Small lathe

A kind of lathe and small technology, applied in the direction of small lathes, lathes, etc., can solve the problems of complex structure, laborious clamping of parts, low efficiency, etc., and achieve the effect of improving rigidity and stability and reducing the moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

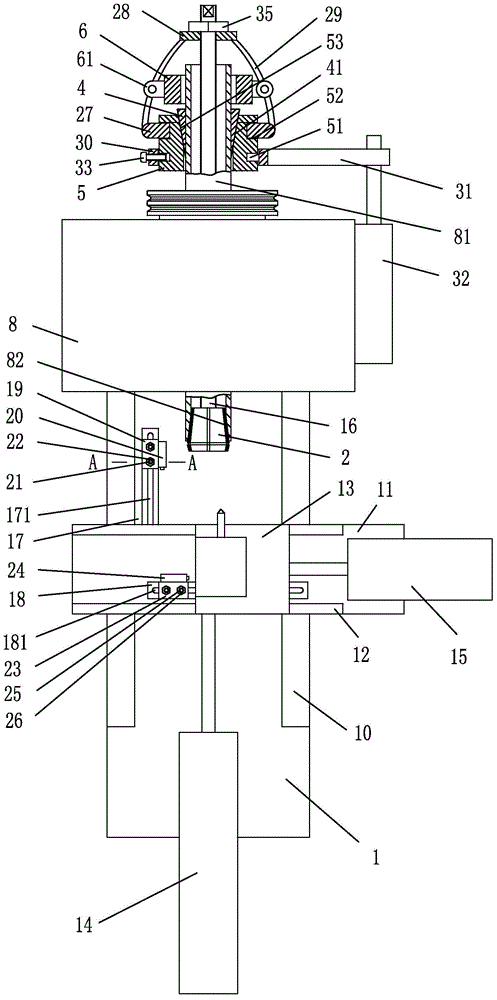

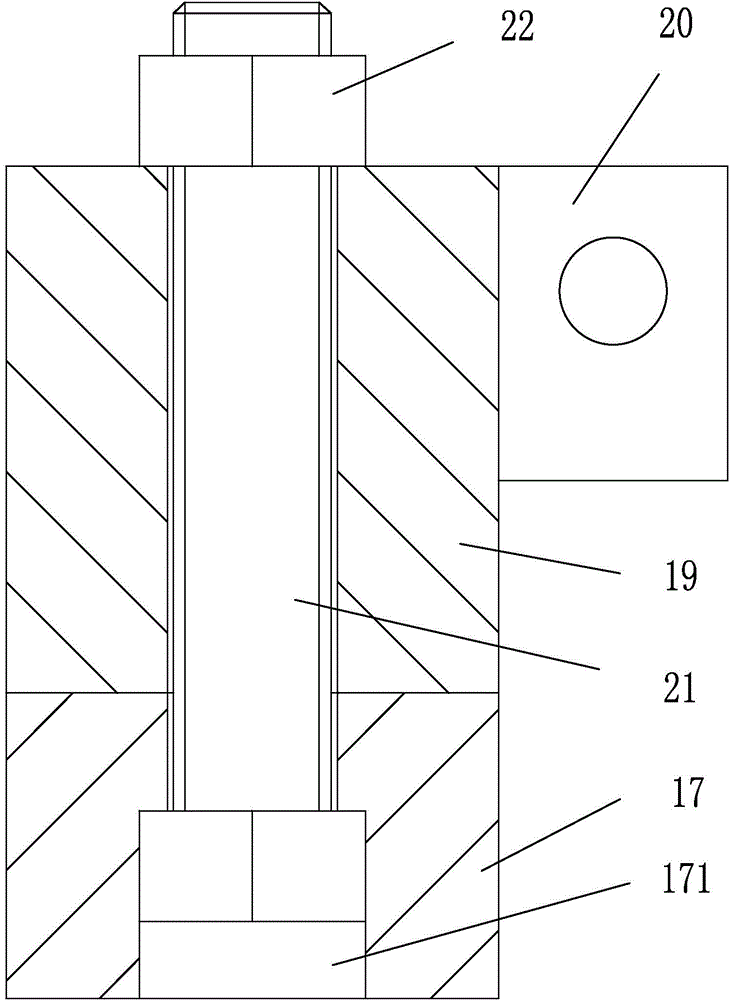

[0017] Embodiment 1, as attached figure 1 , attached image 3 Shown: a small lathe, including a bed 1, a headstock 8 with a spindle 81, a longitudinal carriage 11 connected to the bed 1 through a longitudinal guide rail 10, and a horizontal carriage 11 connected to the longitudinal carriage 11 through a transverse guide rail 12 Plate 13, the longitudinal cylinder 14 whose cylinder rod is screwed to the rear end of the longitudinal carriage 11 and screwed to the bed 1, the horizontal cylinder 15 whose cylinder rod is threaded to the rear end of the horizontal carriage 13 and screwed to the longitudinal carriage 11, The longitudinal limit assembly positioned at the front side of the longitudinal slide 11, the transverse limit assembly positioned at the front side of the horizontal slide 13, the tapered collet 2, the threaded connecting rod 16 and the connecting rod drive assembly; the front end of the main shaft 81 is provided with a cone The tapered hole 82 that the type colle...

