Steel pusher for pushing steel heating furnace

A technology of heating furnace and steel pusher type, which is applied in the field of material pusher, which can solve the problems of uneven horizontal thrust, high replacement cost of spare parts, corrosion of equipment, etc., achieve good reliability of work, convenient maintenance and operation, and solve the problem of The effect of synchronization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

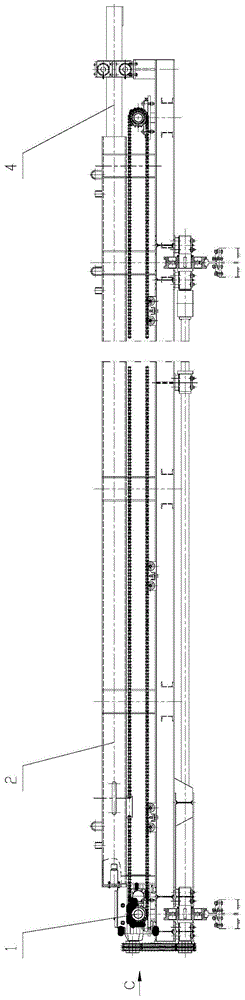

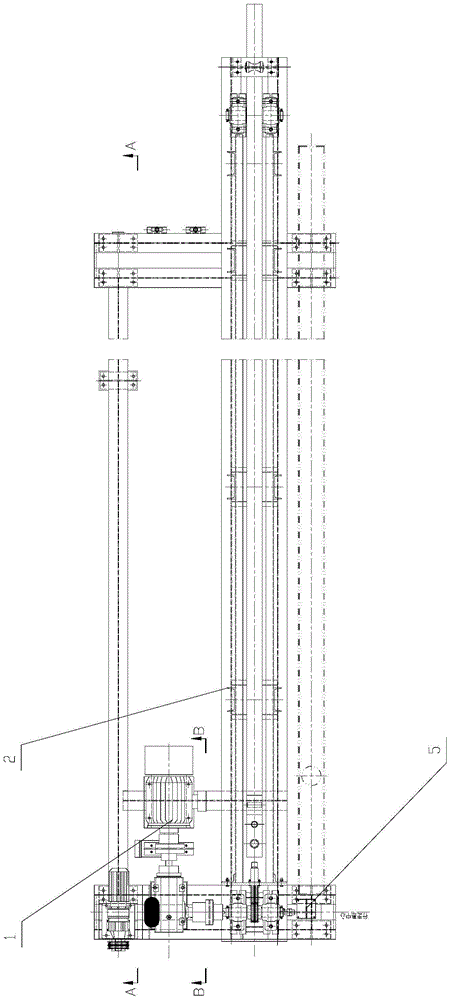

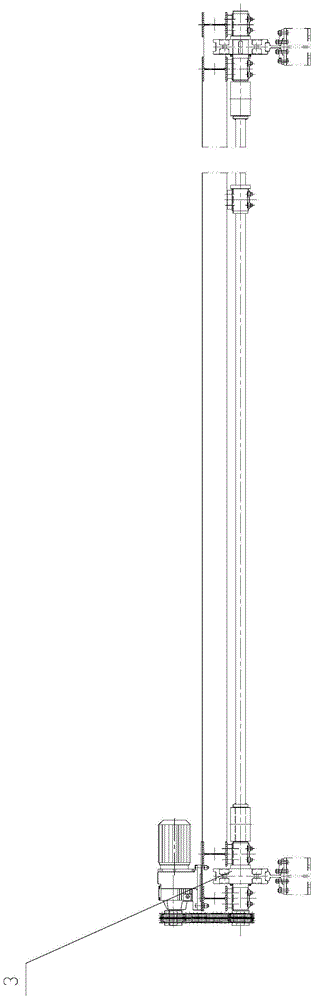

[0028] Such as Figures 1 to 5 As shown, the material pushing machine for the pusher type heating furnace in this embodiment includes a push rod propulsion transmission mechanism 1, a push rod guide frame 2, a traverse trolley 3, a push rod mechanism 4, a stroke control unit 5 and a push rod Water cooling system6. Among them, the ejector rod propulsion transmission mechanism 1 is set on the ejector rod guide frame 2, and the ejector rod mechanism 4 and the ejector rod propulsion transmission mechanism 1 work together to realize the main process functions of the steel pusher; the traverse trolley 3 is assembled with the guide frame 2 , the motor-driven wheeled traversing trolley (3) drives the ejector rod guide frame (2) to realize the horizontal traversing function. The ejector rod water cooling system 6 is connected with the water inlet and outlet in the ejector rod mechanism 4 to realize the cooling function of the ejector rod. The ejector rod mechanism 4 is matched with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com