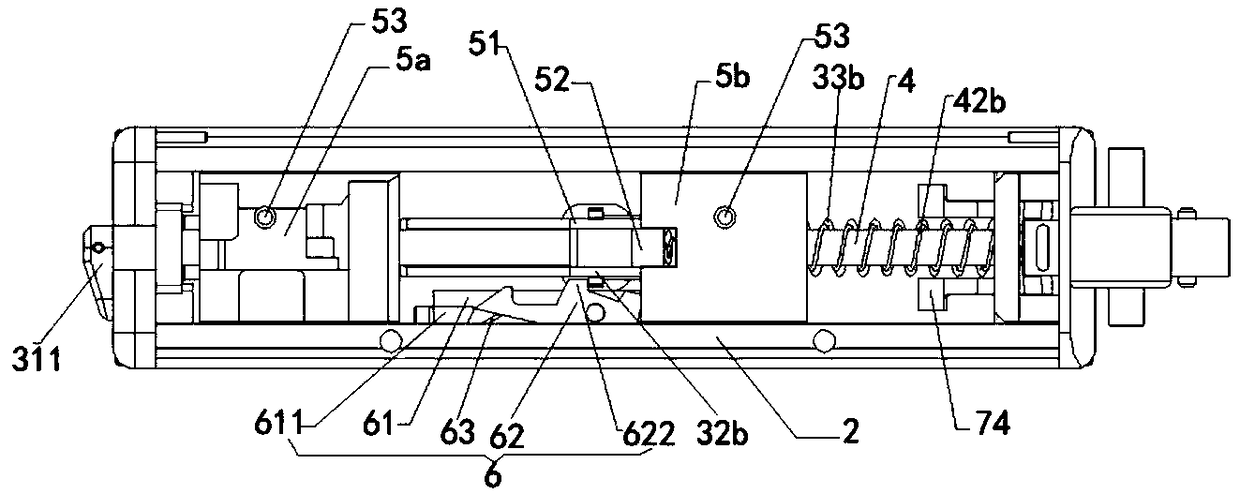

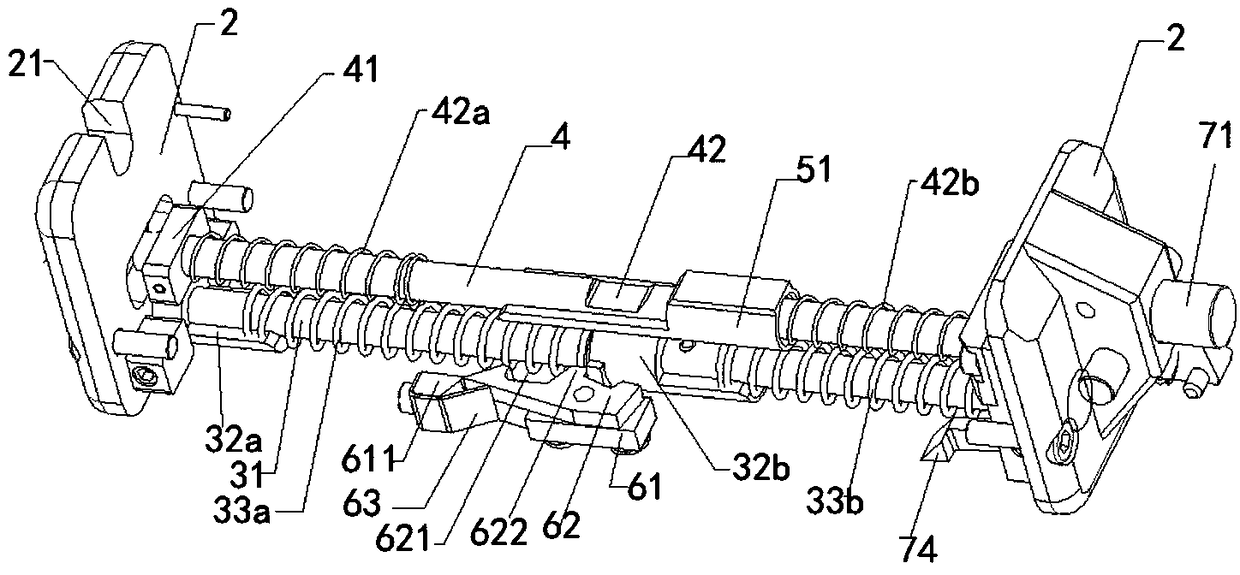

Puncture gun with adjustable puncture depth

PendingCN109009352ASimple structureEasy stroke adjustmentSurgical needlesTrocarEngineeringMechanical engineering

The invention discloses a puncture gun with adjustable puncture depth. The puncture firing distances of a puncture needle and a puncture cylinder of the puncture gun can be synchronously adjusted by setting a gear shifting member. The specific structure of the gear shifting member includes a rotating shaft and two gear shifting blocks spaced forward and backward on the rotating shaft, and the lower parts of the rear ends of the gear shifting blocks respectively extend backward by the same length. When the rotating shaft is rotated until the extending portion of each gear shifting block is located below, the firing distances of two sliding blocks are the longest. When the rotating shaft is rotated until the extending portion of each gear shifting block is located above the rotating shaft, the firing distances of the two sliding blocks are the shortest, and the difference between the longest distance and the shortest distance is the length of the extending portion of each gear shifting block. The puncture gun is simple in structure, high in safety, and easy to use.

Owner:SHIKANGPEI MEDICAL TECH WUHAN CO LTD

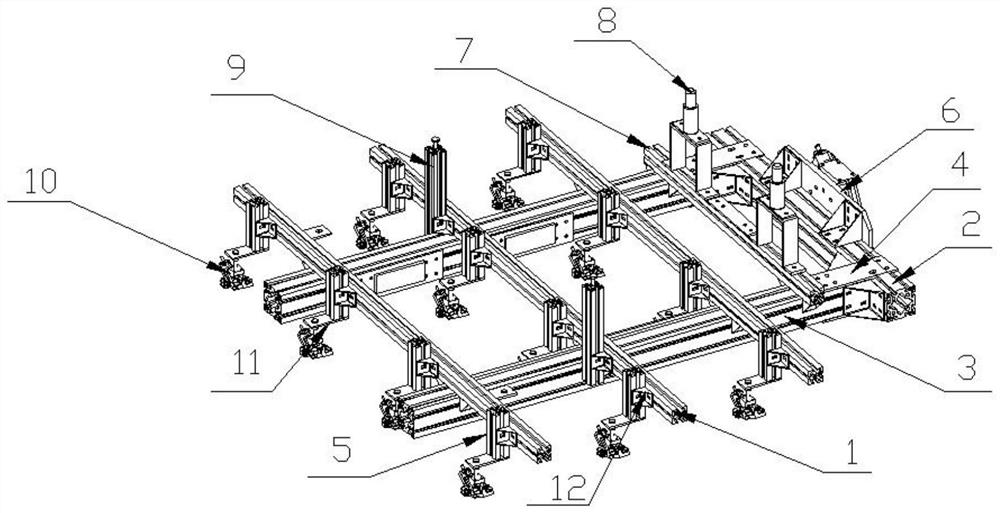

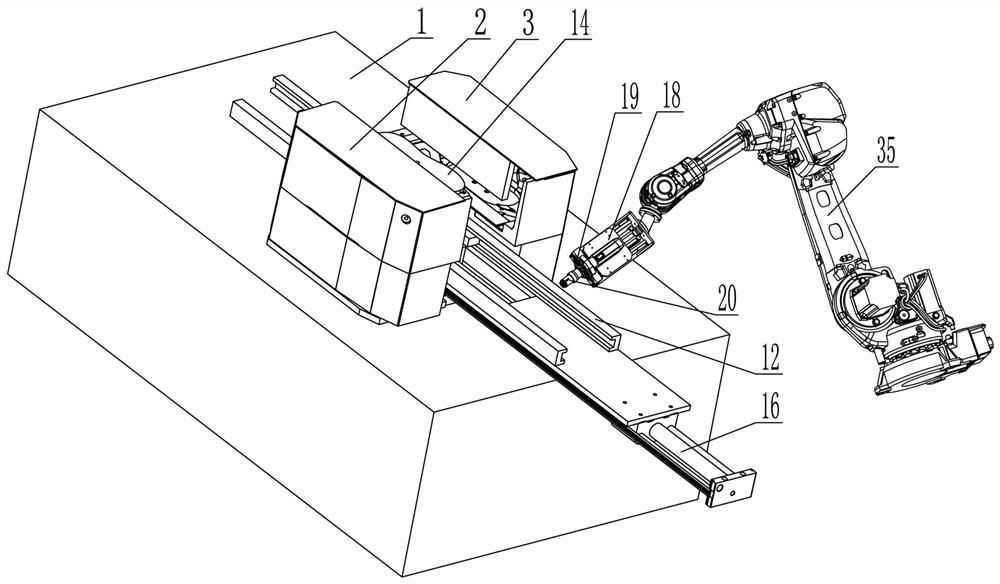

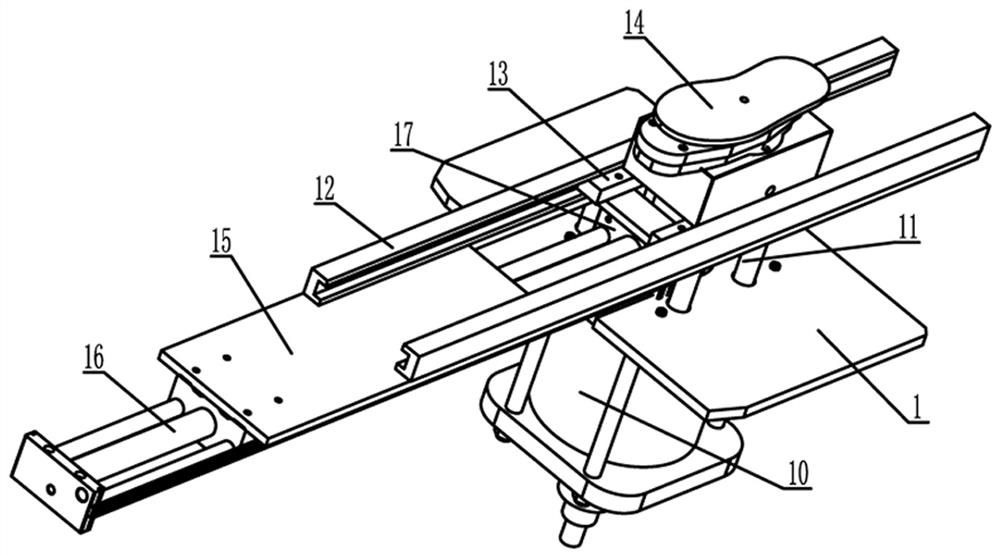

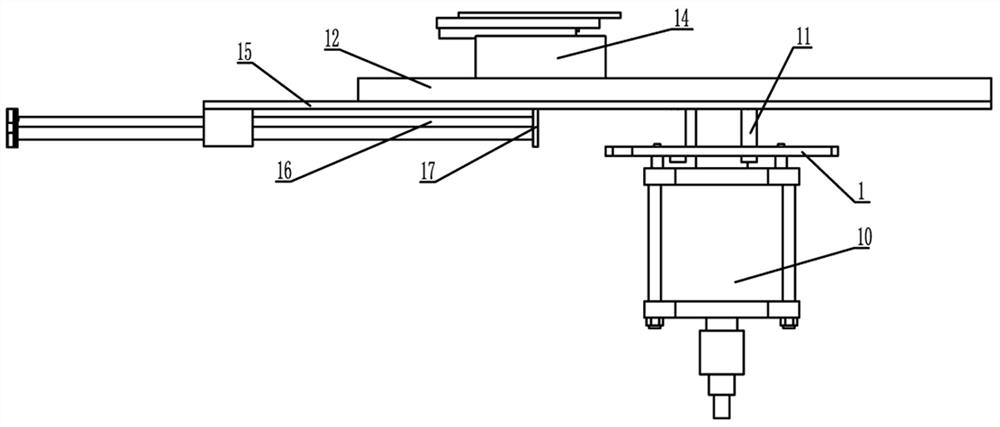

Automatic grabbing device for composite material prefabricated body and laminated piece

PendingCN112537641AEasy access to driving forceReduce energy consumptionStacking articlesDe-stacking articlesProduction lineStringer

The invention discloses an automatic grabbing device for a composite material prefabricated body and a laminated piece. The automatic grabbing device comprises a frame assembly and a grabbing assembly. An aluminum alloy floral tube sectional material or an aluminum alloy octagonal tube is adopted as the material of a main frame and three auxiliary cross beams, and the effects that assembling is convenient and fast, the structural weight is light, and the stroke is easy to adjust are achieved. A quick-change disc is arranged in the middle of the side wall, away from a longitudinal beam, of a main cross beam, so that grippers are quickly replaced, quickly connected with a robot and communicate with a circuit and compressed air; grabbing assemblies are arranged on the auxiliary cross beams, proper vertical clamping force is generated, and the breathable prefabricated body and the laminated piece are picked up; by arranging height sensors on the auxiliary cross beams, the grabbing assemblies are guided to stably and rapidly pick up one workpiece each time, the requirement for stacking and discharging at the material position on a production line is met, the labor cost is reduced, and the production efficiency is improved; and therefore, automatic grabbing can be achieved, the production takt is shortened, the operation stability is kept, the comprehensive cost is reduced, and the applicability is wide.

