Fan type pneumatic power executor

A pneumatic actuator, fan-shaped technology, applied in the field of actuators, can solve the problems of high manufacturing cost and maintenance cost, increased wear of gears and racks, no way to achieve accurate control, etc., to achieve easy travel, no delay in transmission, The result is a simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

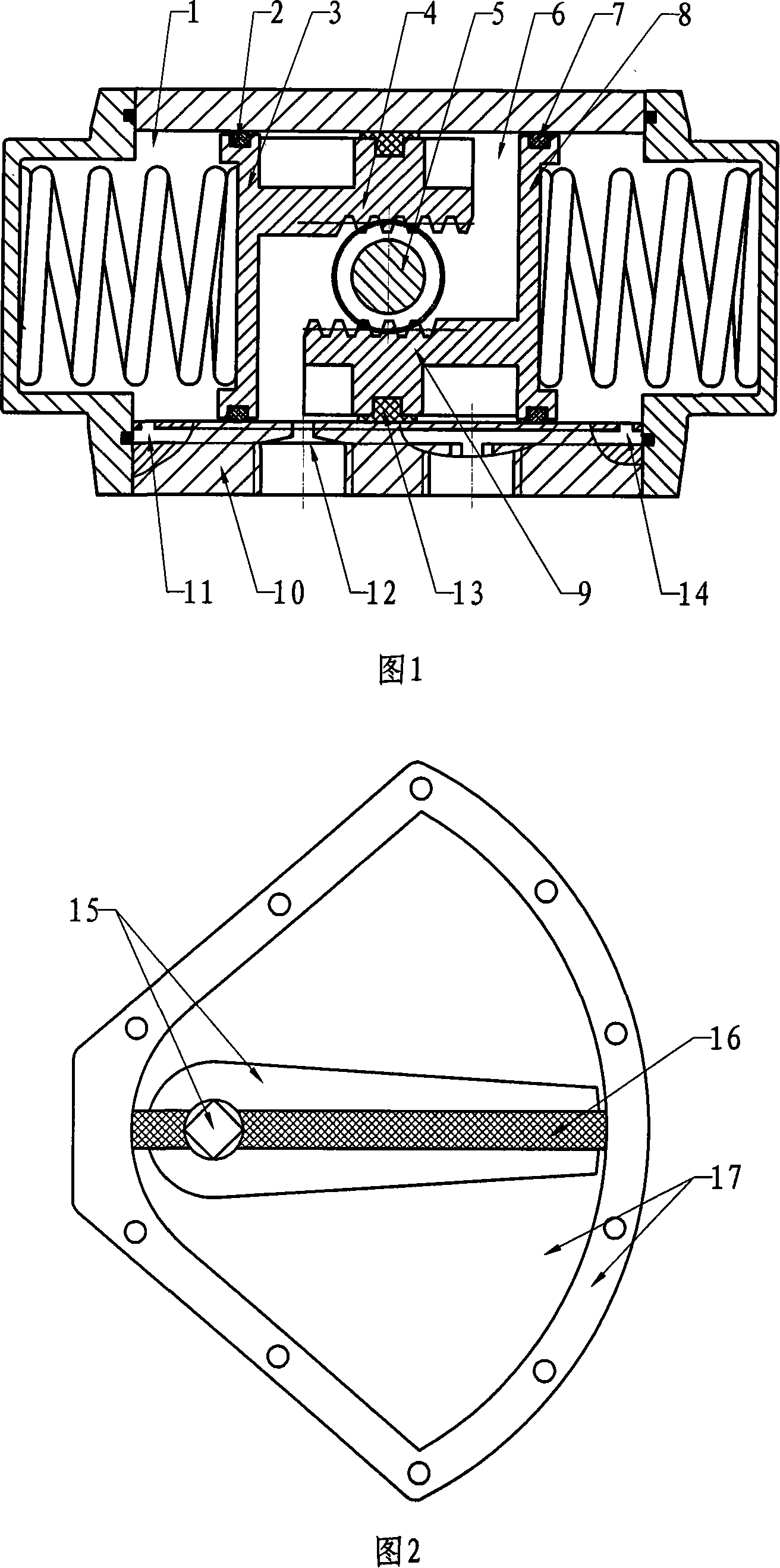

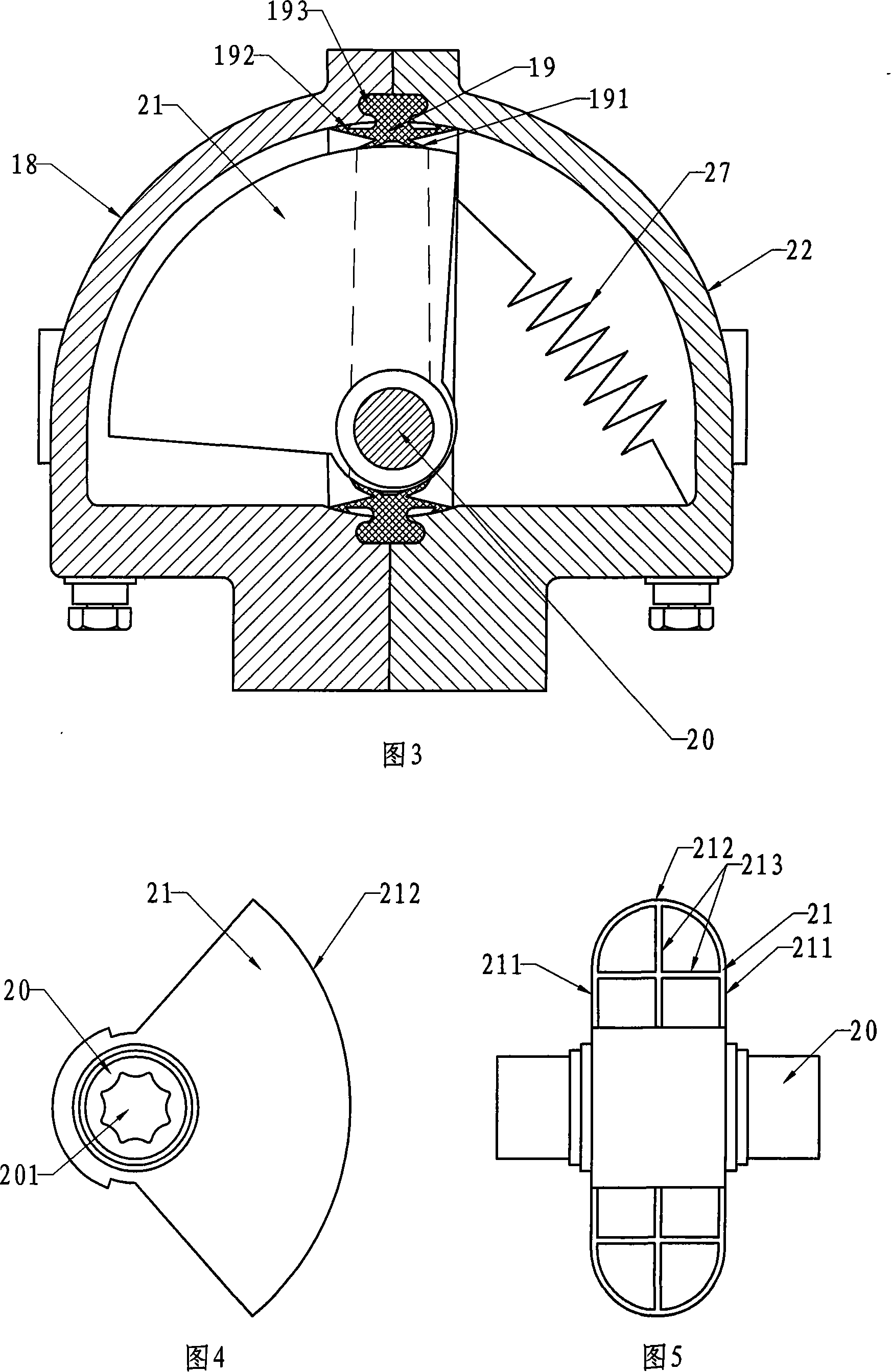

[0029] Embodiment 1: As shown in FIG. 3 , the housing of the fan-type pneumatic actuator consists of a left outer housing 18 and a right outer housing 22 . The two casings are made of plastic steel, and are molded by one injection injection molding machine, with good mechanical properties, good corrosion resistance and low cost. The structure and size of the two shells are identical, and the left shell 18 rotates 180° to be the right shell 22, so that a pair of molds can produce the whole shell. The production cost is further reduced.

