Jig gravity separation process of pyrite

A pyrite, jigging technology, used in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of damage, large diaphragm, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

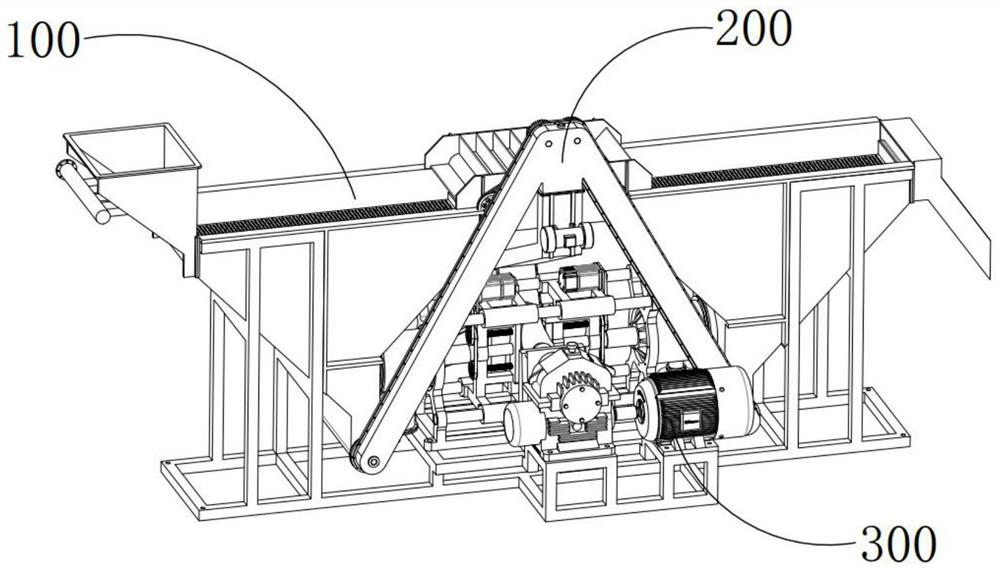

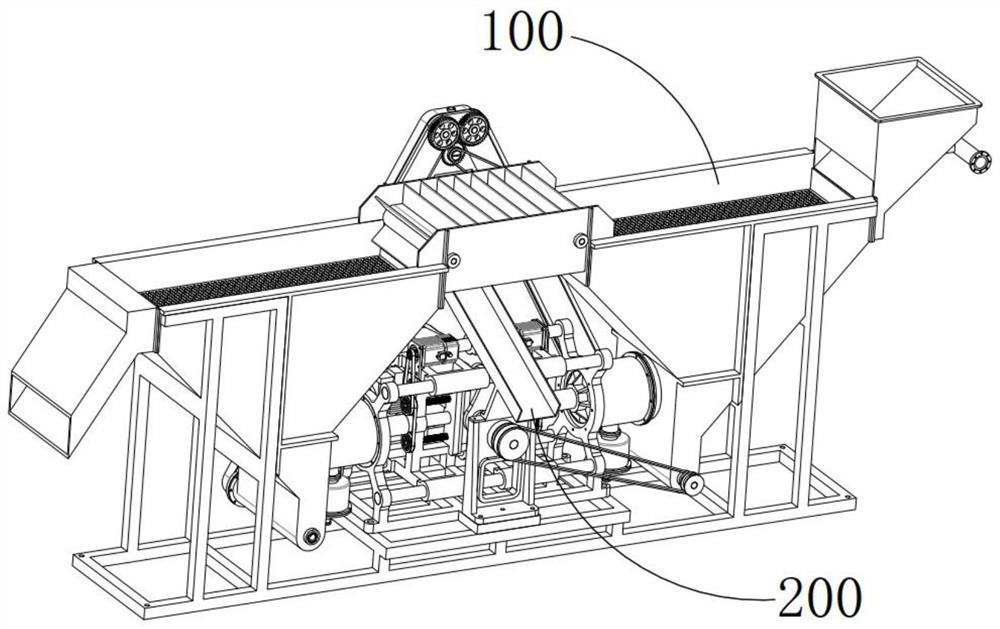

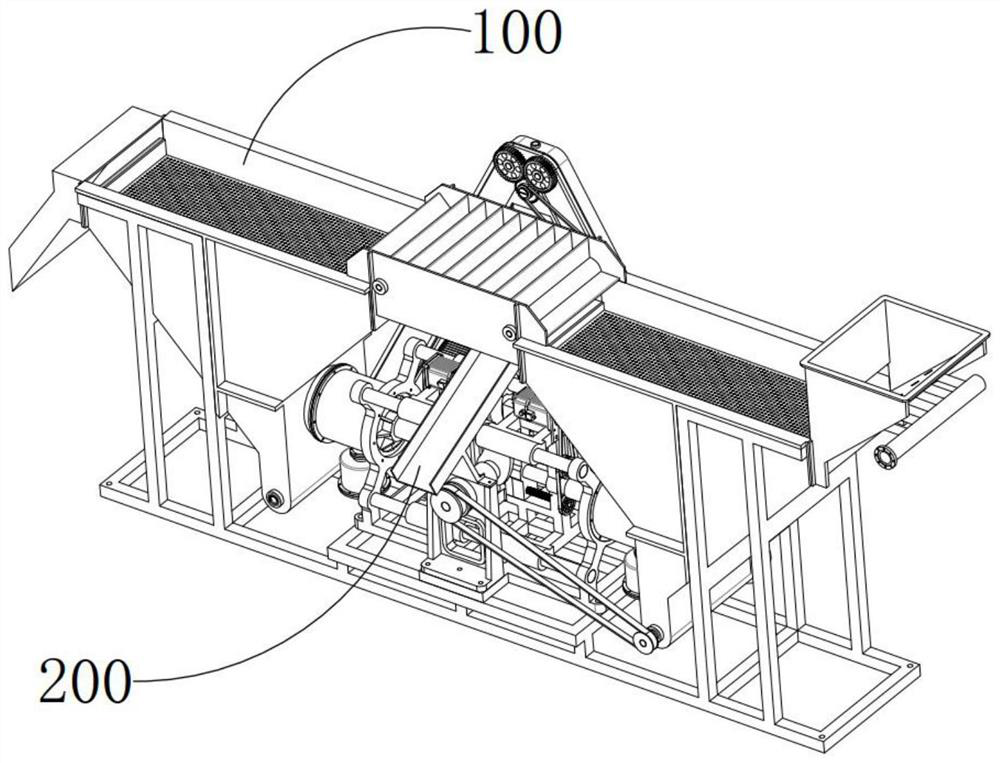

[0067] The jigging gravity separation process of pyrite comprises the following steps:

[0068] (1) First-level jigging stage;

[0069] S1: Transport the mixture of ground pyrite and waste rock monomers to the first jigging box 100a through the belt transport mechanism, and the power drive device 300 transmits the power to the agitation mechanism 120, and the agitation mechanism 120 makes the first jigging The medium water in the box 100a and the second jigging box 100b generates a sawtooth wave vibration, and the first jigging box 100a performs a concentrate gravity separation on pyrite and waste rock monomers, and the concentrate is deposited in the first jigging box 100a bottom of the box;

[0070] The bottom of the jigging box 100 is provided with a mounting frame 101 for supporting it. The jigging chamber in the jigging box 100 is a V-shaped structure and the opening of the jigging box 100 is arranged as a rectangular opening. Jigging box 100a and the second jigging box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com