Digital coal yard intelligent control scheme based on GPU computing

A technology of intelligent control and scheme, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as high cost of use and maintenance, poor stability and reliability of wireless communication, and adverse effects on the health of wireless people, so as to ensure safety Operation, shortening of operation time, protection from harmful gas environment and dust environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

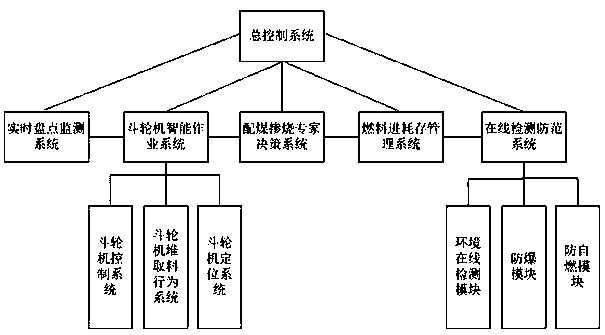

[0039] A digital coal yard intelligent control scheme, including a general control system, a real-time inventory monitoring system, a bucket wheel intelligent operation system, an expert decision-making system for coal blending and blending, a fuel consumption management system, and an online detection and prevention system.

[0040] The general control system is located in the general control room and consists of a group of parallel computers operating independently, which can perform fast, complex and diverse big data calculations with the help of GPU graphics processors. By collecting surface 4D data and data of quality, temperature, humidity, heat, and impurity content of coal piles, GPU rendering, arrangement, segmentation, remixing, screening, and resampling are performed to obtain a very high accuracy and computing efficiency. As a result, cross feedback is given to the real-time inventory monitoring system, bucket wheel machine intelligent operation system, coal blendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com