Glass plate processing device

A processing device and glass disk technology, applied in glass forming, glass remolding, glass manufacturing equipment and other directions, can solve the problems of poor processing uniformity, slow glass disk processing speed, unstable product quality, etc. Good uniformity, convenient independent rotation, convenient feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

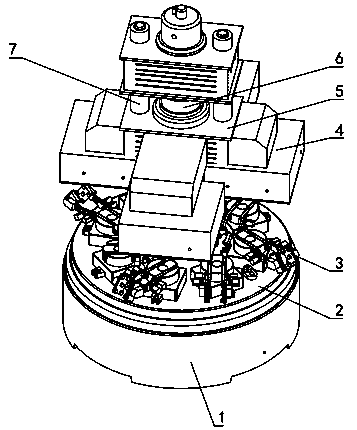

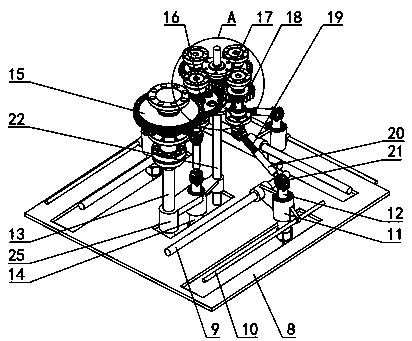

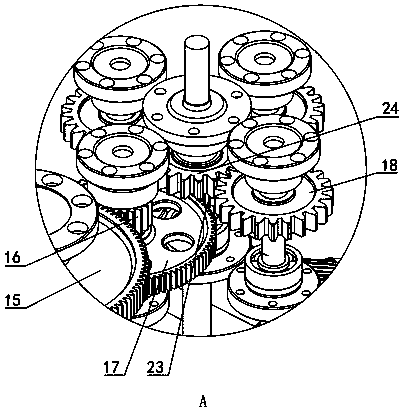

[0035] Figure 1~10 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~10 The present invention will be further described.

[0036]A glass disk processing device, comprising a lifting mechanism, a plurality of stamping frames 8 arranged around the lifting mechanism, and molds corresponding to the stamping frames 8 one by one, the molds include an upper mold 41 and a lower mold 40, and the stamping frame 8 is provided with corresponding The upper mold 41 is connected to the feeding mechanism, the lower mold 40 is arranged on the lower side of the corresponding upper mold 41, and the lower mold 40 is installed on the clamp 3; a plurality of rollers 38 are also rotatably installed on each stamping frame 8, and the rollers The wheel 38 is arranged on the upper side of the lower mold 40, and the roller 38 is connected with a translation mechanism that pushes it to move close to or away from the lower mold 40. The clamp 3 includes a tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com