Owner:廊坊市飞泽复合材料科技有限公司

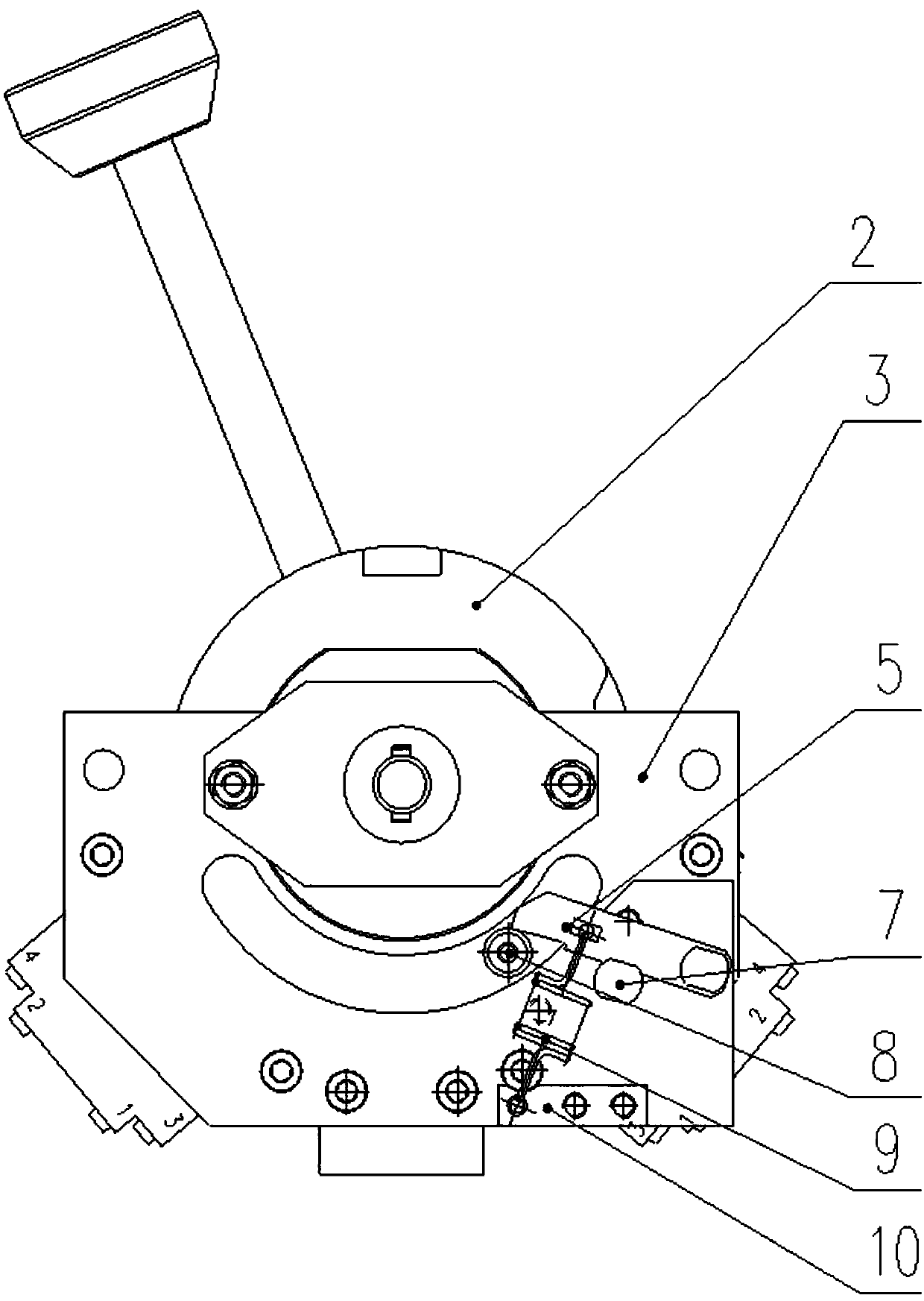

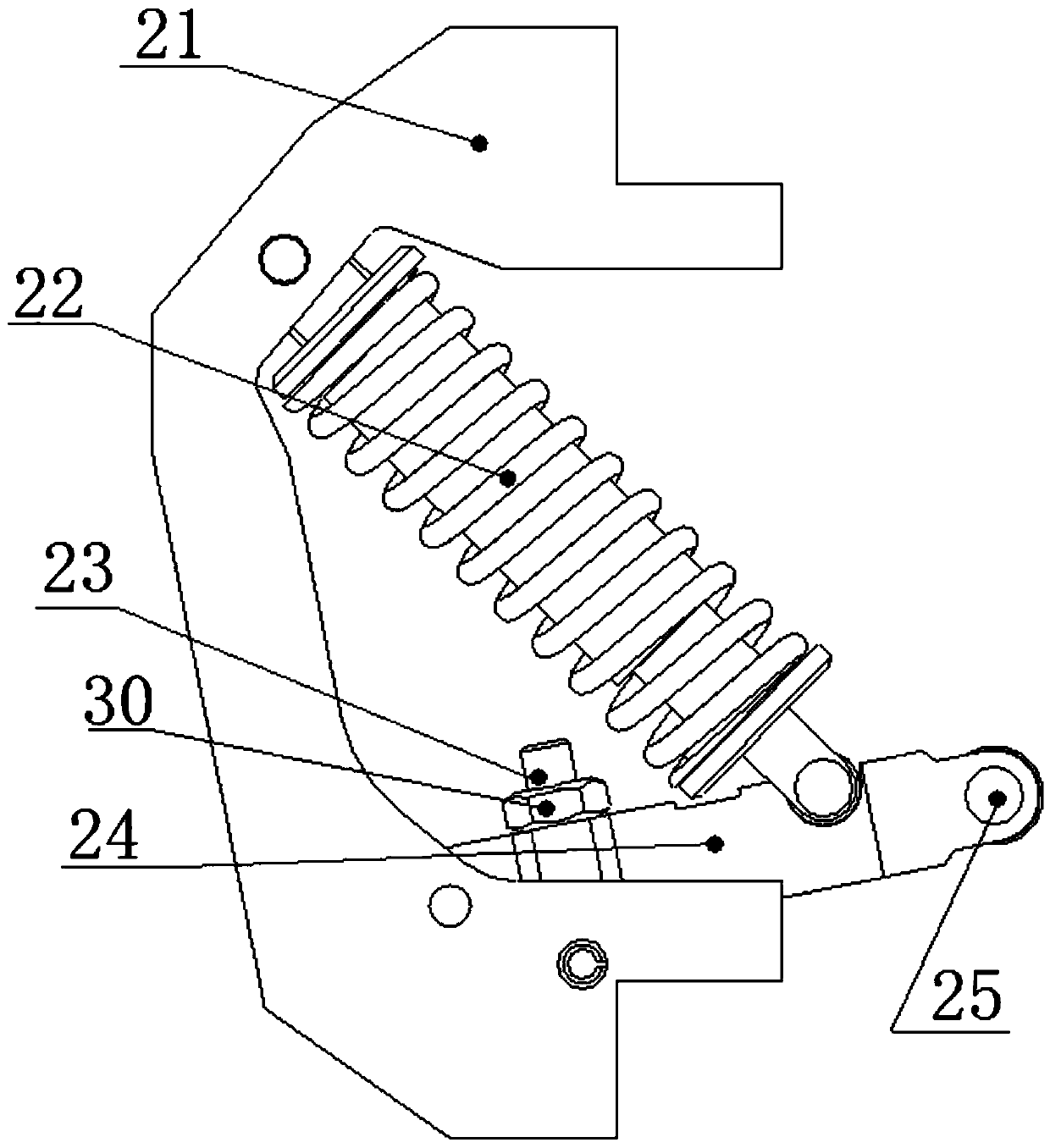

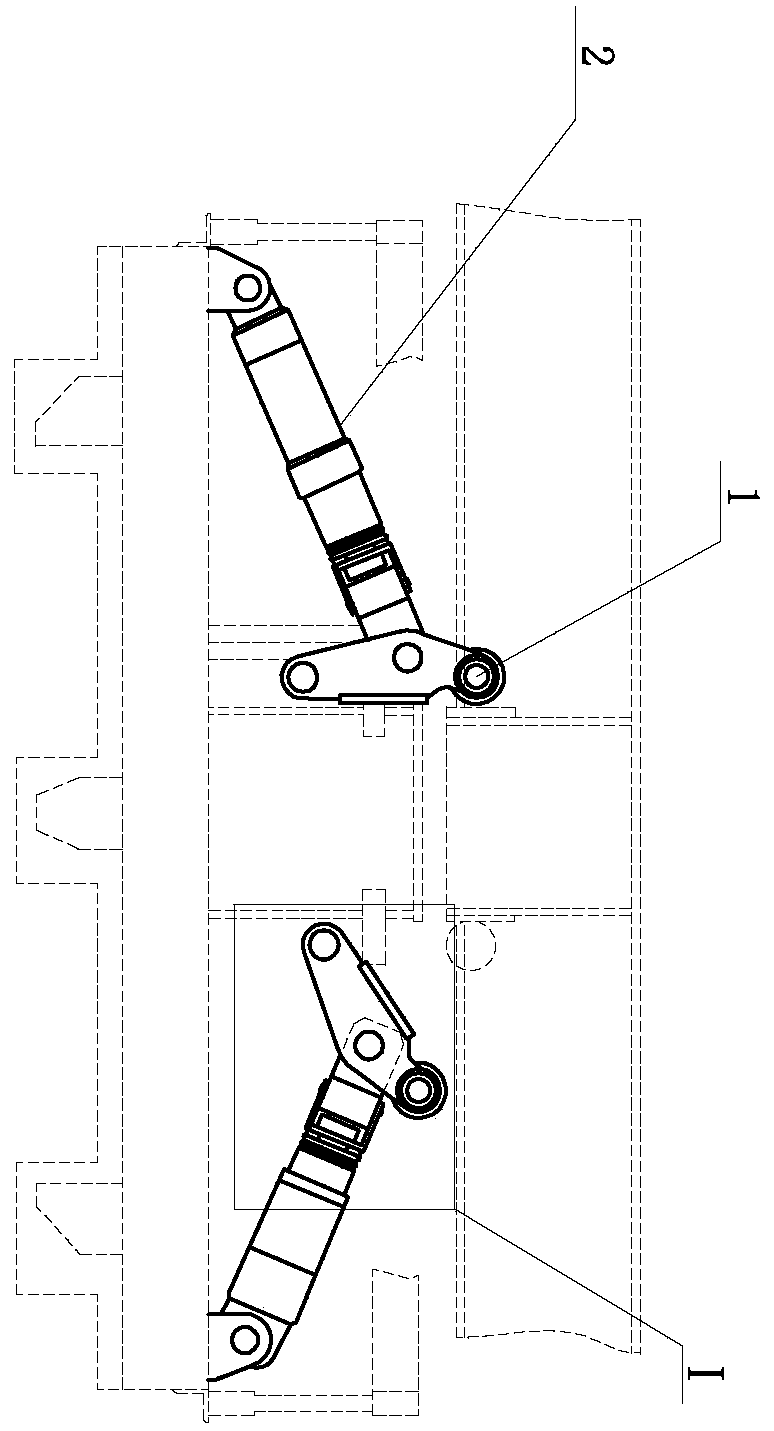

One-way resetting mechanism for locomotive brake controller and brake controller

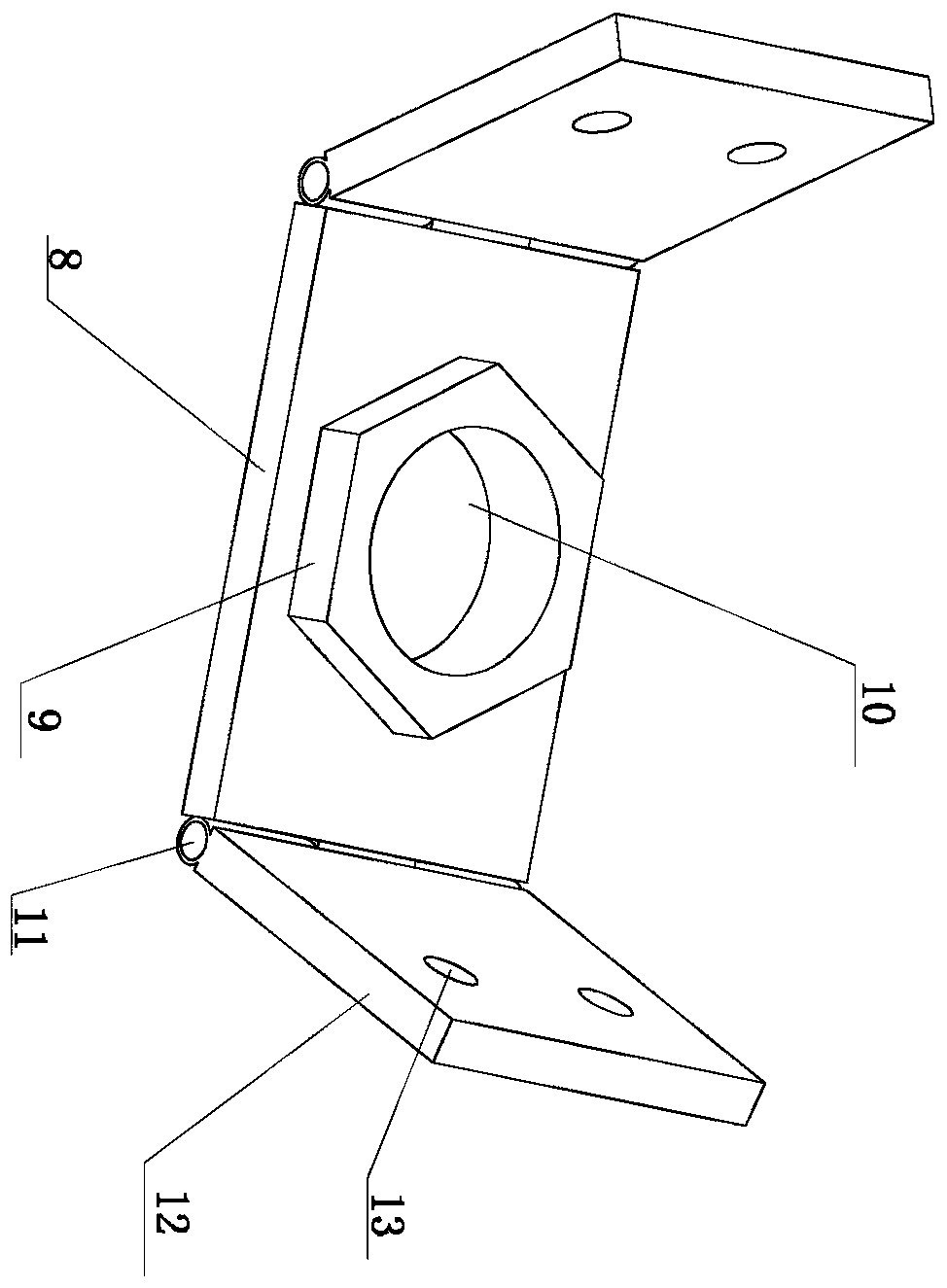

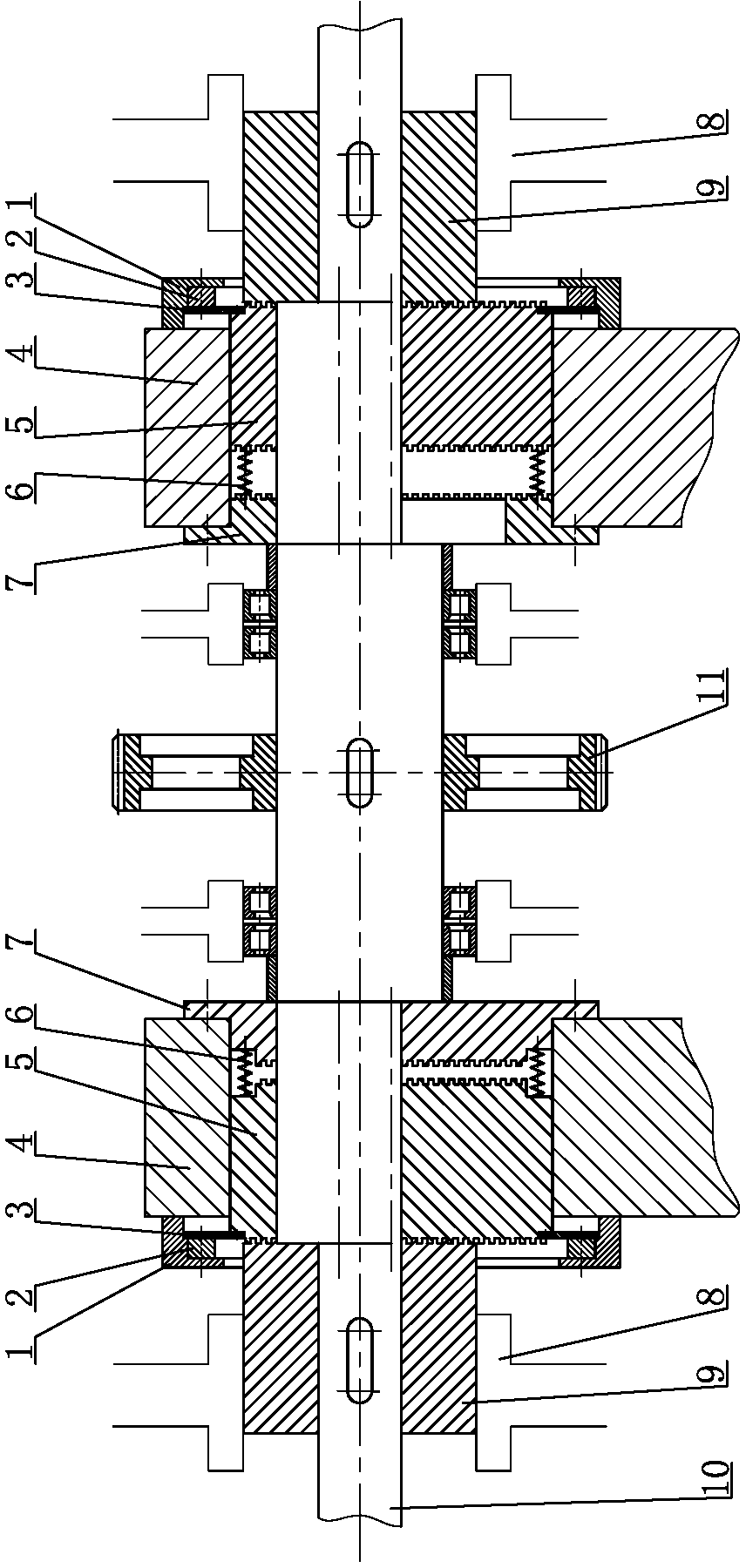

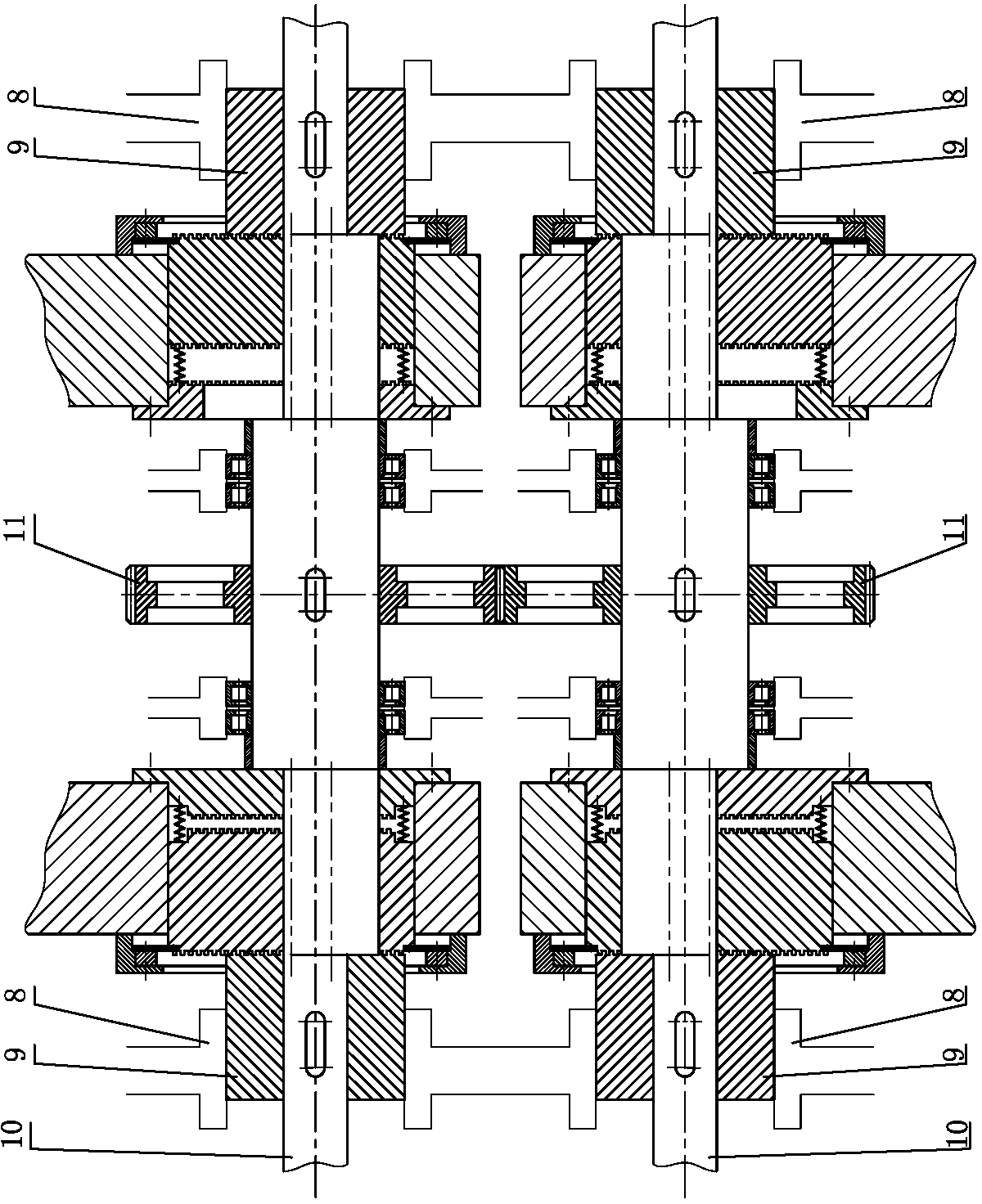

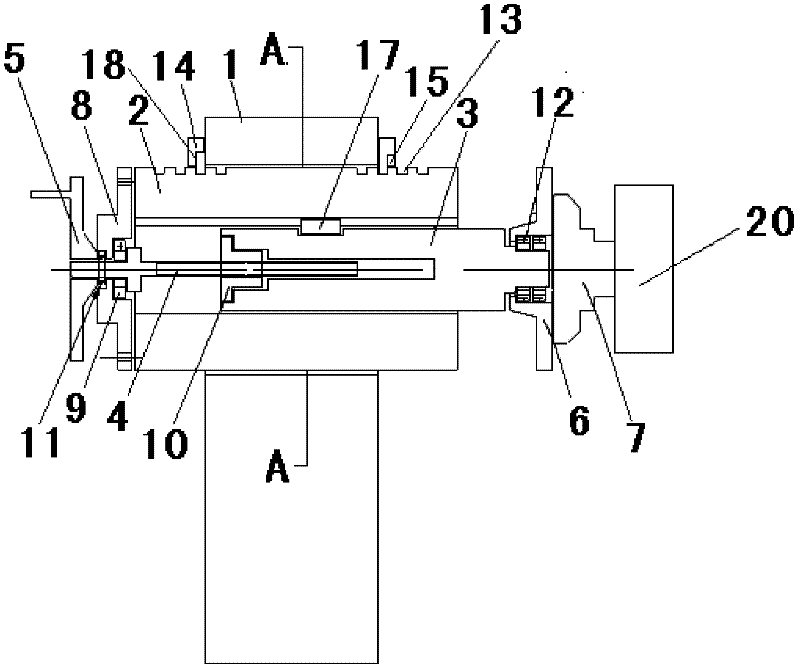

ActiveCN109532932ASolution to short lifeHigh working reliabilityRail brake actuationHand actuated initiationsEngineering

The invention discloses a one-way resetting mechanism for a locomotive brake controller and the brake controller. The one-way resetting mechanism comprises a resetting frame, an elastic mechanism anda resetting lever; one end of the resetting lever is hinged to the resetting frame, and the other end of the resetting lever is hinged to a roller; one end of the elastic mechanism is hinged to the resetting frame, and the other end of the elastic mechanism is hinged to a middle portion of the resetting lever; the elastic mechanism includes a resetting compression spring, a guide cylinder and a guide rod, wherein one end of the guide rod extends into the guide cylinder from one end of the guide cylinder, the other end of the guide rod is hinged to the middle section of the resetting lever, andthe other end of the guide cylinder is hinged to the resetting frame; the resetting compression spring sleeves the guide rod and the guide cylinder; the outer wall of the guide rod is provided with afirst limiting portion limiting one end of the resetting compression spring, and the outer wall of the guide cylinder is provided with a second limiting portion for limiting the other end of the resetting compression spring. The one-way resetting mechanism has high working reliability, good interchangeability, compact structure, capable of making an adjustment stroke easy to adjust, easy to mountand dismount and good in maintenance-free performance.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

