Quick clamping device

A clamping device and fast technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of long auxiliary time, low efficiency, slow clamping action, etc., and achieve fast and convenient stroke adjustment, low precision requirements, and easy processing The effect of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

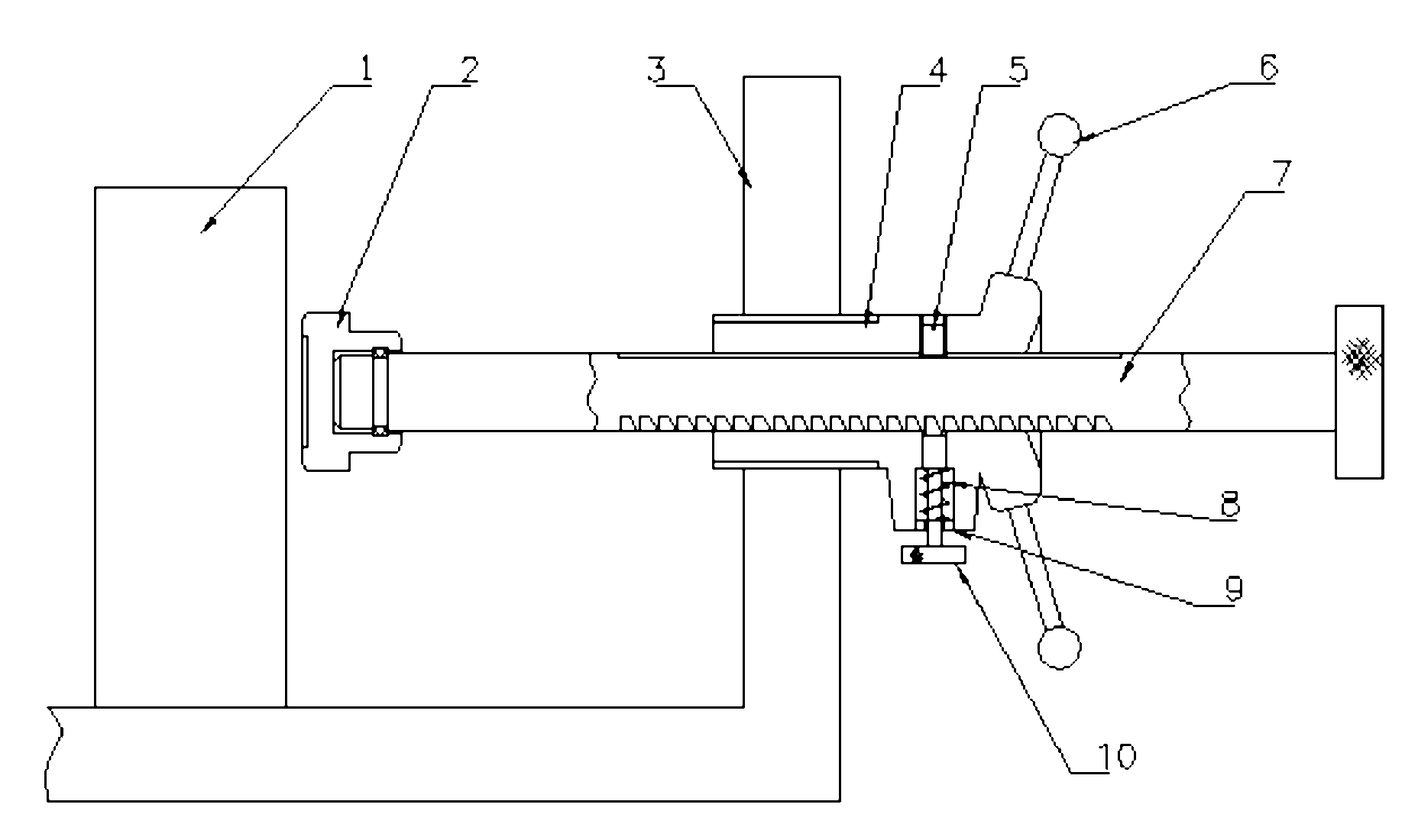

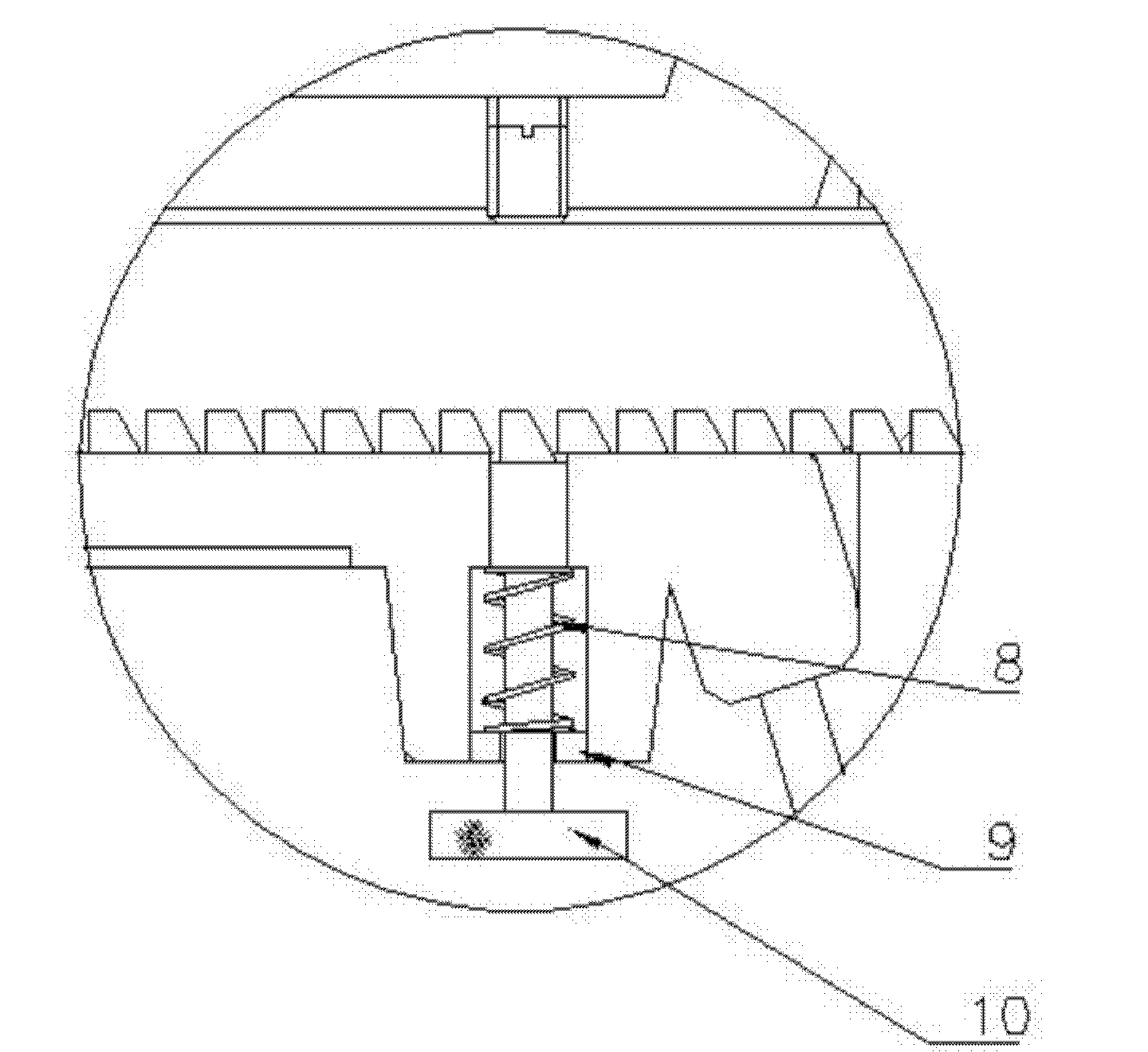

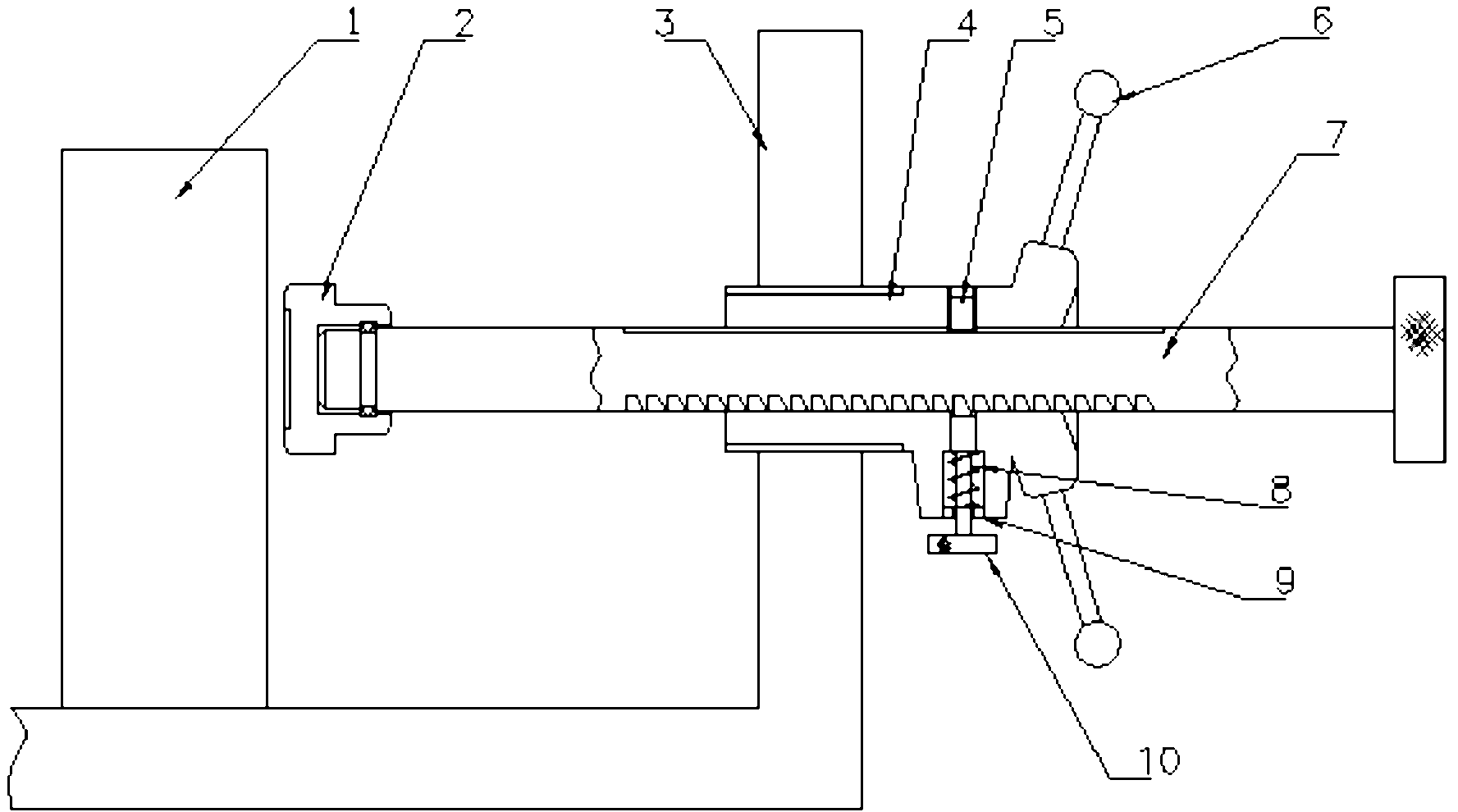

[0011] The details and working conditions of the specific device proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The technical scheme of the present invention is: whole clamping device structure such as figure 1 Shown: including smooth pressing block 2, clamp body 3, clamping screw 4, anti-rotation pin 5, handle 6, ejector rod 7, spring 8, gland 9, positioning pin 10, clamping screw 4 and clamping body 3 It is threaded connection; for the convenience of rotation, a handle 6 is installed at the right end of the clamping screw 4; gap fit between the ejector rod 7 and the clamping screw 4, so that the clamping screw 4 can slide freely; the anti-rotation pin 5 can prevent the screw from rotating , the other side of the anti-rotation screw on the clamping screw 4 is equipped with a positioning pin 10 to prevent the ejector rod from retreating, and the spring 8 and the gland 9 are arranged between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com