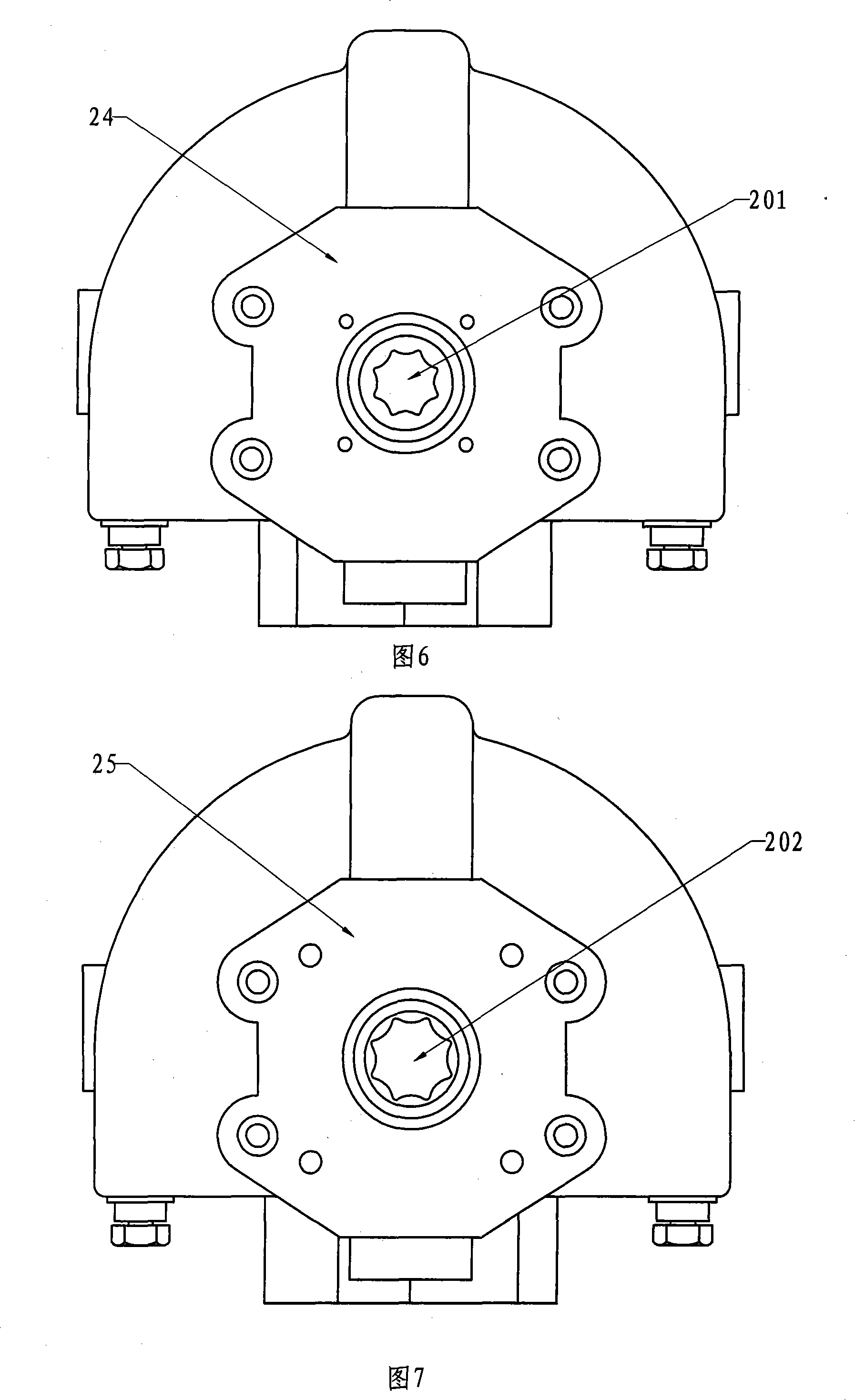

[0030] The housing is provided with a rotor 21, as shown in Figure 4 and Figure 5, the rotor is a hollow sector, the hollow part is provided with reinforcing ribs 213, located at the top of the rotor 21 and the busbar of the curved surface 212 connected to the fan-shaped surfaces 211 on both sides for the arc. The two ends of the central axis 20 of the actuator are respectively provided with a shaft hole 201, 202, which allows the actuator to...

Embodiment 2

[0036] Embodiment 2: As shown in FIG. 10 , the difference from Embodiment 1 is that in this embodiment, a helical spring returner 26 is used instead of the return spring 27 in Embodiment 1, which can also realize the function of resetting the rotor. The homing device is located outside the housing, and one end of the helical spring 261 of the homing device is fixed on its main shaft, and the other end is fixed on the housing of the homing device; the main shaft of the homing device is connected to the central axis of the actuator. The helical spring is the prior art, and the structure of the return device is relatively common in the mechanical field, and it is easy for those skilled in the art to realize it, so it will not be repeated here.

[0037] Due to the long life of the helical spring can reach two million times. Moreover, the energy consumption is low, and the loss of about 10% of the output torque attenuation from the start to the closing stroke, so the preferred embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com