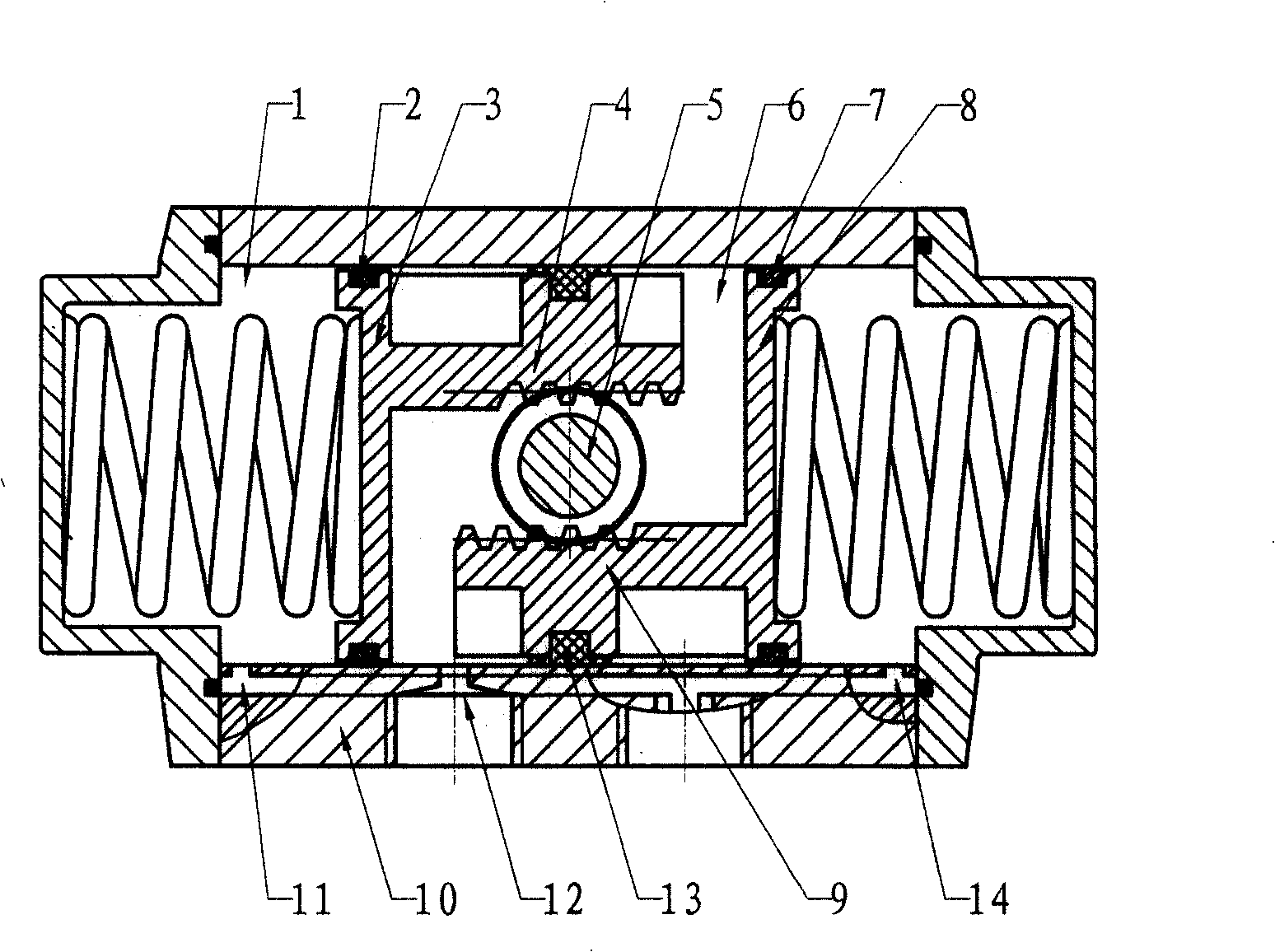

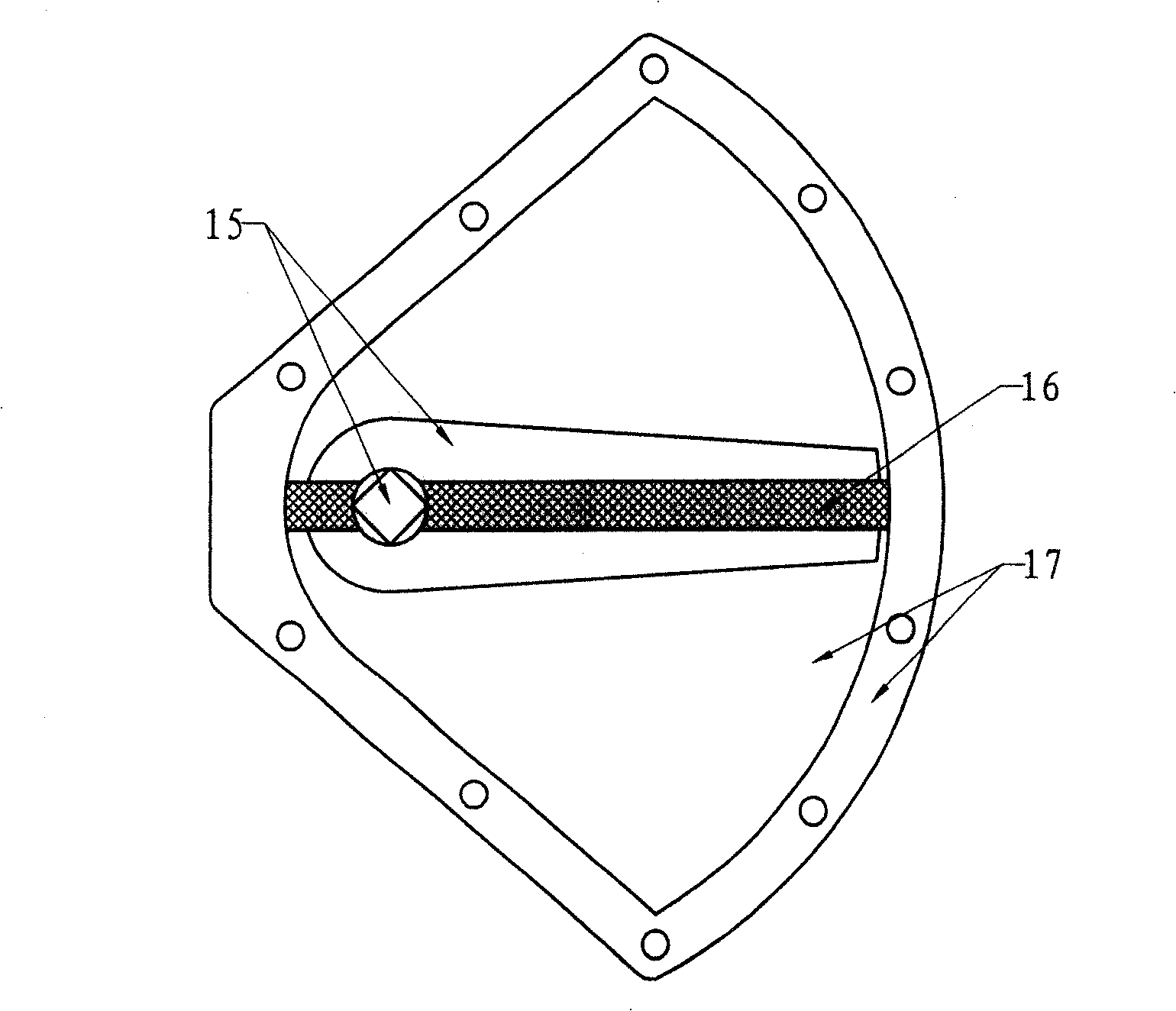

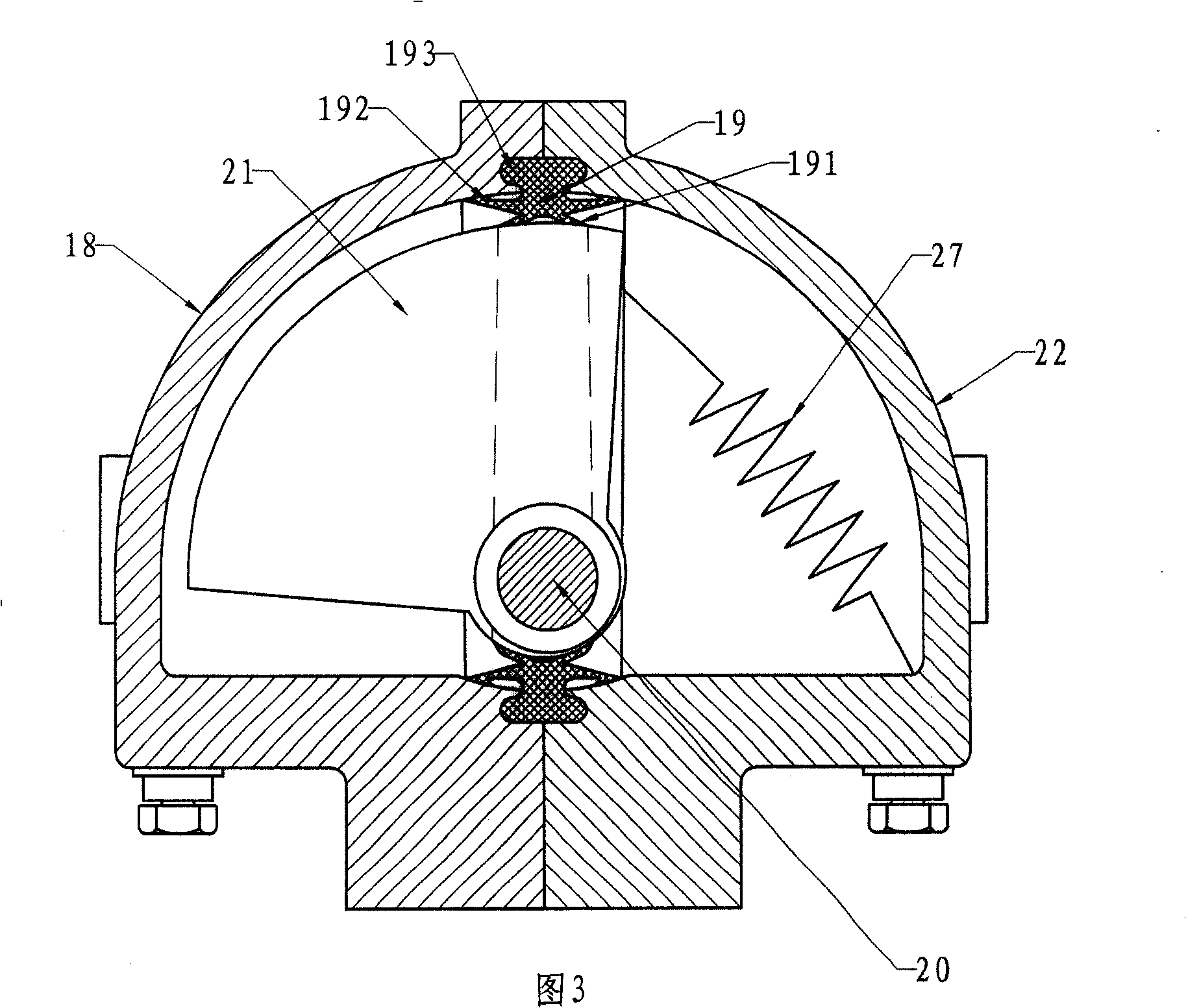

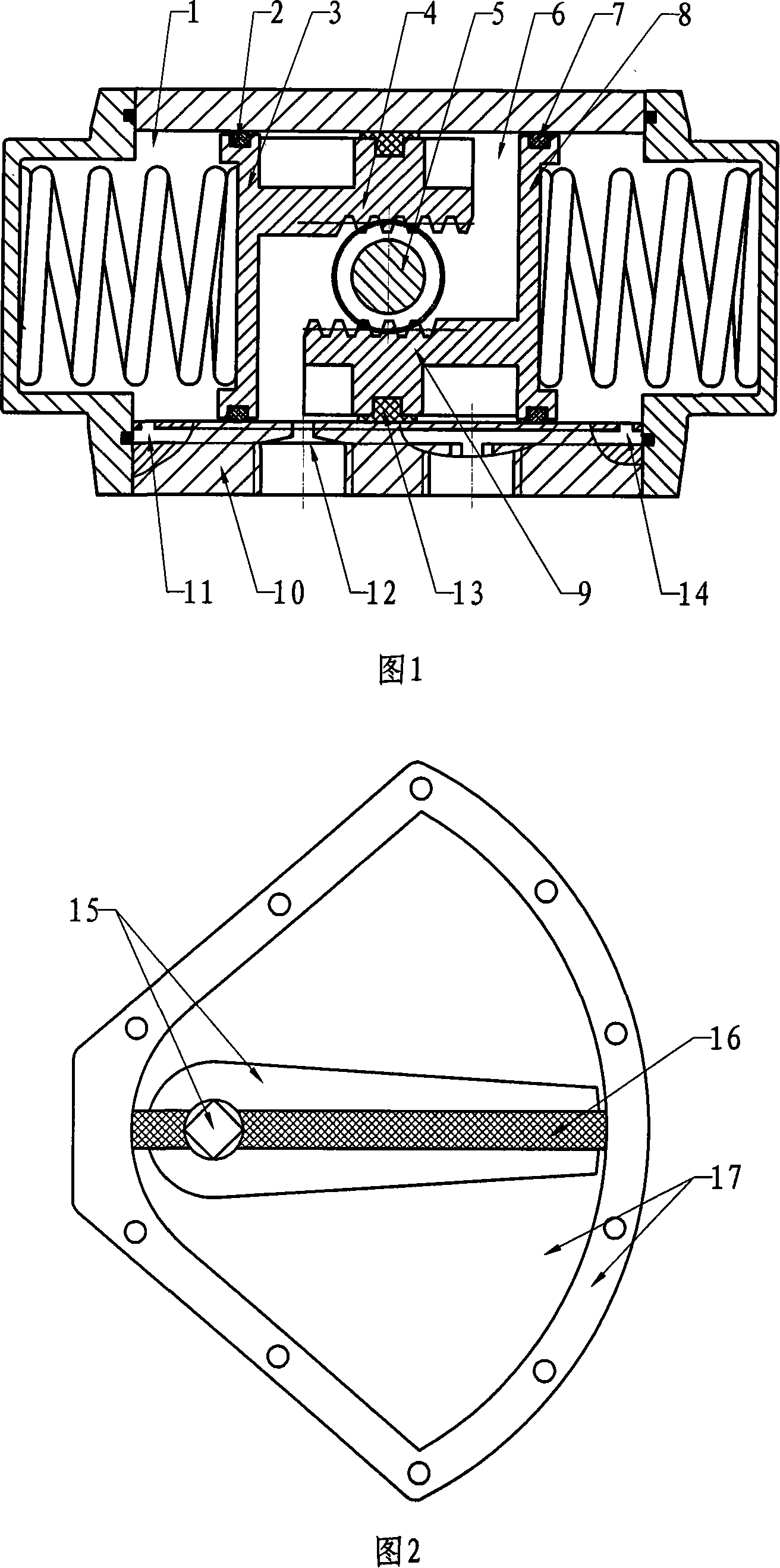

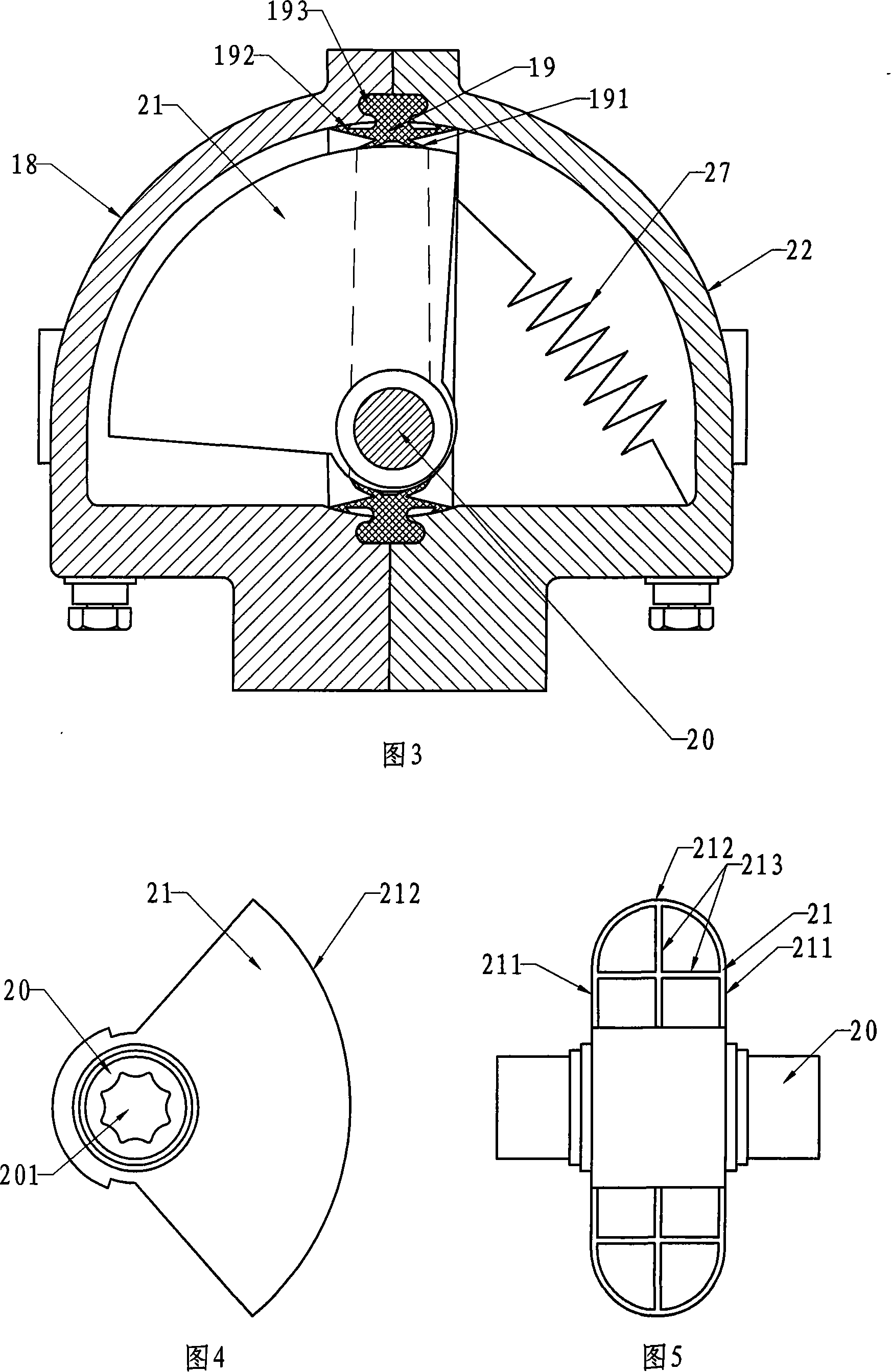

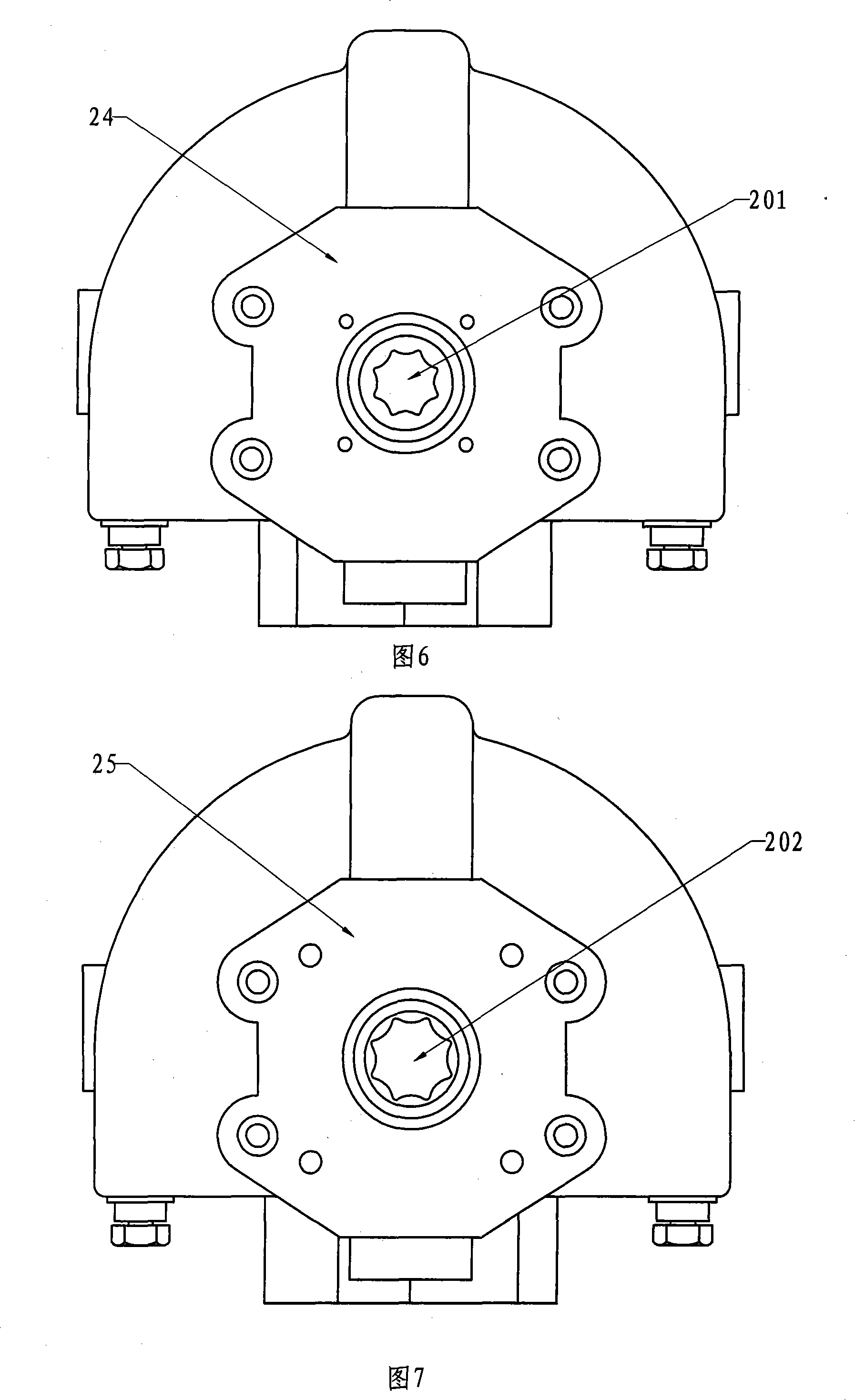

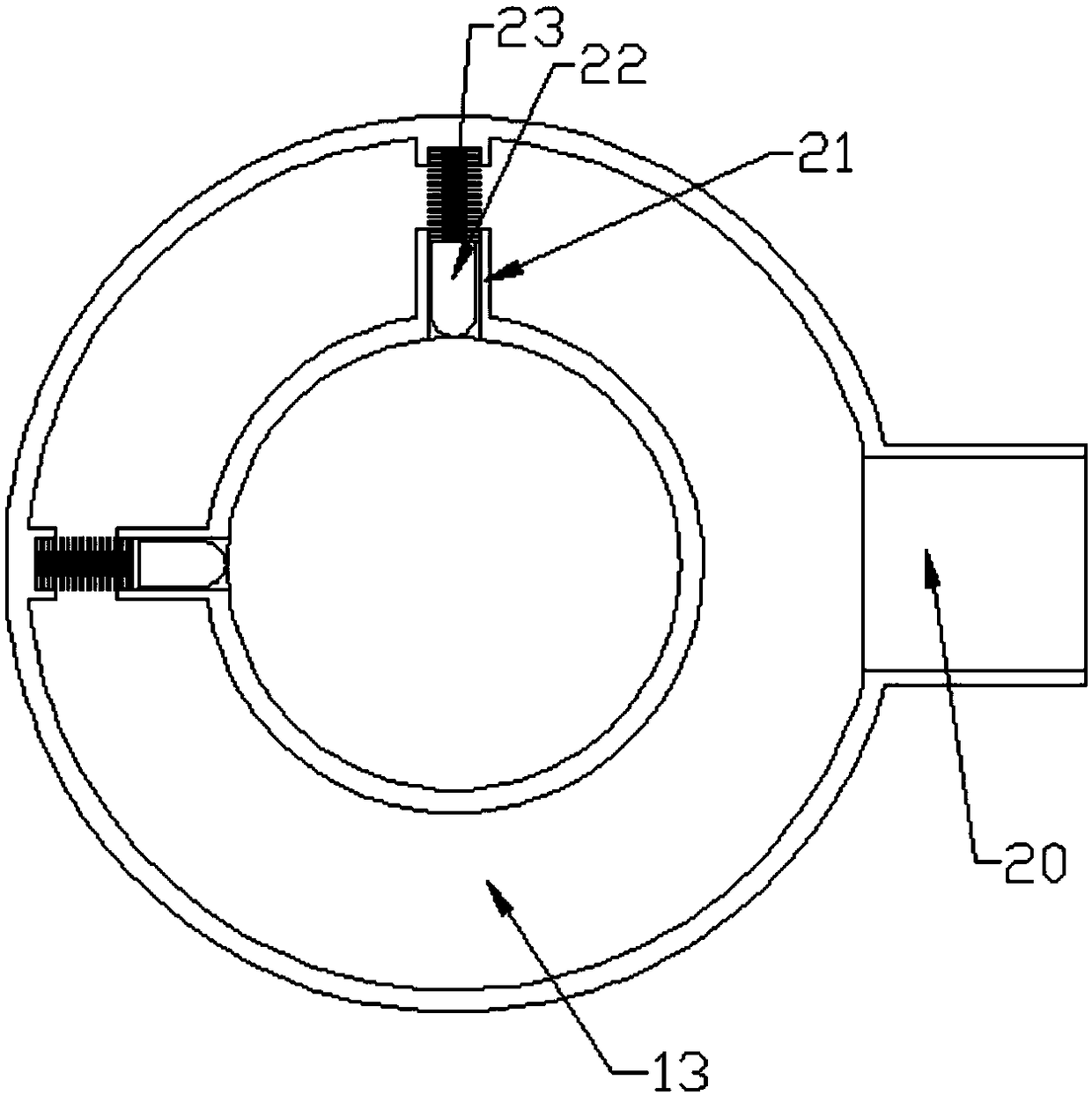

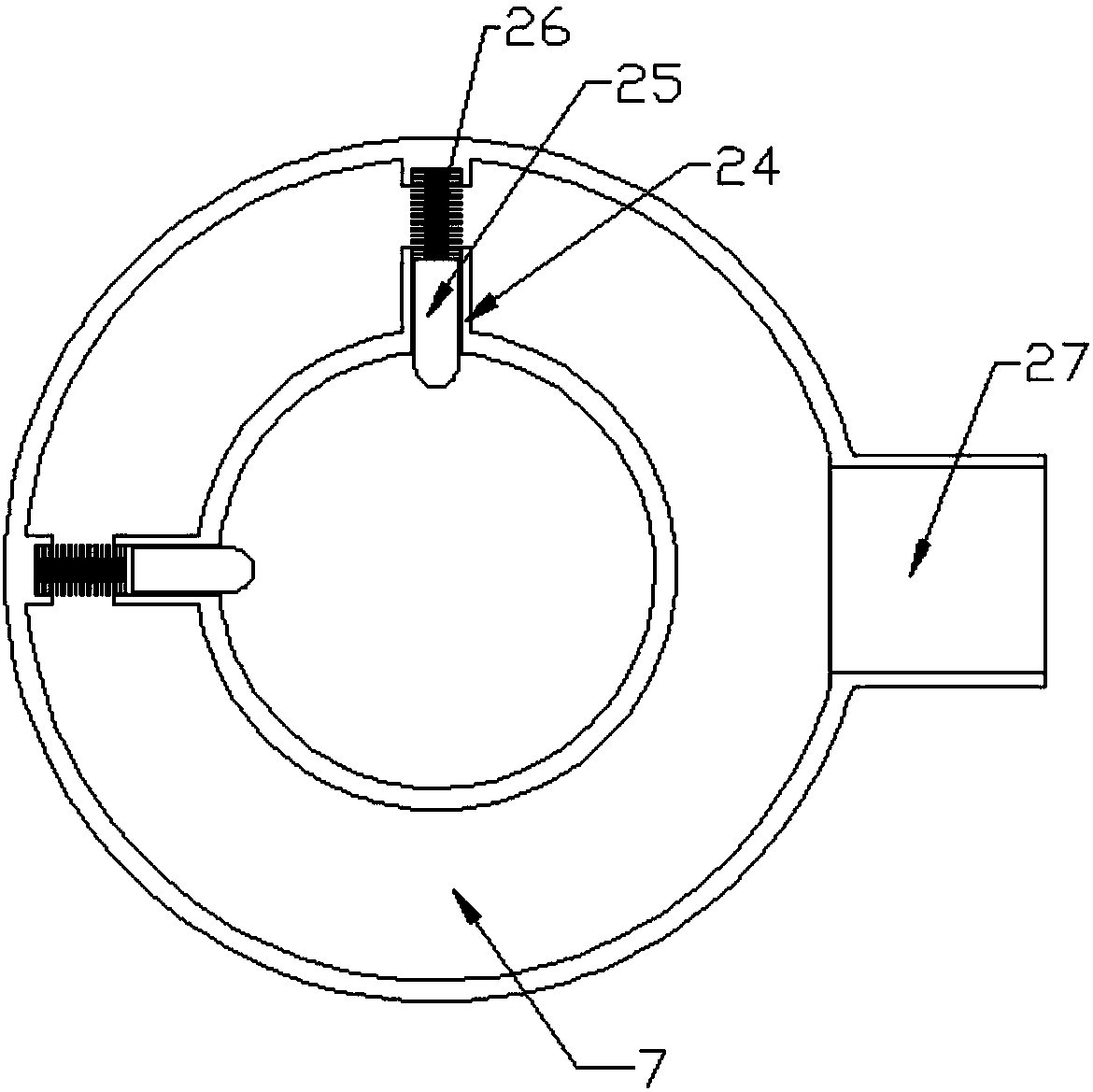

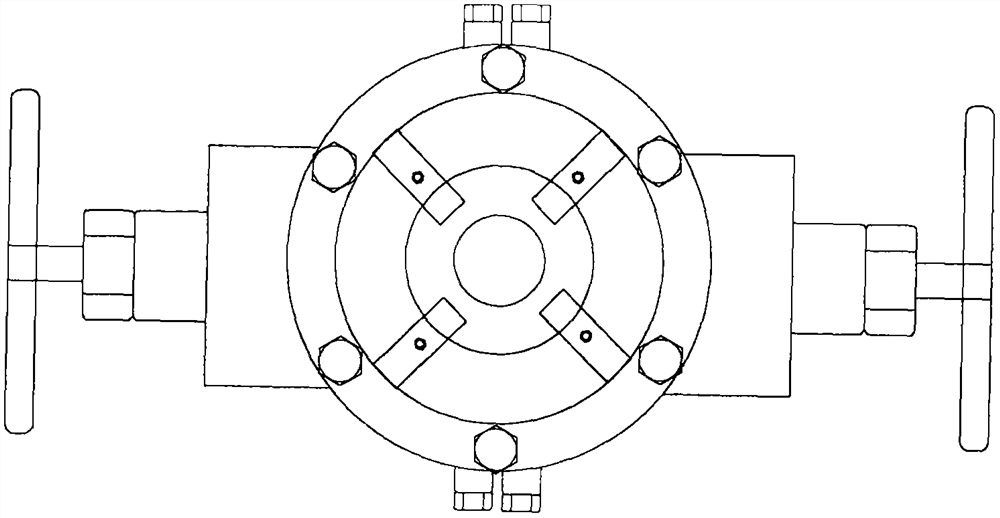

Fan type pneumatic power executor

ActiveCN100458250CReduce energy consumptionFew partsOperating means/releasing devices for valvesAutomatic controlMedial axis

A kind of fan type pneumatic actuator belongs to control valve switch contains external shell, medial axis, rotor and sealing device installing in the external shell body. It has characteristics as that, then rotor is fan type, sealing device is a fixed seal ring which contains rotor seal blade and shell body seal blade. The rotor blade is on the surface of seal ring medial cling to the rotor. The body seal blade is on the inner surface of seal ring lateral cling to shell body. Both sides of rotor seal blade and shell body seal blade setting as '>', '<'type. Both sides of shell body seal blade peripheral setting lug boss. Seal ring fixed on binding surface of two parts of shell. The invention has low energy consumption, simple structure, less components, low cost, is suitable for switch 90 degree of automatic control valve.

Owner:JINAN GAOSHI MACHINERY

Concrete pouring device for highway construction

The invention discloses a concrete pouring device for highway construction, and relates to the technical field of highway construction. The device further comprises a knocking mechanism. Knocking mechanisms are respectively mounted on the bottom plate and the top plate; the knocking mechanism comprises a guide bracket, a crankshaft, a connecting rod, a push rod, a knocking head and a belt pulley; the lower end of each push rod is fixedly connected with a pressure spring; mounting blocks are fixedly connected to the lower ends of the pressure springs; a knocking head is mounted at the lower part