A pumping unit driven by a cylindrical linear motor

A linear motor, cylindrical technology, used in natural gas, coal bed methane extraction equipment, petroleum fields, can solve problems such as poor effect, large starting torque, and large speed unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

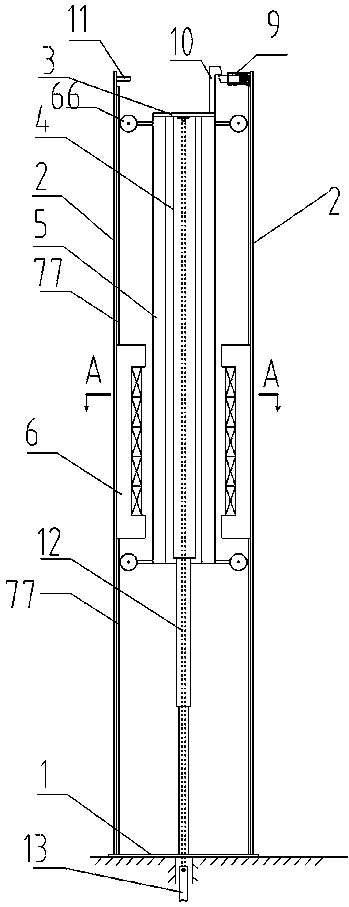

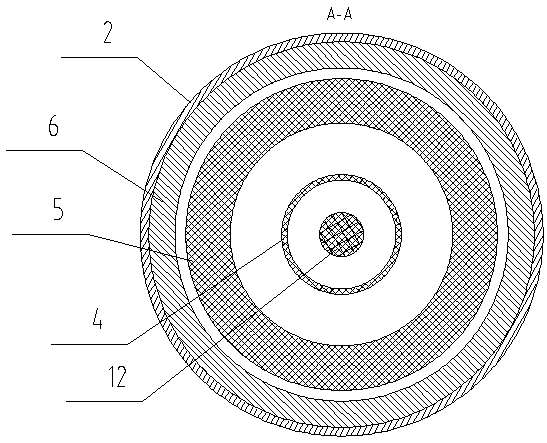

[0029] A pumping unit driven by a cylindrical linear motor, such as figure 1 , 2 . Locate the guiding device, the braking device, the sucker rod connector 12 and the sucker rod 13.

[0030] For the well-known linear motor, the general definition: the side with the armature winding is called the primary of the linear motor, and the side with the magnet or induction plate is called the secondary of the linear motor. Also defined: the moving part is the mover of the linear motor, and the fixed Part is a linear motor stator. According to the length of the mover and stator, it can be divided into two categories: long mover, short stator and short mover and long stator. The working principle of the linear motor is: a current is passed into the primary winding of the linear motor to generate a traveling wave magnetic field that can move relative to the magnet or the induction plate. In addition, the cylindrical linear motor can be converted from the flat linear motor by bending i...

Embodiment 2

[0041] Such as Figure 4 As shown, a cylindrical linear motor-driven pumping unit, the linear motor drive device can also adopt the linear motor primary movement, secondary fixed arrangement, the mover armature winding part is relatively short, the stator permanent magnet Or the reaction plate is longer (also known as short mover, long stator structure). The stator length should not be less than the sum of the mover length and stroke length. The upper end and lower end of the linear motor mover 5 are respectively provided with an upper extension sleeve 44 and a lower extension sleeve 45 having the same outer diameter as the linear motor mover, and the upper end of the upper extension sleeve 44 and the lower end of the lower extension sleeve 45 are respectively provided with Multiple sets of guiding and positioning devices ensure the mechanical air gap between the mover 5 of the linear motor and the stator of the linear motor so that the two can move with each other. Setting ...

Embodiment 3

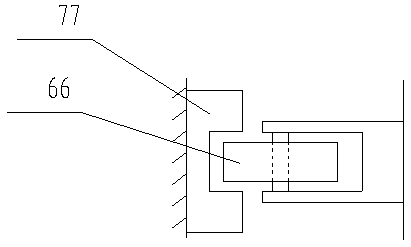

[0044] Such as Figure 5 As shown, four sets of guiding and positioning devices are symmetrically arranged on the upper end and the lower end of the cylindrical linear motor rotor 5, respectively, and four stator slots 65 are provided in the axial direction on the circumference of the linear motor stator 6, and the linear motor stator 6 is divided into equal parts. It is four circular arc segments, and the parts of the guiding and positioning device are accommodated in the four stator slots, that is, the guiding and positioning device needs to pass through the linear motor stator 6. The positioning and guiding device of the linear motor mover 5 described in this embodiment is as follows: Figure 8 As shown, it can be completed by guide wheels and linear guide grooves, or as Figure 9 It is completed by linear guide rails and sliders, and can also be completed by T-shaped guide rails 771 and concave guide wheels 772. The specific positioning is as in Embodiment 1.

[0045] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com