Synchronous regulation structure for stroke of pressing machine

A technology of synchronous adjustment and press, which is applied in the field of presses, and can solve the problems of cumbersome adjustment steps, complex structure, and inability to ensure the adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

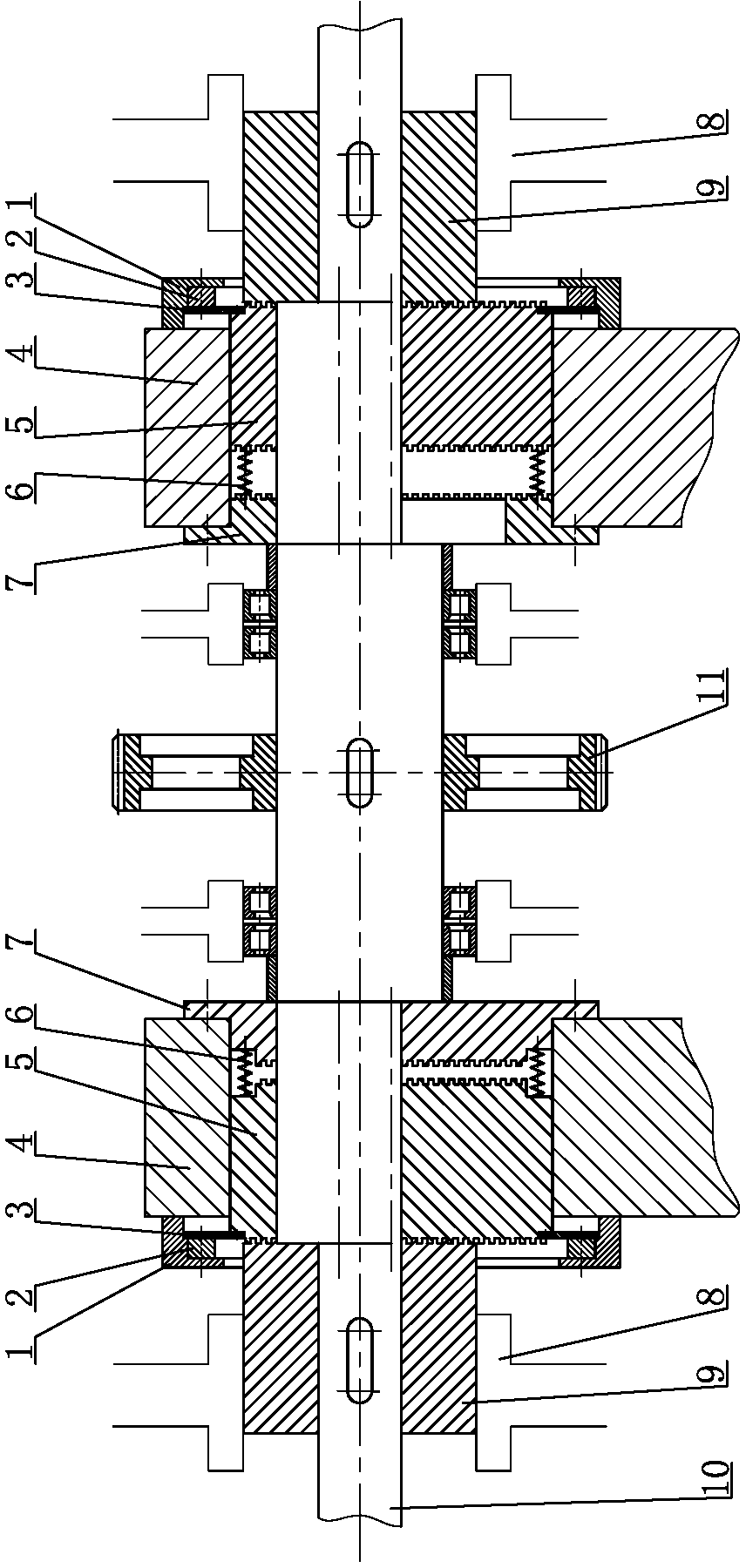

[0015] Such as figure 1 Shown is the structural diagram of embodiment 1 of the press stroke synchronous adjustment structure of the present invention, including the crankshaft 10, the connecting rod 4 and the eccentricity adjustment device, the crankshaft 10 is a group, supported on the fuselage support 8, and the connecting rod 4 is The two groups are respectively connected to the crankshaft 10 through two sets of eccentric distance adjustment devices to synchronously drive the slider mechanism. It is fitted on the outer circumference of the connecting rod journal of the crankshaft 10 and can rotate and slide along the axial direction of the connecting rod journal. The connecting rod 4 is connected to the outer circumference of the eccentric sleeve 5 in rotation. At both ends, the locking sleeve 9 and the main journal of the crankshaft 10 are connected and fixed by keys to ensure that the locking sleeve 9 and the crankshaft 10 rotate synchronously, the connecting rod end cove...