of each mounting block; when any one or more knocking heads of the knocking mechanism on the top plate are in contact with the upper end of the template, the knocking heads of the knocking mechanism on the bottom plate are in contact with the rear end face of the template, wherein the positions of the knocking heads are corresponding and the number of the knocking heads is the same. The device has the beneficial effects that bubble discharge in concrete near the formwork can be effectively improved, and the concrete pouring quality is improved.

Owner:田建军 +6

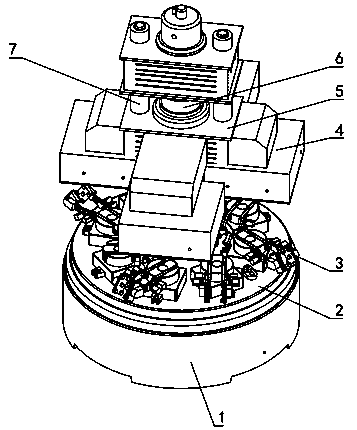

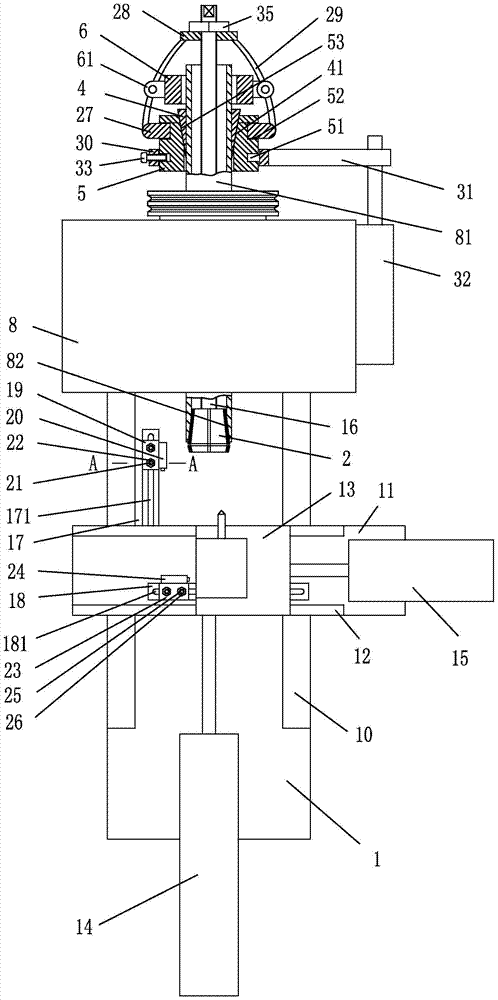

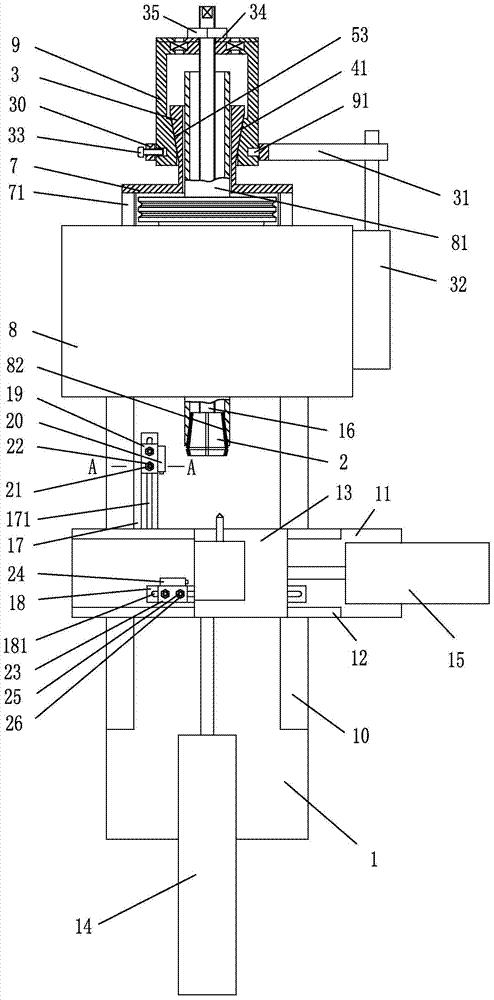

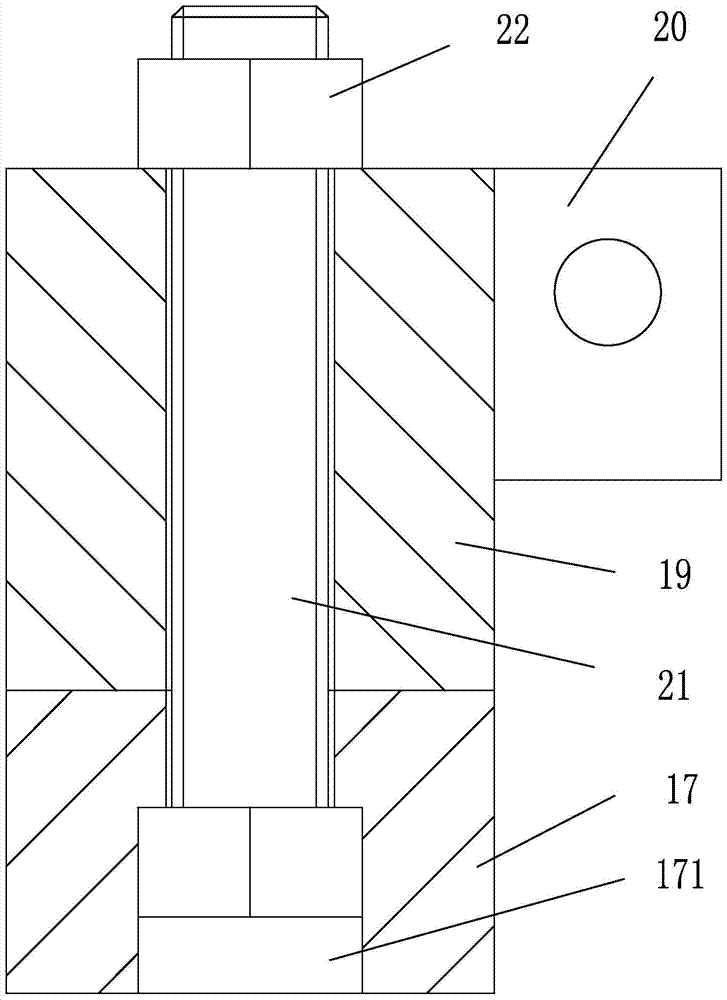

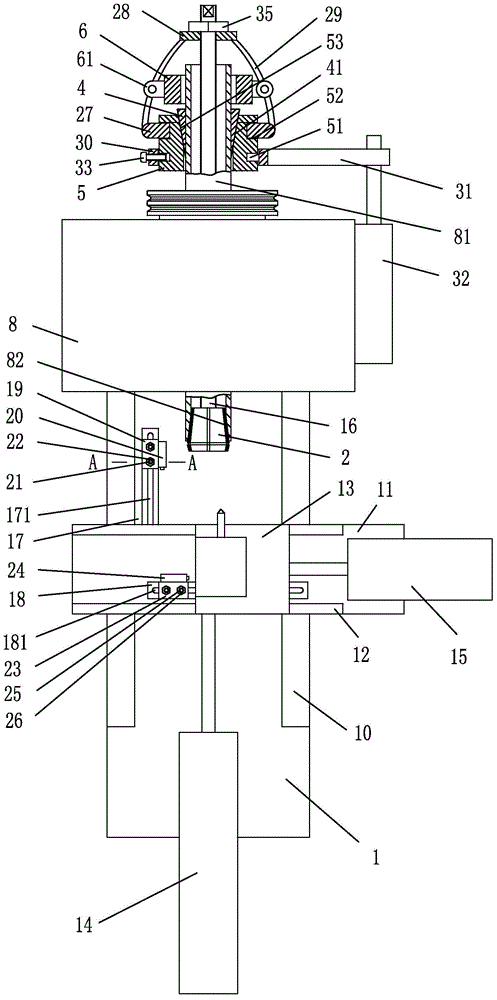

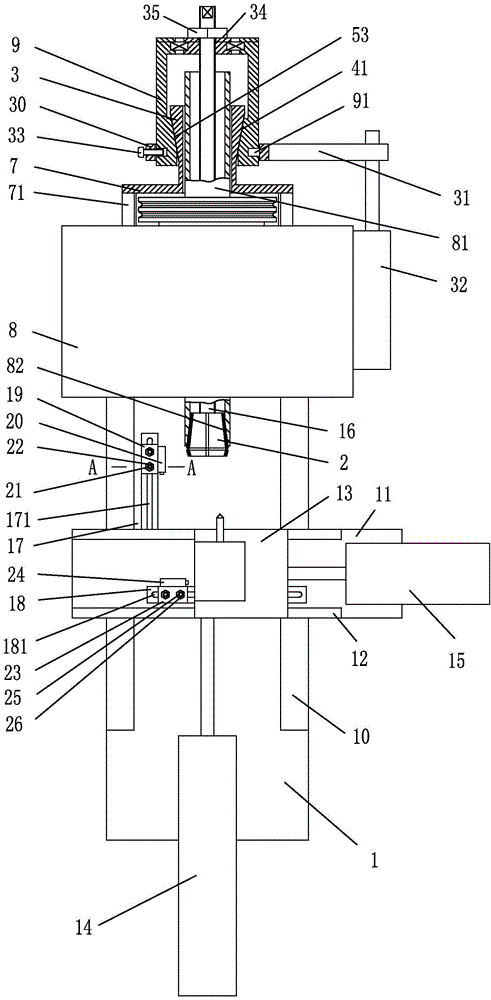

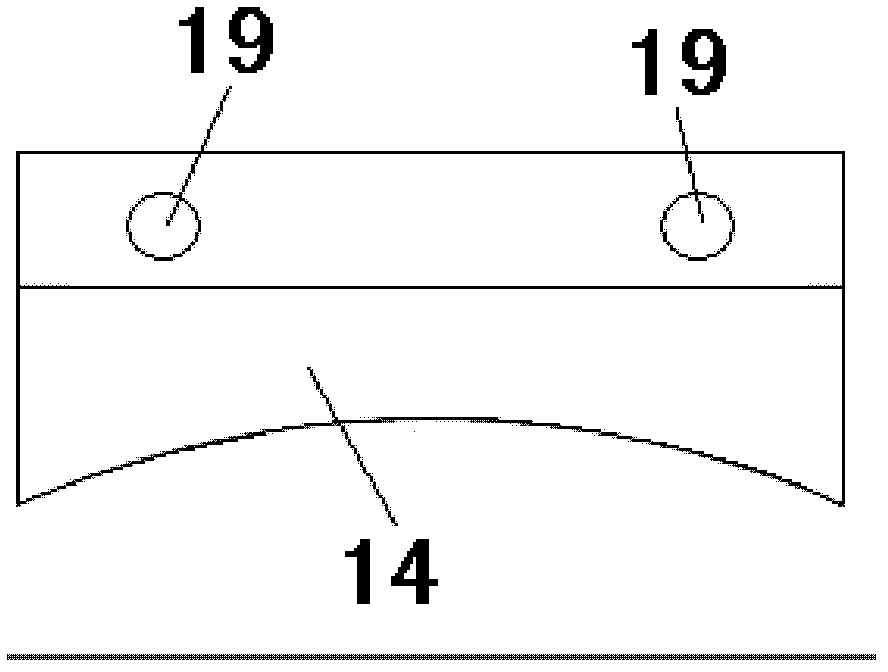

Glass plate processing device

The invention discloses a glass plate processing device and belongs to the technical field of glass plate processing equipment. The device is characterized by comprising a lifting mechanism, a plurality of stamping frames (8) surrounding the lifting mechanism and molds in one-to-one correspondence to the stamping frames (8), wherein a feeding mechanism connected with a corresponding upper mold (41) is arranged on each stamping frame (8), a lower mold is arranged on the lower side of the corresponding upper mold (41), and each lower mold (40) is mounted on each clamp (3); a plurality of rollers(38) are rotationally mounted on each stamping frame (8), arranged on the upper sides of the lower molds (40) and connected with translation mechanisms pushing the rollers to move close to or away from the lower molds (40); each clamp (3) comprises a rotating disc (33), a swing arm and a jaw vice (37), and the rotating disc is connected with a clamp motor driving the rotating disc to rotate. Theglass plate processing device can simultaneously complete processing of multiple glass plates, the glass plate processing speed is high and the product quality is stable.

