Method for continuous drying regenerative piece of polyester bottle, and dedicated drying equipment

A technology of recycled polyester and drying method, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., which can solve the problems of high energy consumption, high energy consumption, and high labor intensity of drum dryers, and achieve drying effects Stable, reliable, uniform, high safety factor, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

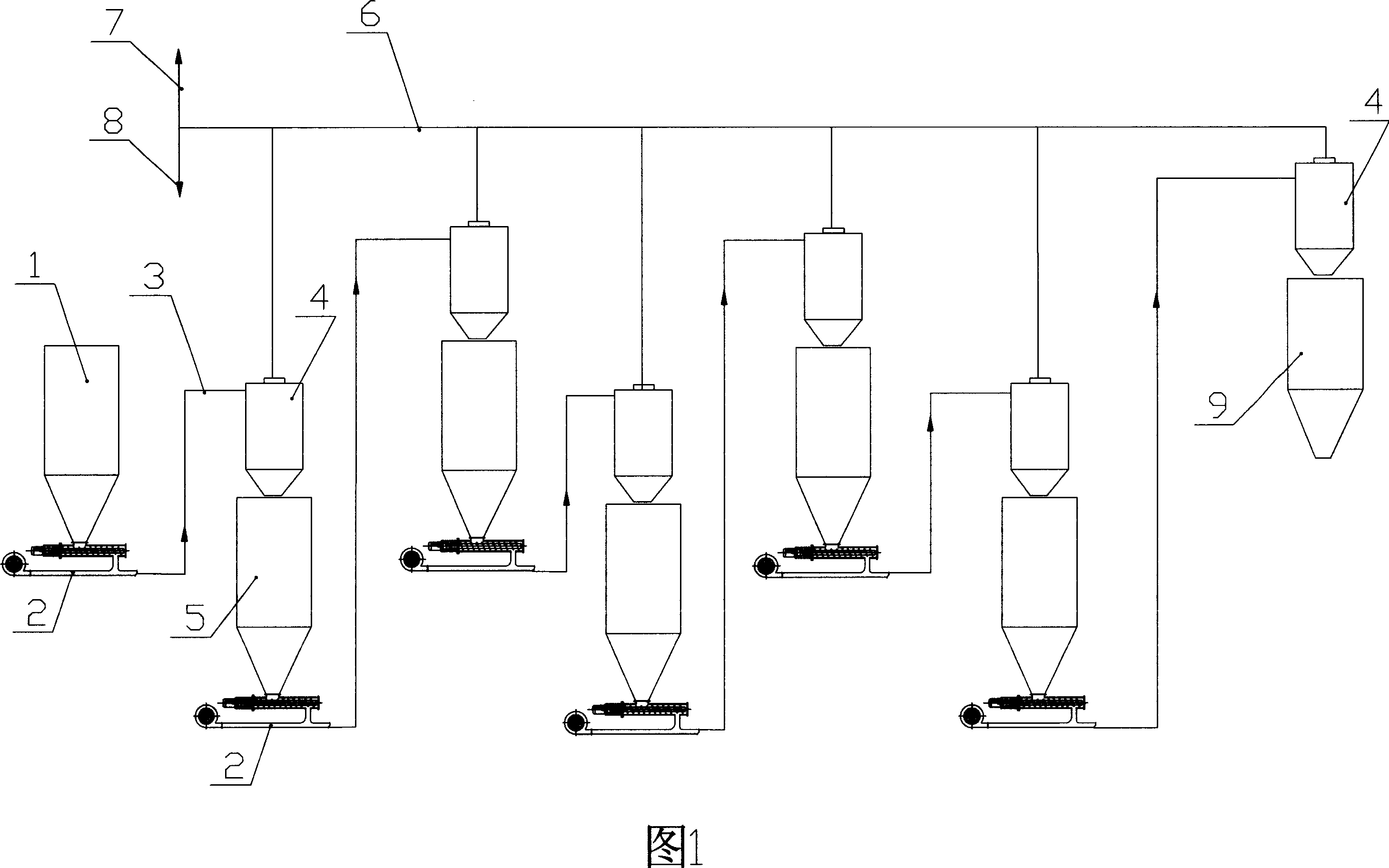

[0032] As shown in Figure 1, a device dedicated to the continuous drying of recycled polyester bottle flakes, including a feed hopper 1, an auger fan combination 2, a combination of 5 sets of cyclone separators 4 and heat preservation hopper 5, and cyclone separation device 4 and storage tower 9.

