In-well hydraulic pumping unit in well

A technology for pumping units and pumps, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc., and can solve the problem that beamless pumping units cannot be installed on oil production platforms and oil production platforms due to the occupied area and height Issues such as limited area and small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

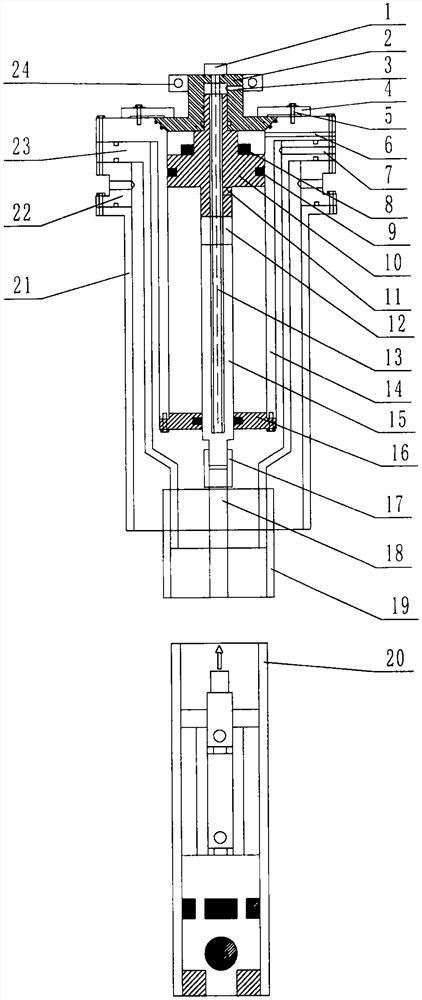

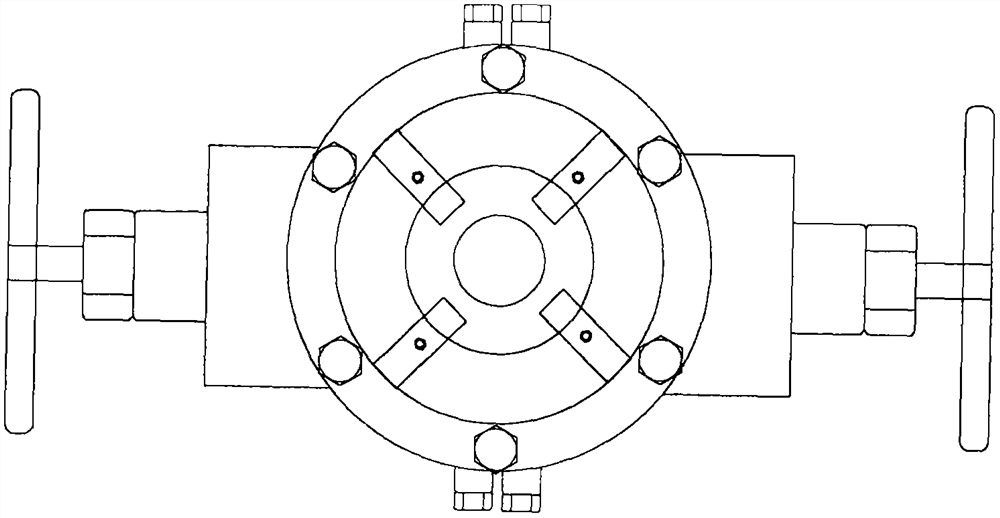

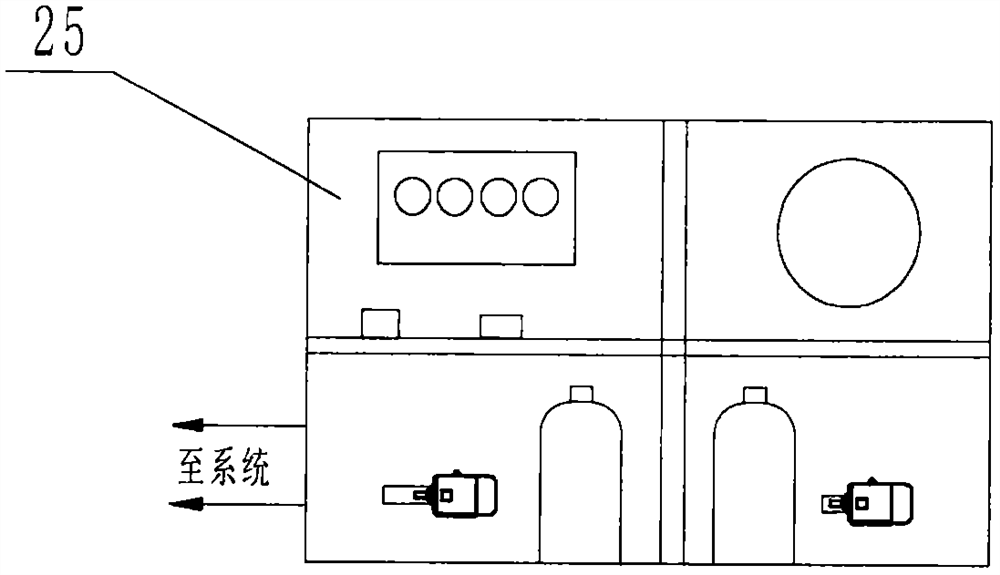

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. A hydraulic pumping unit in a well includes: a displacement sensor electronic compartment, a cylinder head, a hydraulic oil channel, a cylinder head pressure plate, pressure plate bolts, air holes, a crude oil outlet, a magnetic ring, Sealing ring, piston, hydraulic oil connection port, connecting ring, sensor rod, cylinder body, guide column, cylinder bottom cover, oil rod coupling, oil rod, oil pipe coupling, oil pump assembly, casing, Christmas tree, process Oil pipe, cylinder head lifting ring, hydraulic oil source assembly. The sensor electronic compartment is installed at the center of the steel top of the cylinder head, and the cylinder head and the taper surface of the cylinder casing are in contact with the pressure plate bolts for fastening. The oil cylinder liner flange is installed on the process tubing flange, the process tubing is made of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com