Owner:QINGDAO TECHN COLLEGE +1

Fan type pneumatic power executor

ActiveCN101082381APlay a sealing roleReduce manufacturing costOperating means/releasing devices for valvesAutomatic controlMedial axis

A kind of fan type pneumatic actuator belongs to control valve switch contains external shell, medial axis, rotor and sealing device installing in the external shell body. It has characteristics as that, then rotor is fan type, sealing device is a fixed seal ring which contains rotor seal blade and shell body seal blade. The rotor blade is on the surface of seal ring medial cling to the rotor. The body seal blade is on the inner surface of seal ring lateral cling to shell body. Both sides of rotor seal blade and shell body seal blade setting as '>', '<'type. Both sides of shell body seal blade peripheral setting lug boss. Seal ring fixed on binding surface of two parts of shell. The invention has low energy consumption, simple structure, less components, low cost, is suitable for switch 90 degree of automatic control valve.

Owner:JINAN GAOSHI MACHINERY

small lathe

The invention relates to the field of machining equipment and provides a small lathe. The small lathe comprises a lathe bed, a spindle box provided with a spindle, a longitudinal dragging plate connected with the lathe bed through a longitudinal guide rail and a transverse dragging plate connected with the longitudinal dragging plate through a transverse guide rail. The small lathe further comprises a longitudinal cylinder, a transverse cylinder, a longitudinal limiting assembly, a transverse limiting assembly, a conical elastic clamp, a threaded connecting rod and a connecting rod driving assembly, wherein a cylinder rod of the longitudinal cylinder is connected with the rear end of the longitudinal dragging plate and is also connected with the lathe bed, a cylinder rod of the transverse cylinder is connected with the rear end of the transverse dragging plate and is also connected with the longitudinal dragging plate, the longitudinal limiting assembly is located on the front side of the longitudinal dragging plate, and the transverse limiting assembly is located on the front side of the transverse dragging plate. A conical hole matched with the conical elastic clamp is formed in the front end of the spindle. The front end of the threaded connecting rod penetrates through the spindle to be connected with the rear end of the conical elastic clamp in a threaded mode. The small lathe is simple in structure, capable of clamping parts effortlessly and high in efficiency.

Owner:宁波神丰汽车部件有限公司

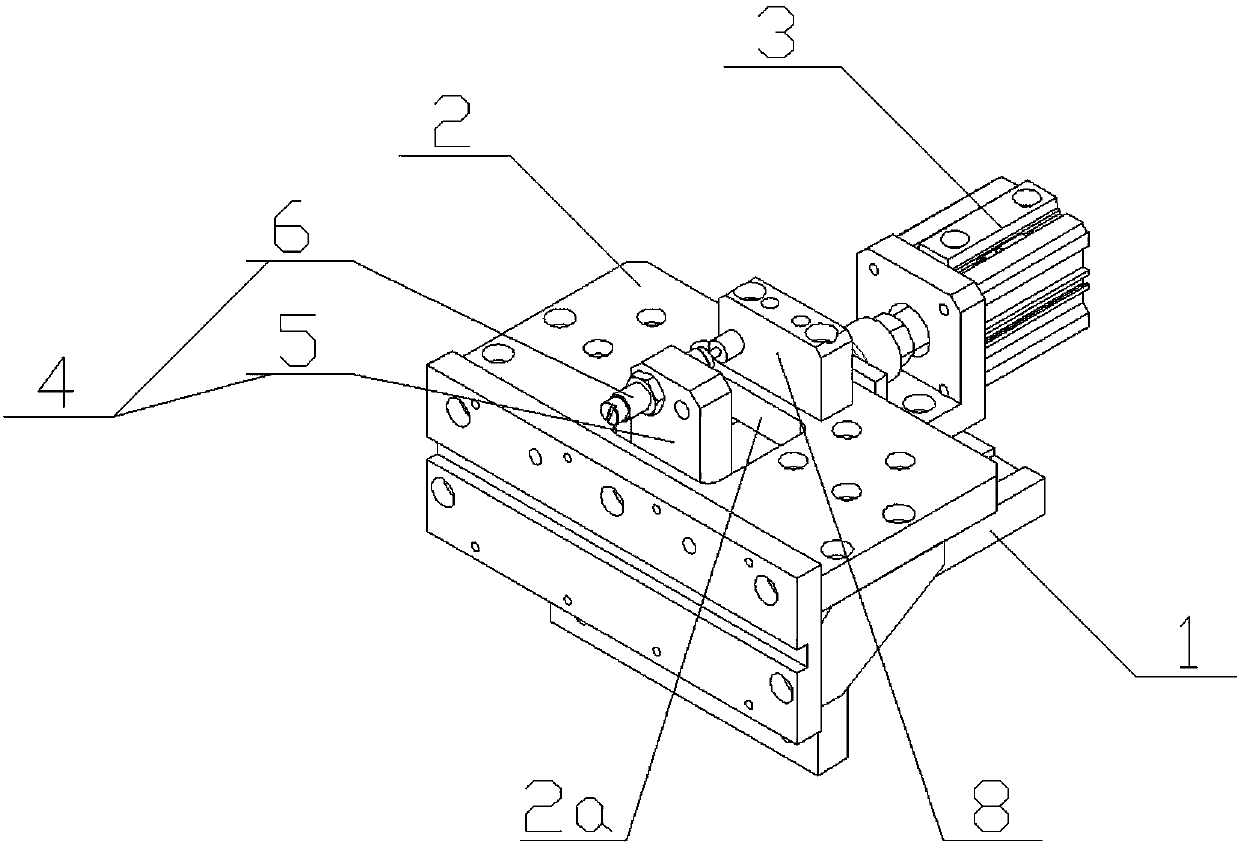

Propulsion mechanism

InactiveCN107720234AAdjustable strokeSimple structureConveyorsConveyor partsControl theoryMechanical engineering

The invention discloses a propulsion mechanism. The propulsion mechanism is characterized by comprising a base (1), a pushing plate (2) movably connected to the base (1), a driving device (3) for driving the pushing plate (2) to move and a limit component (4) connected to the base (1), and the position of the limit component (4) can be adjusted. According to the propulsion mechanism, by arrangingthe limit component adjustable in position, the stroke of the pushing plate can be adjusted; the structure is simple, the stoke adjustment is convenient and reliable, and the cost is low.