Embodiment 2

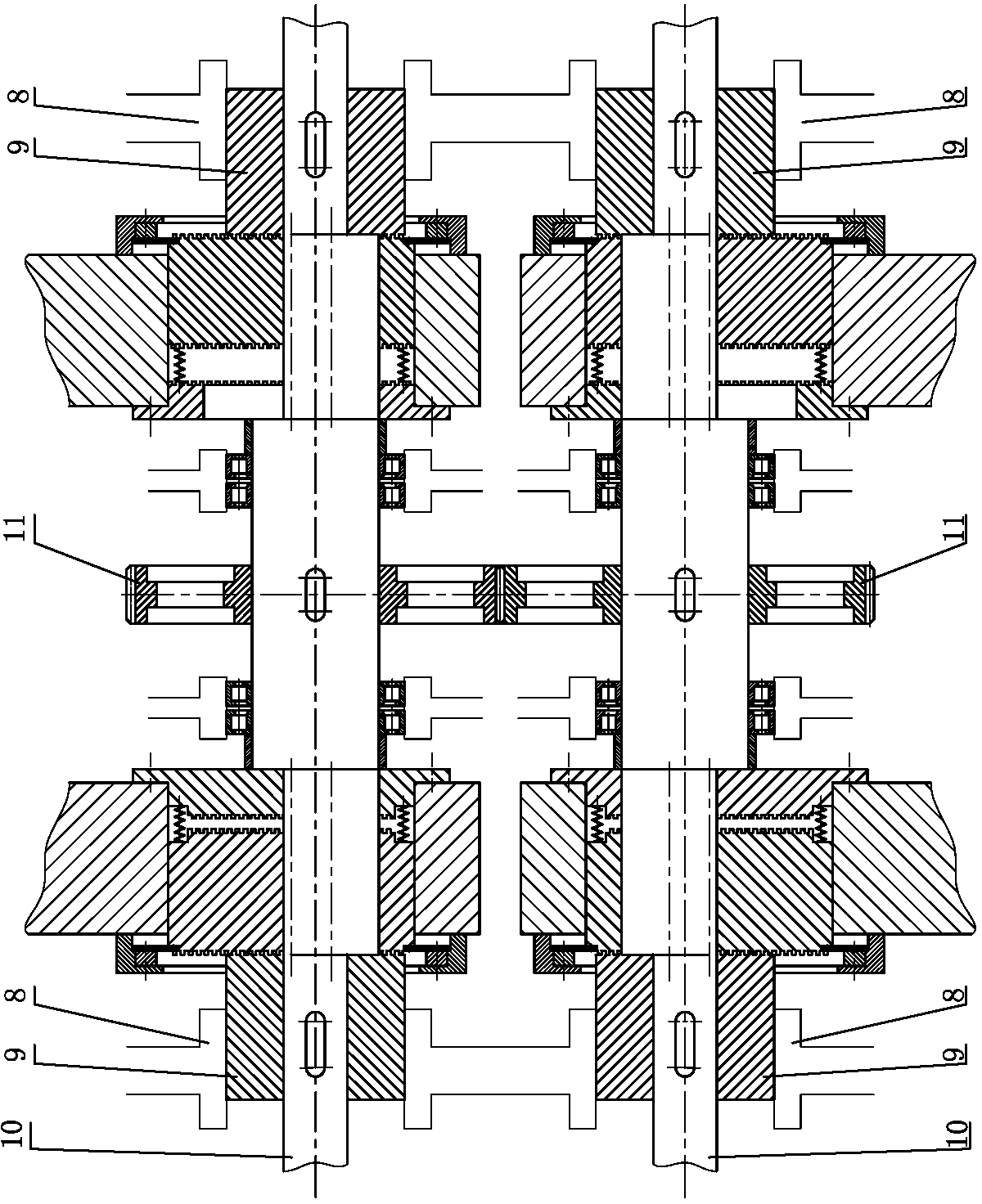

[0018] The difference between this embodiment and Embodiment 1 is that this embodiment is suitable for the stroke adjustment structure of a two-axis four-point large table top press. The crankshafts 10 are connected, and the two groups of crankshafts 10 are driven to rotate synchronously through the gearwheels 10 meshing with each other, and the connecting rods on the two groups of crankshafts 10 synchronously drive the slider mechanism. During operation, the two groups of crankshafts 10 rotate in a completely synchronous manner through the meshing movement of the large gear 11 and drive the components of the eccentricity adjustment device to act synchronously in a completely synchronous manner, so as to realize the synchronous and accurate adjustment of the stroke of the slider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com