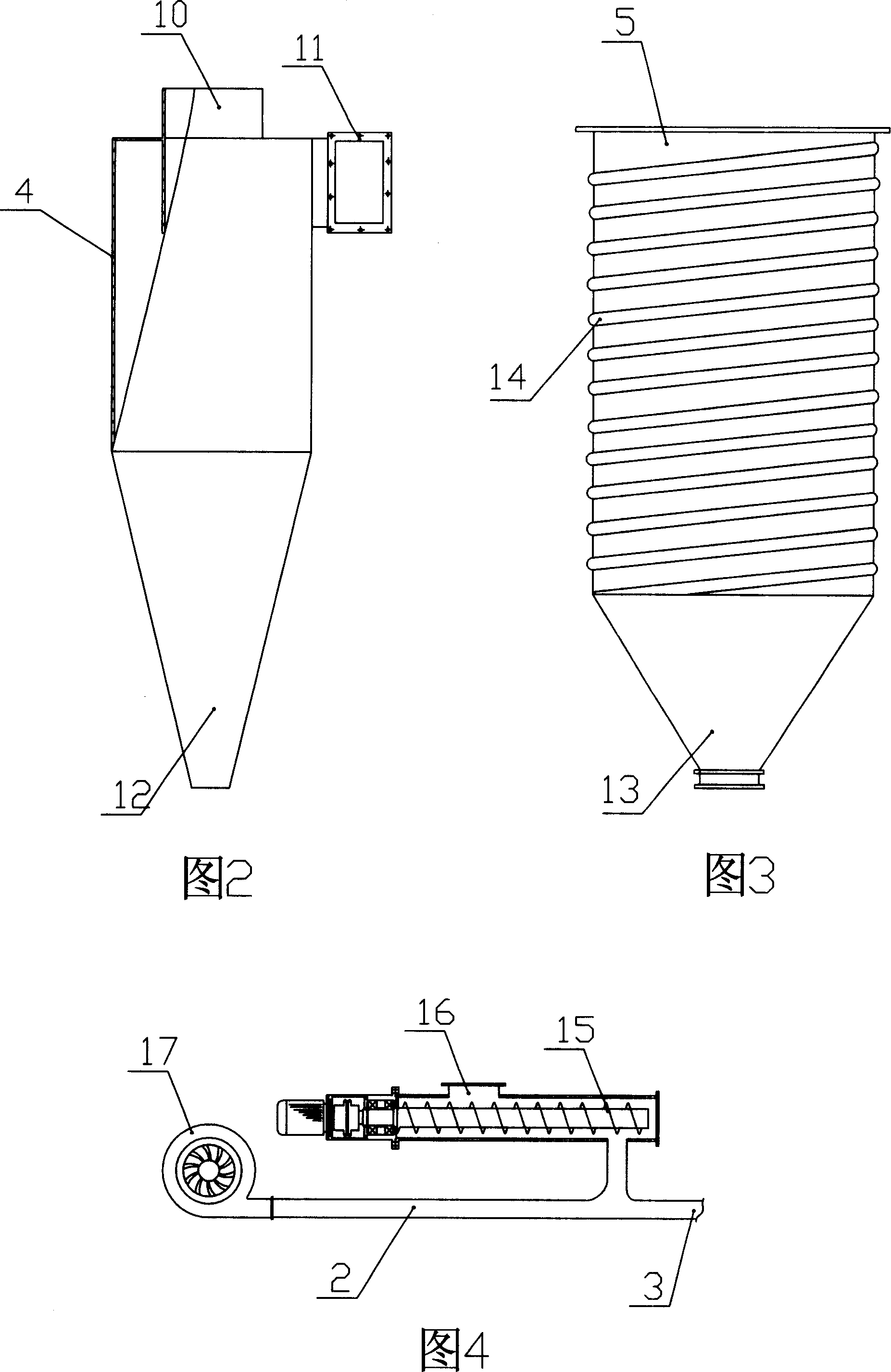

[0033] As shown in Figure 4, the auger fan combination 2 is arranged below the feed hopper 1, and it includes an auger 15 and a hot air blower 17. The feed port 16 of the auger 15 is connected to the feed hopper 1, and the discharge of the auger 15 The mouth is connected to the air channel 3 of the hot air blower 17.

[0034] As shown in FIG. 2 , the cyclone separator 4 is provided with a feed port 11 , an air outlet 10 is provided at the top thereof, and a discharge port 12 is provided at the bottom thereof. The material inlet 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com