Owner:苏州金牛精密机械有限公司

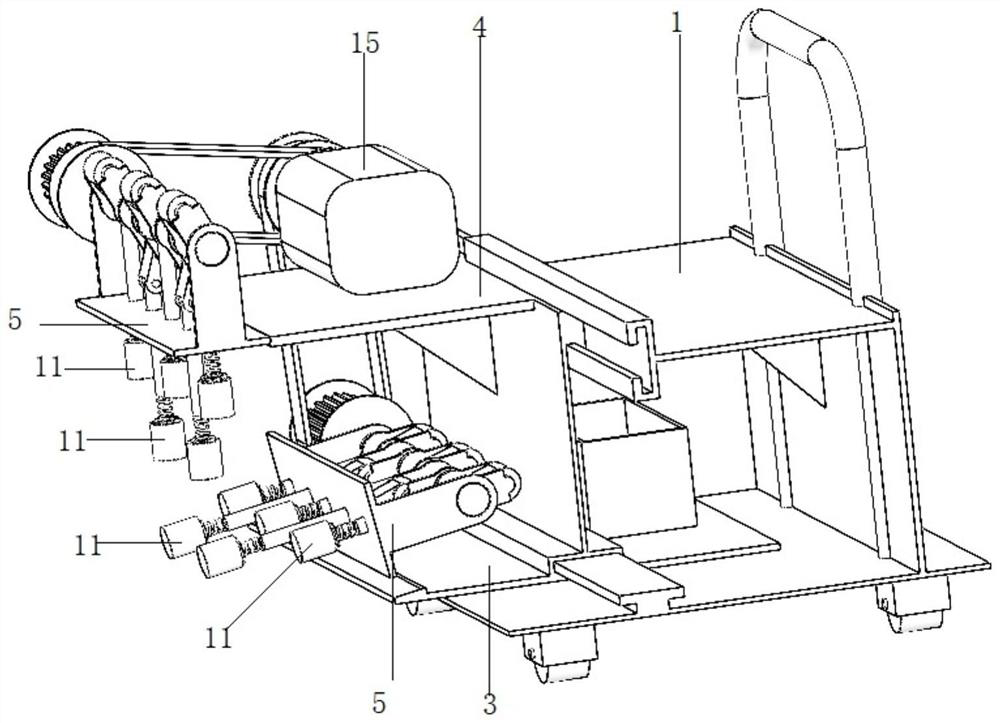

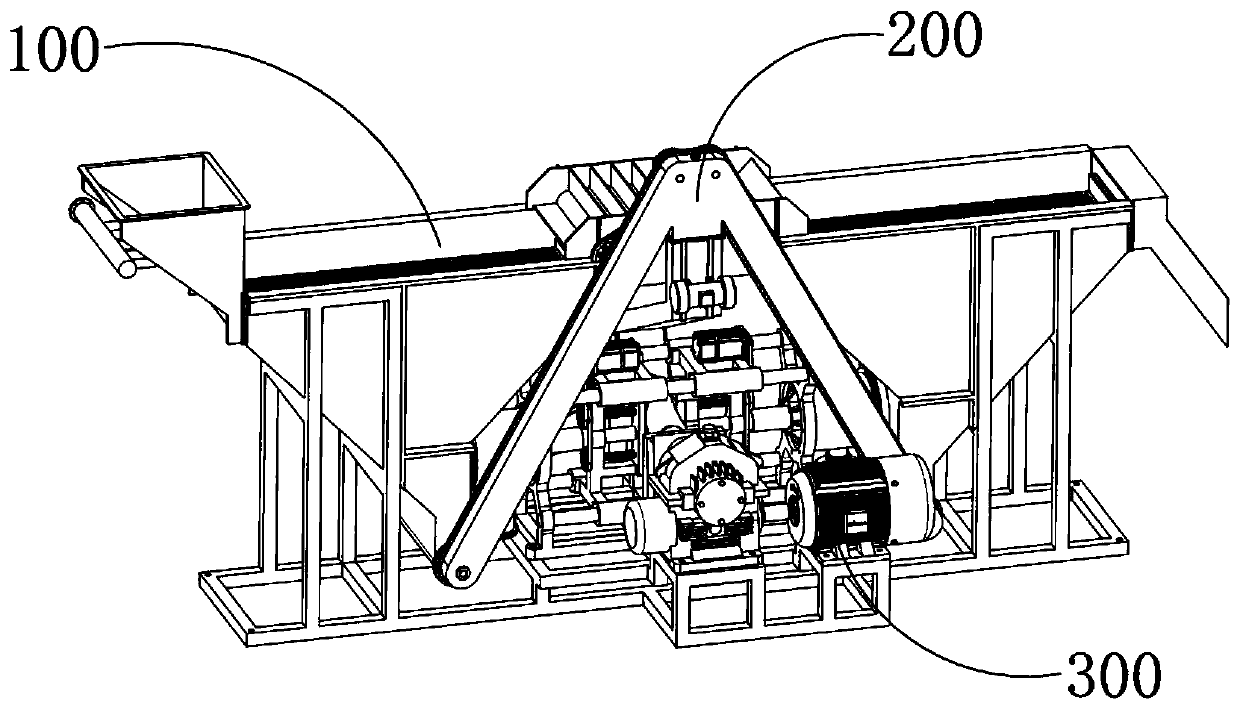

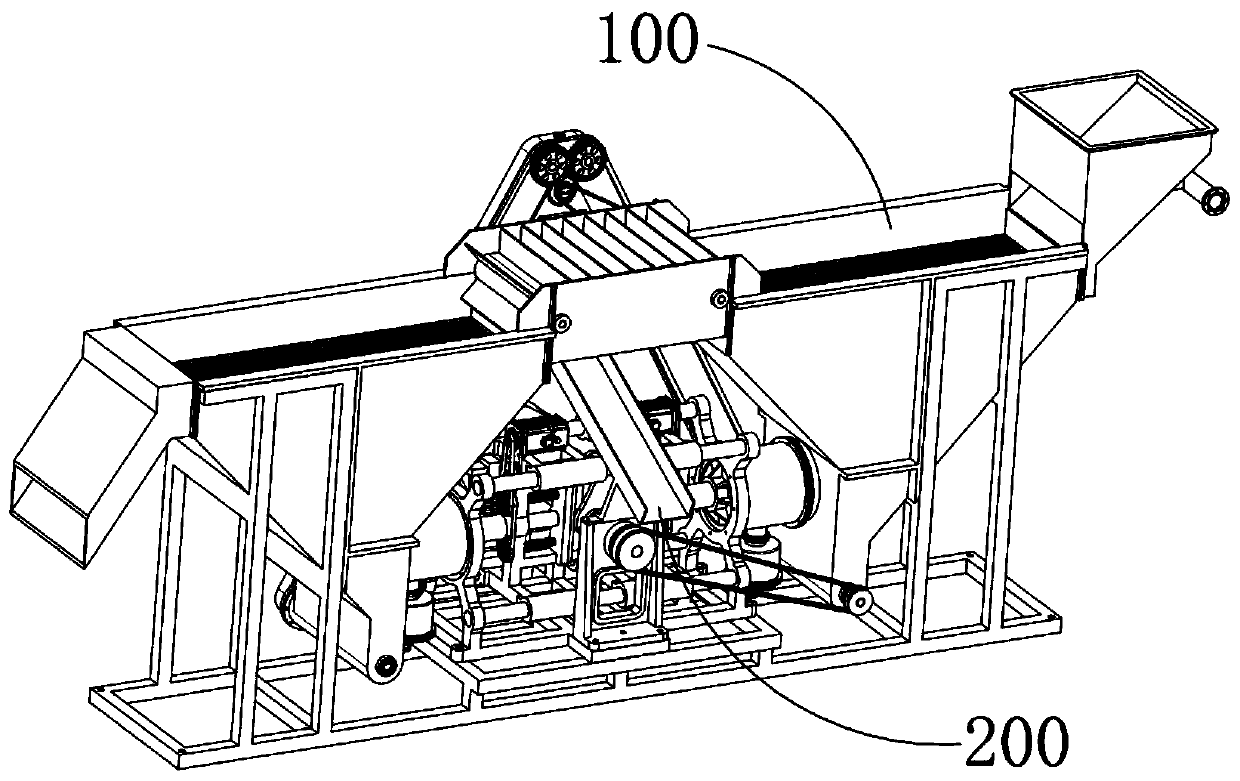

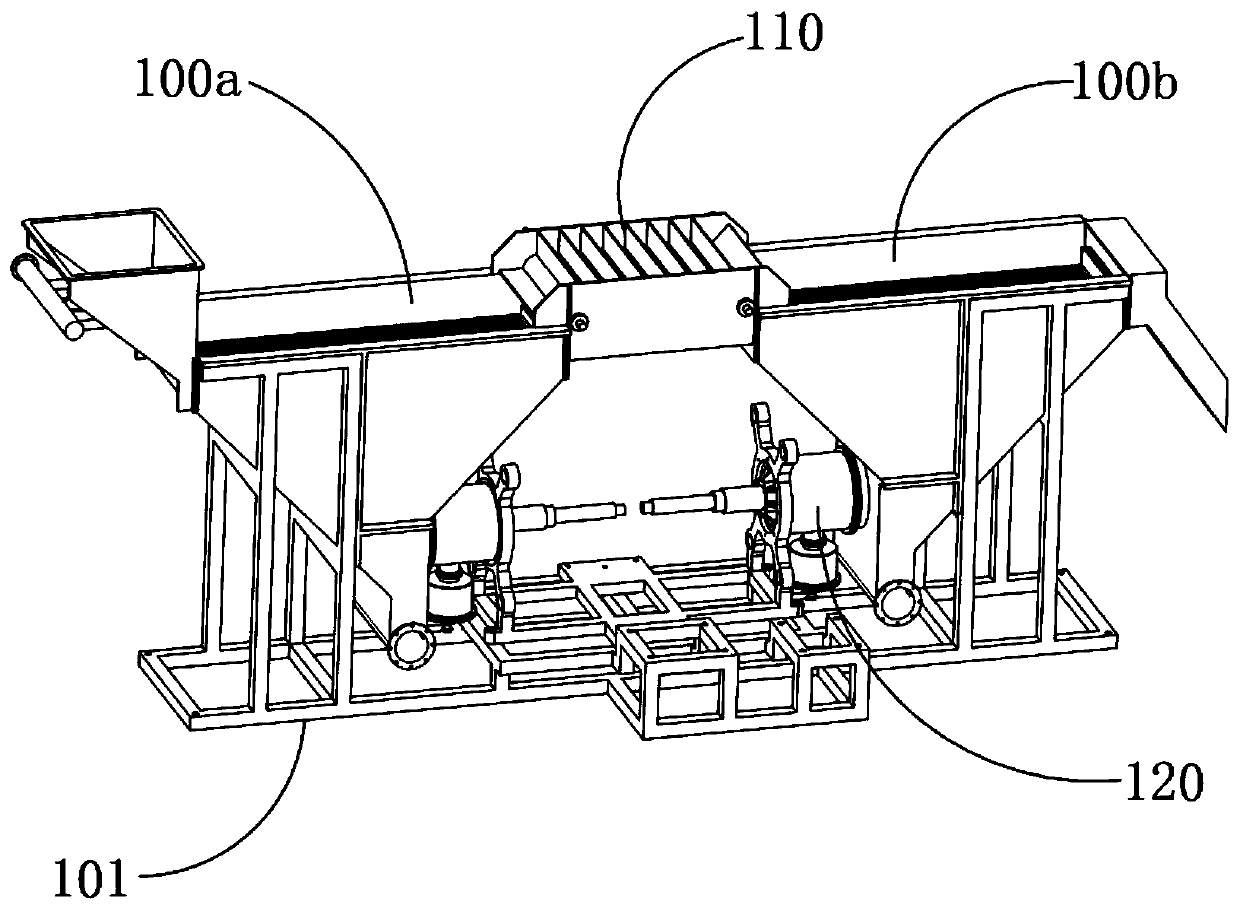

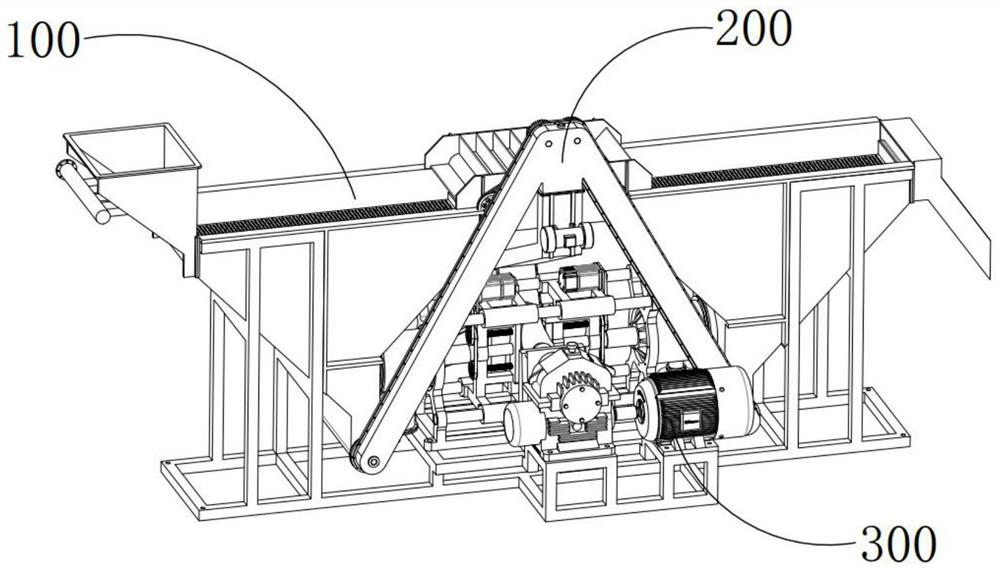

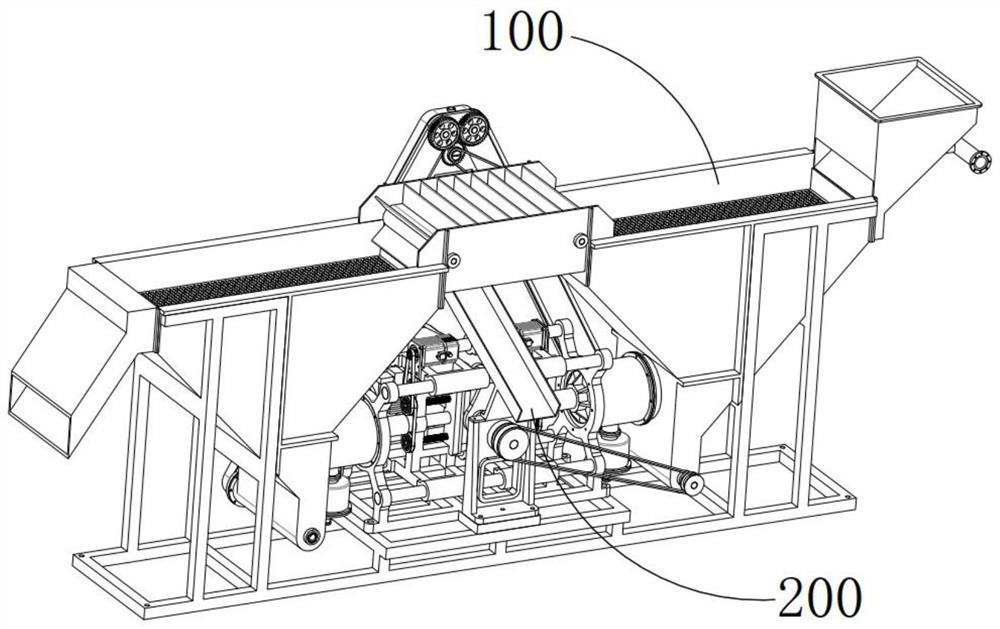

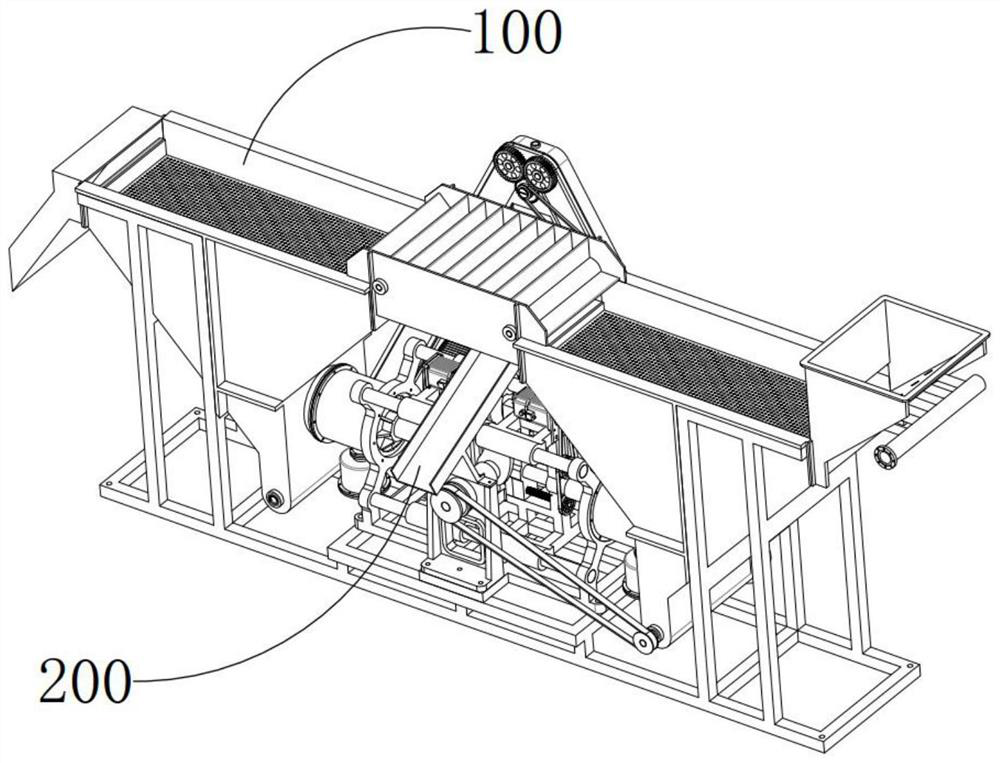

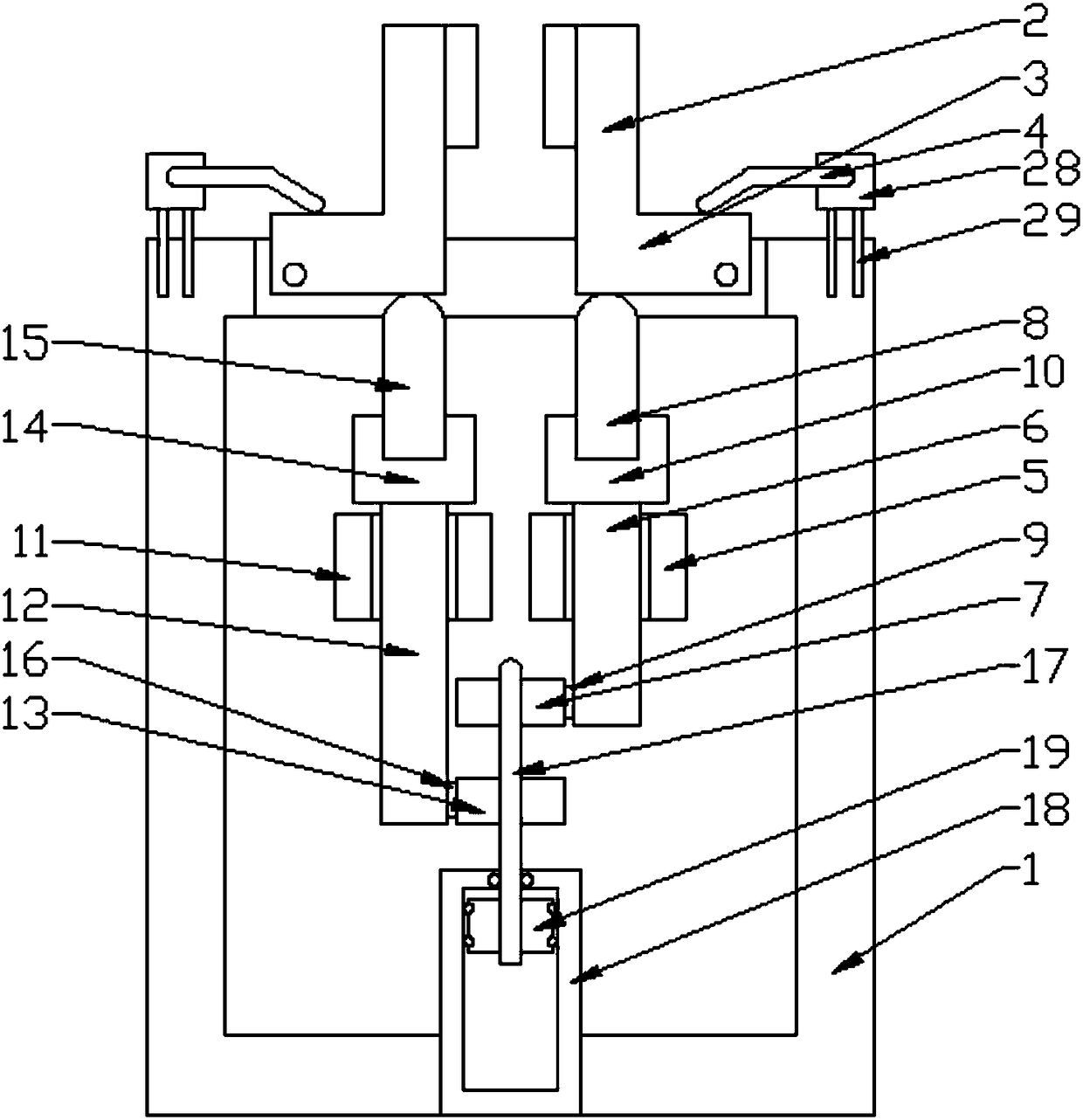

Multistage pyrite water-saving sawtooth wave jig gravity separator

ActiveCN110328043BConvenient telescopic strokeEasy stroke adjustmentWet separationWater savingThermodynamics

The invention provides a multi-stage pyrite water-saving sawtooth wave jigging gravity selection machine. The multi-stage pyrite water-saving sawtooth wave jigging gravity selection machine comprisesjigging boxes which are each of a V-shaped structure with an upward opening and is internally filled with medium water, a discharging device and a power driving device, wherein the jigging box is composed of a first jigging box and a second jigging box which are symmetrically arranged left and right, the first jigging box is used for receiving a mixture of pyrite and waste rock monomer and carrying out concentrate reselection, the second jigging box is used for carrying out secondary concentrate reselection on the mixture of the pyrite and the waste rock monomer and discharging tailings, and aconveying mechanism for connecting the opening of the first jigging box and the opening of the second jigging box is arranged between the opening of the first jigging box and the opening of the second jigging box; and an agitation mechanism used for vibrating the inner medium water is arranged on the side face, close to the bottom, of the jigging box, the discharging device is used for dehydrating and discharging the concentrate deposited at the bottom of the jigging box, and the power driving device is used for providing driving power for the conveying mechanism, the agitation mechanism andthe discharging device.

Owner:安徽省红顺新材料科技有限责任公司

Jig gravity separation process of pyrite

ActiveCN110369115BConvenient telescopic strokeEasy stroke adjustmentWet separationThermodynamicsPyrite

The invention provides a jigging gravity separation process for pyrite, the steps of which are as follows: firstly, the mixture of the ground pyrite and waste rock monomer is transported to the first jigging box, and the power driving device transmits the power to the first jigging box To the agitation mechanism, the agitation mechanism makes the medium water in the first jigging box and the second jigging box produce sawtooth wave vibration, and the first jigging box performs a concentrate gravity separation on pyrite and waste rock monomers and concentrates Deposited on the bottom of the first jigging box; then, the power drive device transmits the power to the transmission mechanism, and the transmission mechanism guides the pyrite, waste rock monomer and medium water in the first jigging box to the second jigging box Then, the second jigging box performs secondary concentrate gravity separation on pyrite and waste rock monomers, and the concentrate is deposited on the bottom of the second jigging box, and the tailings are discharged from the hopper of the second jigging box Discharging; in the process of step 1 to step 3, the discharge device dehydrates and discharges the concentrate at the bottom of the first jigging box and the bottom of the second jigging box.

Owner:LUAN YONGZHEN GRIZZLY ELECTRICAL & MECHANICAL TECH CO LTD

Automatic robot finger

InactiveCN108127676ASimple structureReduce manufacturing costGripping headsAtmospheric pressureCalipers

The invention relates to an automatic robot finger. The automatic robot finger comprises a caliper seat; a connecting opening is formed in the top of the caliper seat; two sets of calipers are symmetrically disposed in the connecting opening; a driver is disposed at the bottoms of the calipers and comprises a linear driver body and two sets of ejector rods; the ejector rods are connected with a piston rod of the linear driver body through sliding rings; bolt blocks are disposed in the sliding rings and are positioned through the air pressure and springs; the number of the ejector rods drivingthe calipers to swing is controlled through combination and separation between the bolt blocks and the piston rod, and asynchronous pneumatic action of the calipers is achieved. A left driving sleeveand a right driving sleeve are driven through the air pressure, and separation and combination between the driving sleeves and a caliper linkage mechanism are achieved through the different pressures,so that a single-action mode or a double-action mode is achieved, the structure is simple, and the manufacturing cost is low.

Owner:张超

Anti-loosening and stroke calibration device for actuator of automatic position system for dry quenching

PendingCN110452720AGuaranteed movement trajectoryAvoid loose phenomenonCoke quenchingHydraulic cylinderActuator

An anti-loosening and stroke calibration device for an actuator of an automatic position system for dry quenching includes a clamping arm and a hydraulic cylinder. A trunnion is mounted between that clamping arm and the hydraulic cylinder, one end of the trunnion is hinged to the clamping arm, the other end of the trunnion is provided with a first threaded hole, the hydraulic cylinder is fitted with a piston rod capable of sliding along the length direction thereof, the outer periphery of the top end of the piston rod is provided with a first external thread which is matched with the first threaded hole, the outer periphery of the piston rod on the low end of that first external thread is provided with a second external thread, the direction of rotation of the second external thread is opposite to the direction of rotation of the first external thread, the invention connects the clamping arm with the piston rod through a detachable fastening device which is not cumbersome, the piston rod adopts two kinds of threads with opposite direction of rotation, which can form self-lock at the connecting part, prevent the thread from loosening, make the hydraulic cylinder complete the settingaction accurately, avoid the wrong operation, and prolong the service life of the equipment to the maximum extent under the premise of ensuring the normal operation.