Embodiment 2

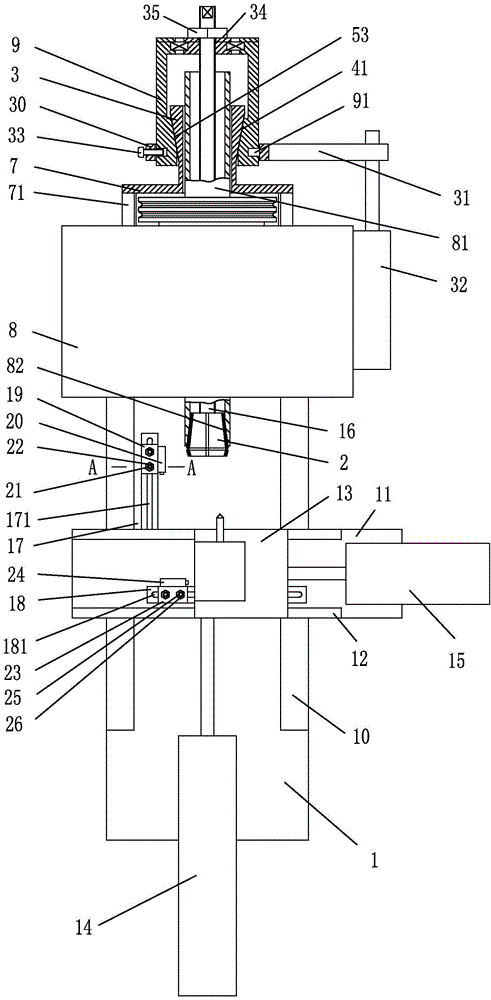

[0023] Embodiment 2, as attached figure 2 , attached image 3Shown: a small lathe, including a bed 1, a headstock 8 with a spindle 81, a longitudinal carriage 11 connected to the bed 1 through a longitudinal guide rail 10, and a horizontal carriage 11 connected to the longitudinal carriage 11 through a transverse guide rail 12 Plate 13, the longitudinal cylinder 14 whose cylinder rod is screwed to the rear end of the longitudinal carriage 11 and screwed to the bed 1, the horizontal cylinder 15 whose cylinder rod is threaded to the rear end of the horizontal carriage 13 and screwed to the longitudinal carriage 11, The longitudinal limit assembly positioned at the front side of the longitudinal slide 11, the transverse limit assembly positioned at the front side of the horizontal slide 13, the tapered collet 2, the threaded connecting rod 16 and the connecting rod drive assembly; the front end of the main shaft 81 is provided with a cone The tapered hole 82 that the type colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com