Bidirectional servo feeding machine

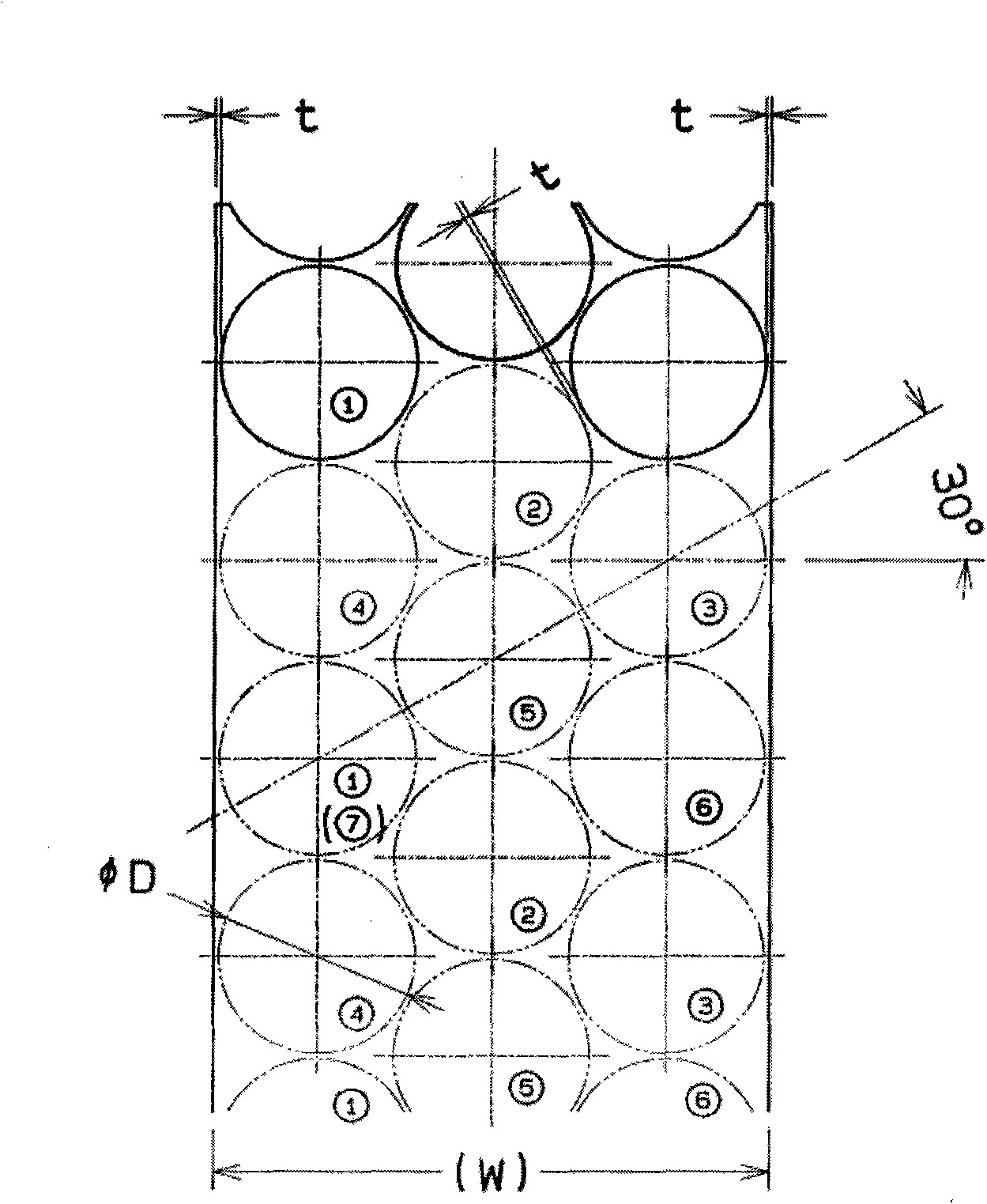

A servo feeding and feeding technology, applied in the field of two-way servo feeder, can solve problems such as difficult to use, large material waste, large area, etc., and achieve the effect of improving utilization rate, convenient adjustment and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