Owner:JIGANG INT ENG & TECH CO LTD

Synchronous regulation structure for stroke of pressing machine

Owner:YANGLI GRP CORP LTD

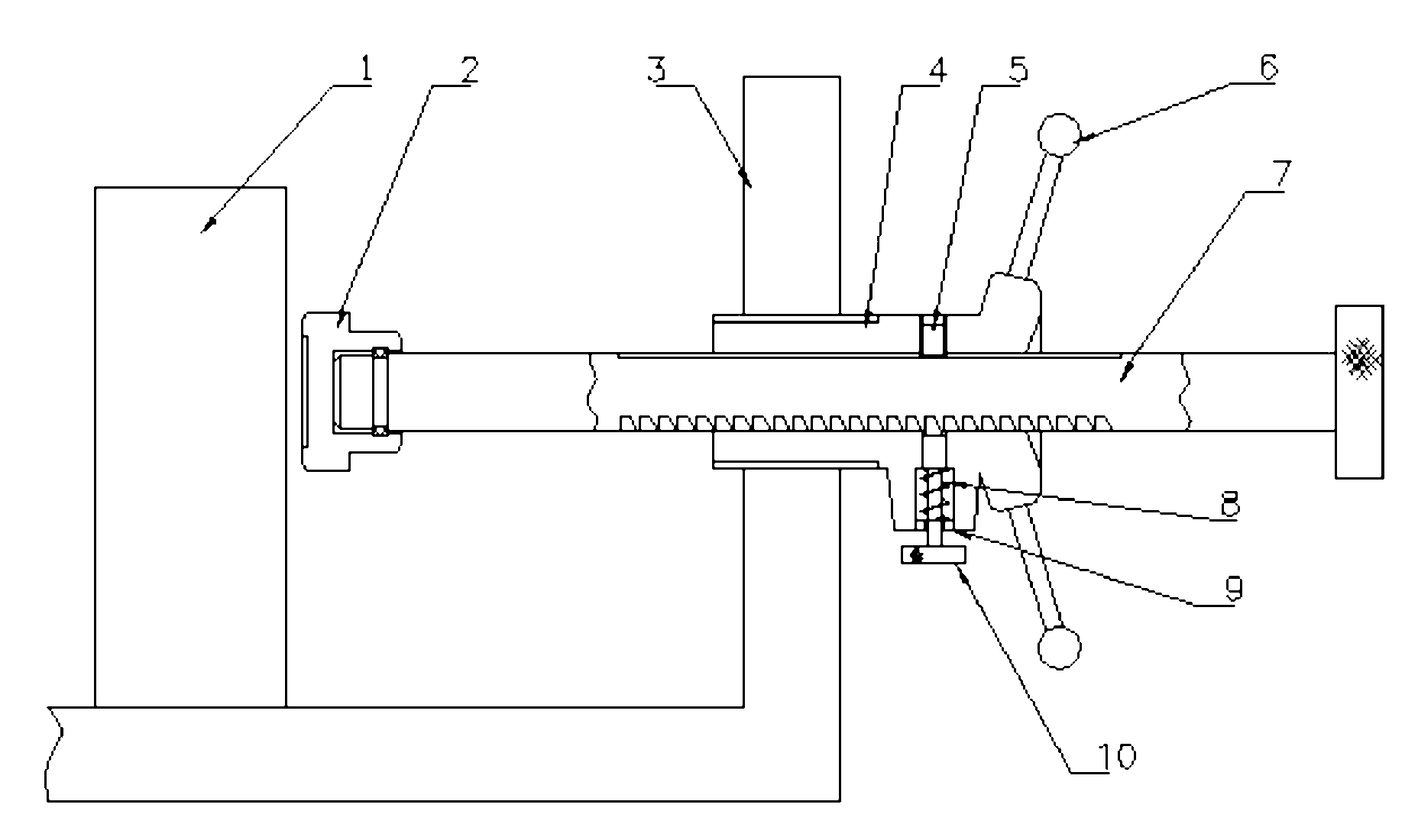

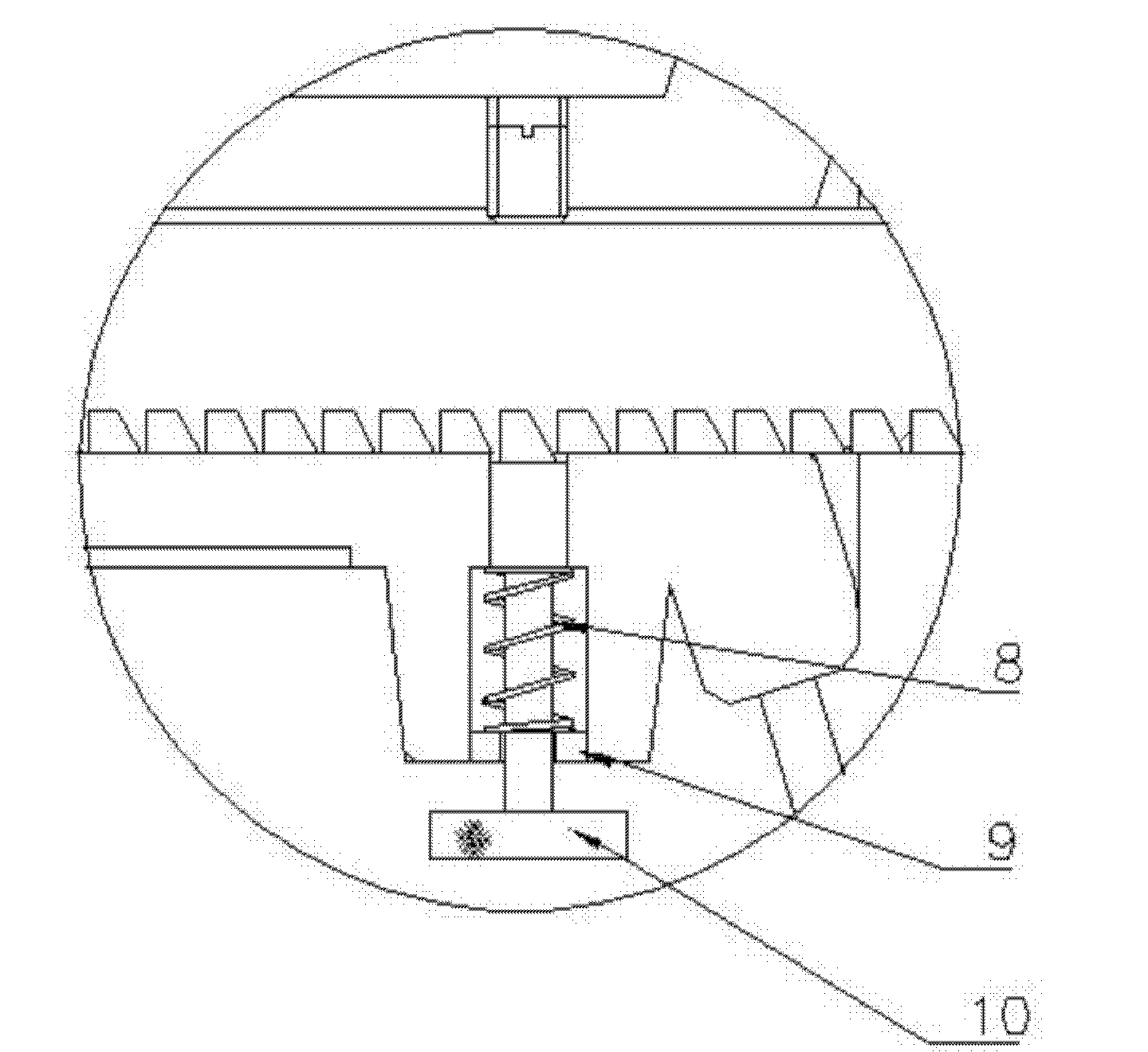

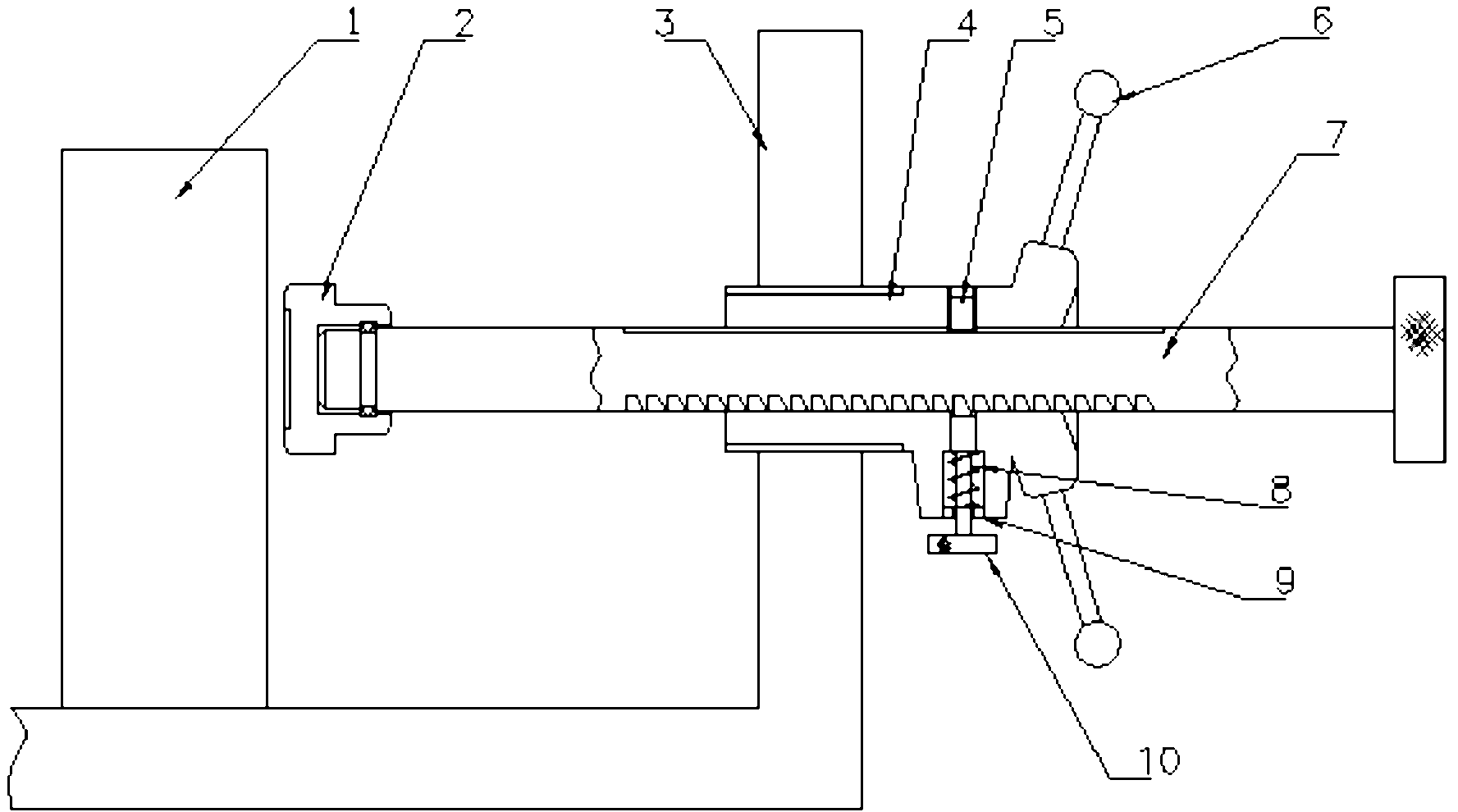

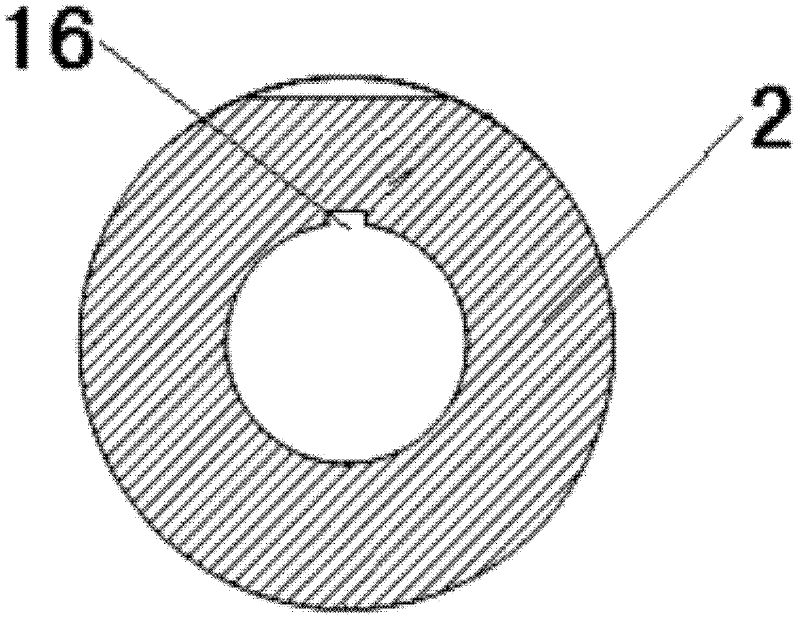

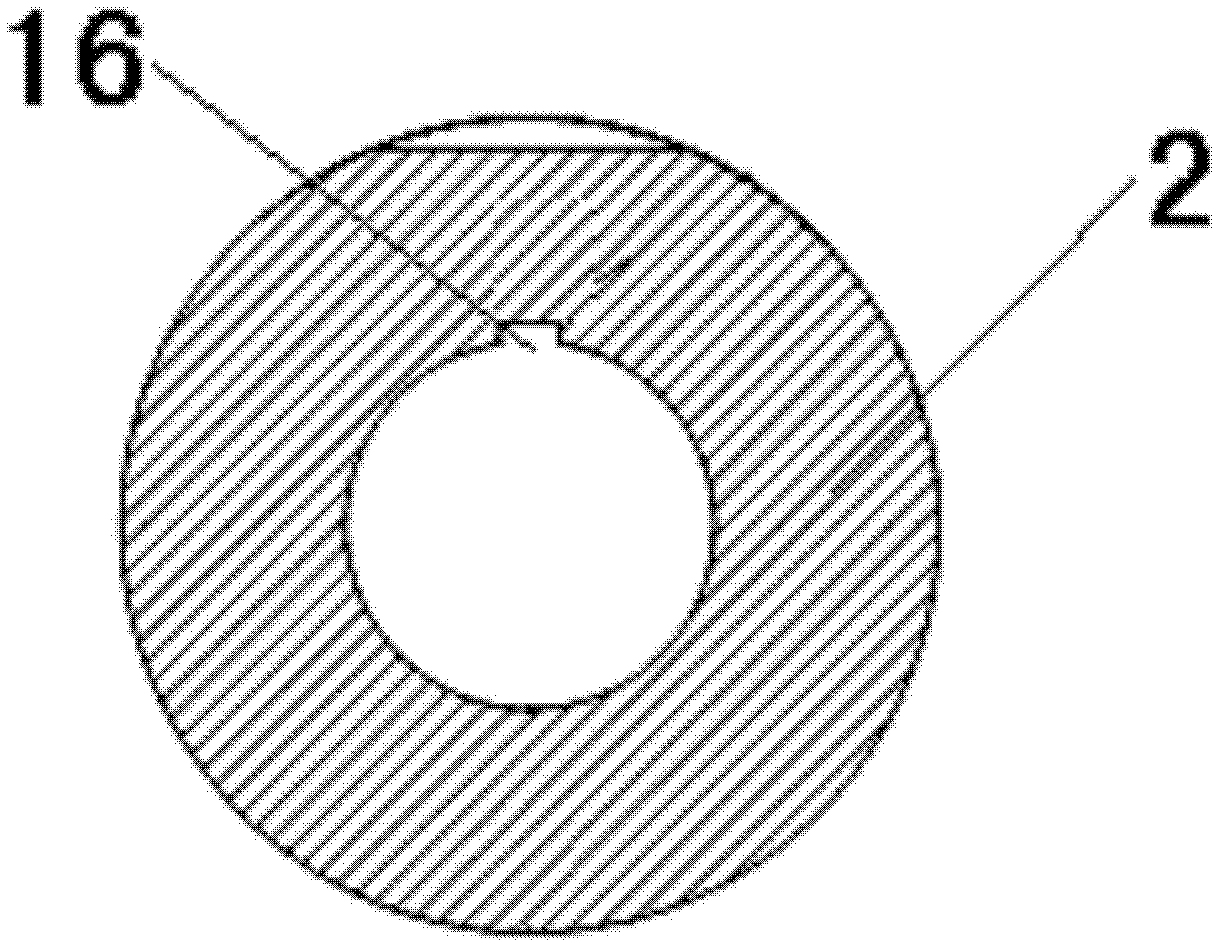

Paying-off device of plastic extruding machine

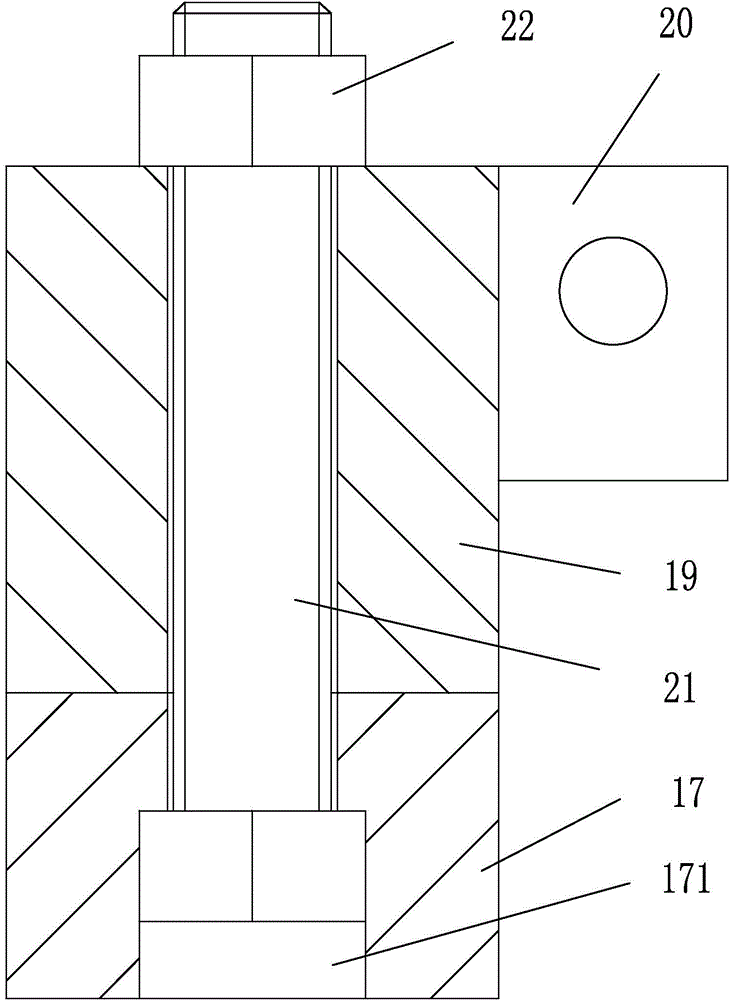

The invention provides a paying-off device of a plastic extruding machine, belonging to the technical field of the plastic extruding machine. One end of a thimble shaft (3) of the paying-off device of the plastic extruding machine is connected with a screw rod (4) which extends out of a thimble shaft sleeve (2); one end of the screw rod (4) extending out of the thimble shaft sleeve (2) is provided with a hand wheel (5) which is used for controlling the rotation of the screw rod (4); the thimble shaft sleeve (2) is arranged into a structure which can only move axially; positioning pins (15) which can prevent the thimble shaft sleeve (2) from moving along a base (1) of the paying-off device are arranged on the thimble shaft sleeve (2); the other end of the thimble shaft (3) is movably connected with a thimble head base (6); and the thimble head base (6) is connected with a detachable combined thimble head (7). According to the technical scheme adopted by the invention, the thimble shaft and the thimble shaft sleeve are simple in machining and high in assembling accuracy, and the stability of high-speed operation of the paying-off device is ensured; bearings are used for supporting in the paying-off device, thus the easiness and convenience in stroke adjustment operation are ensured; and the stroke adjustment in a larger range can be realized.

Owner:安徽鑫鸿电缆有限责任公司

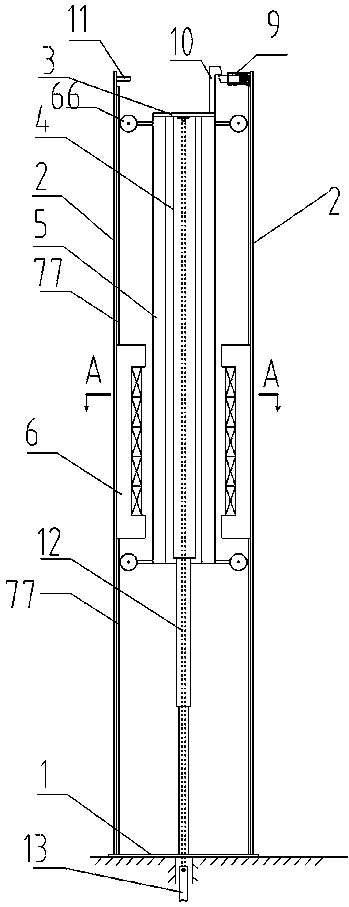

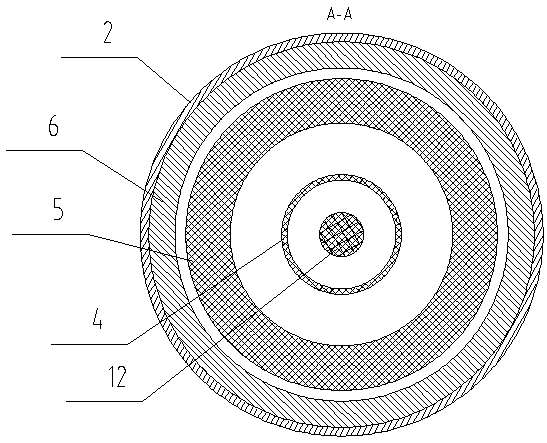

A pumping unit driven by a cylindrical linear motor

ActiveCN104806206BHigh energy storageImprove suspension accuracyFluid removalMechanical energy handlingSingle stageGas spring

The invention provides an oil pumping unit of which a sucker rod is directly driven by a linear motor. The oil pumping unit comprises a rack, a linear motor driving device, a single-stage or multi-stage telescopic machine or a gas spring energy storage device, a linear motor rotor, a sucker rod connector and the like, wherein the linear motor driving device, the single-stage or multi-stage telescopic machine or the gas spring energy storage device, the linear motor rotor, the sucker rod connector and the like are arranged on the rack. The oil pumping unit cancels the connection of elastic pieces or radial components such as hair braids, steel wire ropes and belts for an original oil pumping unit, adopts a direct balance mode, and thus cancels the reversing device (head sheave) of an existing non-beam oil pumping unit, so that the efficiency of the oil pumping unit is further improved, the height and weight of the oil pumping unit are reduced, and the service life, reliability and safety of the oil pumping unit are improved.

Owner:华鹰云智(深圳)技术有限公司

Spiral jet polyurethane upper-connected shoemaking device and preparation process thereof

The invention discloses a spiral jet polyurethane upper-connected shoemaking device. The device comprises a base, a bottom die device, a left side die and a right side die and further comprises a spiral jet device used for spraying raw materials. The invention further discloses a multi-component polymer mixed spiral jet flow shoemaking preparation process. The process comprises the steps: a bottom die moves to the outer portions of the left side die and the right side die; a plurality of polymer raw materials are added into a feeding mechanism of the spiral jet flow device and sprayed to the shoe sole in a spiral airflow mode, and a jet flow layer used for combining the shoe upper and the shoe sole is formed; and the left mold and the right mold press the shoe last to be combined with the bottom mold, and the polymer jet flow layer sprayed on the shoe sole expands and enters the shoe upper and the shoe sole in a diffusion and permeation mode, so that the shoe upper and the shoe sole can be combined. The bottom die can be conveniently and rapidly replaced and cleaned, the spiral jet flow device can conveniently spray raw materials on the bottom die, widened special shoes and boots can be produced, the jet flow amount is large, the edge track of a formed jet flow conical surface is clear, and the device is suitable for production of all the shoes and boots.

Owner:JIHUA 3514 LEATHER & FOOTWARE

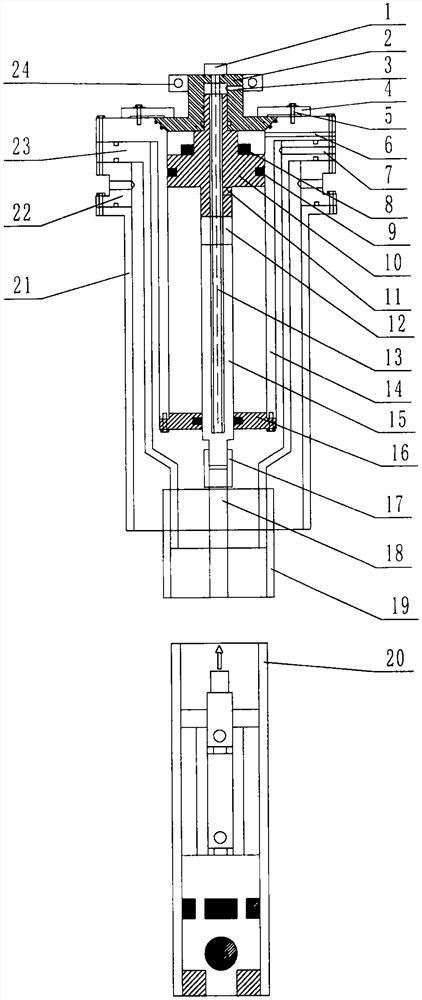

In-well hydraulic pumping unit in well

The invention relates to an in-well hydraulic pumping unit. The in-well hydraulic pumping unit comprises a displacement sensor electronic bin, a cylinder cover, a hydraulic oil channel, a cylinder cover pressing plate, a vent hole, a crude oil outlet, a magnetic ring, a piston, a hydraulic oil communication port, a connecting ring, a sensor rod, an oil cylinder body, a guide column, an oil cylinder bottom cover, an oil rod coupling, an oil rod, an oil pipe coupling, an oil well pump, a sleeve, a Christmas tree, a process oil pipe, a cylinder cover lifting ring and a hydraulic oil source. The process oil pipe is made of steel, the inner diameter is larger than the outer diameter of the oil cylinder, and an annular space is formed as an oil extraction channel. The Christmas tree is a connector leading an oil well to the outside and is provided with a valve, a safety system and the like. A displacement sensor is composed of the electronic bin, the magnetic ring and the sensor rod, and the operating position stroke parameters of the oil well pump piston in the oil well pump can be accurately adjusted through the oil cylinder displacement sensor. The in-well hydraulic pumping unit drives the rod type pump to replace an electric submersible pump, the oil well pump does not need to be pulled out when steam is injected, 'injection and production integration 'can be achieved, and the hydraulic pumping unit can be used for offshore cluster wells and areas with high land cost.

