Multistage pyrite water-saving sawtooth wave jig gravity separator

A technology of pyrite and sawtooth wave, which is applied in the field of multi-stage pyrite water-saving sawtooth wave jigging gravity separator, can solve the problems of large and easily damaged diaphragm, waste of water resources, high energy consumption, etc., and achieve high beneficiation efficiency, The effect of low energy consumption and simple principle of mineral separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

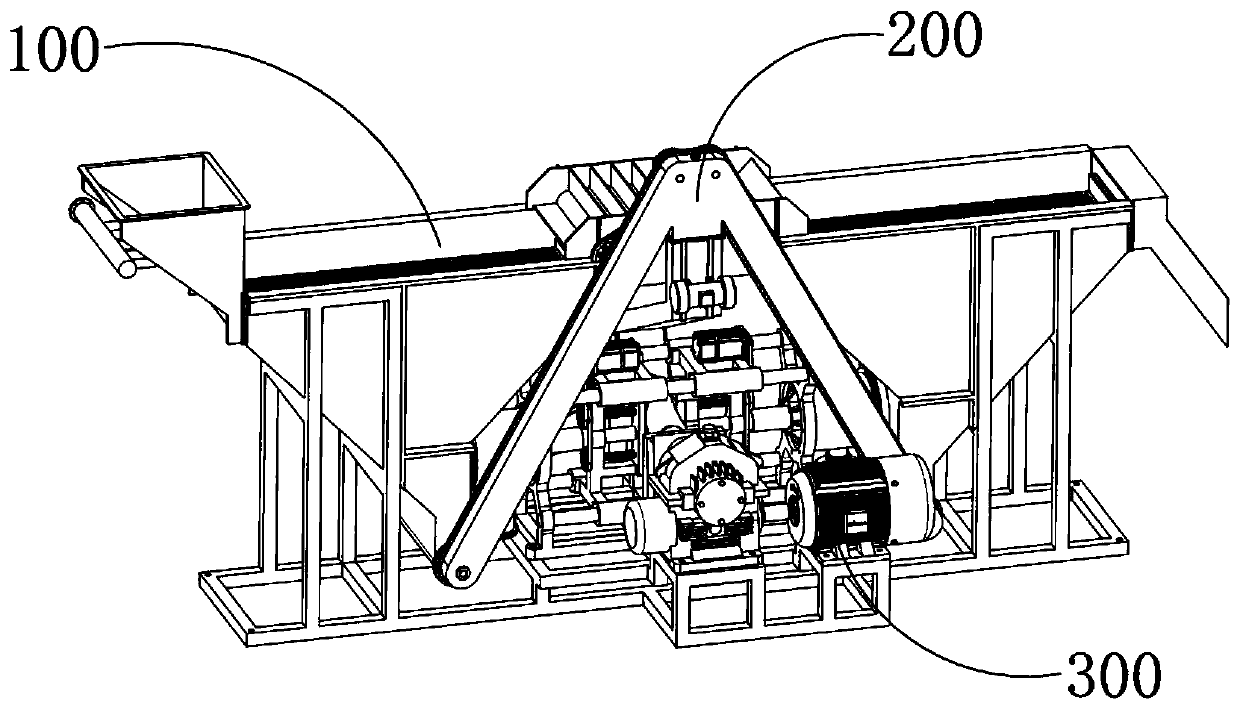

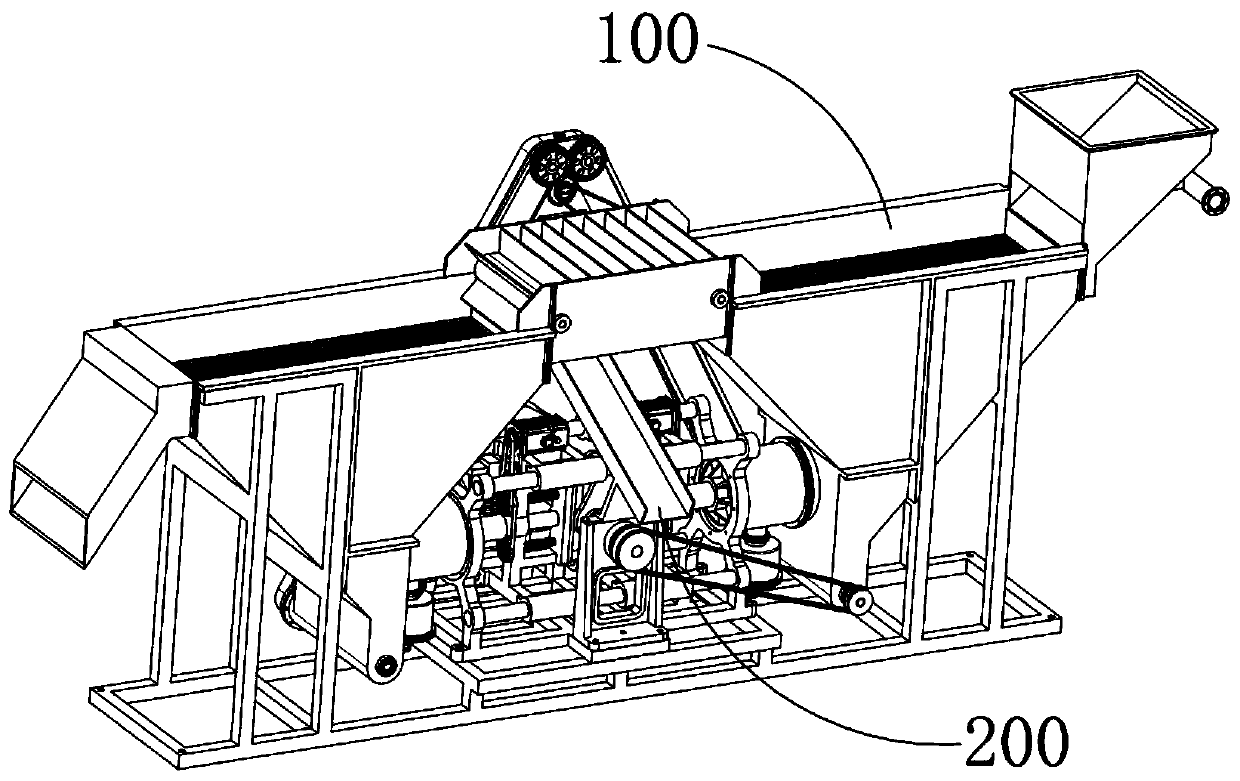

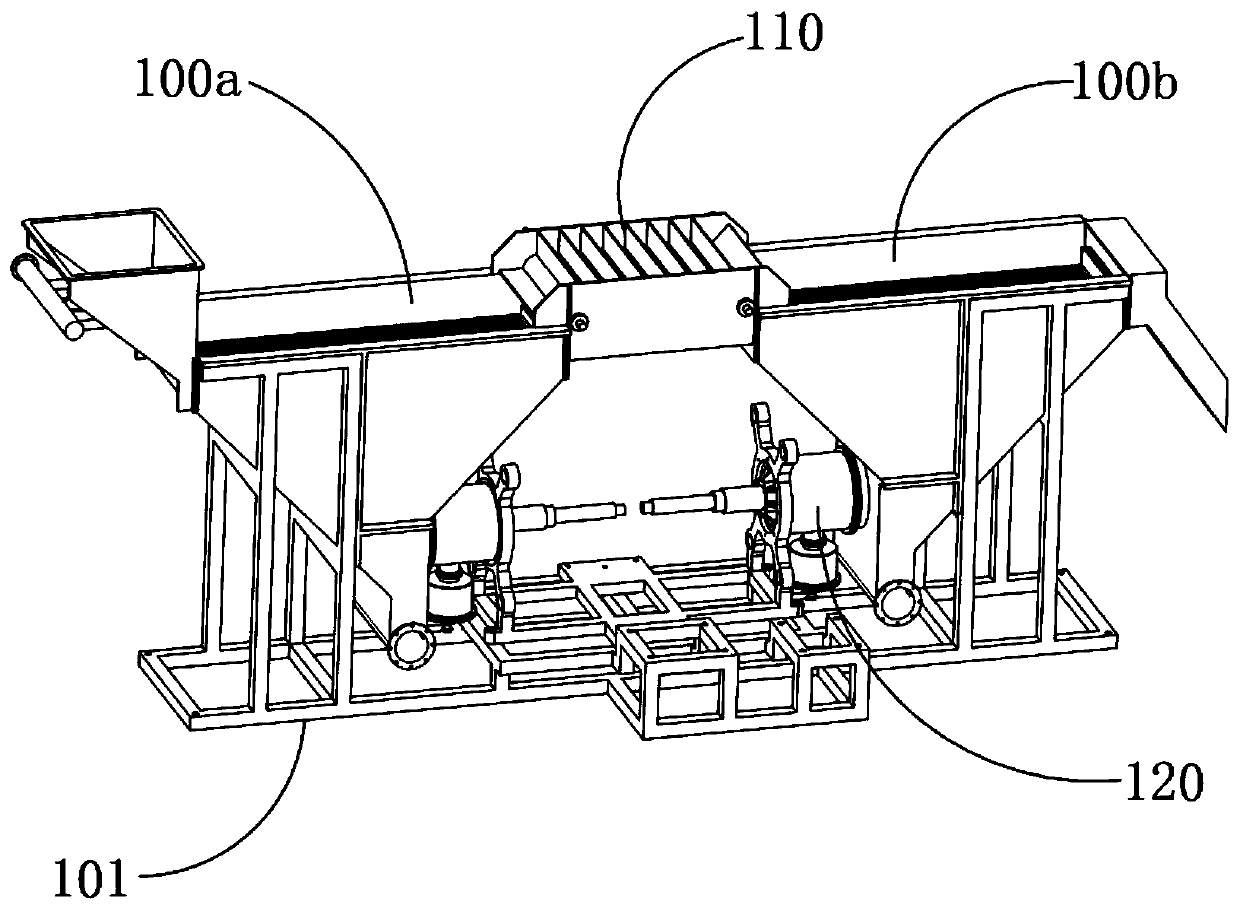

[0061] Multi-stage pyrite water-saving sawtooth wave jigging gravity separator, which includes a jigging box 100 with a V-shaped structure with an upward opening and filled with medium water inside, a discharge device 200, a power drive device 300, and a jigging box 100 It is composed of the first jigging box 100a and the second jigging box 100b arranged symmetrically. The first jigging box 100a is used to receive the mixture of pyrite and waste rock monomers and carry out concentrate gravity separation, and the second jigging box The box 100b is used to carry out secondary concentrate re-selection of the mixture of pyrite and waste rock monomers and to discharge the tailings. Between the openings of the first jigging box 100a and the second jigging box 100b, there is a The conveying mechanism 110, the side of the jigging box 100 near its bottom is provided with an agitating mechanism 120 for vibrating the internal medium water, and the discharge device 200 is used to dehydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com