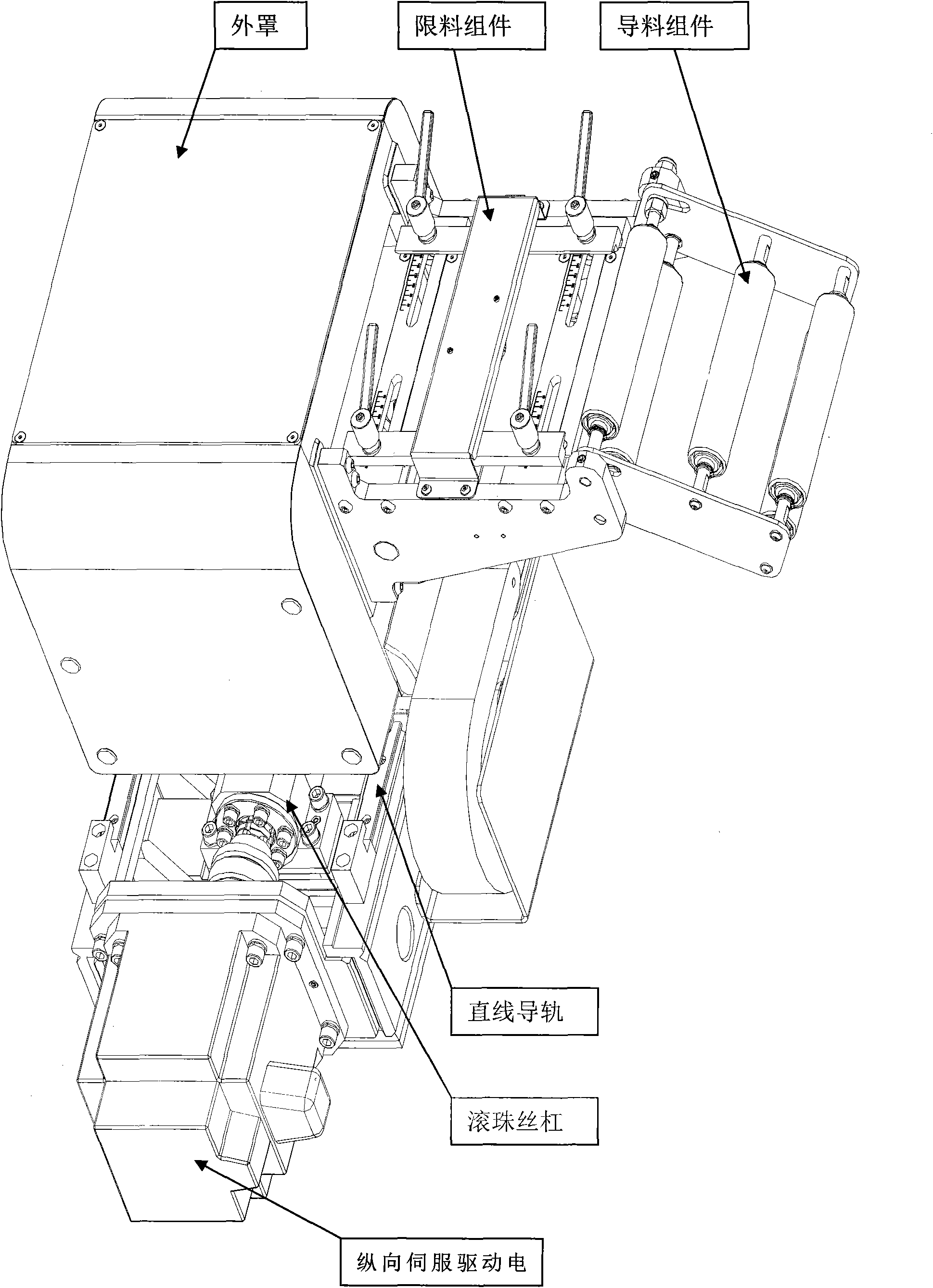

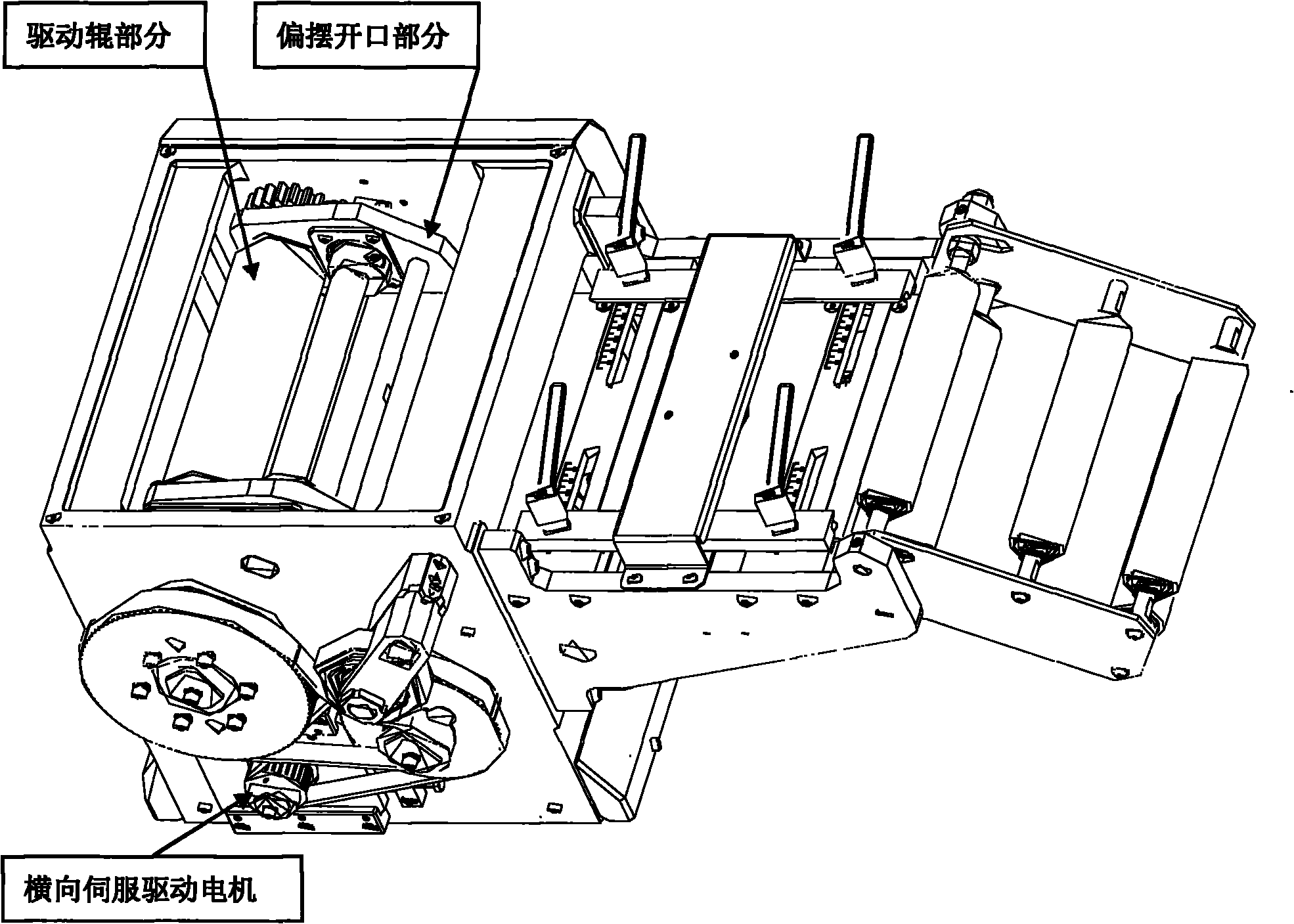

[0017] Such as figure 2 , image 3 Shown is a schematic diagram of the appearance of the bidirectional servo feeder of the present invention. The horizontal feeding mechanism drives the two-stage deceleration synchronous pulley 2, the lower feeding roller 3, and the upper feeding roller 4 to feed materials forward through the lateral servo drive motor 1. Wherein the lower feeding roller 3 is a driving roller, and the upper feeding roller 4 is a driven roller, which transmits power by meshing with the gear 5 at the shaft end of the driving roller, and the synchronous belt 6 is provided with a tensioning device 7 . The cylinder 8 can drive the swing arm 9 and the upper feeding roller 4 to swing around the rotating shaft 10 through the hinged connection. When feeding, the upper feeding roller 4 and the lower feeding roller 3 clamp the coiled material between the upper and lower rollers in close contact to ensure the dimensional accuracy of the feeding. Adjusting the pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com