Owner:高智

Steel pusher for pushing steel heating furnace

ActiveCN104726686BImprove transmission efficiencyReduce mechanical wear and tearFurnace typesHeat treatment furnacesFailure rateReciprocating motion

The invention discloses a novel discharge pusher for pusher-type heating furnaces. The novel discharge pusher for pusher-type heating furnaces comprises an ejector rob mechanism, an ejector rob guide rack and an ejector rob propulsion drive mechanism, wherein the ejector rob propulsion drive mechanism is arranged on the ejector rob guide rack, the ejector rob propulsion drive mechanism comprises a fixed seat and an adjusting bracket, the adjusting bracket supports the fixed seat, the fixed seat is provided with a chain drive device for driving the ejector rob mechanism, the chain drive device comprises a motor, a speed reducer and a chain wheel, the chain wheel is connected with the speed reducer, the chain wheel is provided with a chain, and the motor and the speed reducer drive the ejector rob mechanism to carry out forward and backward reciprocating movement in the ejector rob guide rack through the chain wheel and the chain. The invention provides the novel discharge pusher for pusher-type heating furnaces, which is simple in structure, low in failure rate, economic and practical.

Owner:HUATIAN ENG & TECH CORP MCC

Small lathe

The invention relates to the field of machining equipment and provides a small lathe. The small lathe comprises a lathe bed, a spindle box provided with a spindle, a longitudinal dragging plate connected with the lathe bed through a longitudinal guide rail and a transverse dragging plate connected with the longitudinal dragging plate through a transverse guide rail. The small lathe further comprises a longitudinal cylinder, a transverse cylinder, a longitudinal limiting assembly, a transverse limiting assembly, a conical elastic clamp, a threaded connecting rod and a connecting rod driving assembly, wherein a cylinder rod of the longitudinal cylinder is connected with the rear end of the longitudinal dragging plate and is also connected with the lathe bed, a cylinder rod of the transverse cylinder is connected with the rear end of the transverse dragging plate and is also connected with the longitudinal dragging plate, the longitudinal limiting assembly is located on the front side of the longitudinal dragging plate, and the transverse limiting assembly is located on the front side of the transverse dragging plate. A conical hole matched with the conical elastic clamp is formed in the front end of the spindle. The front end of the threaded connecting rod penetrates through the spindle to be connected with the rear end of the conical elastic clamp in a threaded mode. The small lathe is simple in structure, capable of clamping parts effortlessly and high in efficiency.

Owner:宁波神丰汽车部件有限公司

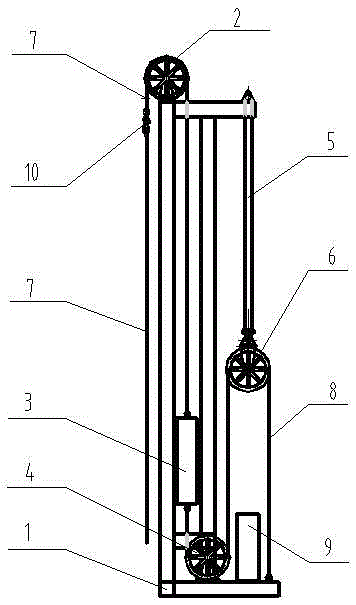

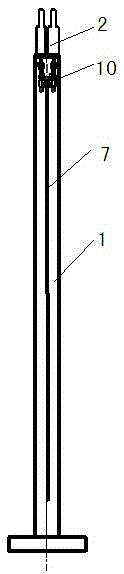

Hydraulic pumping unit with tension-bearing oil cylinder and application method

InactiveCN105257254AIncrease the itinerarySmall diameterFluid removalFluid-pressure actuatorsEngineeringWire rope

The invention relates to a hydraulic pumping unit with a tension-bearing oil cylinder and an application method. According to the technical scheme, the hydraulic pumping unit is characterized in that an upper pulley assembly is mounted at the top of a base and support assembly; a lower pulley assembly is mounted on the lower portion of the base and support assembly; the upper end of an oil cylinder assembly is mounted at the top of the base and support assembly; a movable pulley assembly is mounted at the lower end of the cylinder rod of the oil cylinder assembly; a counter weight assembly is located in the support of the base and support assembly and can move up and down; one end of a power steel wire rope is fixed on the base of the base and support assembly, and the other end thereof winds around the movable pulley assembly and the lower pulley assembly to be fixed on the lower portion of the counter weight assembly; one end of a working steel wire rope is connected with the upper portion of the counter weight assembly, and the other end thereof winds around the upper pulley assembly to be connected with a beam hanger. The hydraulic pumping unit has the advantages that the oil cylinder assembly is inverted, the cylinder rod only bears tension, and the oil cylinder is long in stroke, small in diameter and low in manufacturing cost; fixing supports of the working steel wire rope and the power steel wire rope are disposed on the counter weight assembly, the steel wire ropes are soft in transmission, and the pumping unit is small in noise, simple to mount, safe and environmental friendly.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Paying-off device of plastic extruding machine

The invention provides a paying-off device of a plastic extruding machine, belonging to the technical field of the plastic extruding machine. One end of a thimble shaft (3) of the paying-off device of the plastic extruding machine is connected with a screw rod (4) which extends out of a thimble shaft sleeve (2); one end of the screw rod (4) extending out of the thimble shaft sleeve (2) is provided with a hand wheel (5) which is used for controlling the rotation of the screw rod (4); the thimble shaft sleeve (2) is arranged into a structure which can only move axially; positioning pins (15) which can prevent the thimble shaft sleeve (2) from moving along a base (1) of the paying-off device are arranged on the thimble shaft sleeve (2); the other end of the thimble shaft (3) is movably connected with a thimble head base (6); and the thimble head base (6) is connected with a detachable combined thimble head (7). According to the technical scheme adopted by the invention, the thimble shaft and the thimble shaft sleeve are simple in machining and high in assembling accuracy, and the stability of high-speed operation of the paying-off device is ensured; bearings are used for supporting in the paying-off device, thus the easiness and convenience in stroke adjustment operation are ensured; and the stroke adjustment in a larger range can be realized.

Owner:安徽鑫鸿电缆有限责任公司

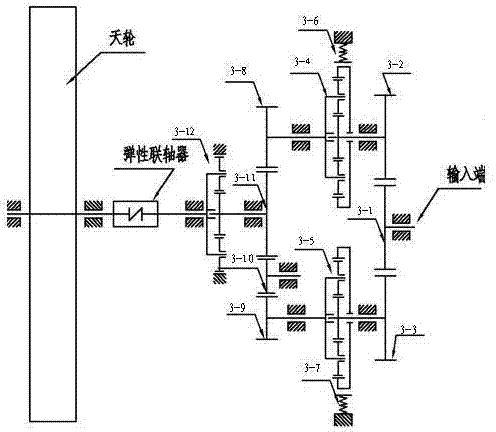

Novel vertical mechanical reversing energy-saving pumping unit

ActiveCN103216216BConvenient well workoverLess actual stroke lossToothed gearingsFluid removalStored energyGear drive

The invention relates to a novel vertical mechanical reversing energy-saving pumping unit. The novel vertical mechanical reversing energy-saving pumping unit is characterized in that a transmission system adopts a mechanical reversing, two-way gear drive and oil-immersed lubrication fully-enclosed reduction gearbox for realizing the positive and negative rotation of a head sheave of the pumping unit, to ensure the immense inertia of a pumping rod and a counterweight to decelerate, buffer until stop before the pumping unit runs to an upper dead point or a lower dead point, a crank buffer device is arranged so that the impact energy is smoothly absorbed and stored, the stored energy is released after passing through the upper dead point and the lower dead point, and a motor is started at an upper dead point or a lower dead point under the conditions of basically smooth input speed and torque. Through the adoption of mechanical reversing and closed oil-immersed lubrication, the adaptability of the pumping unit to the harsh environment is higher; as the motor runs in the same direction all the time, a complex electric control system is not provided, the reliability is high, and the servicing, the maintenance and the repair are simple; and the equipment is controlled to run by a PLC (programmable logic controller), and importantly, the system adopts a two-way backup, and therefore, both the reliability and the stability of the pumping unit are enhanced.

Owner:常州新槃威智能科技有限公司

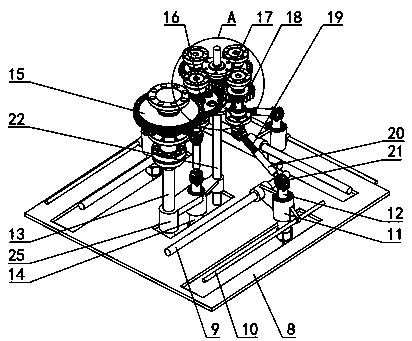

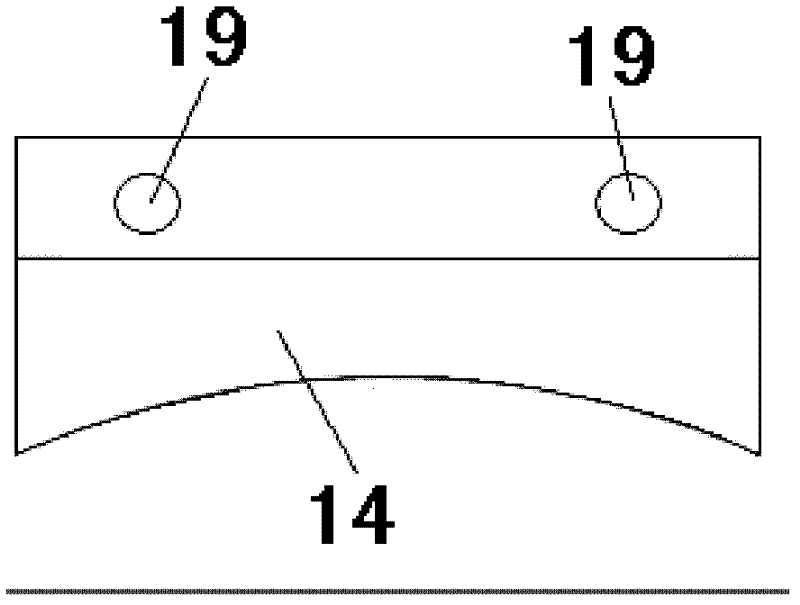

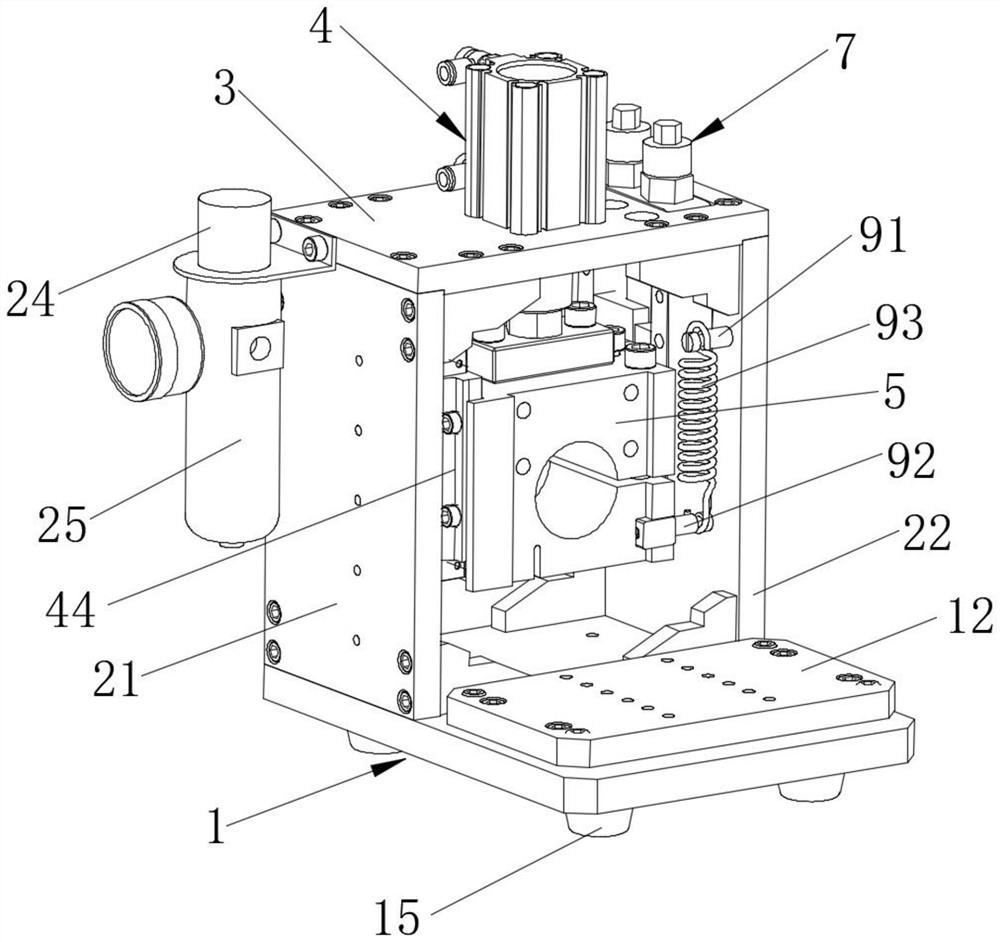

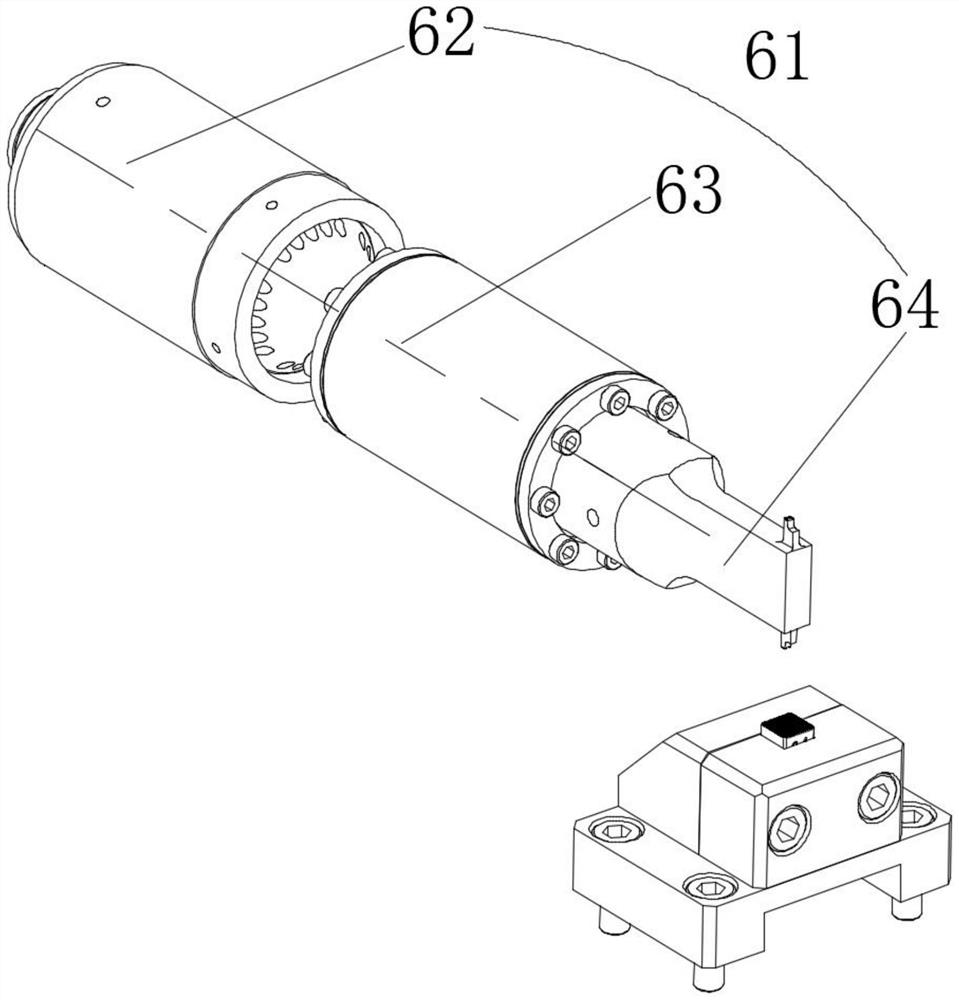

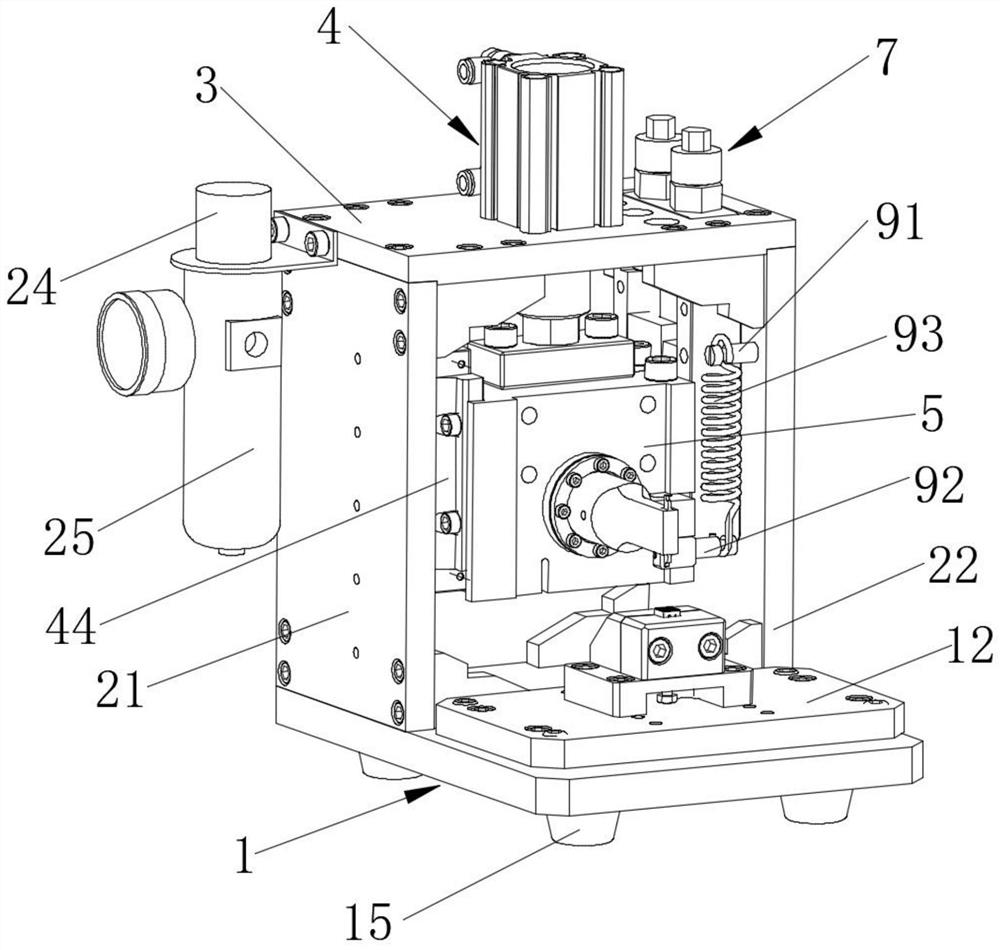

Ultrasonic welding rack with stroke convenient to adjust

PendingCN112809162AConvenient itineraryEasy to adjustWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingReciprocating motion

The invention discloses an ultrasonic welding rack with a stroke convenient to adjust. The rack comprises a bottom plate assembly, a first supporting plate is arranged at one side of the bottom plate assembly, a second supporting plate is arranged at the other side of the bottom plate assembly, a top plate is arranged at the top of the first supporting plate and the top of the second supporting plate, and a driving device is arranged on the top plate; and a hoop is movably connected to the lower portion of the driving device, the driving device drives the hoop to move up and down in a reciprocating manner, a welding executing assembly is arranged on the hoop, a limiting adjusting mechanism used for adjusting the stroke of the hoop is movably arranged at one side of the hoop, and the limiting adjusting mechanism is fixedly arranged at one side of the second supporting plate. According to the ultrasonic welding rack with the stroke convenient to adjust, the stroke of the welding head can be conveniently adjusted, welding parameters can be conveniently adjusted, executing mechanisms of half-wave ultrasonic waves and full-wave ultrasonic waves are compatible, exchange is easy, and space and cost are saved.

Owner:东莞市索莱德自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com