One-way resetting mechanism for locomotive brake controller and brake controller

A technology of brake controller and reset mechanism, which is applied to the operating mechanism of railway vehicle brake, railway braking system, manual starting device, etc. Easy to adjust, easy to install and disassemble, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

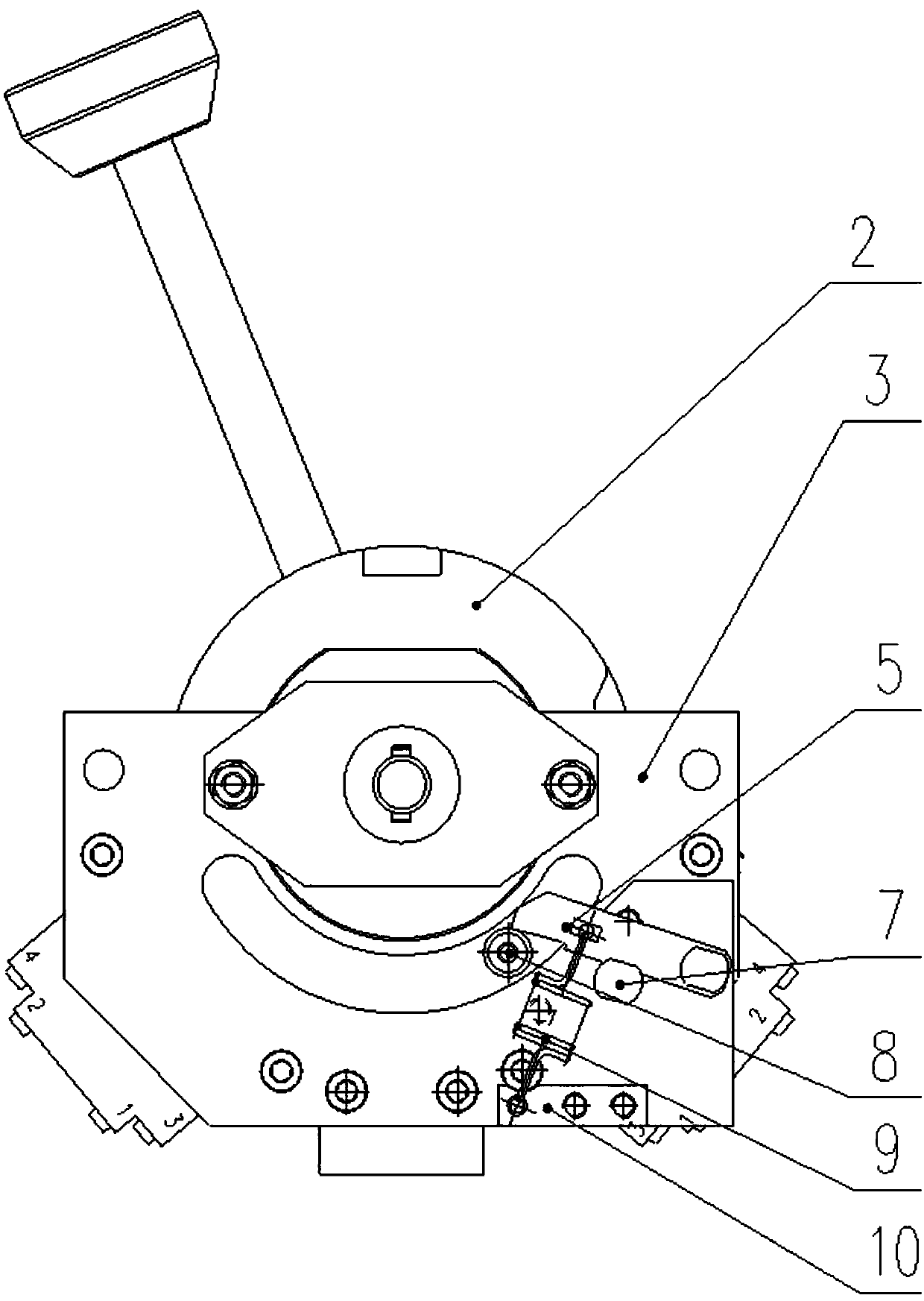

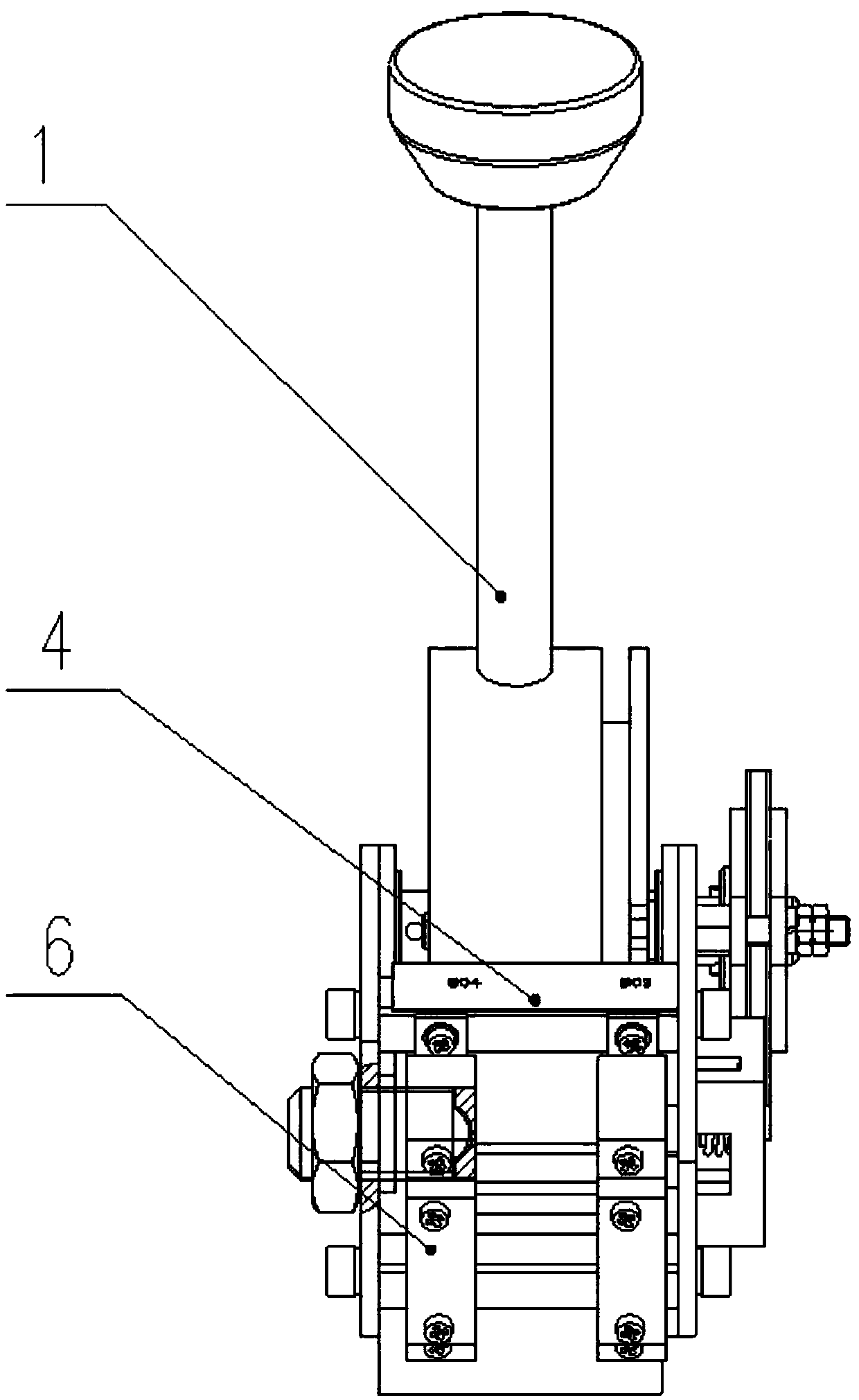

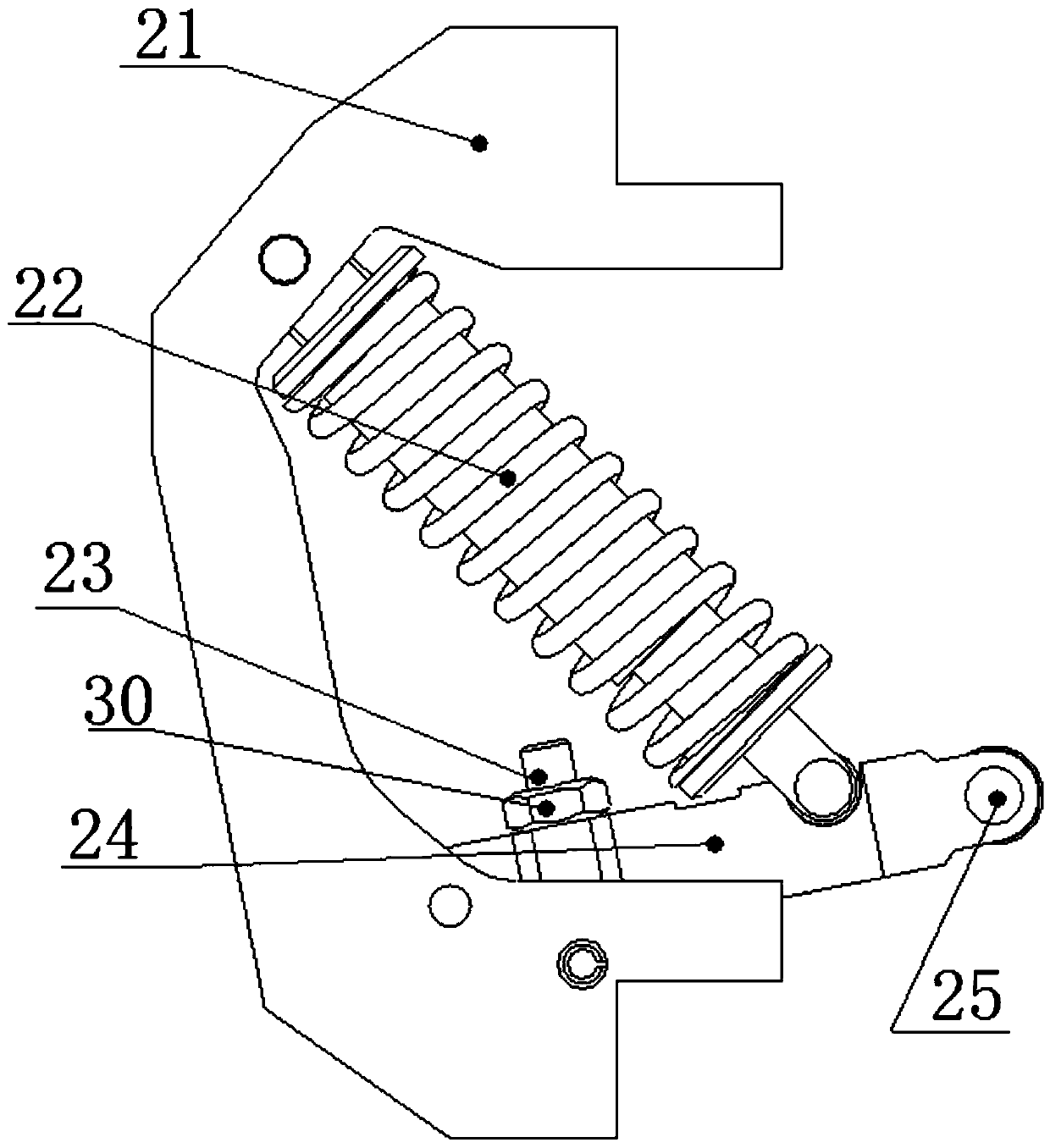

[0029] Such as Figure 3 to Figure 5 As shown, the one-way reset mechanism for the locomotive brake controller includes a reset frame 21, elastic mechanisms 22, 26, 27, and a reset lever 24; one end of the reset lever 24 is hinged with the reset frame 21, and the other end of the reset lever 24 is hinged with the roller 25. ; One end of the elastic mechanism 22,26,27 is hinged with the reset frame 21, and the other end of the elastic mechanism 22,26,27 is hinged with the middle section of the reset lever 24.

[0030] Described elastic mechanism 22,26,27 comprises reset stage clip 22, guide cylinder 27 and guide rod 26, and one end of guide rod 26 stretches in guide cylinder 27 from guide cylinder 27 one ends, and the other end of guide rod 26 and reset lever 24 The middle section is hinged, and the other end of the guide cylinder 27 is hinged with the reset frame 21; the reset compression spring 22 is sleeved outside the guide rod 26 and the guide cylinder 27; The position po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com